Patents

Literature

68 results about "Thermal discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal pollution. noun. : the discharge of heated liquid (such as wastewater from a factory) into natural waters at a temperature harmful to the environment.

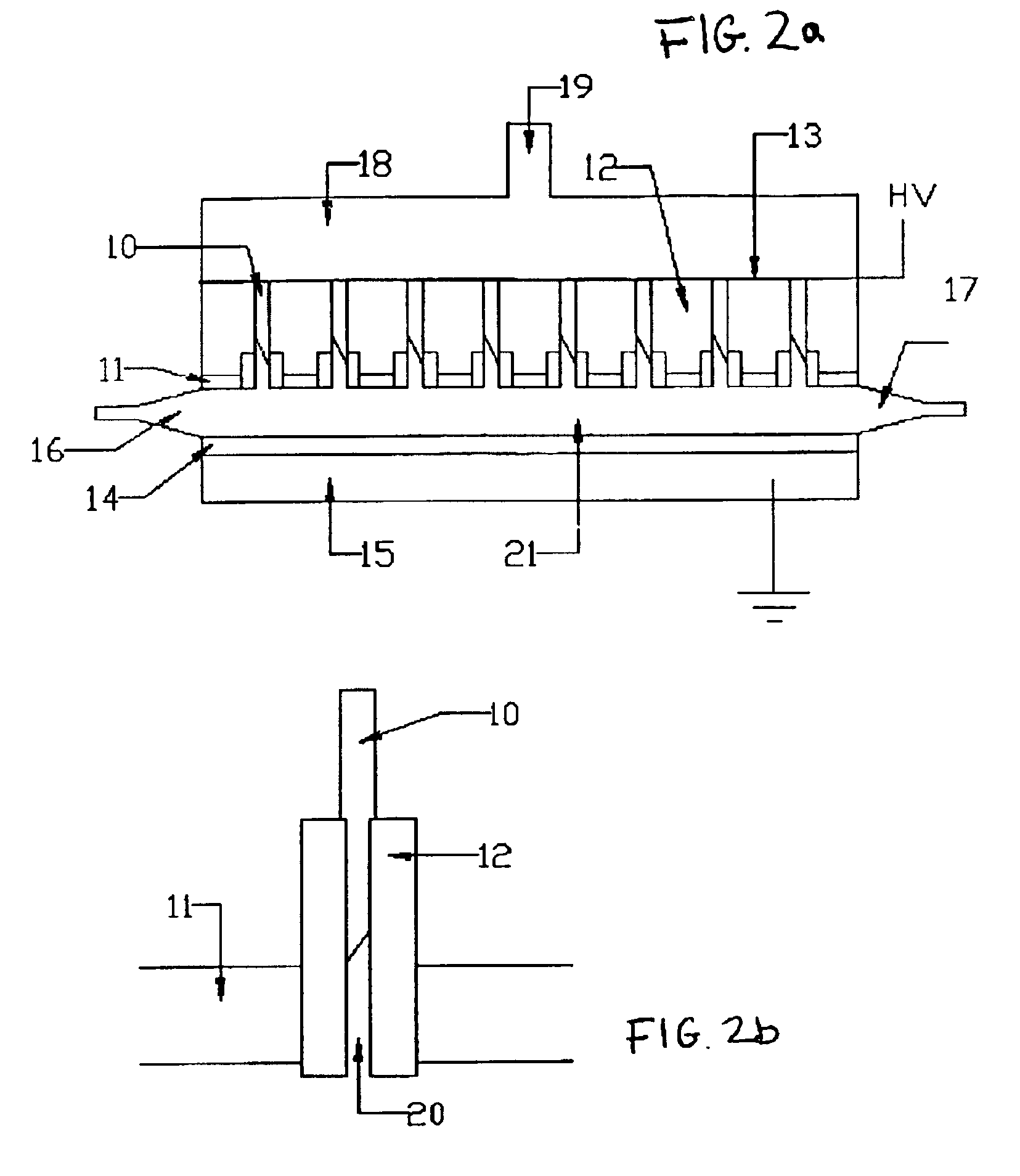

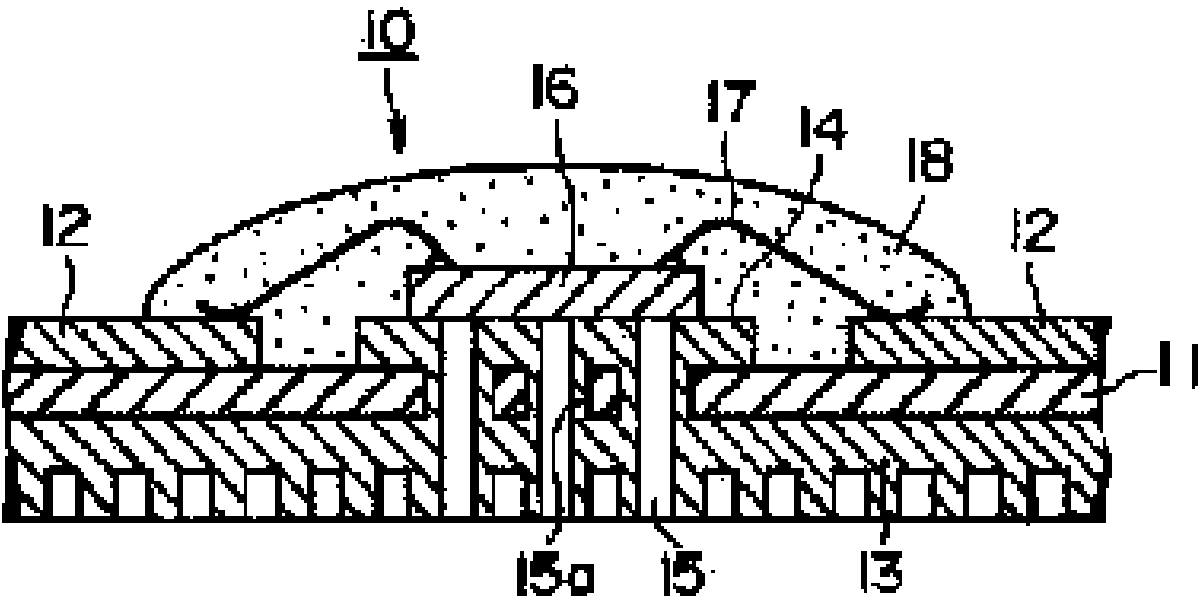

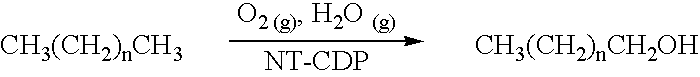

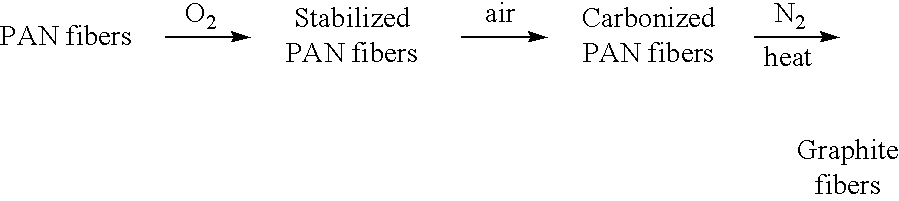

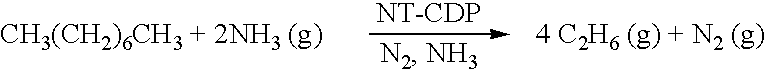

Chemical processing using non-thermal discharge plasma

InactiveUS6923890B2Simple processEnhanced water gas shiftingHydrogenMolecular sieve catalystsChemical treatmentFiber

A method for activating chemical reactions using a non-thermal capillary discharge plasma (NT-CDP) unit or a non-thermal slot discharge plasma (NT-SDP) unit (collectively referred to as “NT-CDP / SDP”). The NT-CDP / SDP unit includes a first electrode disposed between two dielectric layers, wherein the first electrode and dielectric layers having at least one opening (e.g., capillary or a slot) defined therethrough. A dielectric sleeve inserted into the opening, and at least one second electrode (e.g., in the shape of a pin, ring, metal wire, or tapered metal blade) is disposed in fluid communication with an associated opening. A non-thermal plasma discharge is emitted from the opening when a voltage differential is applied between the first and second electrodes. Chemical feedstock to be treated is then exposed to the non-thermal plasma. This processing is suited for the following exemplary chemical reactions as (i) partial oxidation of hydrocarbon feedstock to produce functionalized organic compounds; (ii) chemical stabilization of a polymer fiber (e.g., PAN fiber precursor in carbon fiber production; (iii) pre-reforming of higher chain length petroleum hydrocarbons to generate a feedstock suitable for reforming; (iv) natural gas reforming in a chemically reducing atmosphere (e.g., ammonia or urea) to produce carbon monoxide and Hydrogen gas; or (v) plasma enhanced water gas shifting.

Owner:PLASMASOL CORP

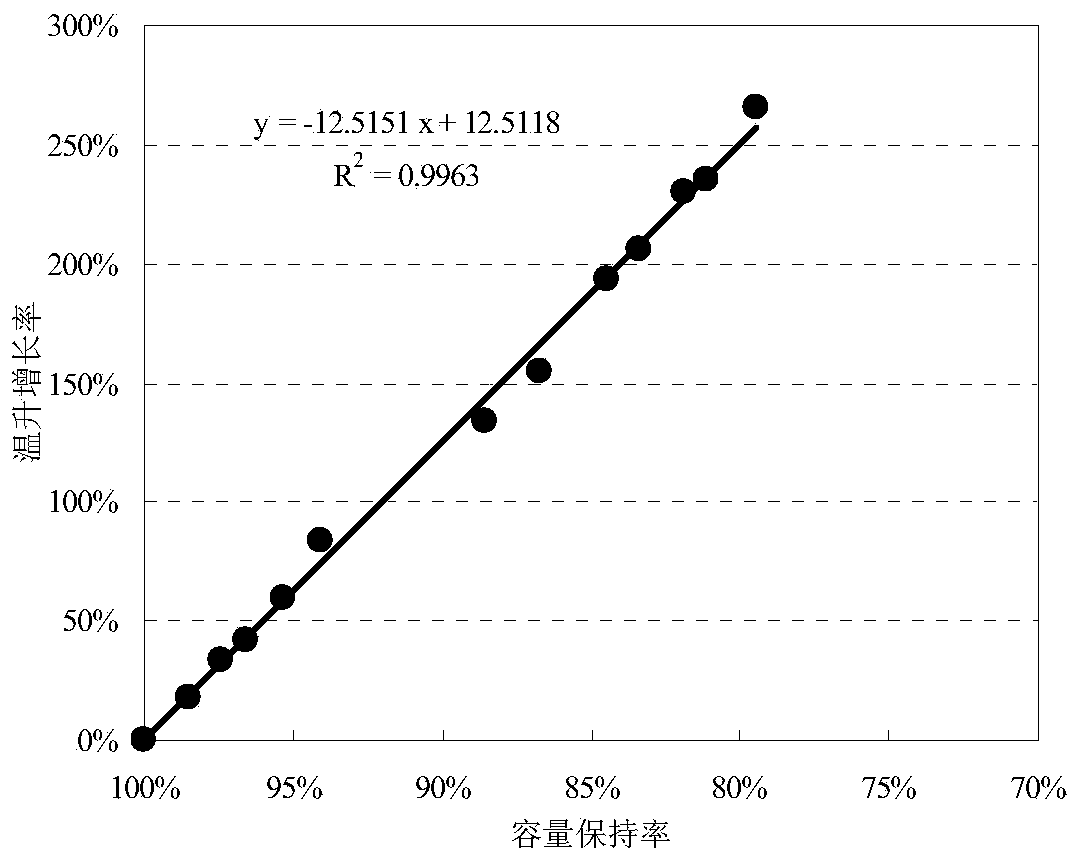

Method for predicating cycle life of lithium ion battery

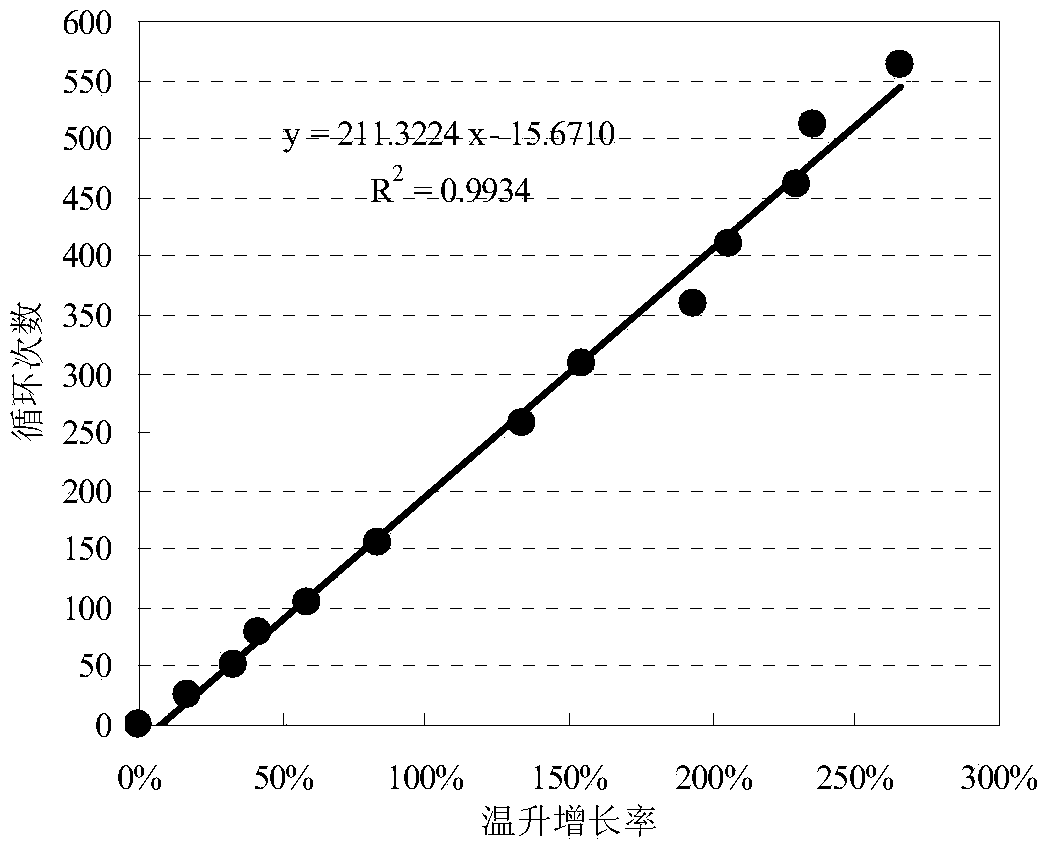

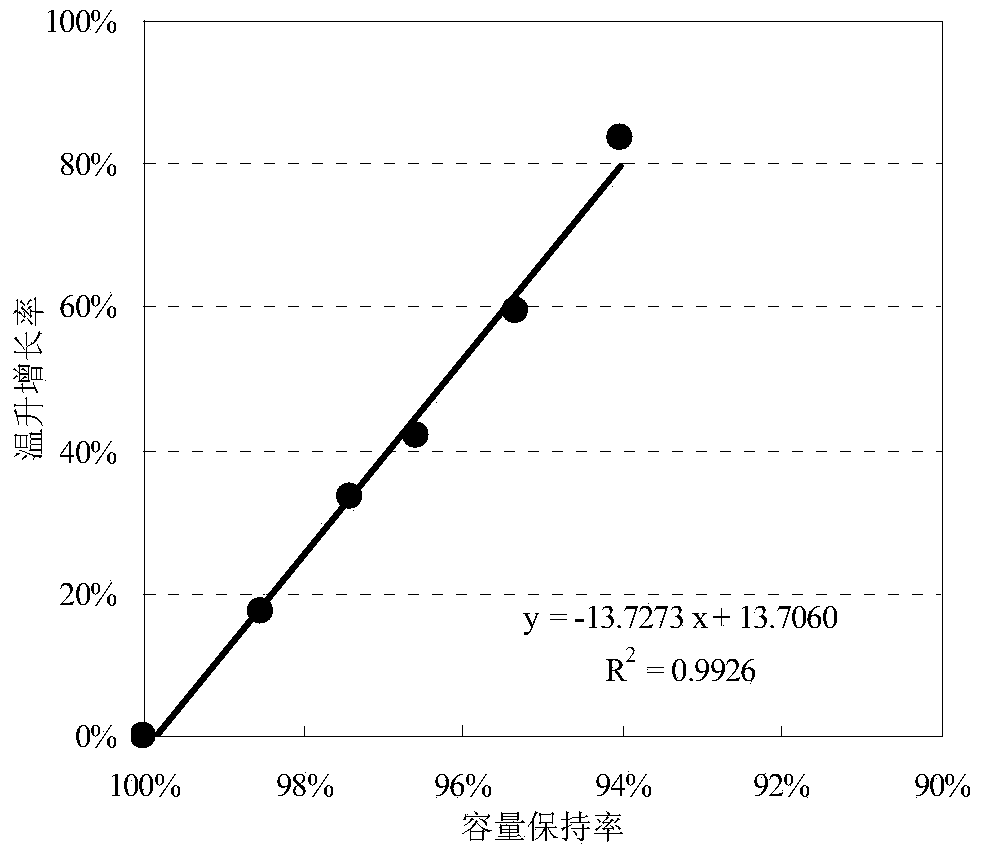

ActiveCN103698712ACycle Life PredictionReduce time-consuming issues with performance evaluationElectrical testingCyclic testProcess engineering

The invention relates to a method for predicating the cycle life of a lithium ion battery. The method comprises the following steps of performing batch-type cycle test on a to-be-evaluated battery in a to-be-evaluated cycle condition, and recording an accumulated cycle index and cycle volume conservation rate of the battery; transferring the battery not subjected to the batch-type cycle test and the battery subjected to the batch-type cycle test to an accelerating rate calorimeter, testing the thermal discharge in a charging process, recording temperature change data of the battery in the charging process, and calculating the temperature rise rate of the battery relative to an initial state; performing data fitting and calculation according to the accumulated cycle index and cycle volume conservation rate of the battery and predicating the cycle life of the battery. Compared with a conventional cycle test, the method provided by the invention has the advantages of greatly shortening the test period and avoiding energy consumption and resource waste generated by long-term test; in addition, data fitting is performed on the basis of short-term measured data, so that compared with pure-theory calculation and an empirical model, the method has the advantages of better universality and higher predicating accuracy.

Owner:TIANJIN LISHEN BATTERY +1

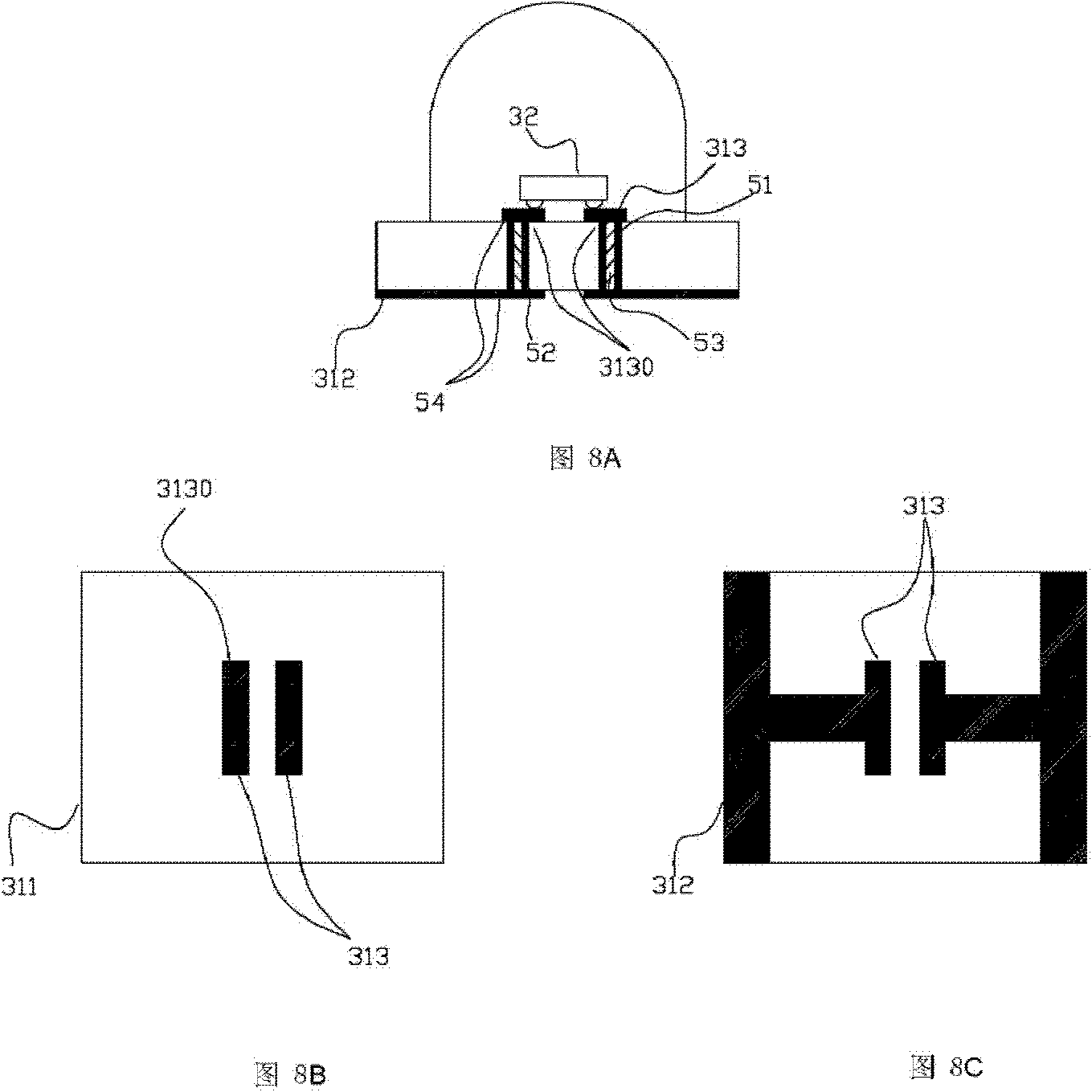

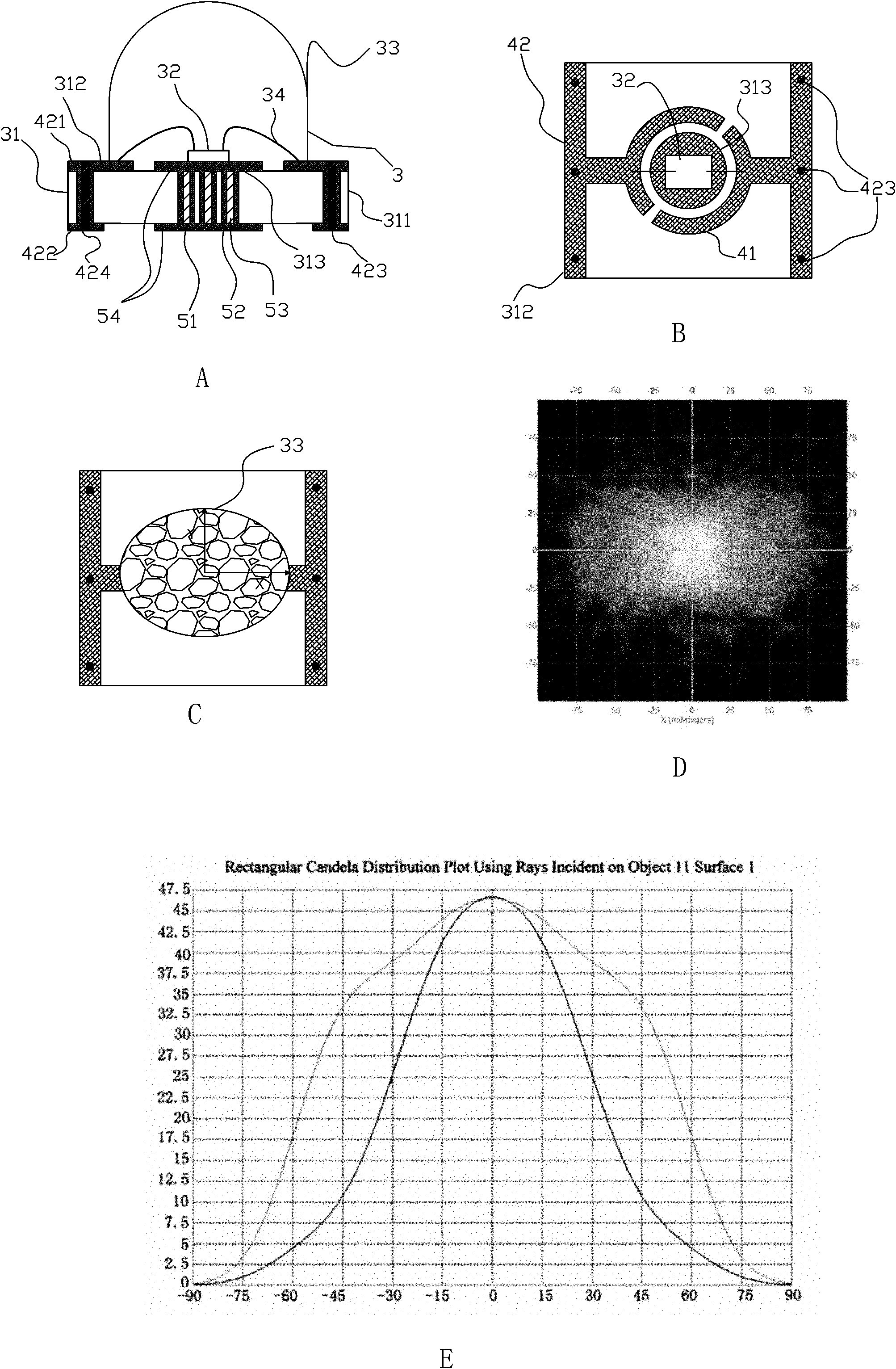

Surface mounted device (SMD) light emitting diode (LED) device and display module thereof for outdoor display screen

