Refrigeration compressor

a refrigeration compressor and compressor technology, applied in the direction of pump components, positive displacement liquid engines, liquid fuel engine components, etc., can solve the problems of the performance of refrigeration compressors, achieve the effects of improving the performance of the compressor, reducing the internal temperature reliably and efficiently, and increasing the thermal efficiency of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

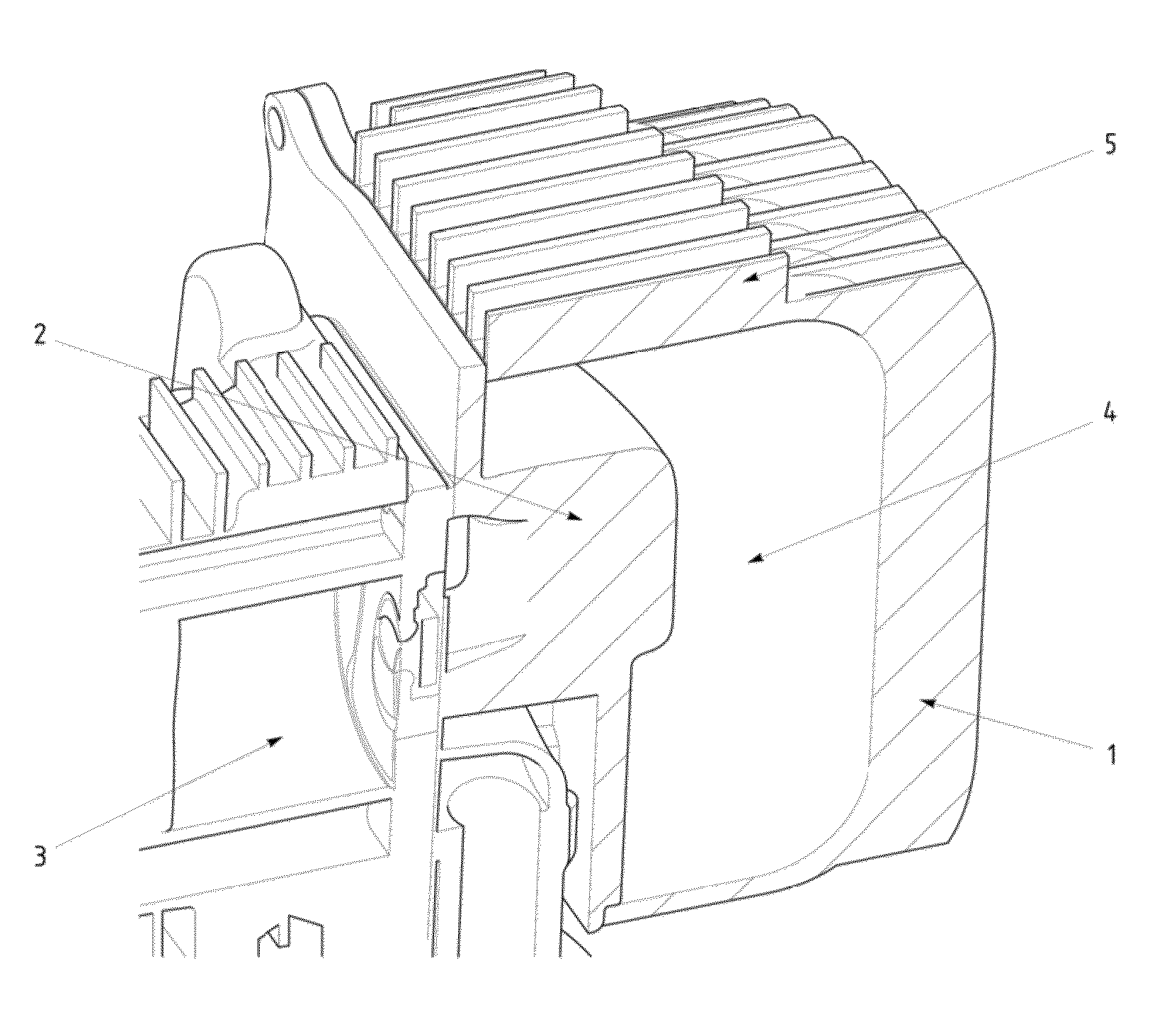

[0051]FIG. 1 shows the present invention, where the heat accumulating material is located in a volume formed between a casing which surrounds the cylinder cap and the compressor cylinder cap.

[0052]This region of the cylinder cap is critical for the compressor, since various gas communications flow therethrough. The suction gas, in order to get into the cylinder, passes over the region of the suction muffler which is in contact with the cylinder cap. The high temperature gas from the compression is also discharged to the cap, from where it follows to the remainder of the discharge system. Thus, by removing the gas heat on the cylinder cap and hence lowering the temperature thereof, one may observe a lower heating on the suction muffler output and the heat dissipation throughout the discharge system downstream the cap is reduced, since the temperature potential between the gas itself and the internal environment of the compressor is decreased. In addition, the cap, upon cooling, absor...

third embodiment

[0066]FIGS. 5a, 5b, and 5c show the present invention, wherein the heat accumulating material is employed externally to the region of the compressor crankcase 8.

[0067]As shown in FIG. 5a, in this embodiment a volume of phase-change material 6 is provided on the lower portion of the compressor in a volume separate from the internal environment of the compressor. This volume may assume the form of a reservoir 9 to be closed by means of welding, gluing, or other forms that can assure the airtightness of the subject region, so as to ensure the sealing between the internal compressor volume and the heat accumulator volume.

[0068]As shown in FIGS. 5a to 5b, this reservoir 9 may include metal fins 10 in the region of the heat accumulator volume, in order to facilitate the heat transfer from the heat accumulating material into the external environment, thereby maximizing the efficiency of the heat discharge process.

[0069]The embodiment shown in FIGS. 5a-5c has two significant advantages: Onc...

sixth embodiment

[0090]Thus, in the present invention, the heat accumulating material acts on the cooling of the gas when it passes through the tube 19, reducing its temperature on the cylinder entrance, and consequently increasing the energetic and volumetric efficiency.

[0091]Where a latent heat accumulator (PCM) is used, the phase change temperature should be lower than the gas temperature at the region of the tube, such as to generate a temperature potential which favors heat removal. One may choose a sensitive heat accumulator (e.g., water or oil), however, this design should be carefully planned in order to ensure the thermal discharge of the heat accumulator while the compressor is off.

[0092]Similarly to what was said with respect to the other embodiments of the present invention, the fins as seen in the drawings are only an illustrative embodiment, and whether they should be provided depends upon the application design for the heat accumulator. The provision of such fins aims at enhancing gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com