Reciprocating compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

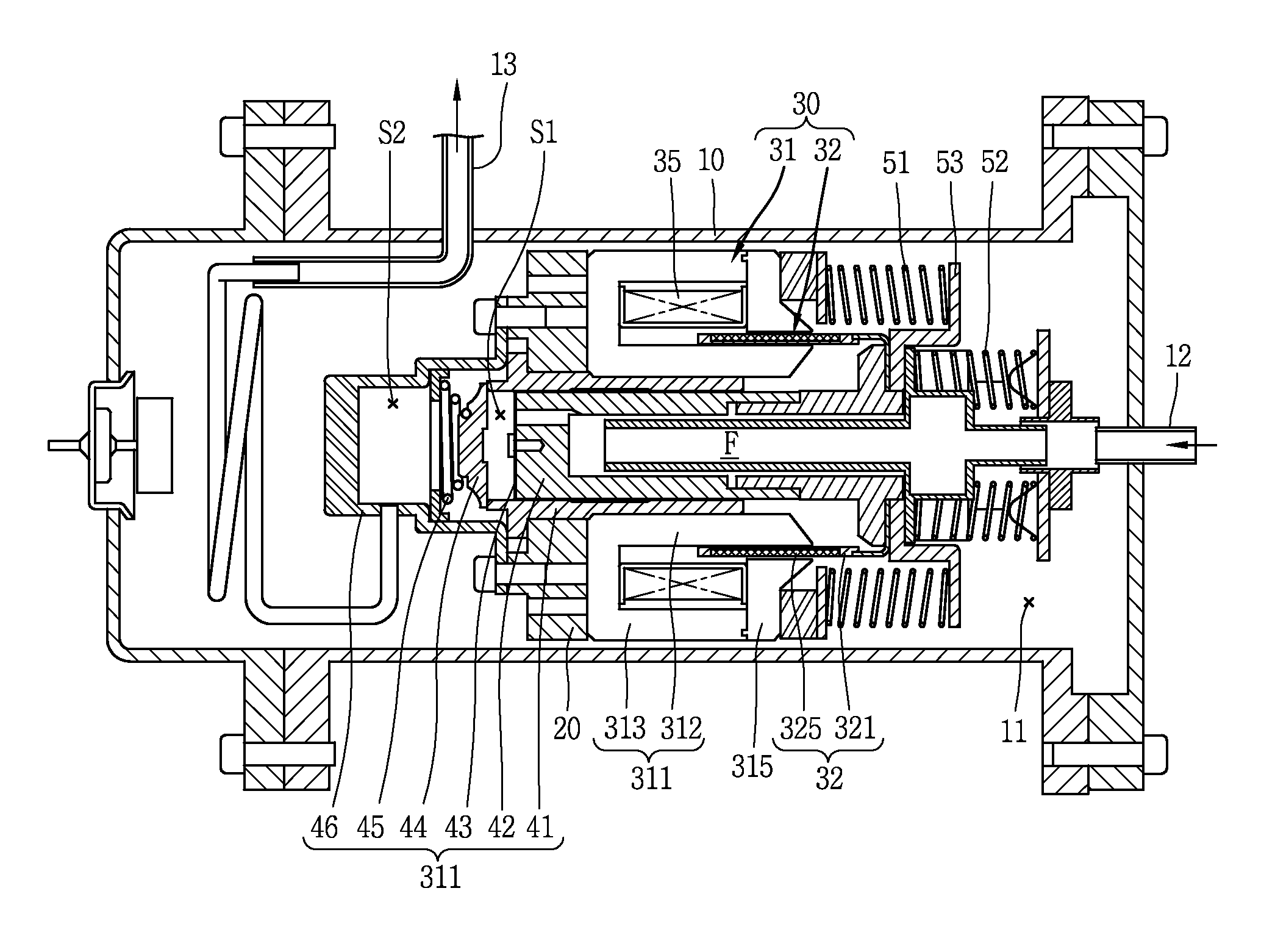

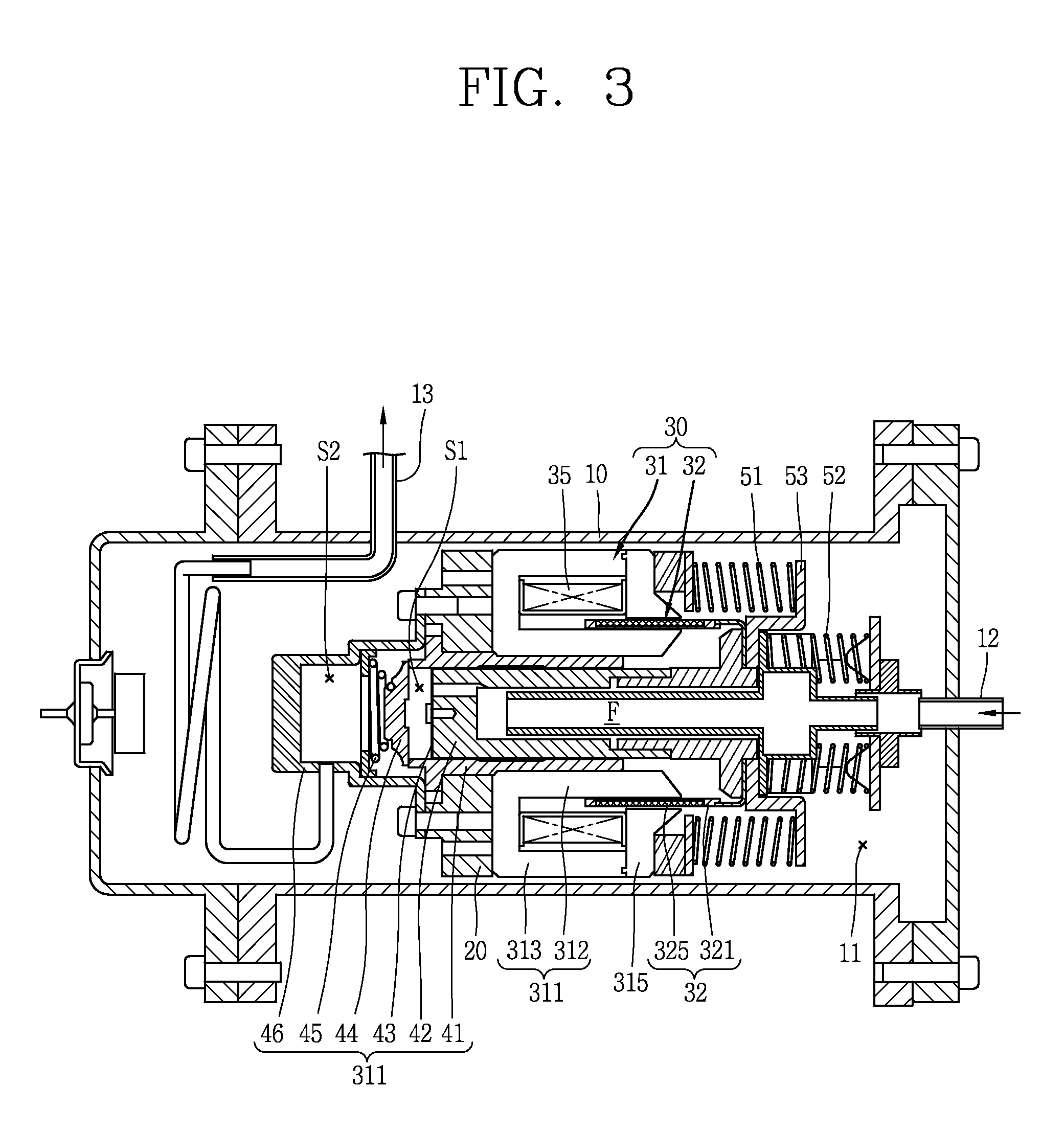

[0033]Hereinafter, a reciprocating compressor according to the present invention will be described in detail with reference to an embodiment illustrated in the accompanying drawings.

[0034]As shown in FIG. 3, in the reciprocating compressor according to this embodiment, a frame 20 is installed within a sealed casing 10, a reciprocating motor 30 and a cylinder 41 are fixed to the frame 20, a piston 42 coupled to a mover 32 of the reciprocating motor 30 is inserted into the cylinder 40 to reciprocate, and resonant springs 51 and 52 for inducing a resonating motion of the piston 42 are installed at both sides of the piston 42 in the motion direction of the piston 42.

[0035]In the aforementioned reciprocating compressor according this embodiment, when power is applied to a coil 35 of the reciprocating motor 30, the mover 32 of the reciprocating motor 30 reciprocates. Then, the piston 42 coupled to the mover 32 sucks and compresses a refrigerant gas while linearly reciprocating within the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com