ActiveCN102044535AFast deliveryImprove cooling effectSolid-state devicesIdentification meansSurface mountingLight spot

The invention provides a surface mounted device (SMD) light emitting diode (LED) device and a display module thereof for an outdoor display screen. The invention solves problems of LED devices for current outdoor display screens, such as poor thermal discharge effect, complicated technology, low production efficiency, high cost, limited light emitting, and poor consistency. The display module provided by the invention effectively avoids quality problem of uneven light spots of the current outdoor display screens in the prior art, greatly improves quality and yield of the outdoor display screen, and reduces cost. The outdoor display module with the SMD LED device comprises an LED panel, a shell and sealing glue, wherein the LED panel is arranged inside the shell and the sealing glue is applied on the LED panel. The SMD LED device for the outdoor display screen has the advantages of low cost, simple structure and good thermal discharge effect and is suitable for down-stream batch production. The outdoor display module with the SMD LED device provided by the invention has low cost and simple technology, and can effectively improve resolution and quality of outdoor display screens.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

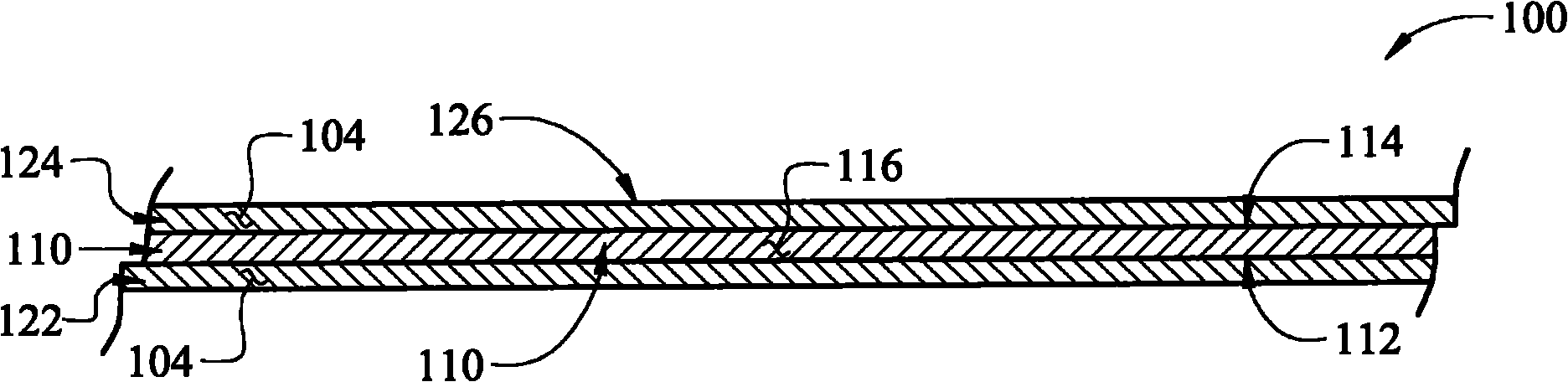

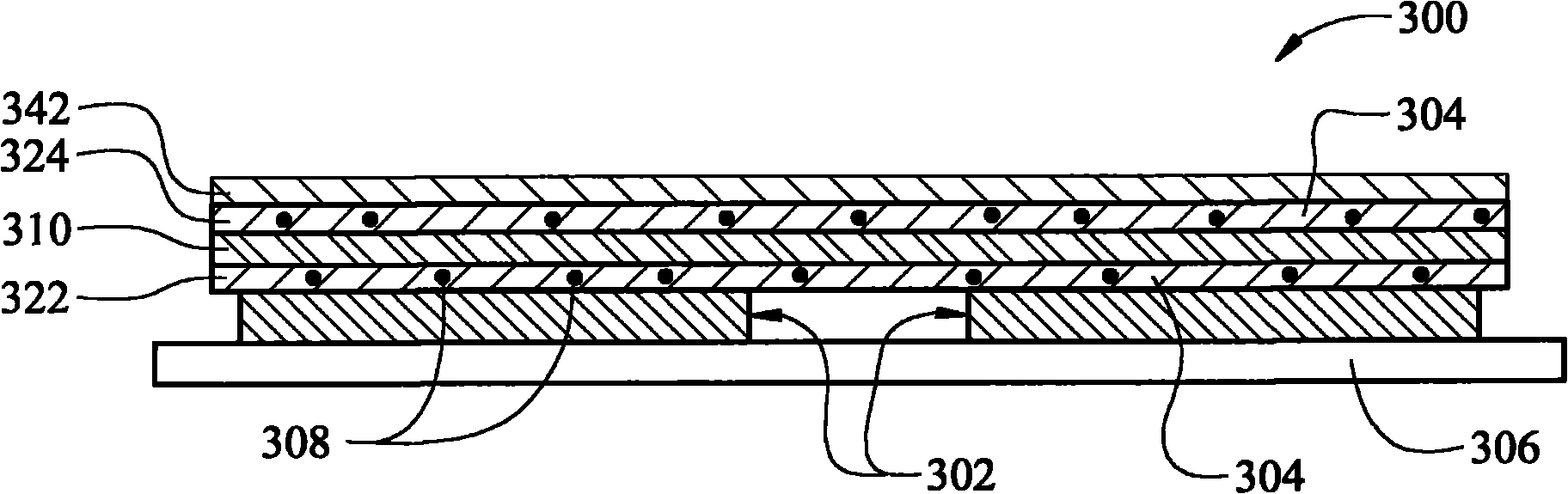

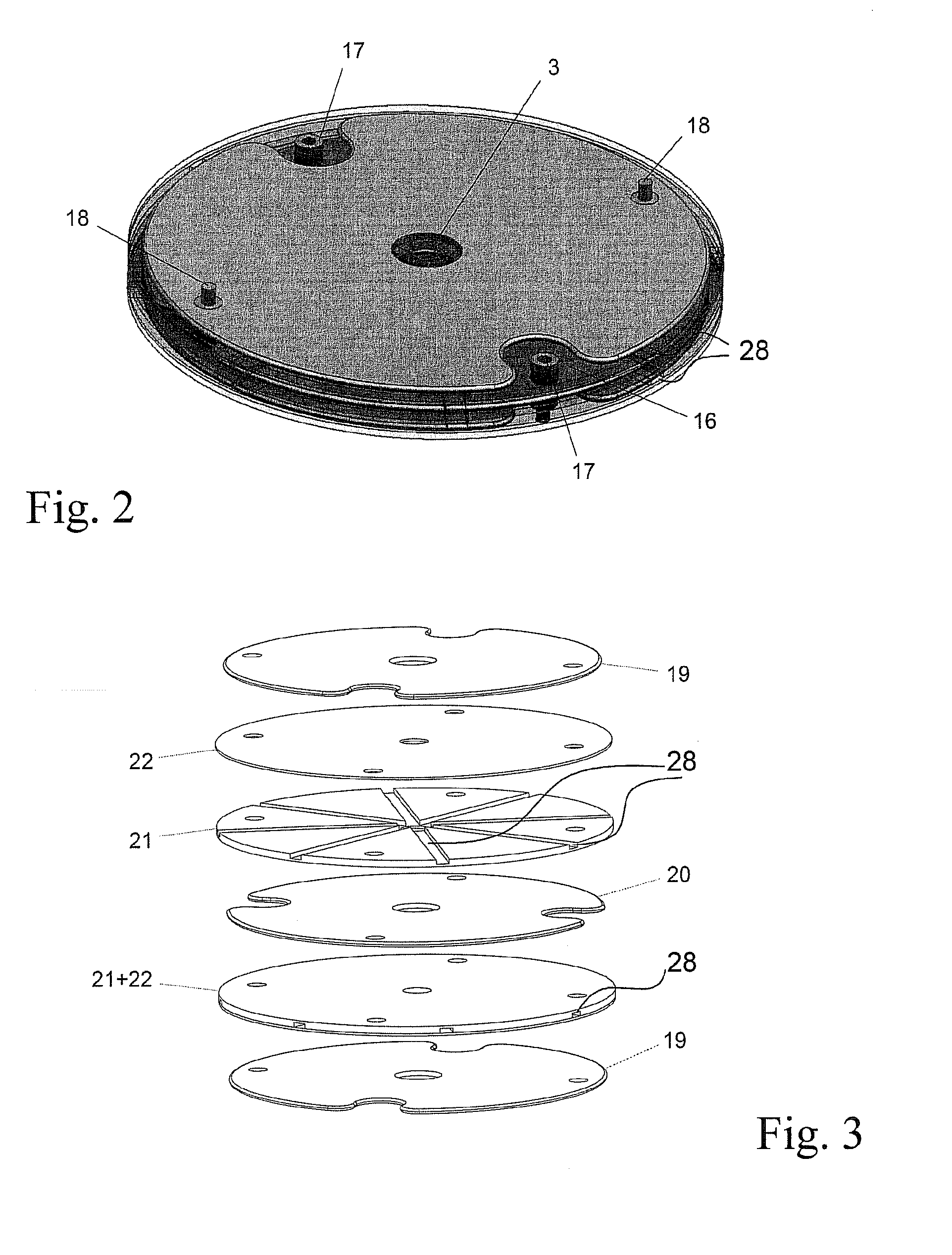

Compliant multilayered thermally-conductive interface assemblies and memory modules including the same

ActiveCN101930952ASemiconductor/solid-state device detailsSolid-state devicesConductive polymerComputer module

A thermally-conductive interface assembly is suitable for dissipating heat from a memory module or other components. Thermal interface material is disposed on or along one side of a flexible thermally-conductive sheet. The thermally-conductive sheet can be bonded to, encapsulated within, or sandwiched between first and second layers of the thermal interface material. The thermally-conductive sheet may be a flexible perforated graphite sheet. The thermal interface material may be thermally-conductive polymer. The perforations in the graphite sheet may enable a polymer-to-polymer bond to form that may help mechanically bond the first and second layers to the graphite sheet and / or may help provide heat conduction between the first and second layers. The thermally-conductive interface assembly may include flexible thermal discharge material having a first side, a second side and perforations, and may be sandwiched between the first and second layers of the thermal interface material. Part of the thermal interface material may be disposed in the perforations. The thermally-conductive interface assembly may be positioned with respect to the components, so as to provide a thermally-conductive path from the components to the first layer of the thermal interface material.

Owner:TIANJIN LAIRD TECH LTD

Chemical processing using non-thermal discharge plasma

A method for activating chemical reactions using a non-thermal capillary discharge plasma (NT-CDP) unit or a non-thermal slot discharge plasma (NT-SDP) unit (collectively referred to as "NT-CDP / SDP"). The NT-CDP / SDP unit includes a first electrode disposed between two dielectric layers, wherein the first electrode and dielectric layers having at least one opening (e.g., capillary or a slot) defined therethrough. A dielectric sleeve inserted into the opening, and at least one second electrode (e.g., in the shape of a pin, ring, metal wire, or tapered metal blade) is disposed in fluid communication with an associated opening. A non-thermal plasma discharge is emitted from the opening when a voltage differential is applied between the first and second electrodes. Chemical feedstock to be treated is then exposed to the non-thermal plasma. This processing is suited for the following exemplary chemical reactions as (i) partial oxidation of hydrocarbon feedstock to produce functionalized organic compounds; (ii) chemical stabilization of a polymer fiber (e.g., PAN fiber precursor in carbon fiber production; (iii) pre-reforming of higher chain length petroleum hydrocarbons to generate a feedstock suitable for reforming; (iv) natural gas reforming in a chemically reducing atmosphere (e.g., ammonia or urea) to produce carbon monoxide and Hydrogen gas; or (v) plasma enhanced water gas shifting.

Owner:PLASMASOL CORP

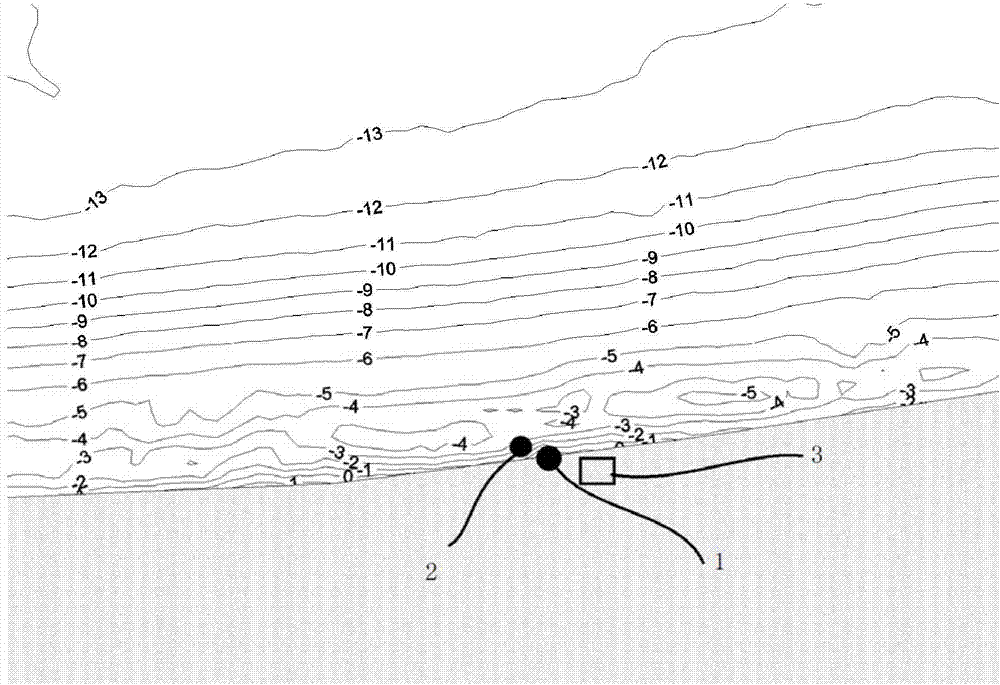

Method for coastal power plant thermal discharge prediction by utilizing actually-measured surface heat transfer coefficient

InactiveCN104751252AForecastingInformation technology support systemEngineeringHeat transfer coefficient

The invention discloses a method for coastal power plant thermal discharge prediction by utilizing the actually-measured surface heat transfer coefficient, belongs to the field of environmental engineering, and particularly relates to a method for coastal power plant thermal discharge prediction to acquire the surface heat transfer coefficient. The method specifically includes: collecting meteorological measuring data; establishing a hydrodynamic model in a study area; calculating the sequence of the thermal discharge surface heat transfer coefficient in a measurement time interval; brining the thermal discharge surface heat transfer coefficient to a temperature transport equation of the hydrodynamic model; measuring the scope of influence by power plant thermal discharge. The method has the advantages that a novel method for actually measuring the surface heat transfer coefficient is provided, and the method for coastal power plant thermal discharge prediction by utilizing the actually-measured surface heat transfer coefficient is achieved. Meanwhile, the invention provides a surface heat transfer measuring device.

