Discharge valve arrangement for a hermetic compressor

a technology of hermetic compressor and discharge valve, which is applied in the direction of machines/engines, mechanical equipment, and positive displacement liquid engines, etc., can solve the problems of affecting the capacity and affecting the efficiency of these applications, and rarely using multiple orifices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

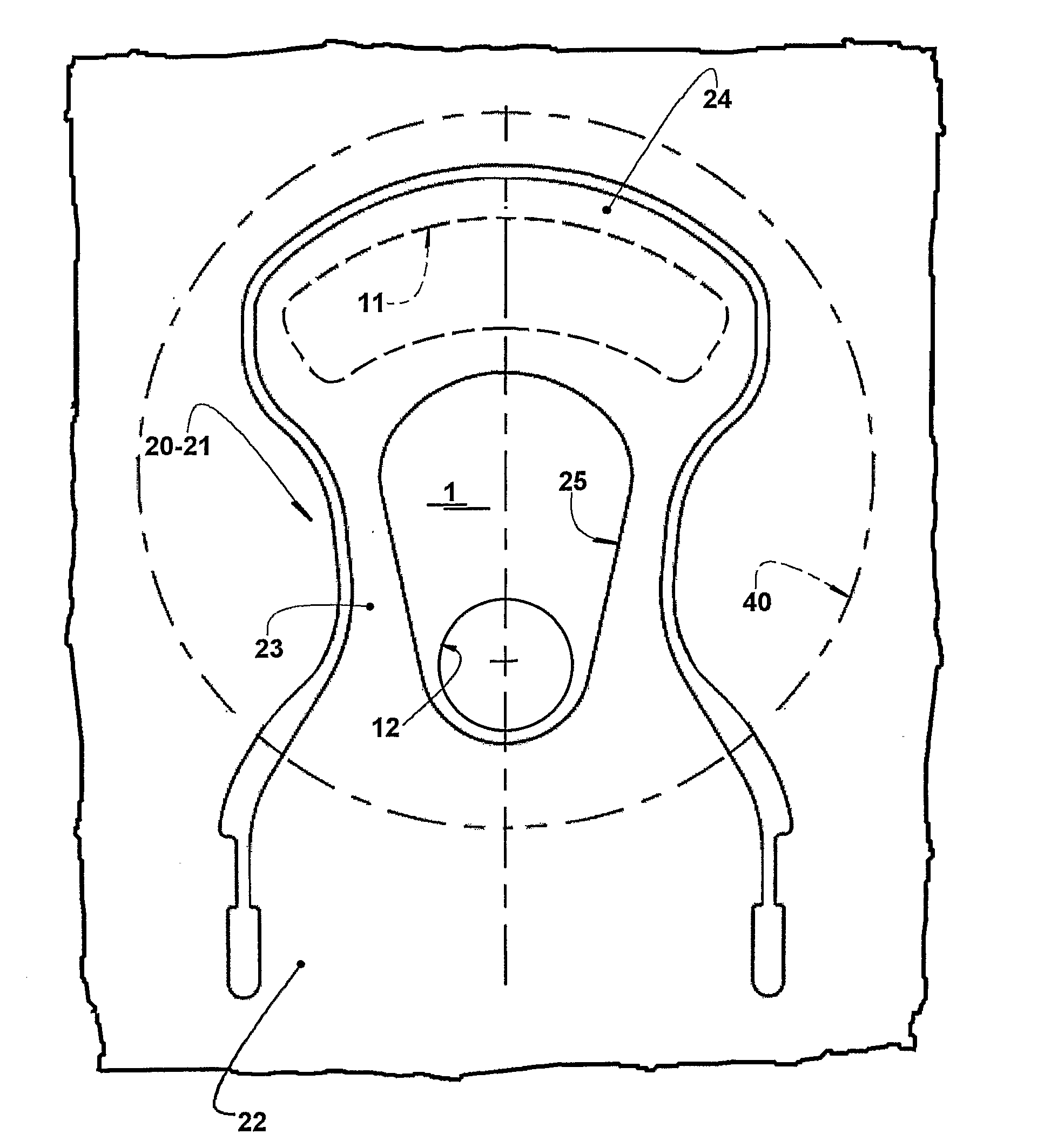

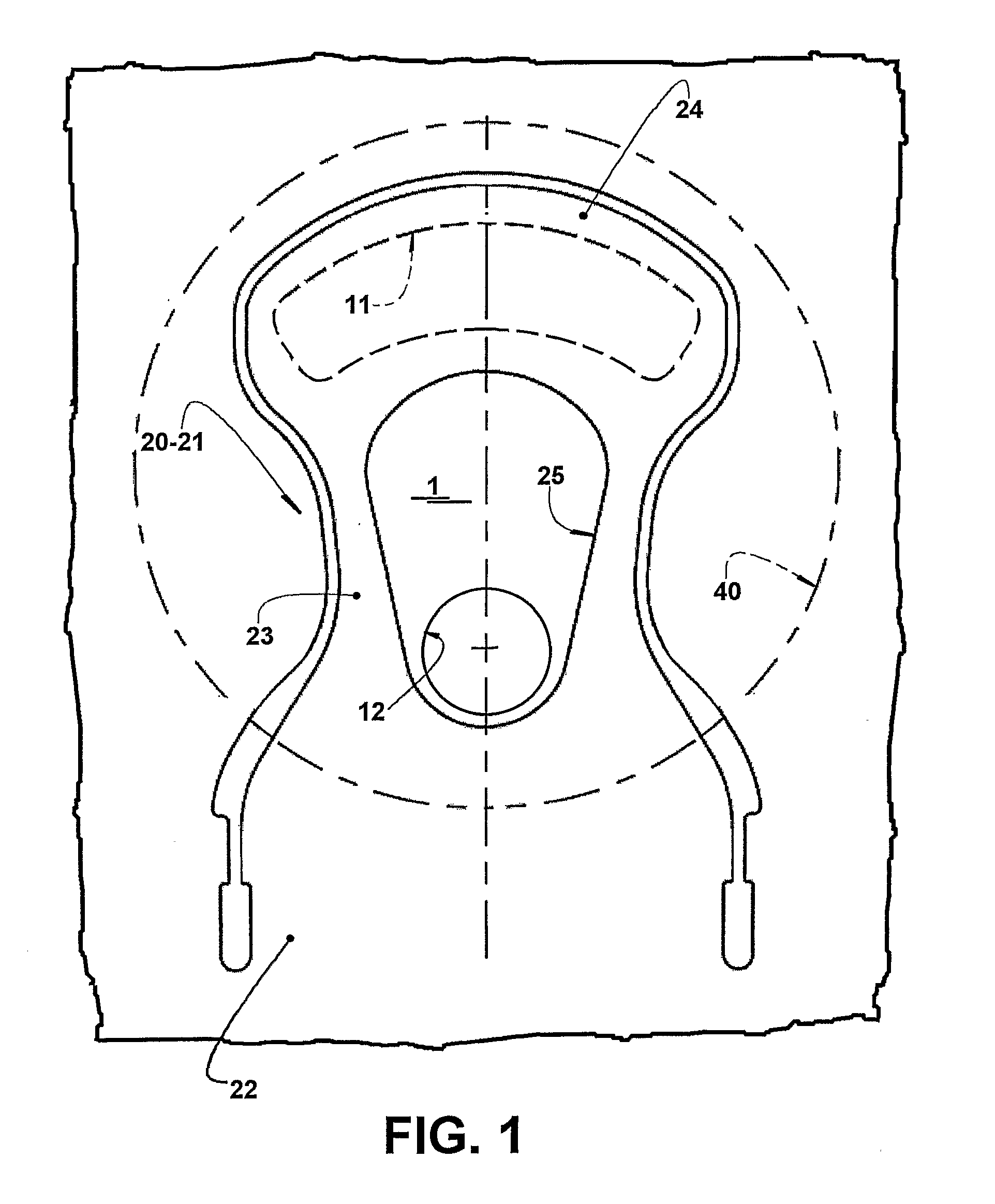

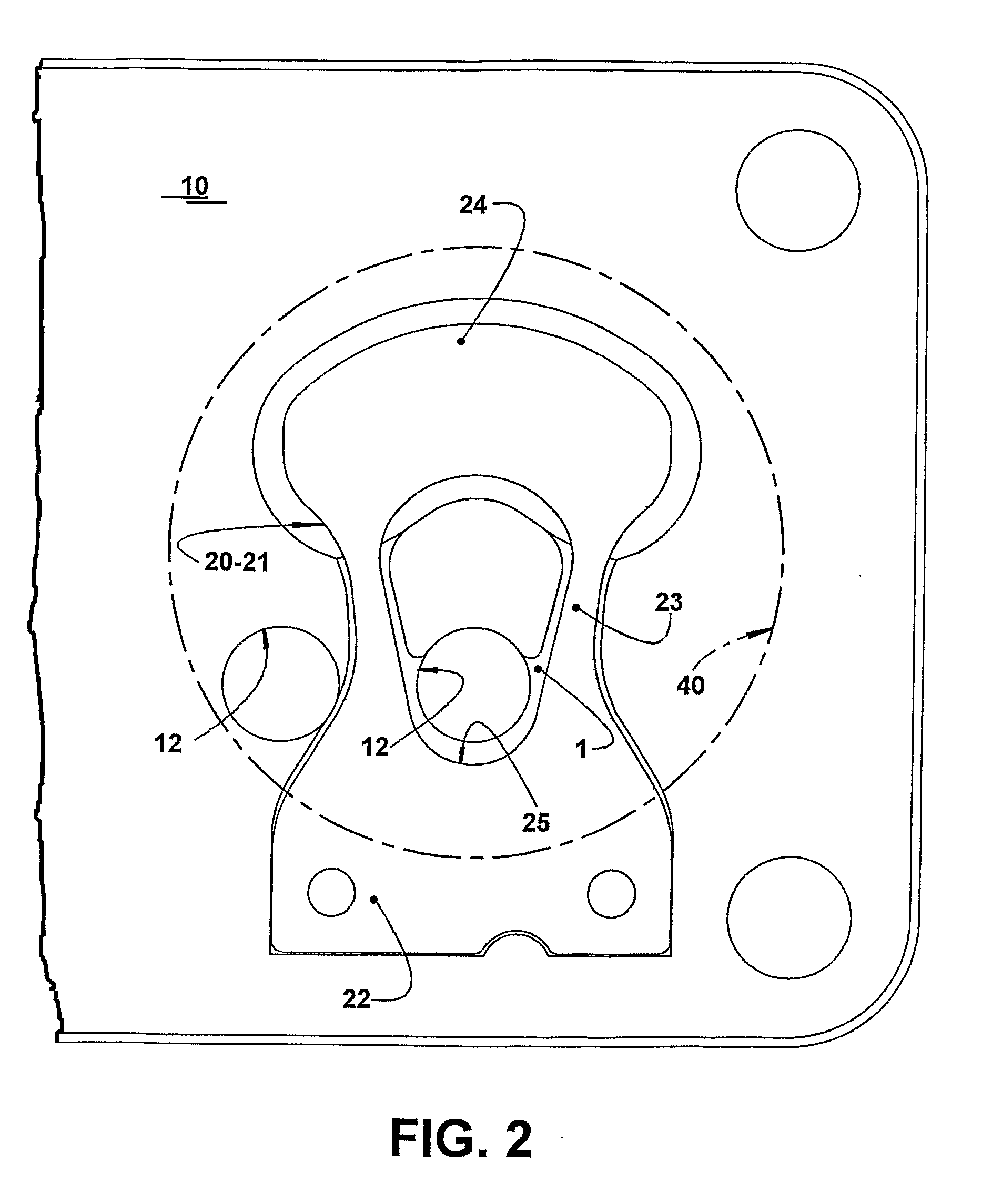

[0031]The present invention will be described for a hermetic compressor of refrigeration systems, to be applied, for example, in household refrigeration systems and comprising, in the interior of a non-illustrated casing, a motor-compressor assembly (not illustrated) including a cylinder block defining a compression cylinder 1 inside which is housed a reciprocating piston 2, which draws and compresses the refrigerant gas when driven by an electric motor of the motor-compressor assembly. In these constructions, the compression cylinder 1 and the reciprocating piston 2 have a reduced diameter, which restricts the space to provide and arrange the suction and discharge valves.

[0032]The compression cylinder 1 has an end closed by a valve plate 10 affixed to the cylinder block and provided with suction orifices 11 and discharge orifices 12. In the interior of the compression cylinder 1, between the top of the reciprocating piston 2 and the valve plate 10, it is defined a compression chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com