Owner:OCEAN UNIV OF CHINA +1

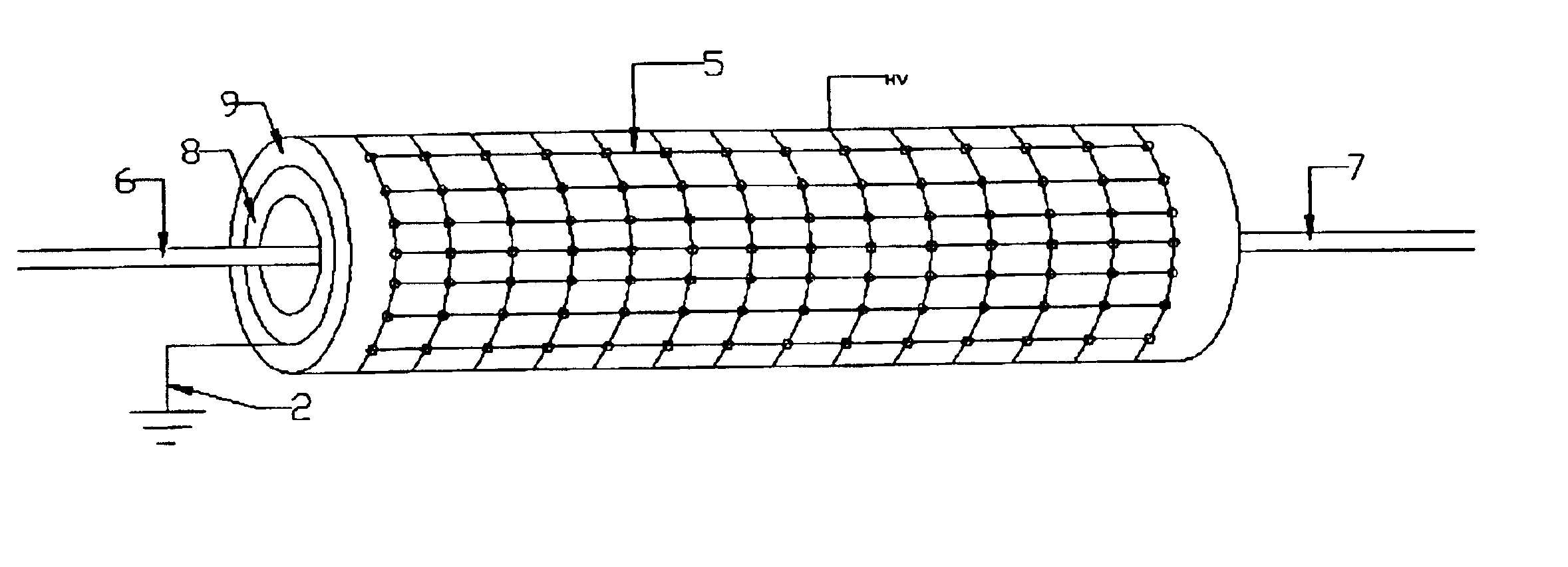

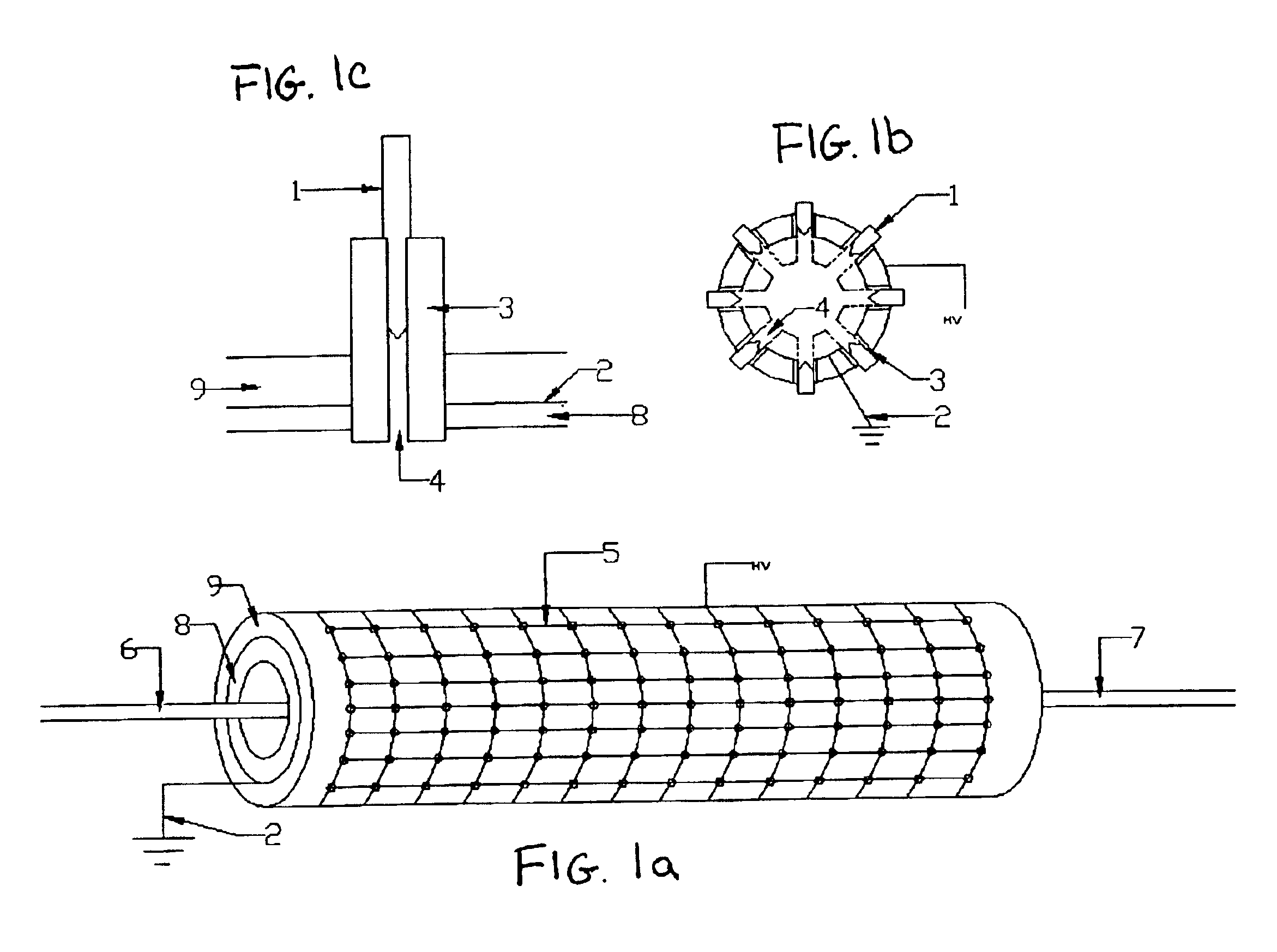

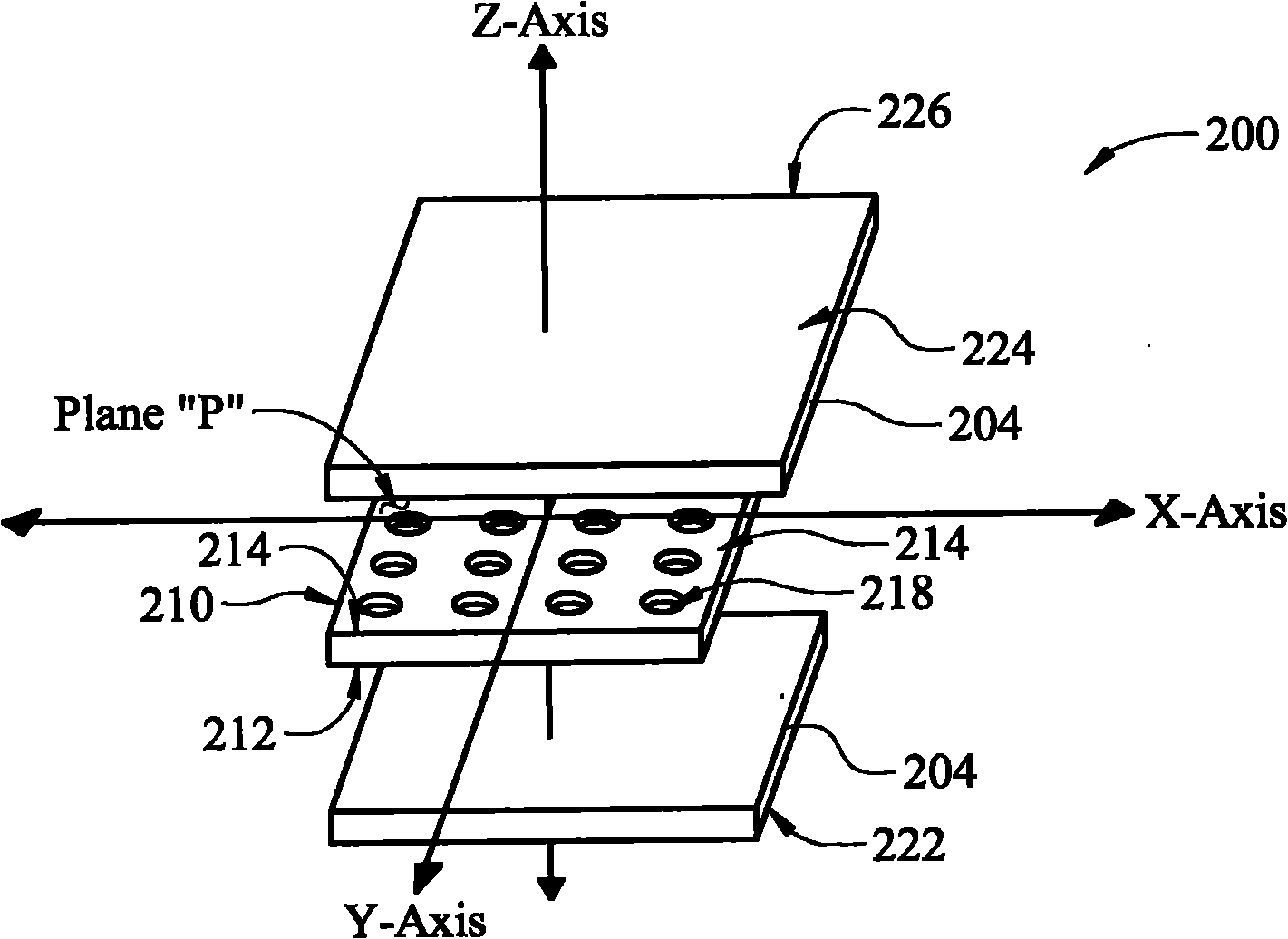

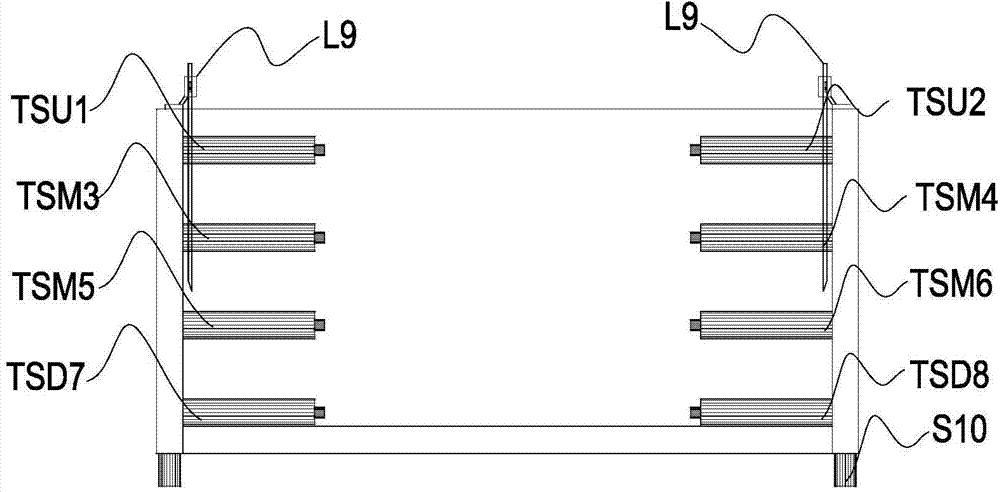

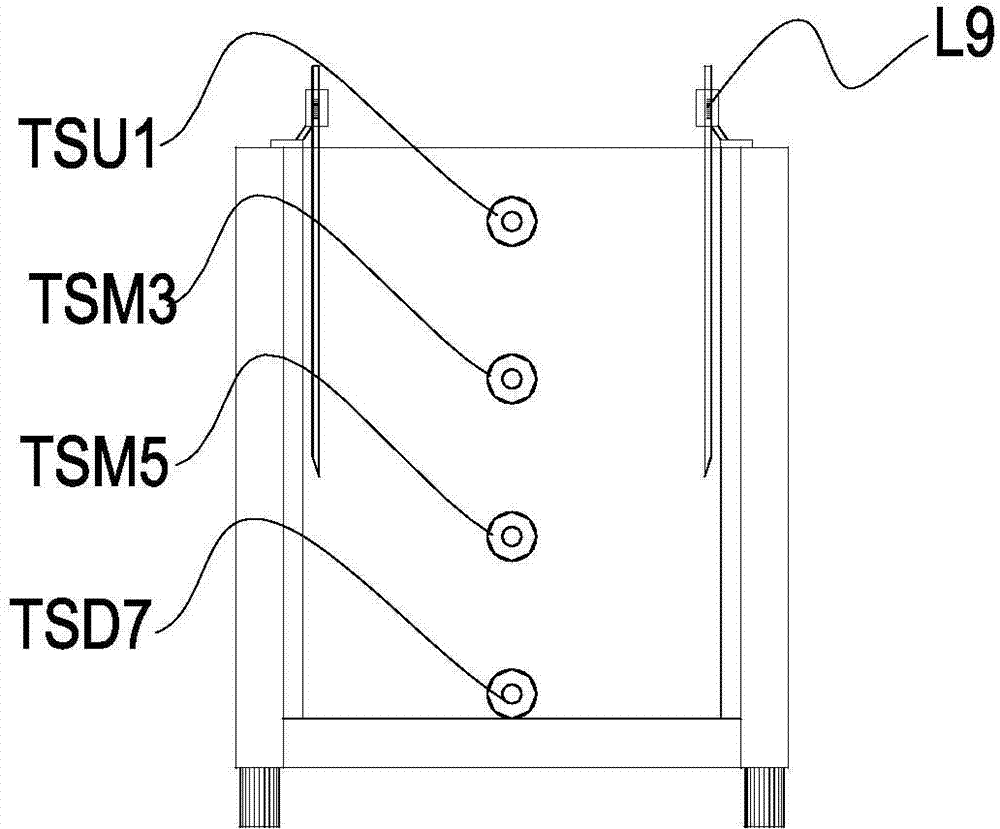

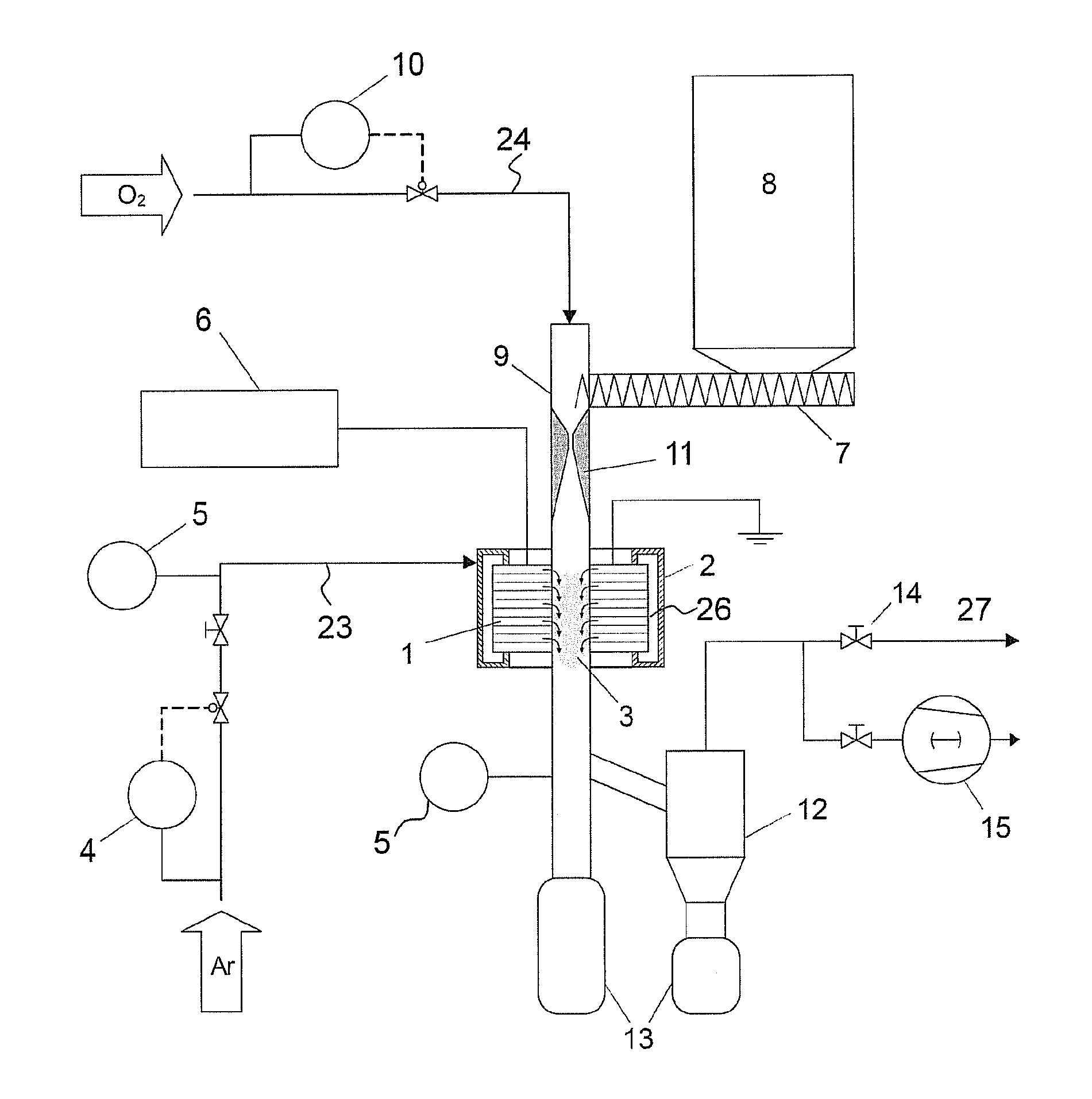

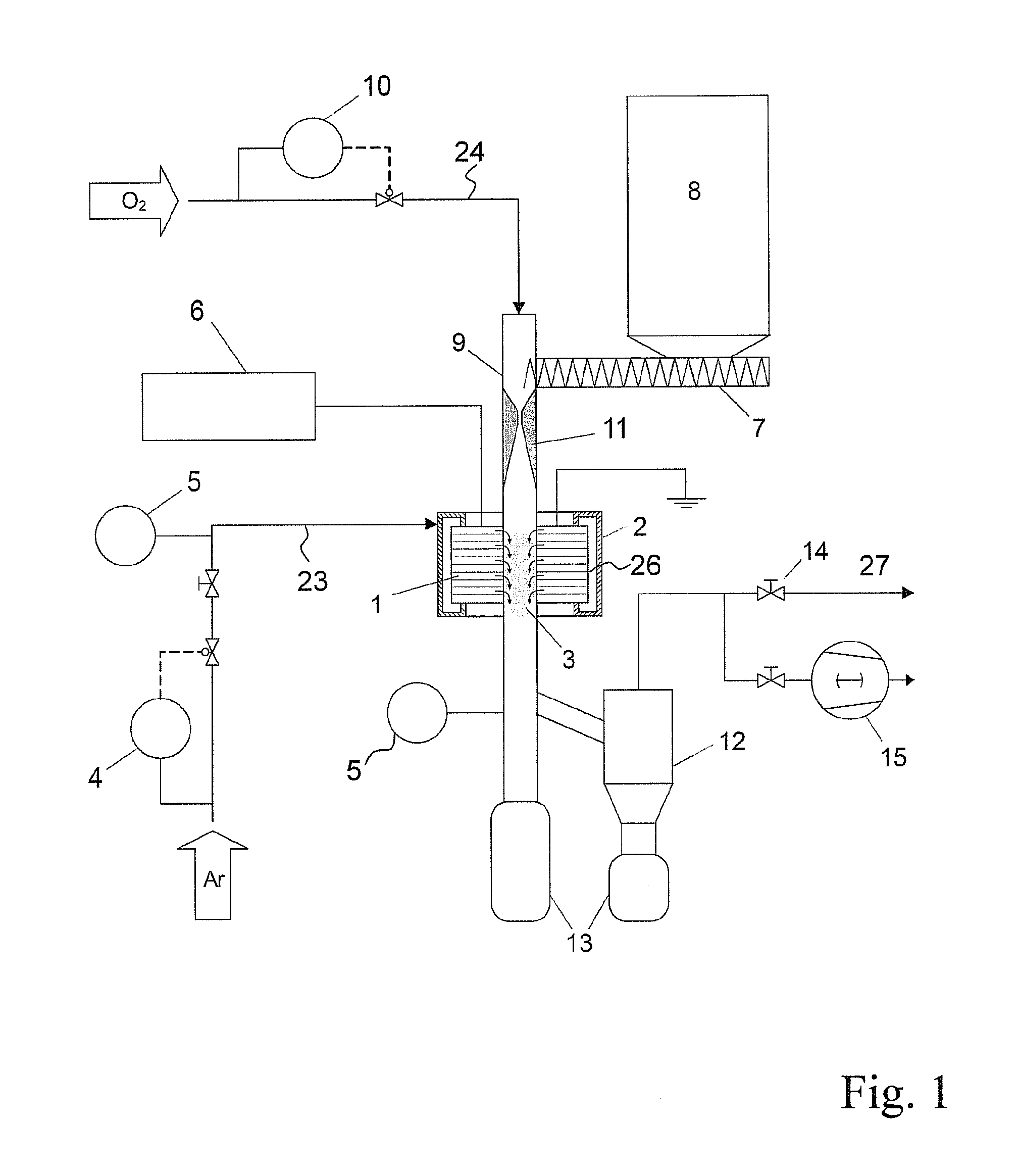

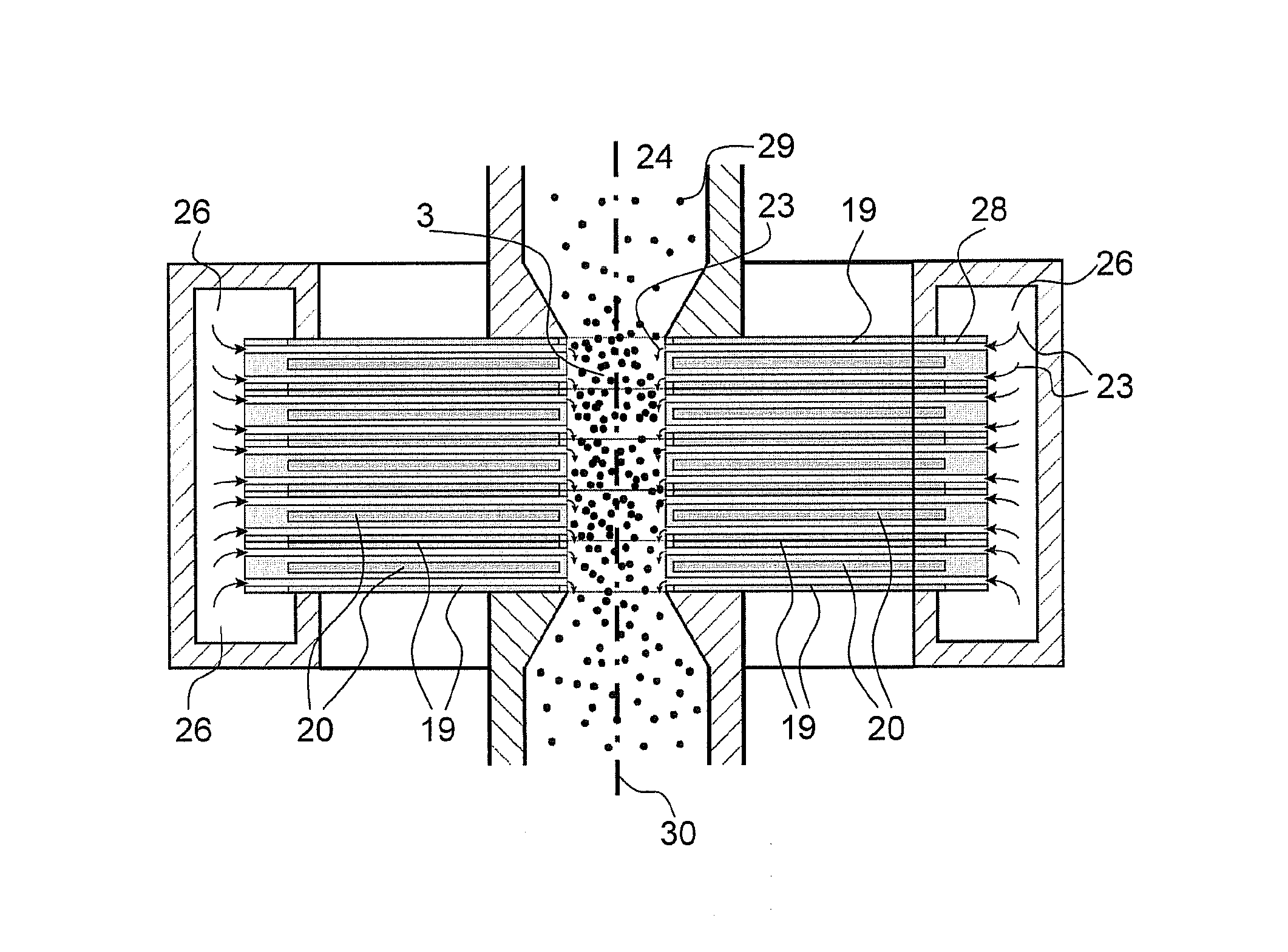

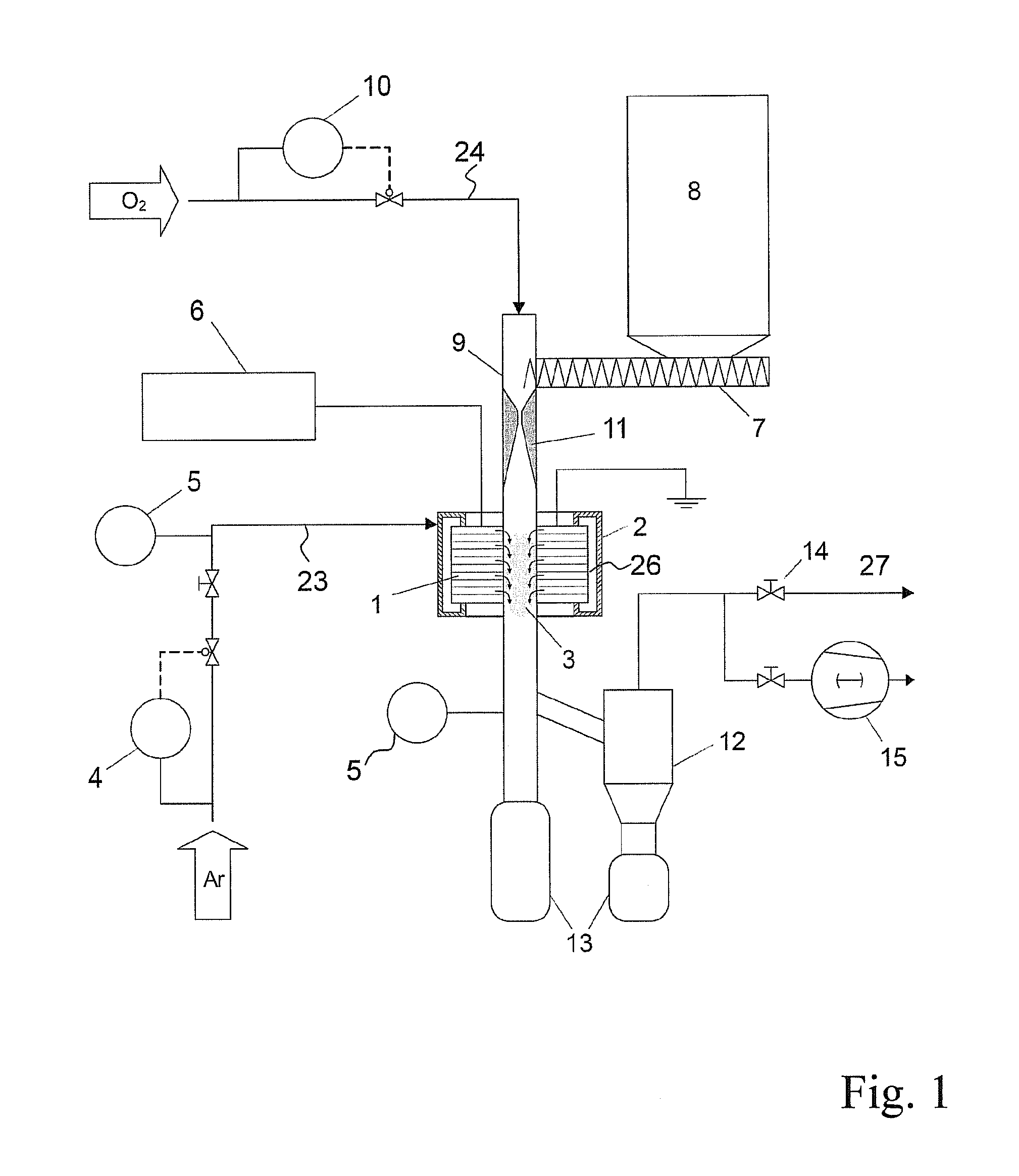

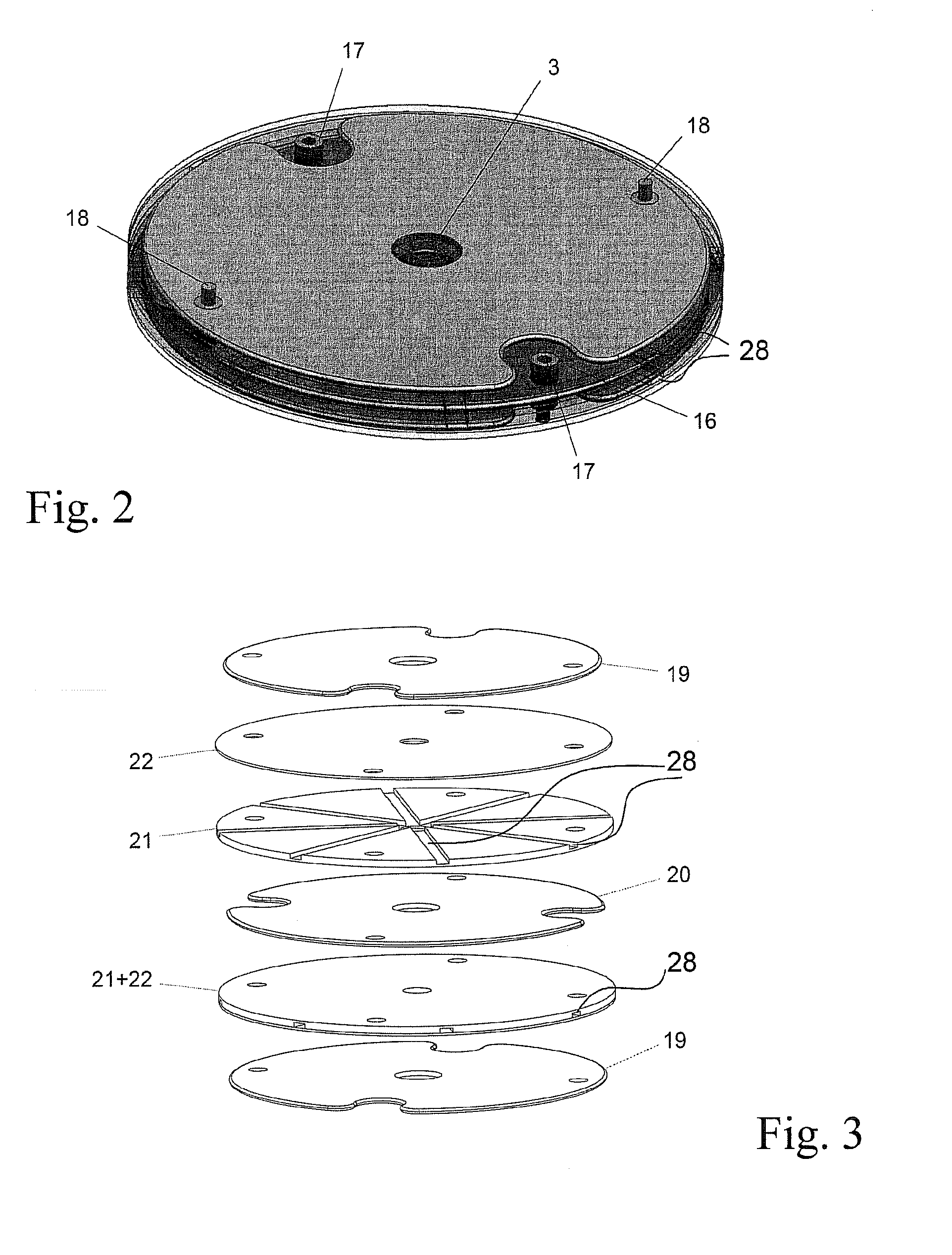

Remote non-thermal atmospheric plasma treatment of temperature sensitive particulate materials and apparatus therefore

InactiveUS20110039036A1Molten spray coatingChemical vapor deposition coatingParticulatesSystem pressure

The present invention relates to a novel process for the remote plasma surface treatment of substrate particles at atmospheric pressure. The invention is motivated by the urge to overcome major drawbacks of particle treatment in low pressure plasmas and in-situ particle treatment at atmospheric pressure. The former requires complex and mostly expensive vacuum installations and vacuum locks usually prohibiting continuous processing. Independent of the system pressure, in-situ plasma treatment causes particle charging and therefore undesirable interaction with the electric field of the discharge, which is seen to contribute to the process of reactor clogging. Additionally, the filamentary discharges modes of atmospheric pressure plasmas are inflicted with inhomogeneous surface treatment. Furthermore, short radical lifetimes at elevated pressures complicate a remote plasma treatment approach as widely used in low pressure applications. The key-element of the invention is that by reducing the dimension of the atmospheric discharge arrangement to the micrometer range, transonic flow conditions can be achieved in the discharge zone while maintaining moderate flow rates. The resulting superimposition of high drift velocity in the gas flow and the inherent diffusion movement is to prolong the displacement distance of activated species, thus making a remote plasma treatment of substrate particles feasible and economically interesting. The circumferential arrangement of e.g. micro discharge channels around the treatment zone of variable length allows a remote plasma treatment independently of the discharge mode and benefits additionally from the aerodynamic focusing of a particle-gas stream to the centre, reducing reactor clogging. Furthermore, taking advantage of non-thermal discharges, there is no restriction of the concept of the outlined invention in the material properties of the particulate solids especially not with regard to the treatment of temperature sensitive materials as often encountered in polymer or pharmaceutical industries. In conclusion, atmospheric pressure plasma treatment close to ambient gas temperature as well as continuous processing is a specialty of the invention disclosed here.

Owner:ETH ZZURICH

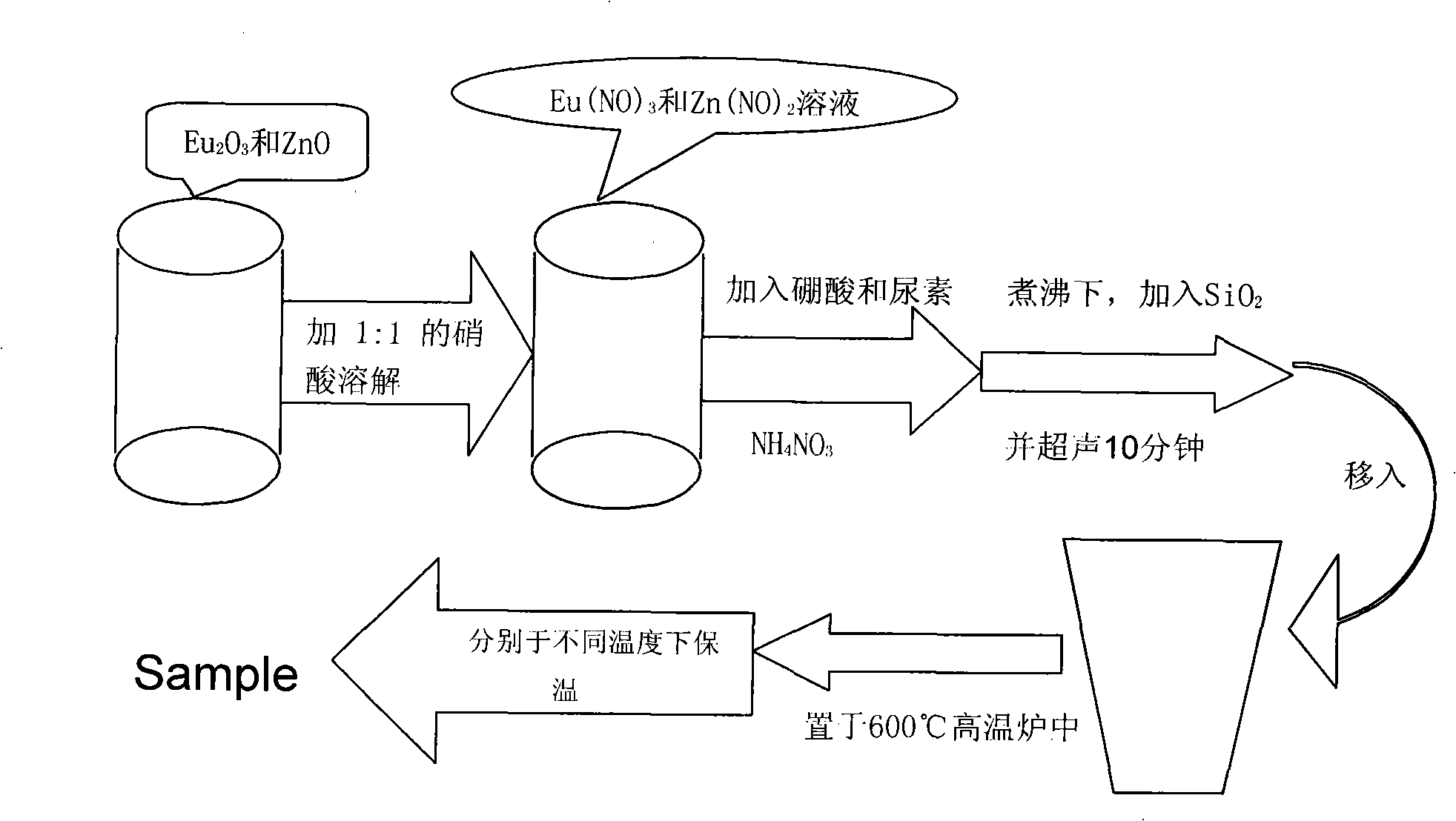

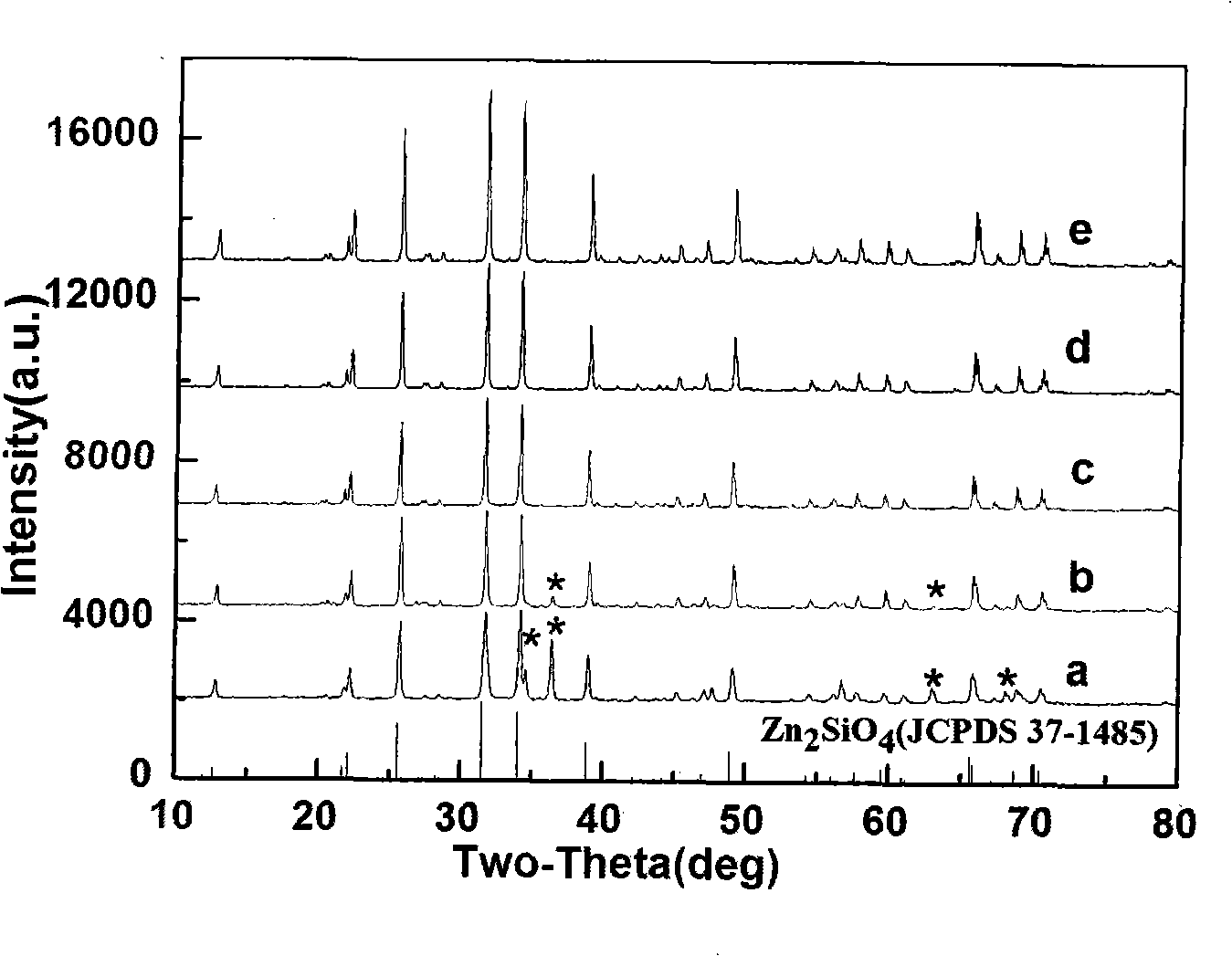

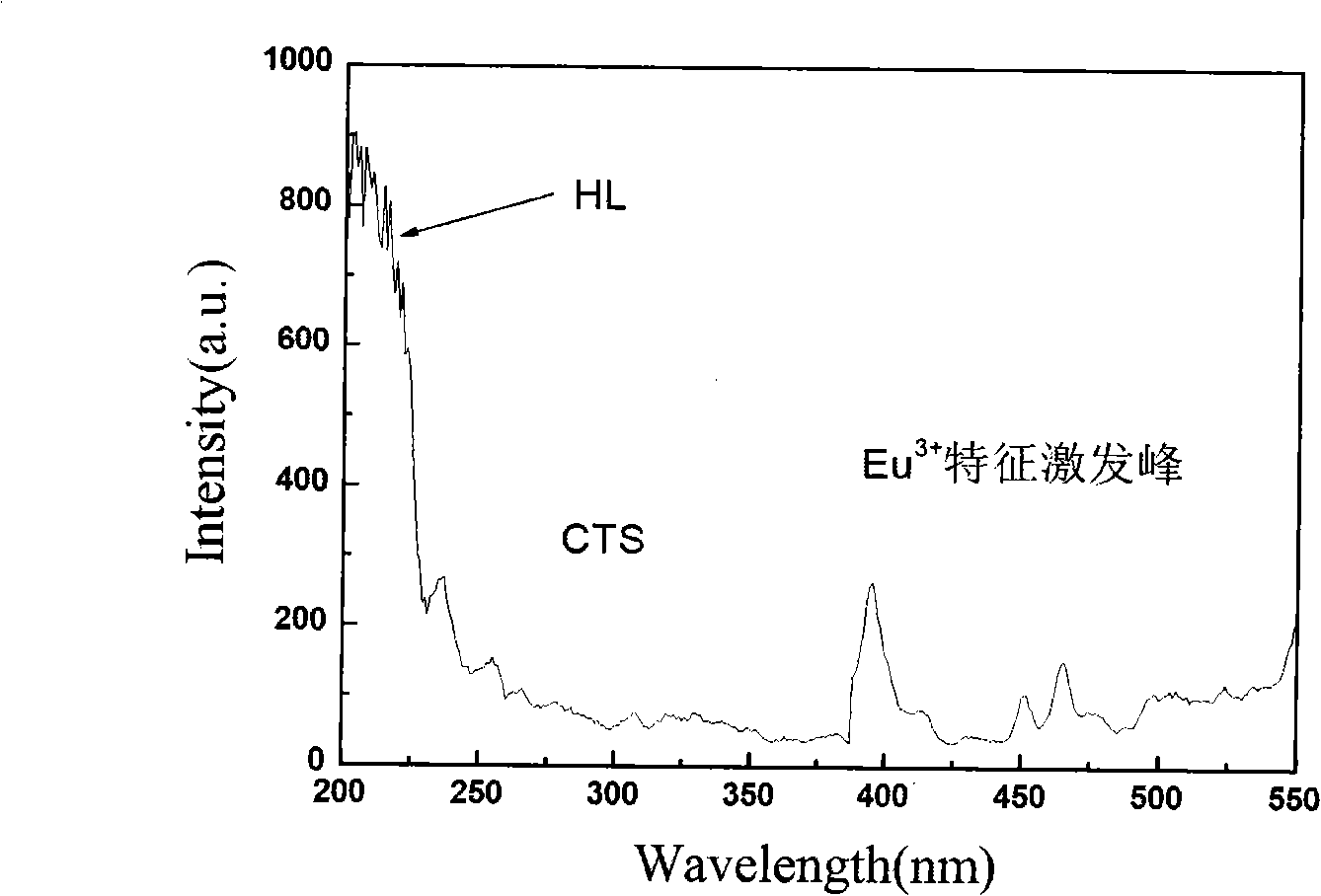

Preparation of red fluorescent powder Zn2SiO4:Eu3+

InactiveCN101280189AIncrease the heat of combustionGood crystal shapeLuminescent compositionsPhosphorBiological activation

The invention discloses the preparation method of red phosphor Zn2SiO4:Eu3+, which adopts the combustion method as the novel preparation method; Urea is used as the incendiary agent to synthesize the red phosphor Zn2SiO4:Eu3+ successfully; the combustion thermal discharge is improved and excessive combustion gas is generated through the addition of a small quantity of combustion auxiliary agent ammonium nitrate so that the combustion product is ensured to be looser; the combustion auxiliary agent is combusted in the interior of the mixture to catalyze the whole combustion reaction, facilitating the system to overcome high reaction activation potential barrier; the raw product is combusted within the temperature range of the experiment; after the continuous heat preservation; the product has small morphological changes; the crystal formation of the product is good, avoiding the decreasing of the luminescent property caused by the damage of the crystal lattice after grinding and crushing.

Owner:SHANGHAI NORMAL UNIVERSITY

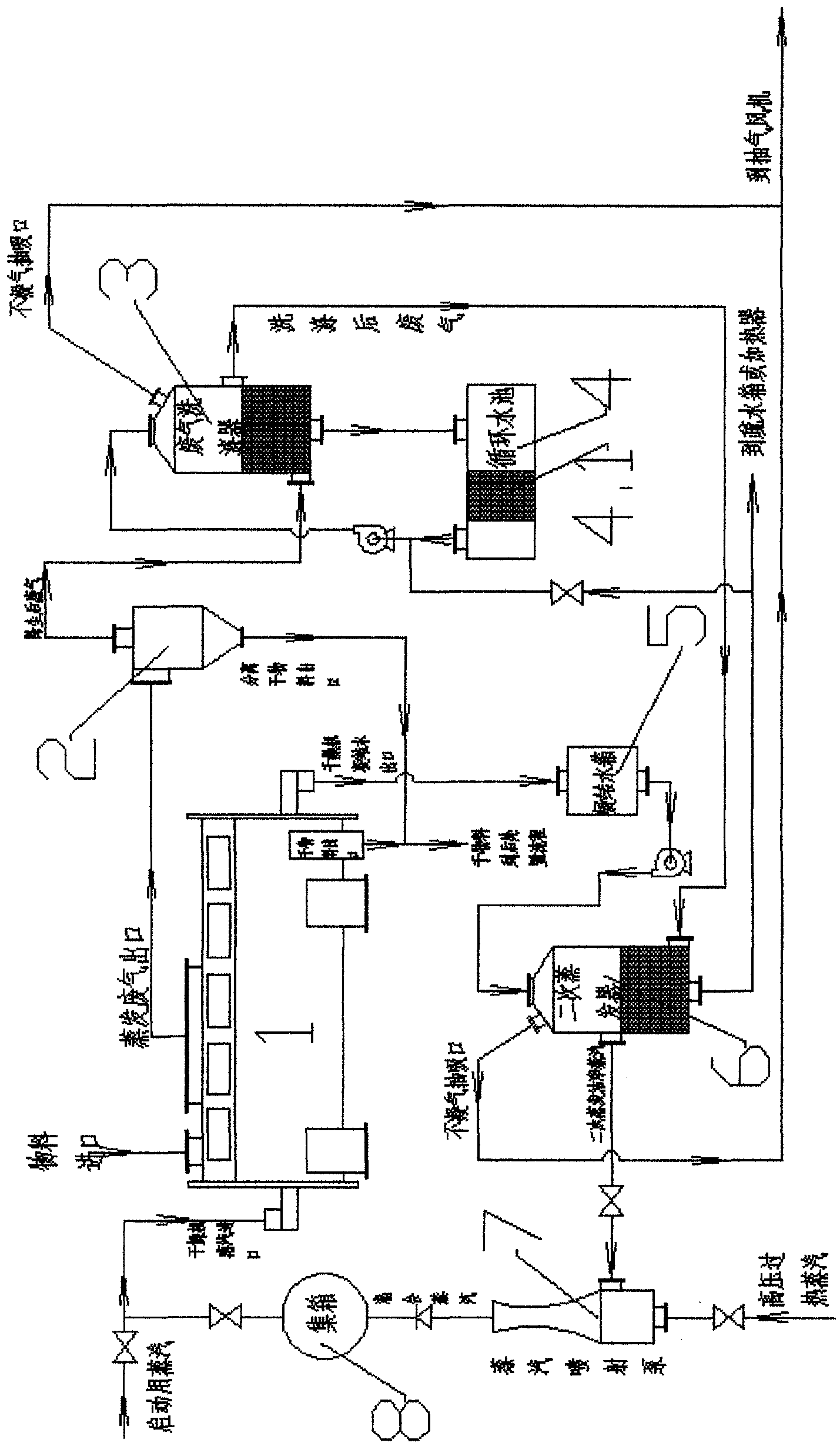

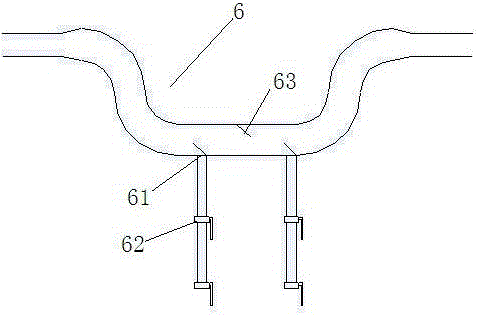

Method for waste steam recycling system

The invention relates to method for a waste steam recycling system. A dryer indirectly heats and dries wet materials by the aid of hot steam, a large quantity of waste gas mainly including water vapor is generated, a cyclone separator, a waste gas scrubber and a secondary evaporator can respectively remove dust, non-condensable gas and the like in the waste gas, the waste gas is changed into pure constant-pressure saturated steam, and a steam jetting pump can increase the pressure and the temperature of a large quantity of constant-pressure saturated steam by a small quantity of high-temperature and high-pressure steam, so that the steam can be recycled by the dryer. Latent heat of vaporization of the large quantity of saturated steam in the waste gas can be sufficiently utilized, waste gas treatment quantity is reduced greatly, a large quantity of cooling water is saved, condensed sewage is eliminated, environmental pollution caused by the dust, sewage, thermal discharge and the like is prevented, and energy conservation and emission reduction are realized. The quantity of equipment of a drying system is greatly reduced, reliability, stability and effectiveness of the system are improved, and running cost is greatly reduced.

Owner:胡彬

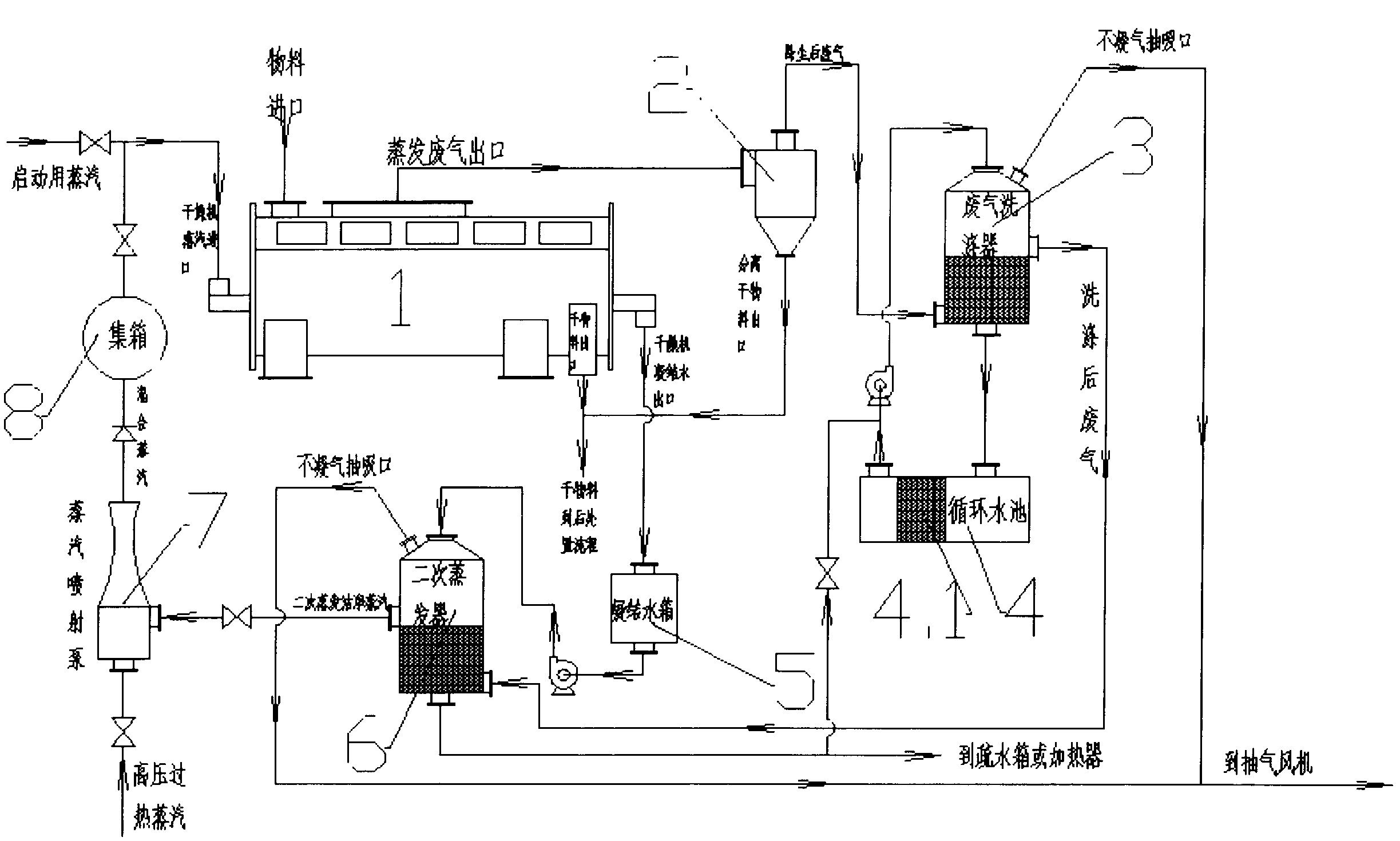

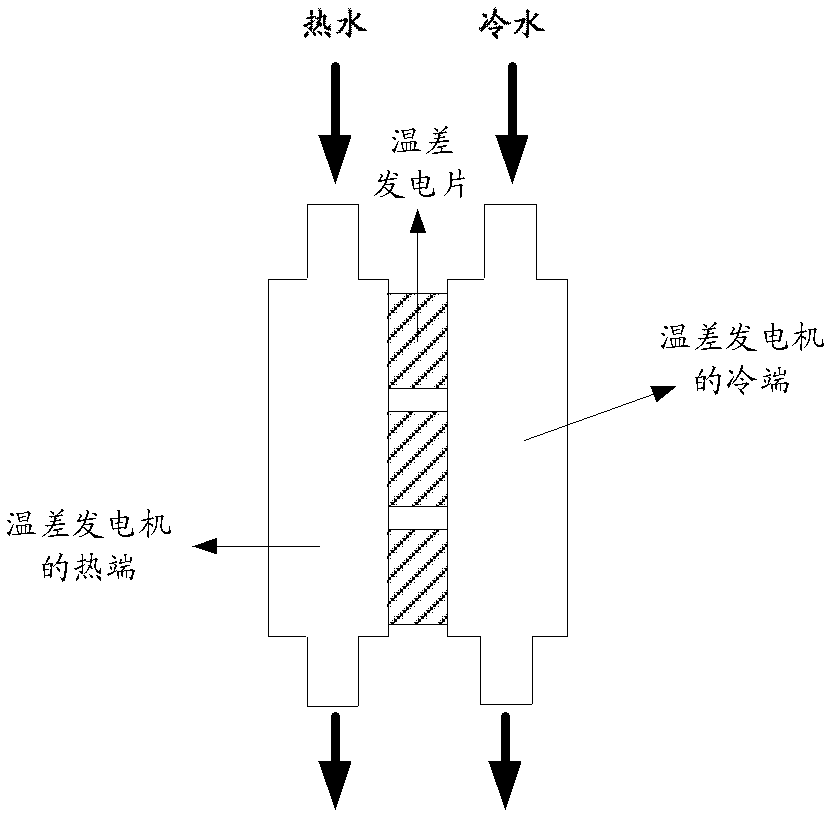

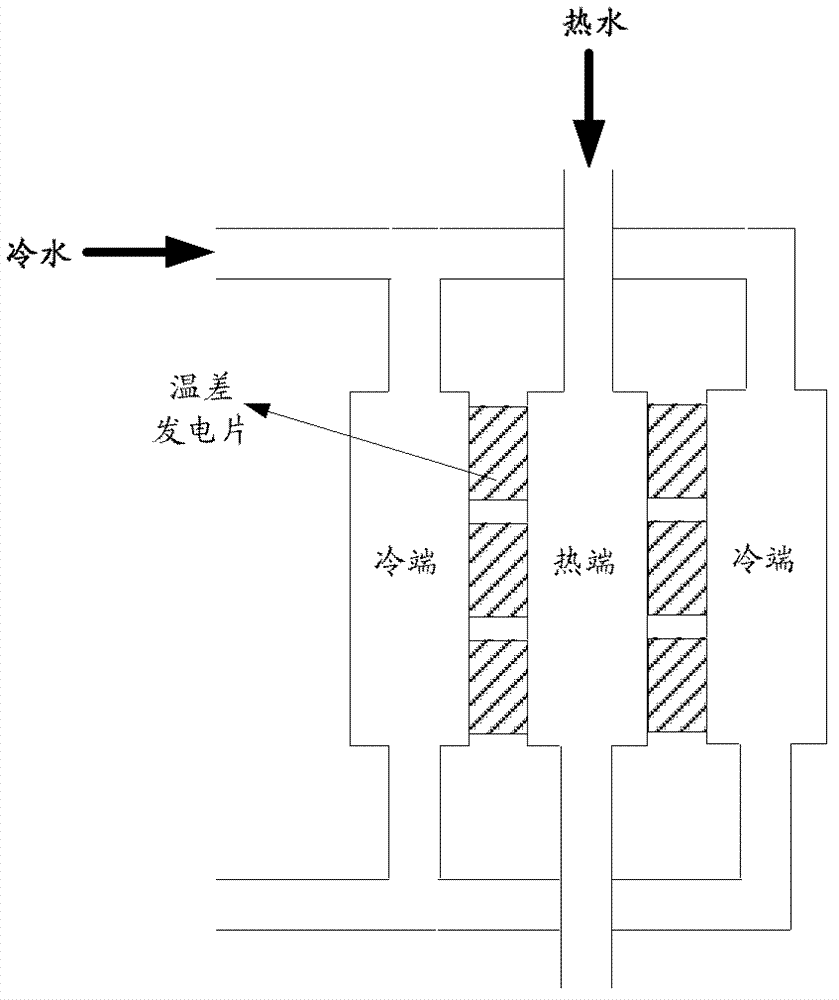

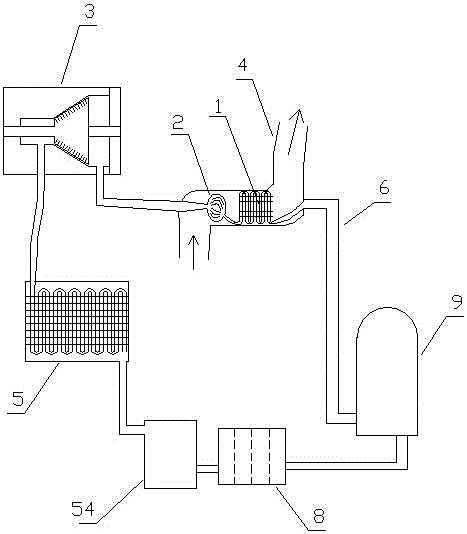

Temperature-difference power generation system

InactiveCN102780424AEmission reductionRealize repeated conversion power generationGenerators/motorsEngineeringTemperature difference

The invention discloses a temperature-difference power generation system, which comprises a temperature-difference generator, a hot pump device, a first heat exchange pool and a second heat exchange pool, wherein hot flowing medium flowing out from a hot source flows through the hot end of the temperature-difference generator via the first heat exchange pool; cold flowing medium flowing out from the second heat exchange pool flows through the cold end of the temperature-difference generator to flow back to the second heat exchange pool; a condenser of the hot pump device is arranged in the first heat exchange pool; heat is released to the flowing medium flowing through the first heat exchange pool; and an evaporator of the hot pump device is arranged in the second heat exchange pool to adsorb heat of the flowing medium in the second heat exchange pool. Because the hot pump technology is utilized, the medium on the cold end of the temperature-difference generator is kept at the low-temperature state, and therefore the temperature-difference generator can be applied to occasions which do not need an external cold source. In addition, energy released from the cold end of the temperature-difference generator is recovered and utilized by the hot pump. After certain energy is supplemented, the hot pump is utilized on the hot end of the temperature-difference generator for generating power, and a purpose of reducing thermal discharge is achieved.

Owner:苟仲武

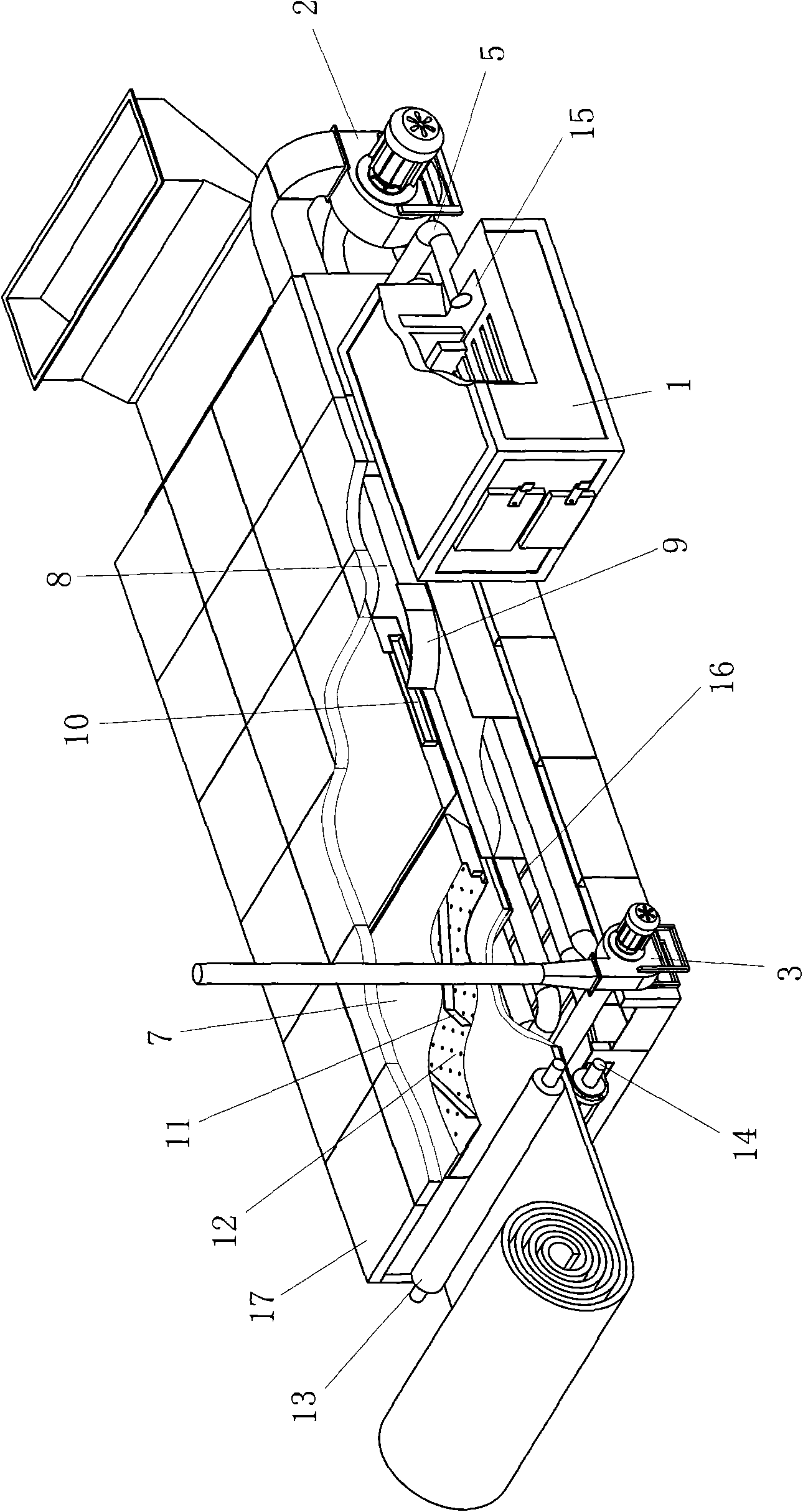

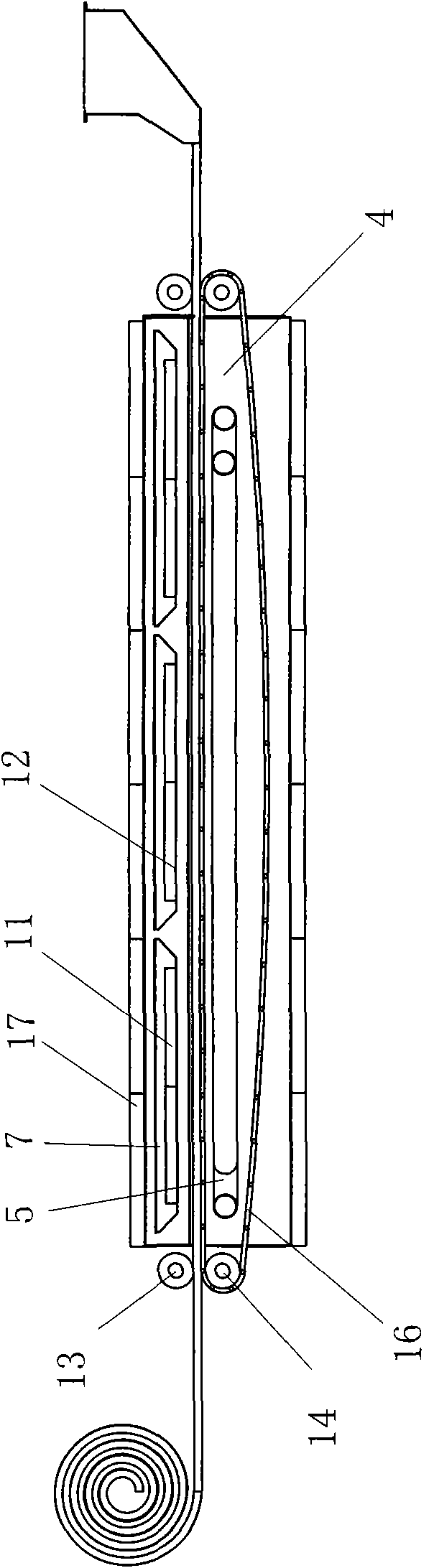

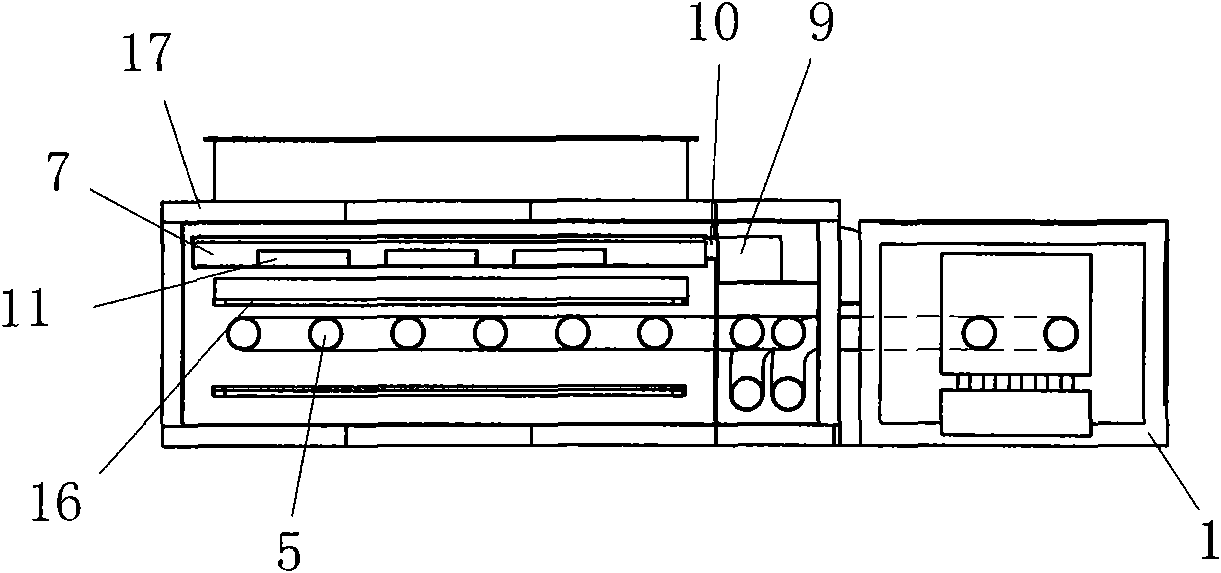

Thermal forming device for producing non-woven cotton

InactiveCN101824707AReduce volumeImprove the heating effectNon-woven fabricsCombustionHeat conducting

The invention relates to a thermal forming device for producing non-woven cotton, which comprises a feed assembly, a material conveying assembly, a discharge assembly, a heating assembly, a circulation heat conducting assembly and a heat preservation assembly. The heating assembly comprises a combustion furnace. The circulation heat conducting assembly comprises a circulating fan, a heat energy conveying pipe and a smoke exhaust fan. The heat preservation assembly comprises an oven. The heat energy conveying pipe comprises two heat conducting pipes uniformly distributed in the oven and a thermal discharge pipe for connecting the heat conducting pipes with the smoke exhaust fan. The thermal forming device has the characteristics of high energy utilization rate and easily controlled temperature and belongs to the technical field of the non-weave cloth machinery.

Owner:朱小明

Dryer

ActiveCN105444555AImprove drying efficiencyEasy to disassemble and repairFood processingDrying gas arrangementsDrying timeAir heating

The invention relates to a dryer, which comprises a dryer housing, an air heating room, an air supply room, a drying channel, an air inlet which is communicated with the air heating room, an air outlet which is communicated with the front end of the drying channel, a material inlet which is formed in the front end of the drying channel, and a material outlet which is formed in the rear end of the drying channel, wherein a heat source heat exchanger is arranged in the air heating room; and a direct-blowing type air supply device is arranged in the air supply room. The dryer also comprises an air regulation guide plate, an exhaust waste heat recycling device, an intelligent fresh air humidity regulation device and a hot air compensation device. The dryer has the beneficial effects that the dryer can be used for drying laver and other products; constant-temperature and stable air supply can be realized; the air supply device is convenient to dismount, maintain and clean; the exhaust waste heat recycling function and partial exhaust recycling function are realized; thermal discharge is reduced and a product is energy-saving so that the production cost is reduced; and the hot air compensation device is capable of improving the drying efficiency of the dryer and shortening the drying time.

Owner:WENZHOU XINGBEI MACHINERY TECH CO LTD

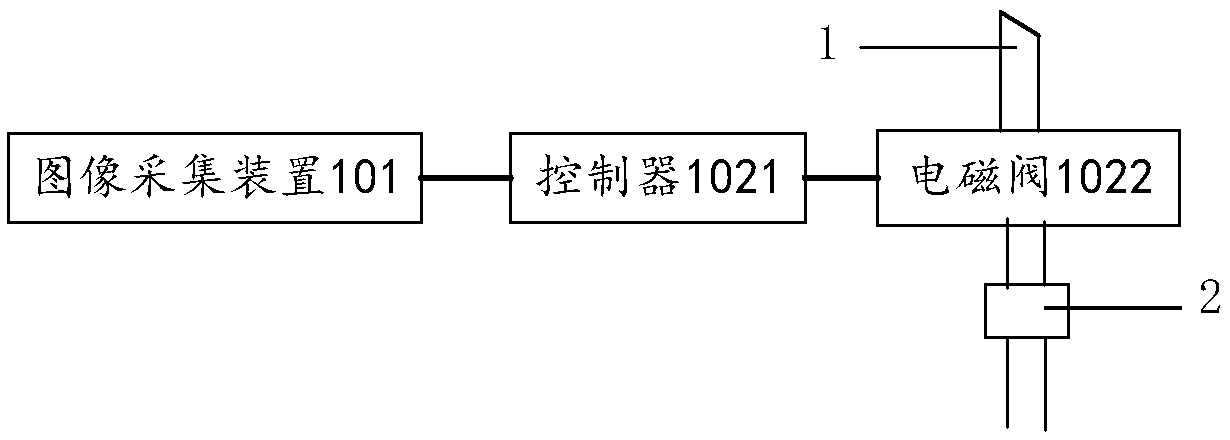

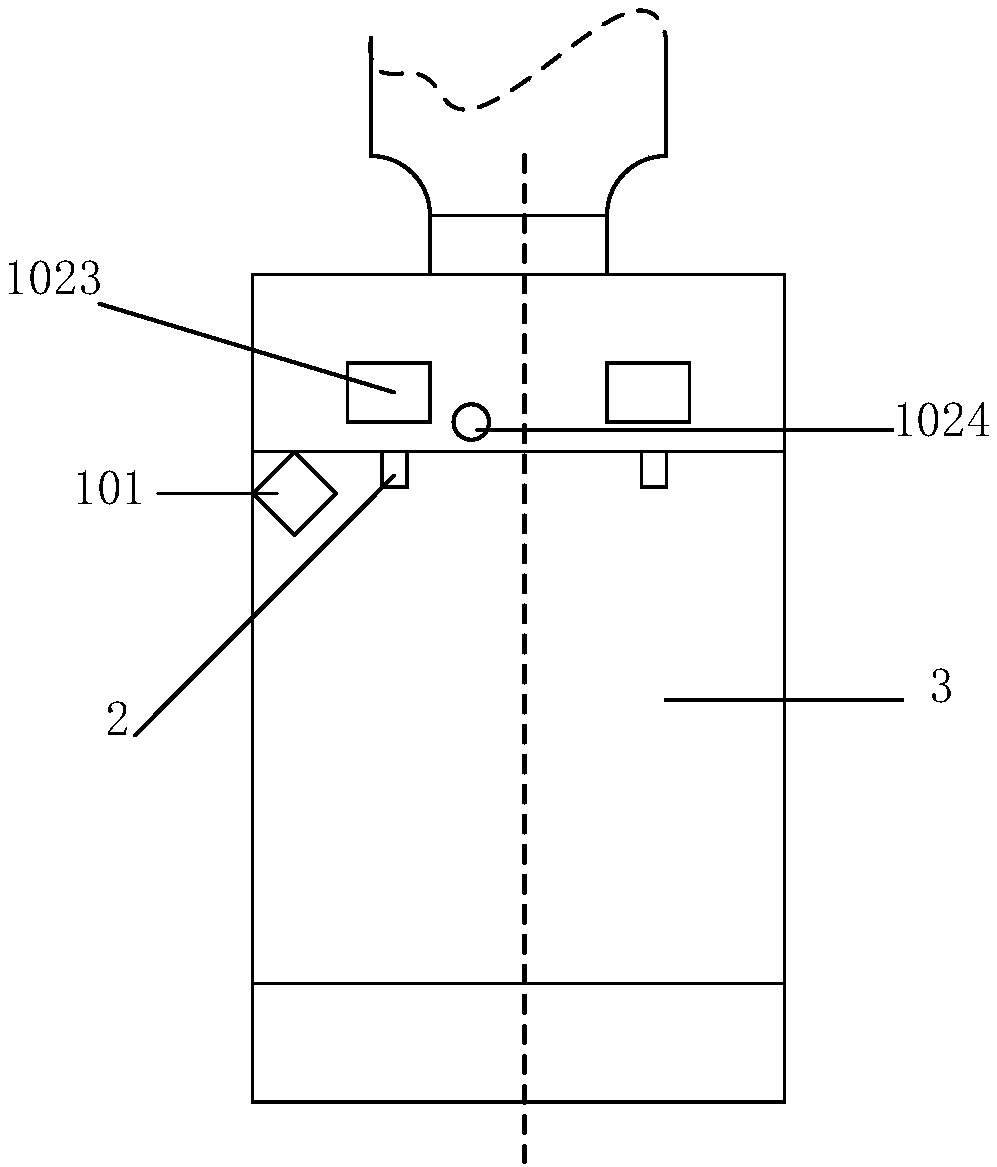

Water dispenser, control method and device for water dispenser

The invention relates to a water dispenser, a water dispenser control method and a water dispenser device. The water dispenser comprises a water receiving window and a thermal discharge pipeline. Theoutlet water control circuit is used for controlling the on-off of the hot water discharge pipeline according to the object image output by the image acquisition device. According to the technical proposal provided by the invention, since you do not need to deploy a personal computer or server, the water outlet control circuit can directly control the on-off of the hot water outlet pipeline according to the object image output by the image acquisition device, thereby realizing safe water outlet, reducing the dependency on the network and high reliability. In addition, the equipment cost and the manpower input for deploying the personal computer and the server are saved, the user cost is reduced, and the user experience degree is high.

Owner:GREE ELECTRIC APPLIANCES INC

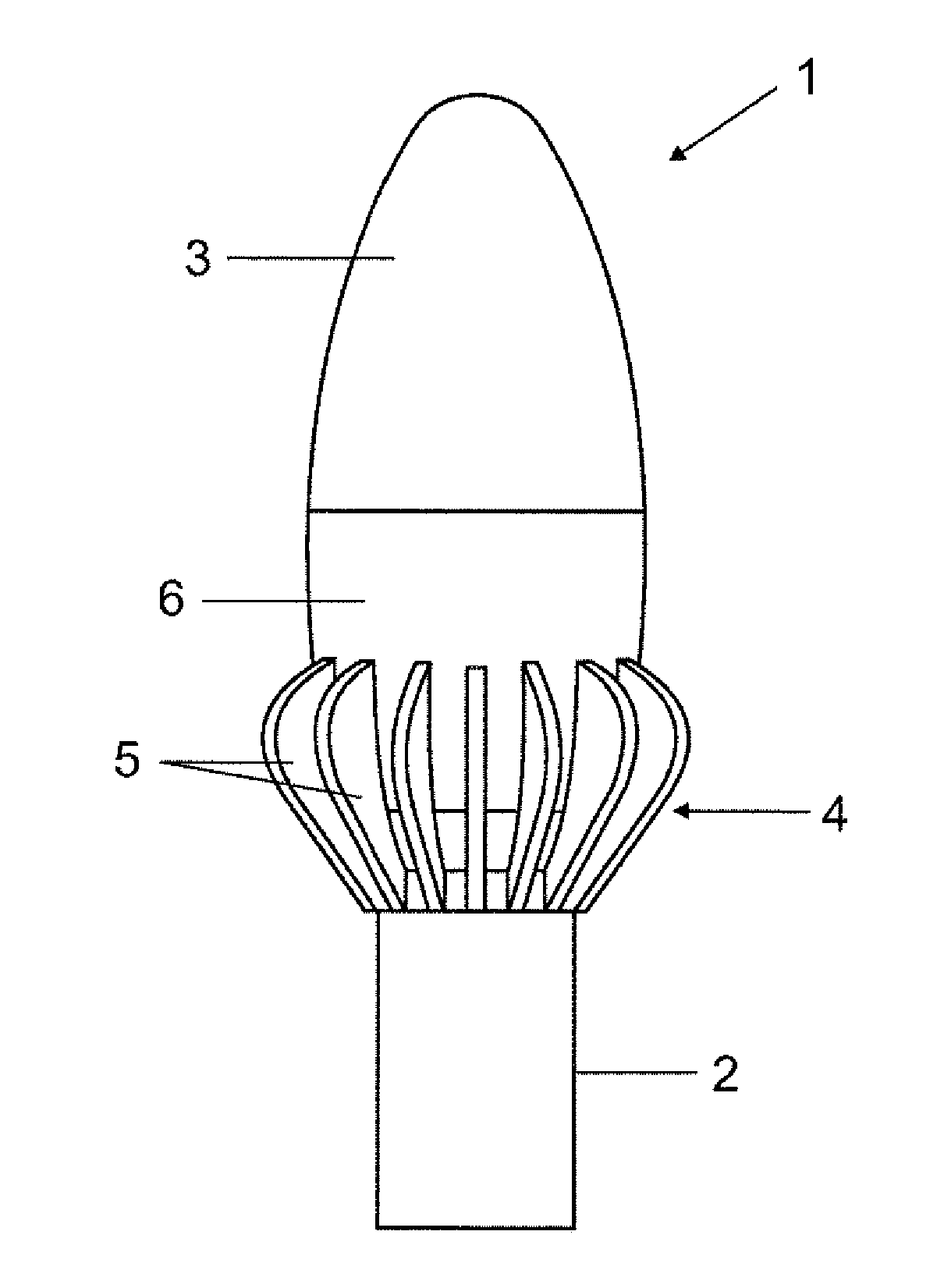

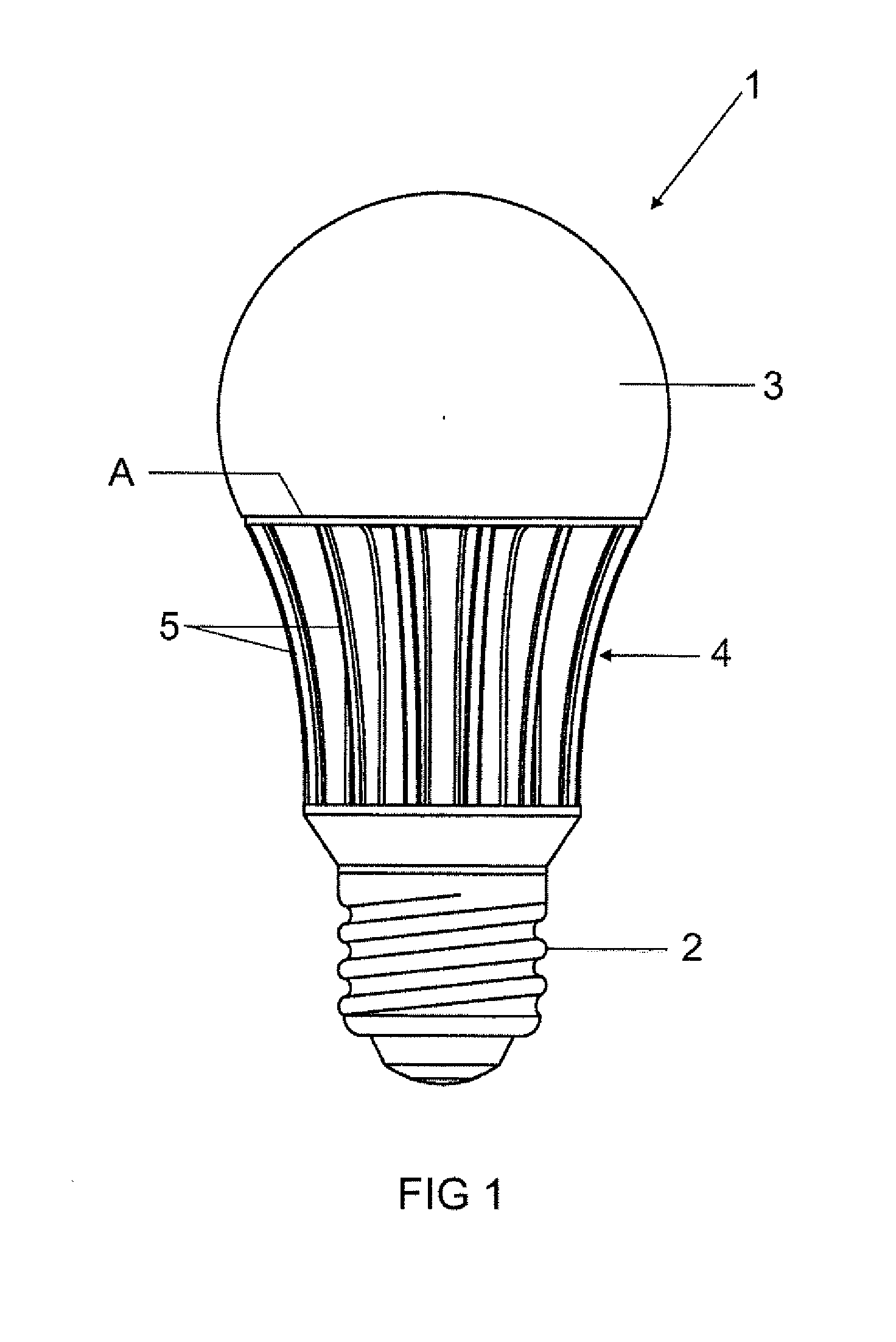

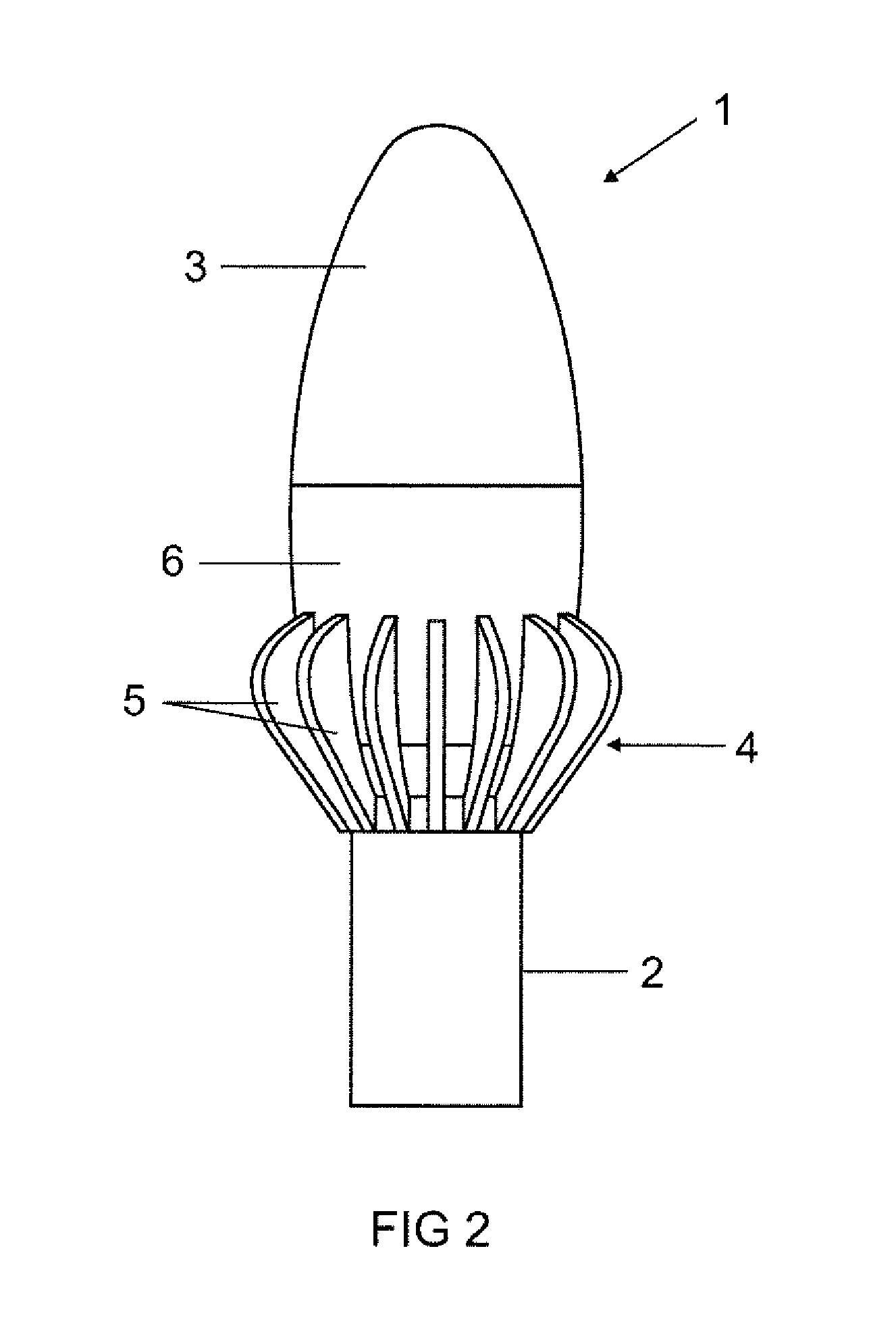

Illumination apparatus with a heat sink

InactiveUS20110170302A1Cut surfaceAvoid contactPoint-like light sourceLighting heating/cooling arrangementsEngineeringLight-emitting diode

An illumination apparatus is provided. The illumination apparatus may include at least one light-emitting diode; and at least one heat sink for cooling the light-emitting diode, wherein at least one component of the illumination apparatus provided for thermal discharge has an emission coefficient of more than 0.75.

Owner:OSRAM GMBH

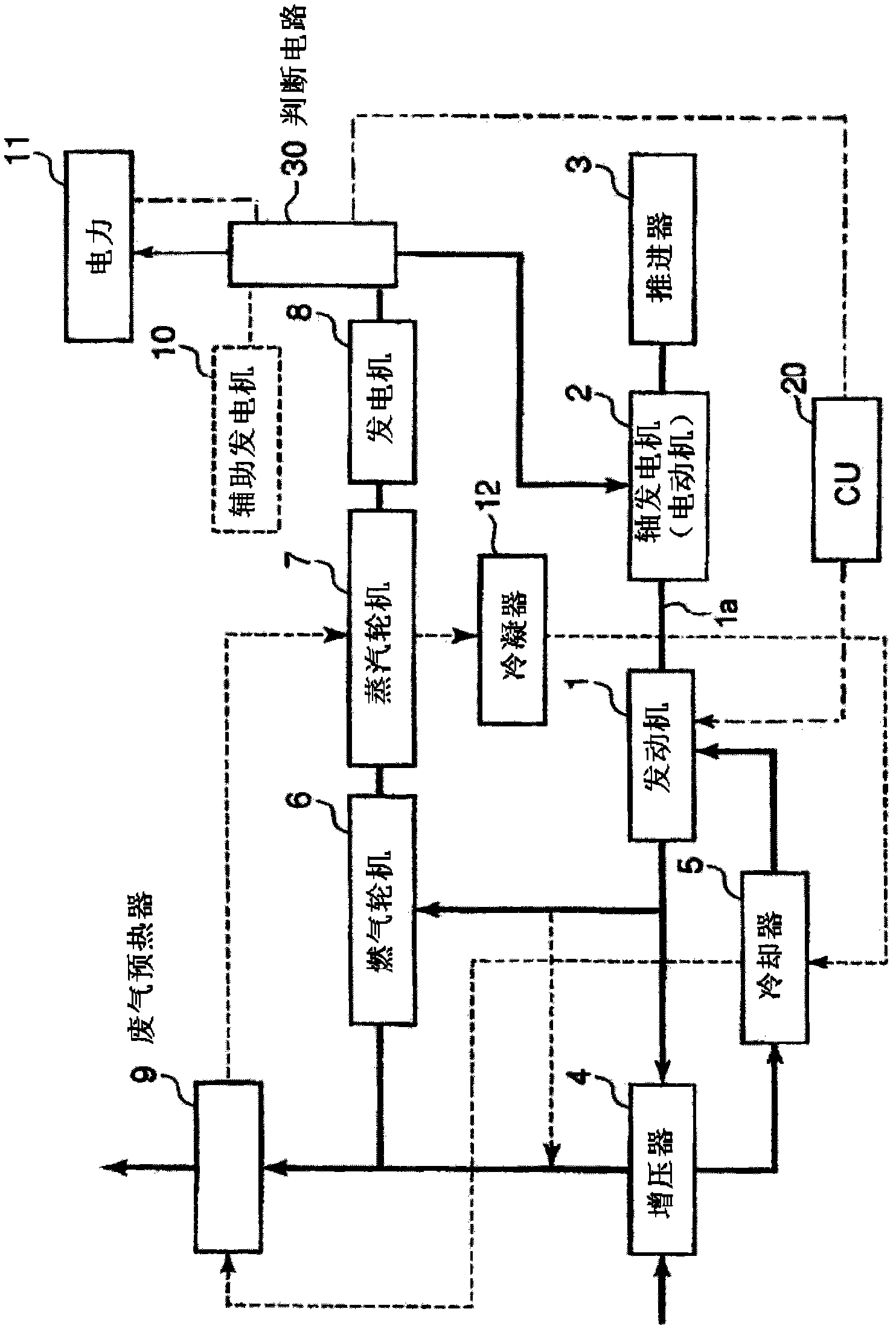

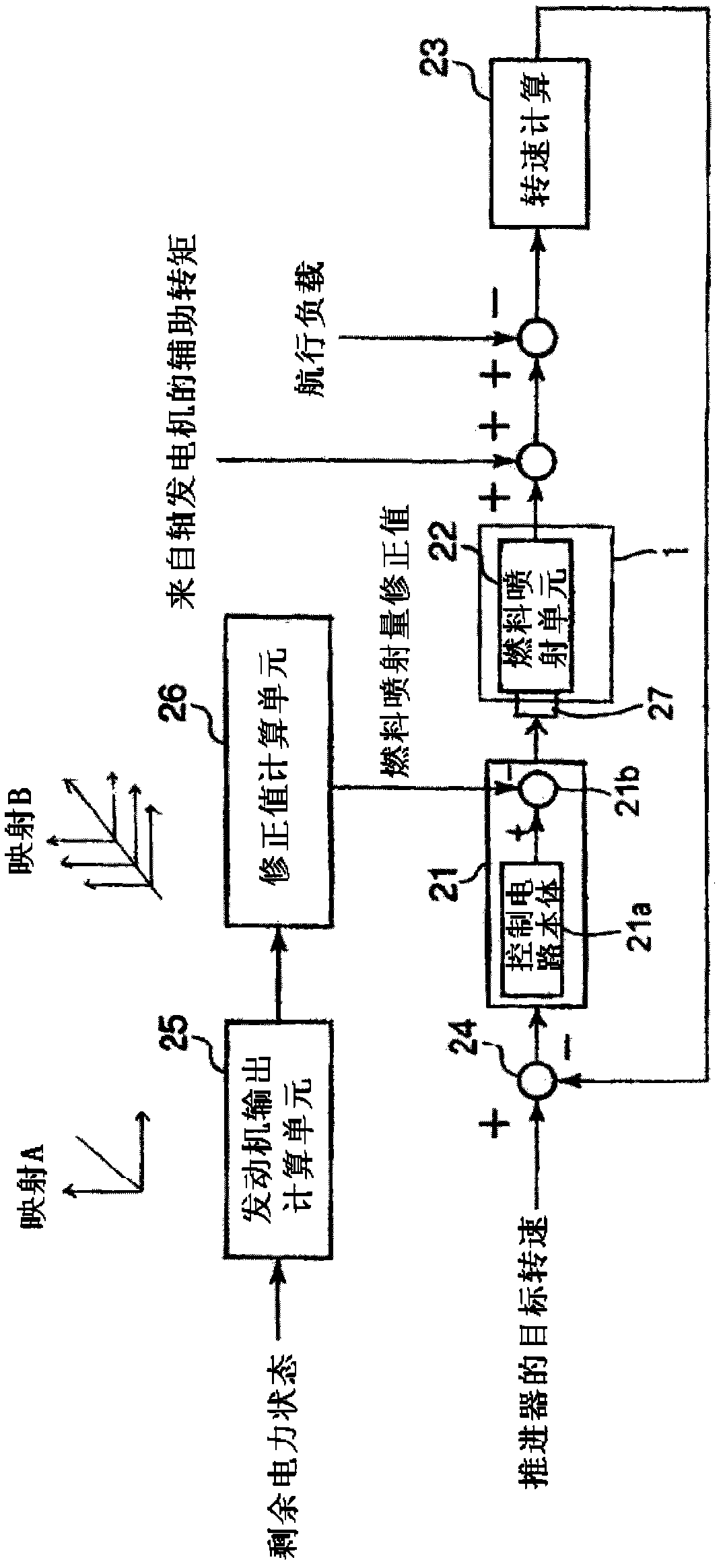

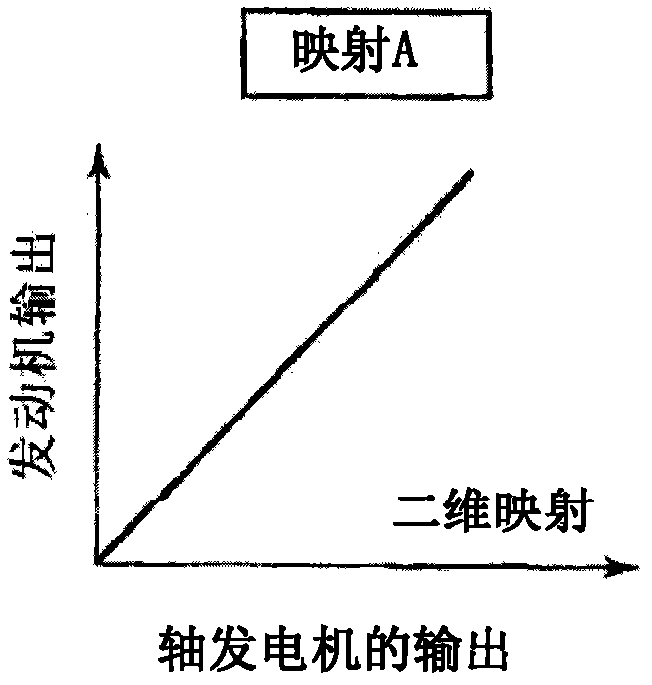

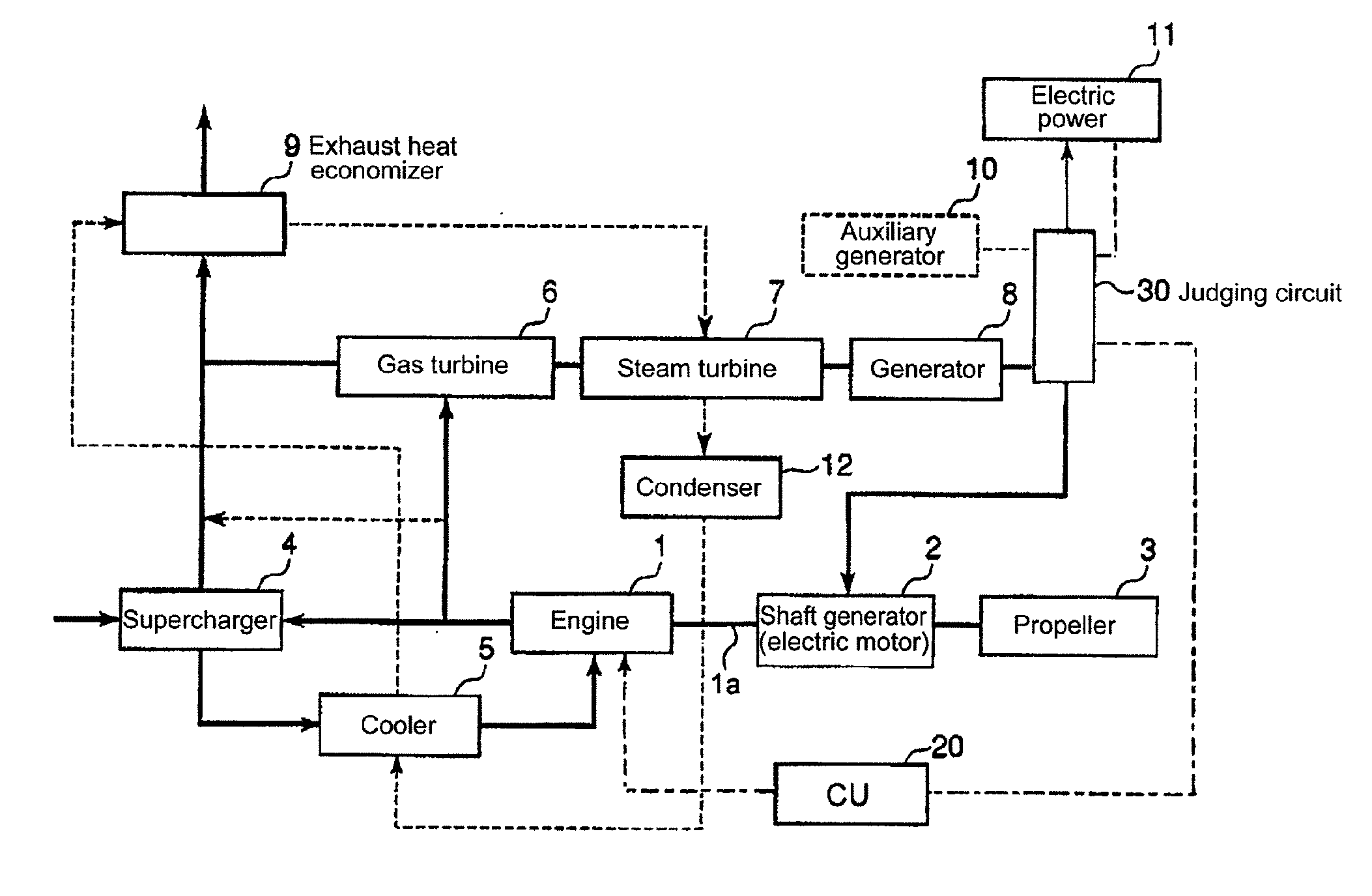

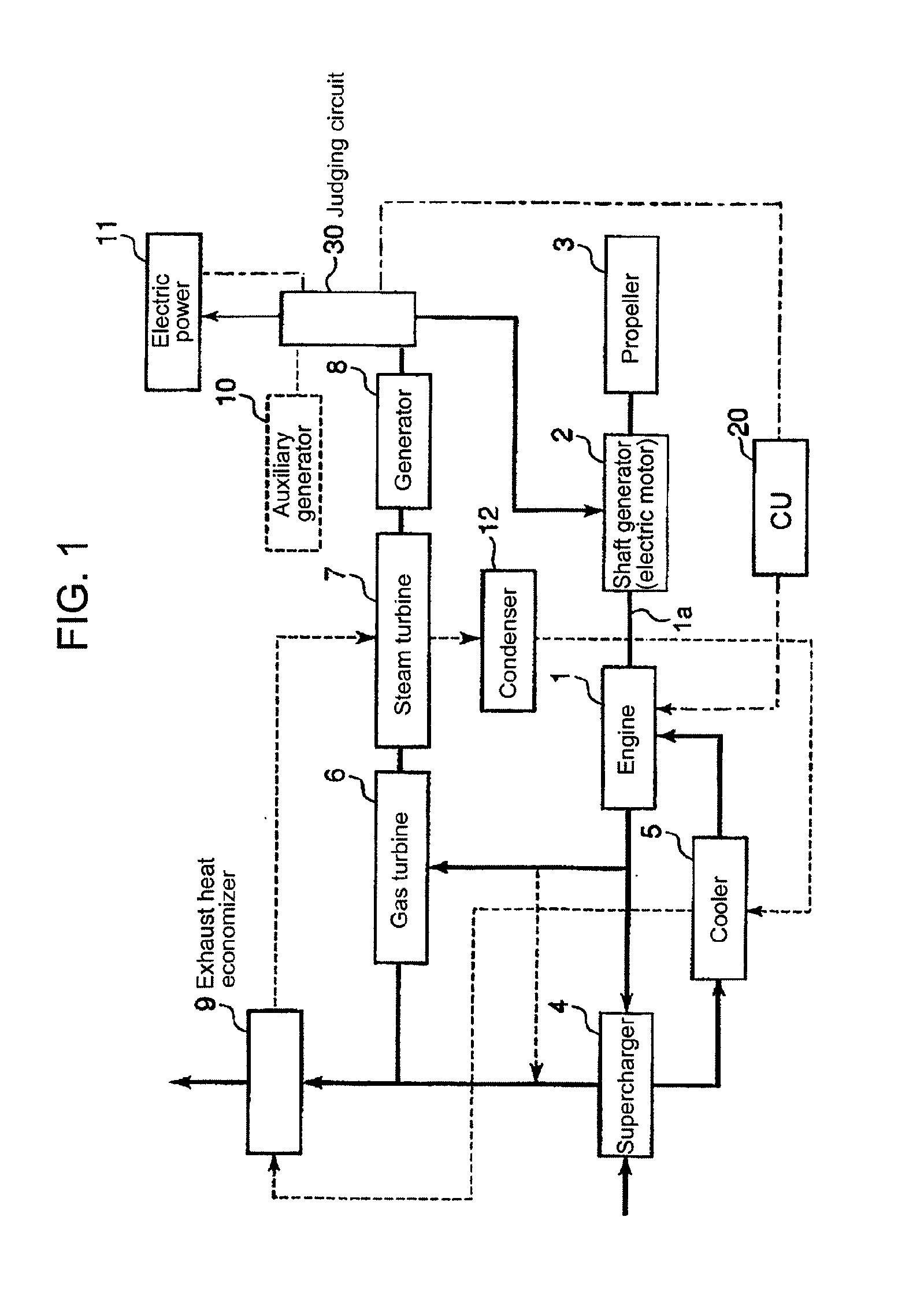

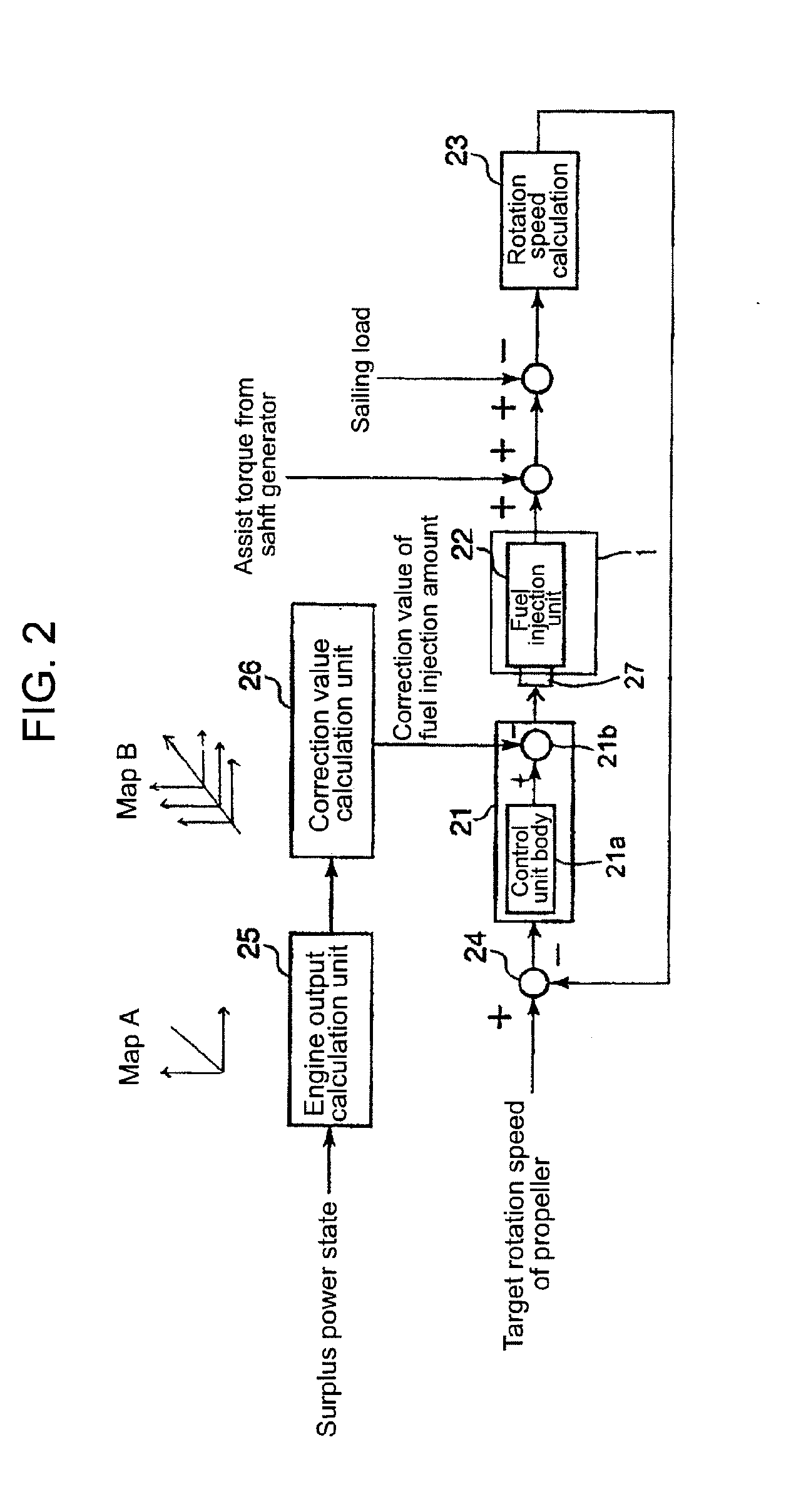

Controller for ship equipped with thermal discharge recovery system and the ship equipped with the controller

ActiveCN102256869AImprove responsivenessSuppression of changes in ship speedElectrical controlPropulsion based emission reductionPropellerInternal combustion engine

A ship powered by an internal combustion engine (1) and an electric motor (2) connected to a propeller (3) powered by surplus electric power obtained by a thermal discharge recovery system has a controller including a feedback control section for controlling a base amount of fuel injected to the internal combustion engine (1) based on the difference between the target number of rotation of the propeller given by the operator and the real number of rotation, and a feed-forward control section having a means (25) for calculating an overall power output and a means (26) for calculating a correction in the amount of fuel injected to the internal combustion engine based on the overall power output and the number of rotation of the propeller. The base amount of fuel is corrected by subtracting the correction obtained by the feed-forward section from the base amount of fuel calculated by the feedback control section whereby preventing a rapid change in the speed of the ship due to rapid change in ship loads.

Owner:MITSUBISHI HEAVY IND LTD +1

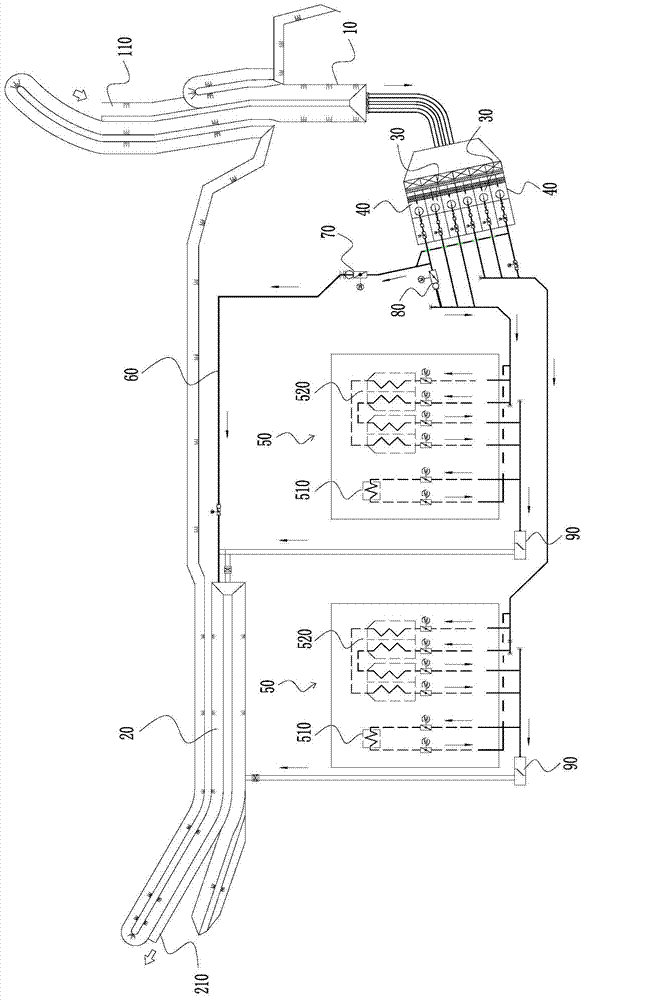

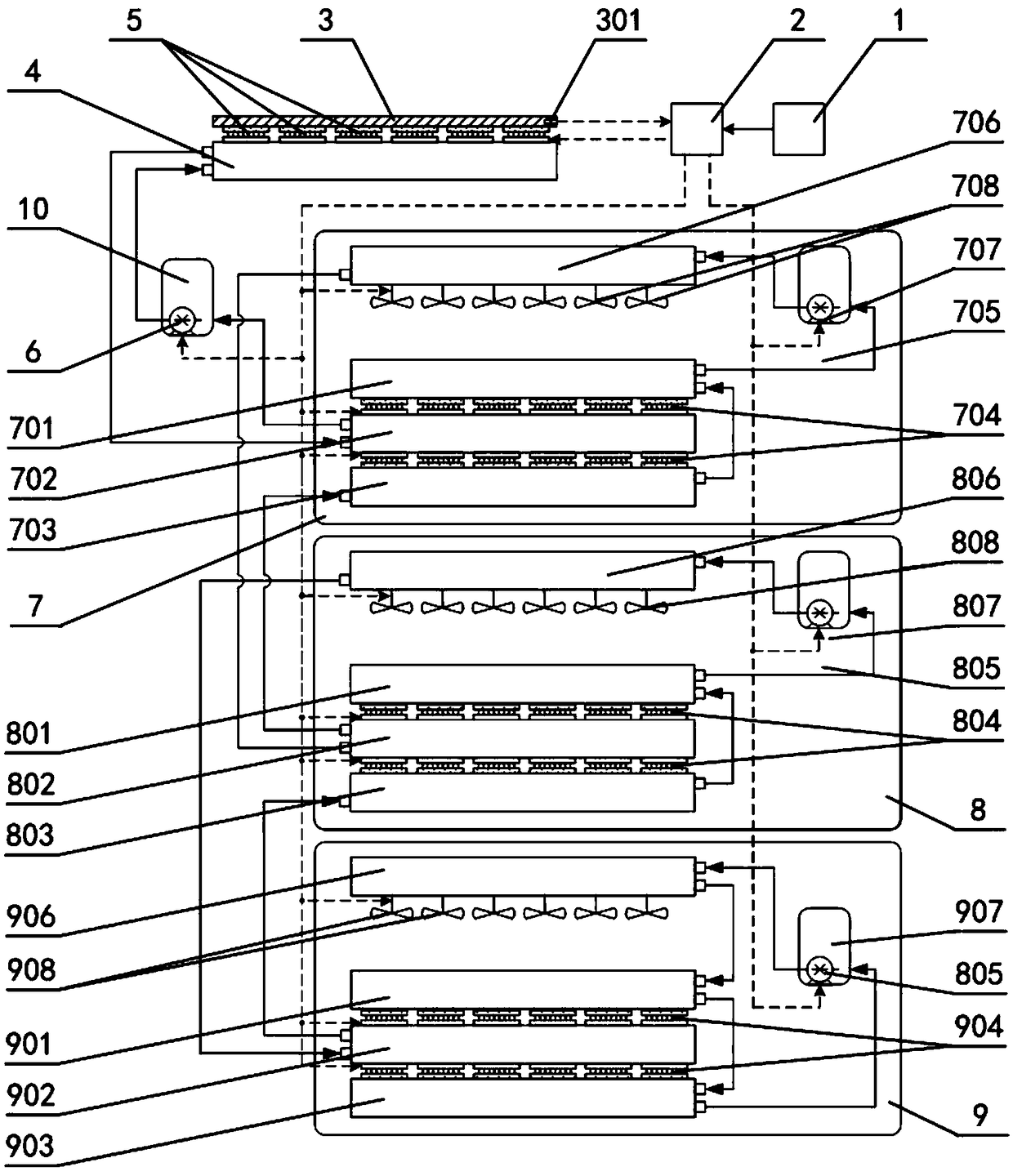

Power plant seawater once-through cooling system

ActiveCN104729178AReduce heat pollutionSave land areaLighting and heating apparatusCooling fluid circulationCooling towerEconomic benefits

The invention relates to a power plant seawater once-through cooling system. The power plant seawater once-through cooling system comprises an intake canal with a water inlet, a drainage canal with a water outlet, a circulating water pump, a mixing water pump, a heat exchange device and pipelines; the intake canal, the circulating water pump, the heat exchange device and the drainage canal are sequentially connected through the pipelines to form a main cooling system body, the intake canal, the mixing water pump and the drainage canal are sequentially connected through the pipelines to form a mixing cooling system body, and a first valve is connected between the mixing water pump and the drainage canal. According to the power plant seawater once-through cooling system, the main cooling system body and the mixing cooling system body are arranged, original seawater directly transported by the mixing cooling system body and thermal discharge water output by the main cooling system body are mixed in the drainage canal, and therefore the temperature, discharged to a sea, of the thermal discharge water is reduced; the temperature, entering the sea, of the thermal discharge water can be reduced without needing to arrange a cooling tower, the thermal pollution of the thermal discharge water of a power plant is reduced, the plant area is greatly decreased, the initial investment is reduced, the energy consumption is reduced, and the economic benefit is improved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

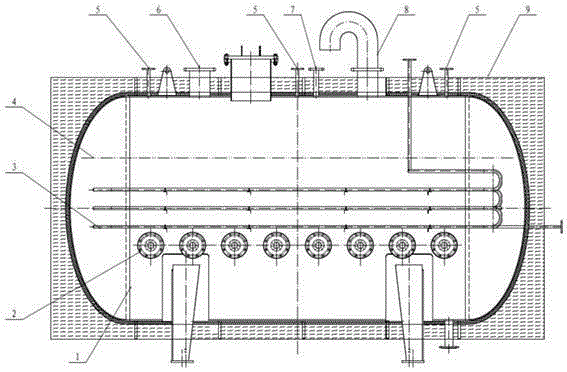

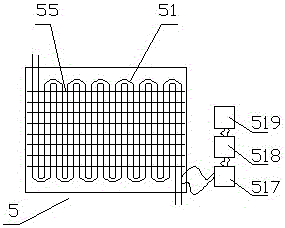

Molten salt thermal storage heater

InactiveCN105115336ARealize direct heat exchangeHigh thermal efficiencyHeat storage plantsThermal energy storageHeat transfer fluid

A molten salt thermal storage heater comprises a tank body, a molten salt temperature measurement device, a molten salt adding hole, a molten salt liquid level measurement device and an atmosphere vent hole welded on the top of the tank body, wherein molten salt is disposed inside the tank body, a resistance heater auto-control system is disposed inside the molten salt, the resistance heater auto-control system comprises a high-sensitivity molten salt temperature detection component, a PLC programmable controller, frequency-converting control of a feed pump and an auto-switching component used in thermal storage and thermal discharge of a molten salt thermal storage system, a heat exchange coil pipe is disposed inside the molten salt of the tank body, and an inlet and an outlet of the heat exchange coil pipe respectively pass through the middle and the top of the tank body. The device provided by the invention perfectively places the heat exchange coil pipe inside a thermal storage medium and gets rid of necessary dependency on using air as a heat-transfer fluid, so as to realize direct heat exchange between the thermal storage medium and steam or hot water. In this way, a heat transfer coefficient and system thermal efficiency are increased to the optimal level, equipment volume is reduced greatly, equipment losses are also reduced, and social and economic benefits become better.

Owner:HEBEI YINENG BOILER

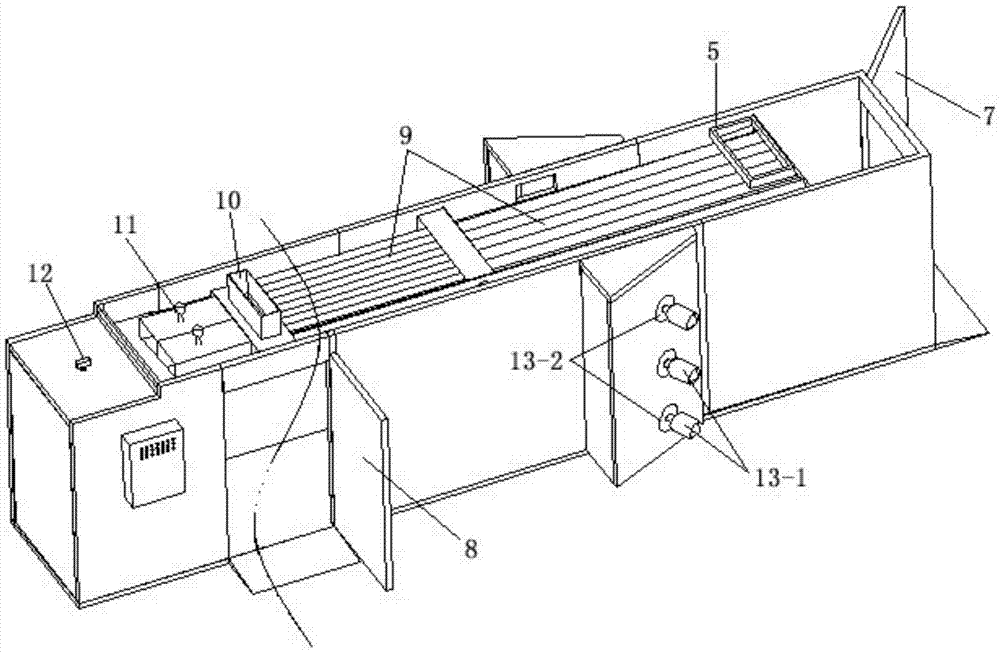

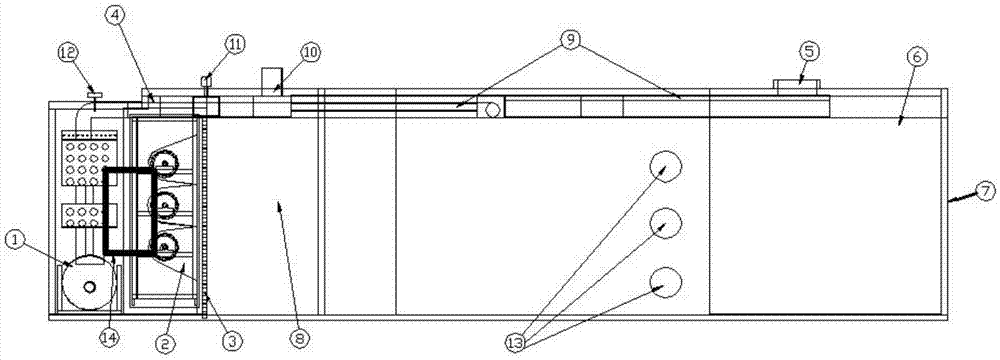

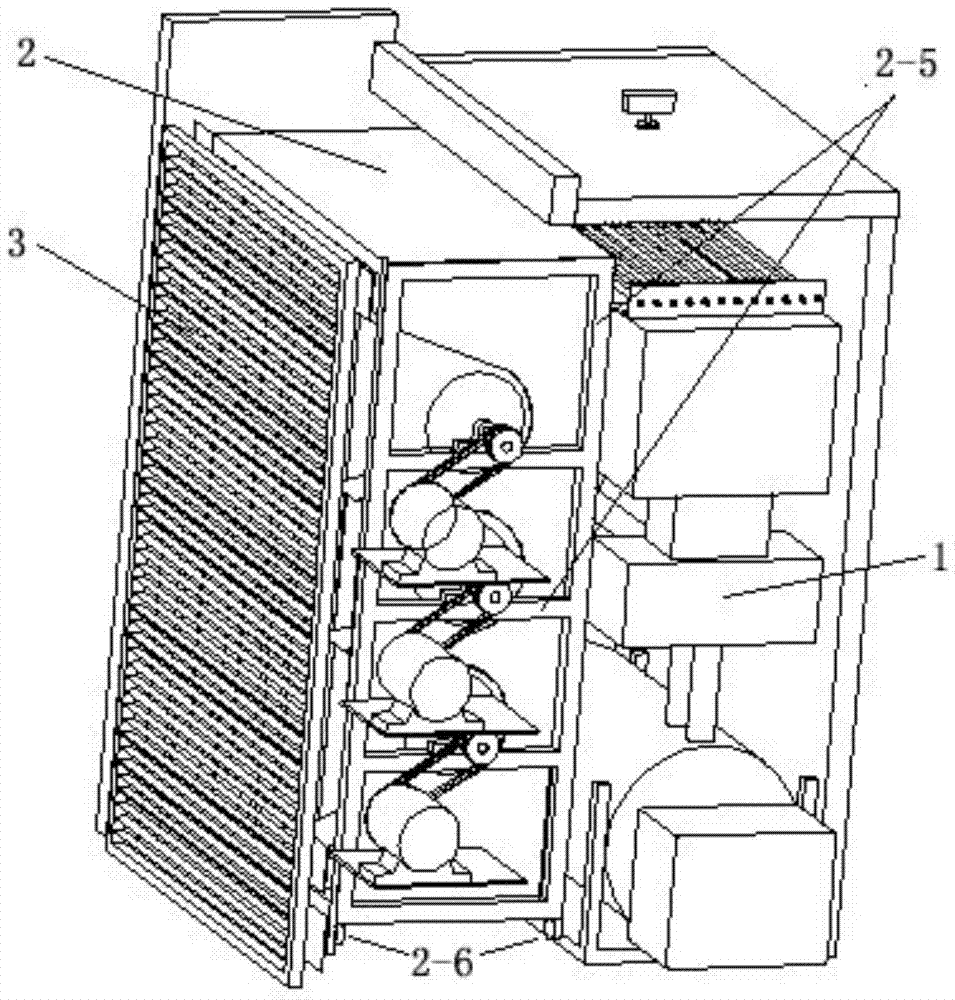

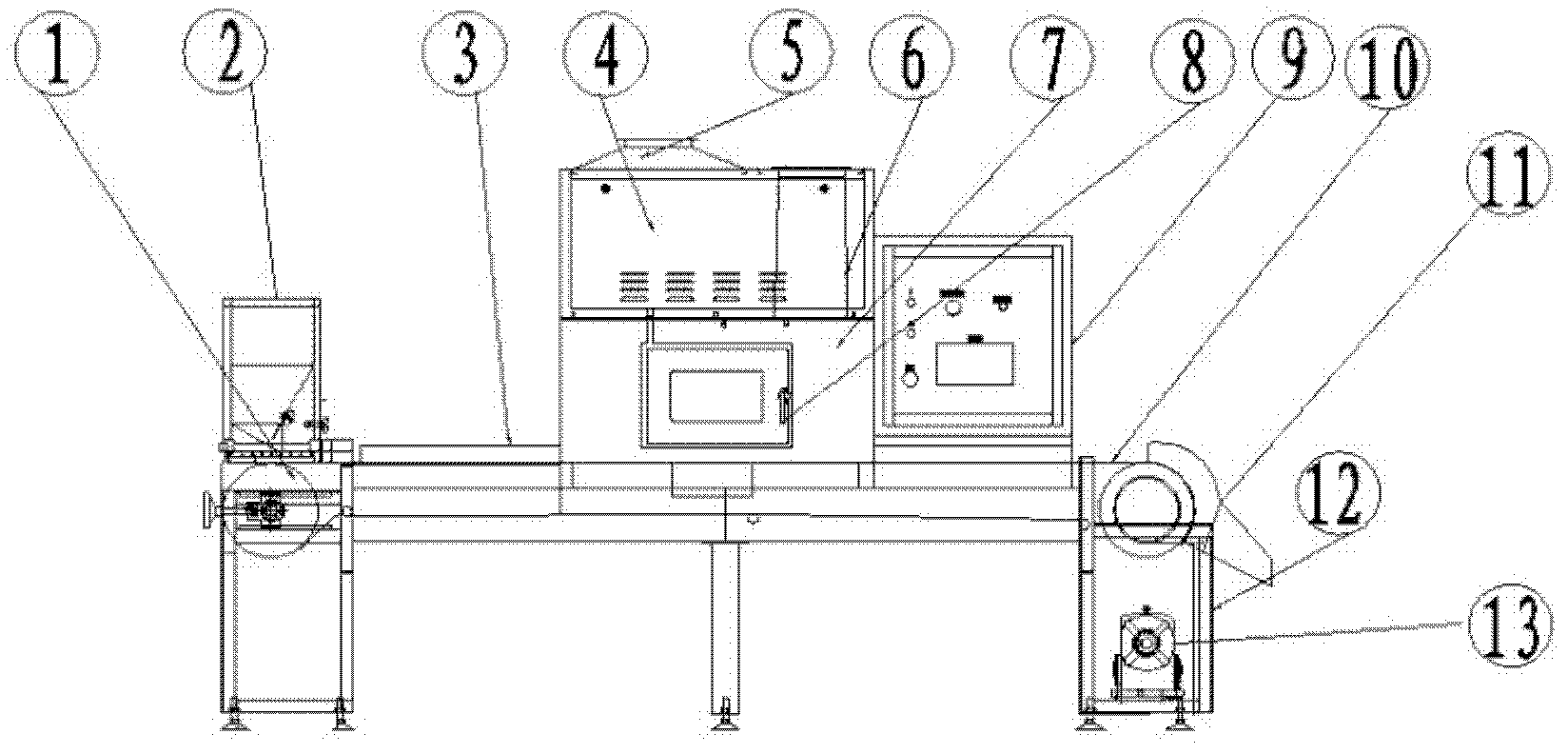

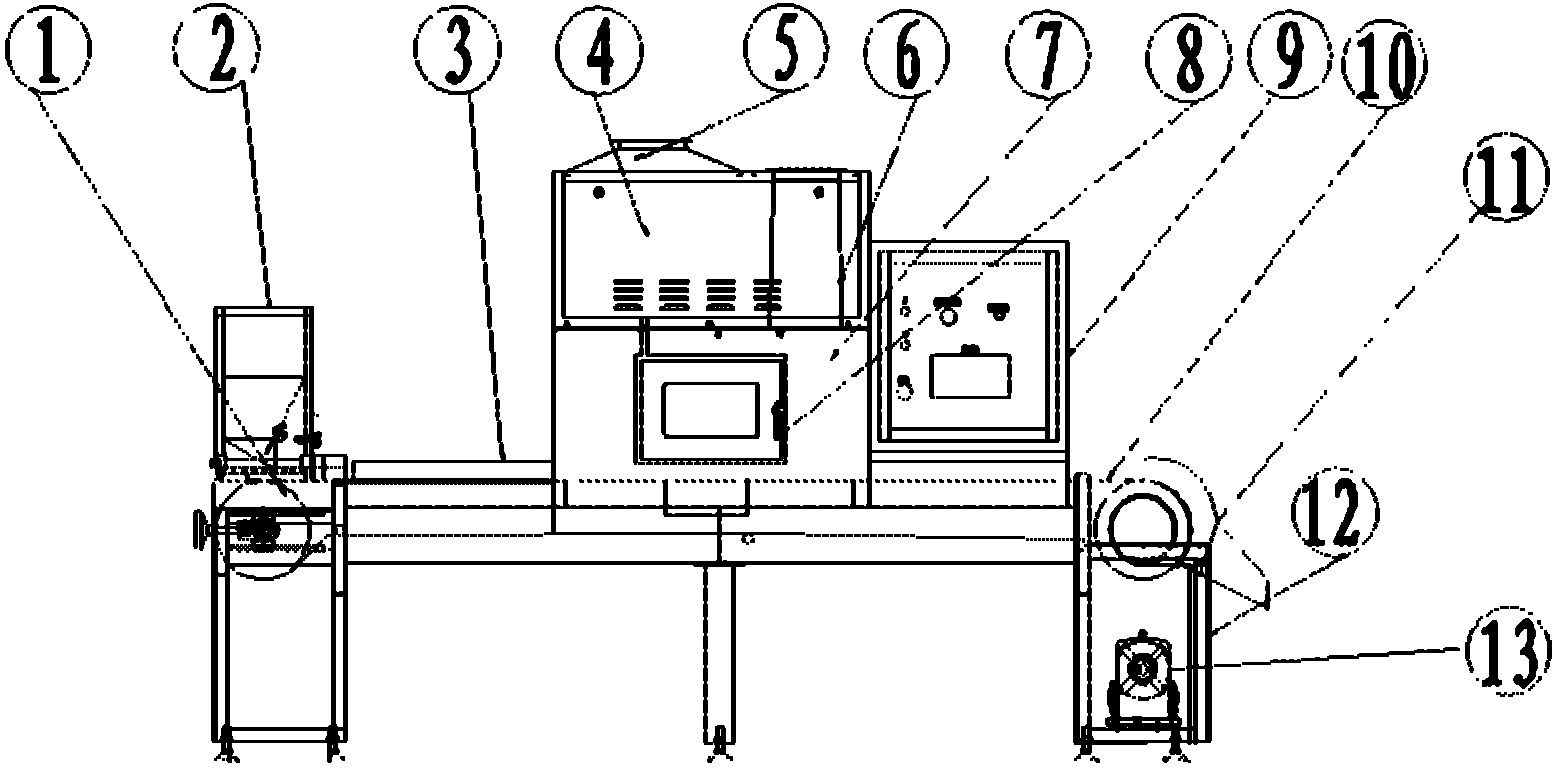

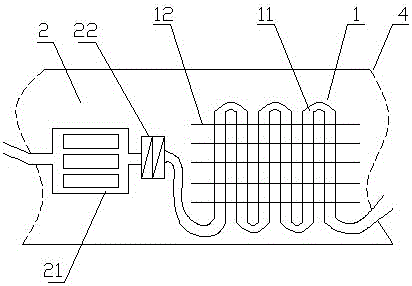

Biomass microwave continuous pretreatment reactor

InactiveCN102658077AEnables continuous preprocessingThe speed can be continuously and linearly adjustedEnergy based chemical/physical/physico-chemical processesHybrid systemHigh density

The invention discloses biomass microwave continuous pretreatment equipment, the structure of which comprises: a material continuous input system, a microwave power continuous linear-tunable reaction system, a microwave leakage prevention system, a control and detection system, a thermal discharge and dehumidification system, a material mixing system, a water supplementing system and a material output system. According to the invention, a high-density material is conveyed into a microwave reaction system through a feed device and a conveyor belt; under the control of a temperature and humidity detection system, the water supplementing system and the material mixing system, the material is adjusted within required temperature and humidity ranges, heat transfer and mass transfer of the material are uniform, and finally the material is outputted by the output system so as to realize continuous pretreatment of the material. The equipment adopts touch screen operation and dynamic display of parameters such as microwave power, temperature, humidity, time and the like, has high automatic and intelligent level, and is easy and convenient for man-machine communication. The equipment provided by the invention realizes continuous pretreatment of biomass at normal pressure, has advantages of high processing efficiency and low energy consumption, and is used to reduce pretreatment cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

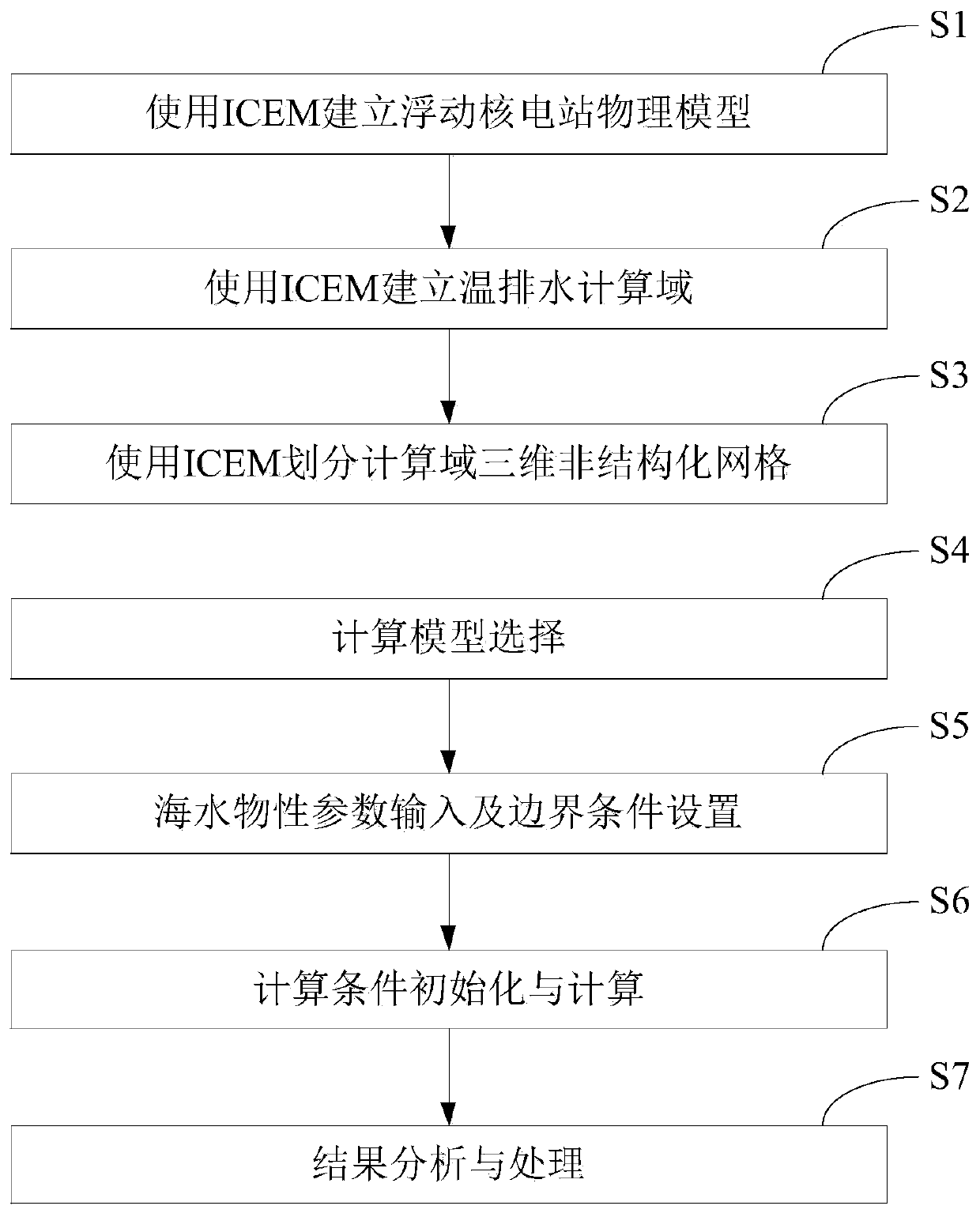

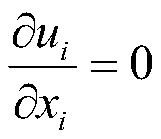

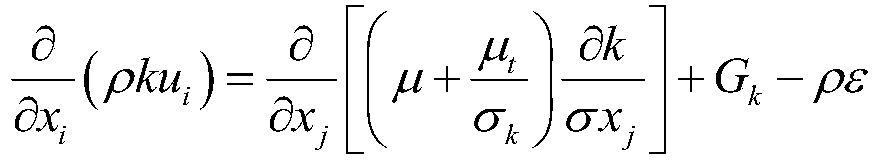

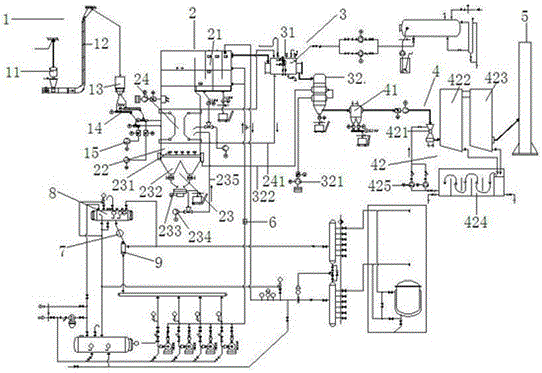

CFD-based floating nuclear power station thermal discharge water heat diffusion numerical simulation method

ActiveCN110298080ASimple designMake up conditionsData processing applicationsDesign optimisation/simulationDiffusionHeat flux

The invention relates to a CFD-based floating nuclear power station thermal discharge water heat diffusion numerical simulation method. The method comprises the steps of establishing a temperature drainage three-dimensional physical model; respectively expanding a certain calculation range around the ship body as a numerical simulation calculation area; performing three-dimensional grid division on the temperature drainage calculation domain of the floating nuclear power station; selecting a corresponding flow mathematical model in the fluent; selecting corresponding boundary conditions for the circulating cooling water taking and draining opening, the computational domain boundary and the ship wall surface; selecting and calculating a convergence format, determining and calculating an initial value, calculating and obtaining thermal discharge water heat diffusion temperature distribution and speed distribution of the floating nuclear power station, and counting a seawater temperaturedistribution curve in a direction found by the circulating cooling water intake; and integrating and analyzing the calculation by combining corresponding national regulation standards, and if the standard requirements are not met, changing the relative positions of the water taking and draining ports or taking and draining heat flux and recalculating until the calculation result meets the regulation requirements.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Control device for vessel equipped with exhaust heat recovery system and the vessel equipped with the control device

InactiveUS20110257820A1Avoid changeImprove responsivenessElectrical controlInternal combustion piston enginesExternal combustion enginePropeller

A ship powered by an internal combustion engine (1) and an electric motor (2) connected to a propeller (3) powered by surplus electric power obtained by a thermal discharge recovery system has a controller including a feedback control section for controlling a base amount of fuel injected to the internal combustion engine (1) based on the difference between the target number of rotation of the propeller given by the operator and the real number of rotation, and a feed-forward control section having a means (25) for calculating an overall power output and a means (26) for calculating a correction in the amount of fuel injected to the internal combustion engine based on the overall power output and the number of rotation of the propeller. The base amount of fuel is corrected by subtracting the correction obtained by the feed-forward section from the base amount of fuel calculated by the feedback control section whereby preventing a rapid change in the speed of the ship due to rapid change in ship loads.

Owner:MITSUBISHI HEAVY IND LTD

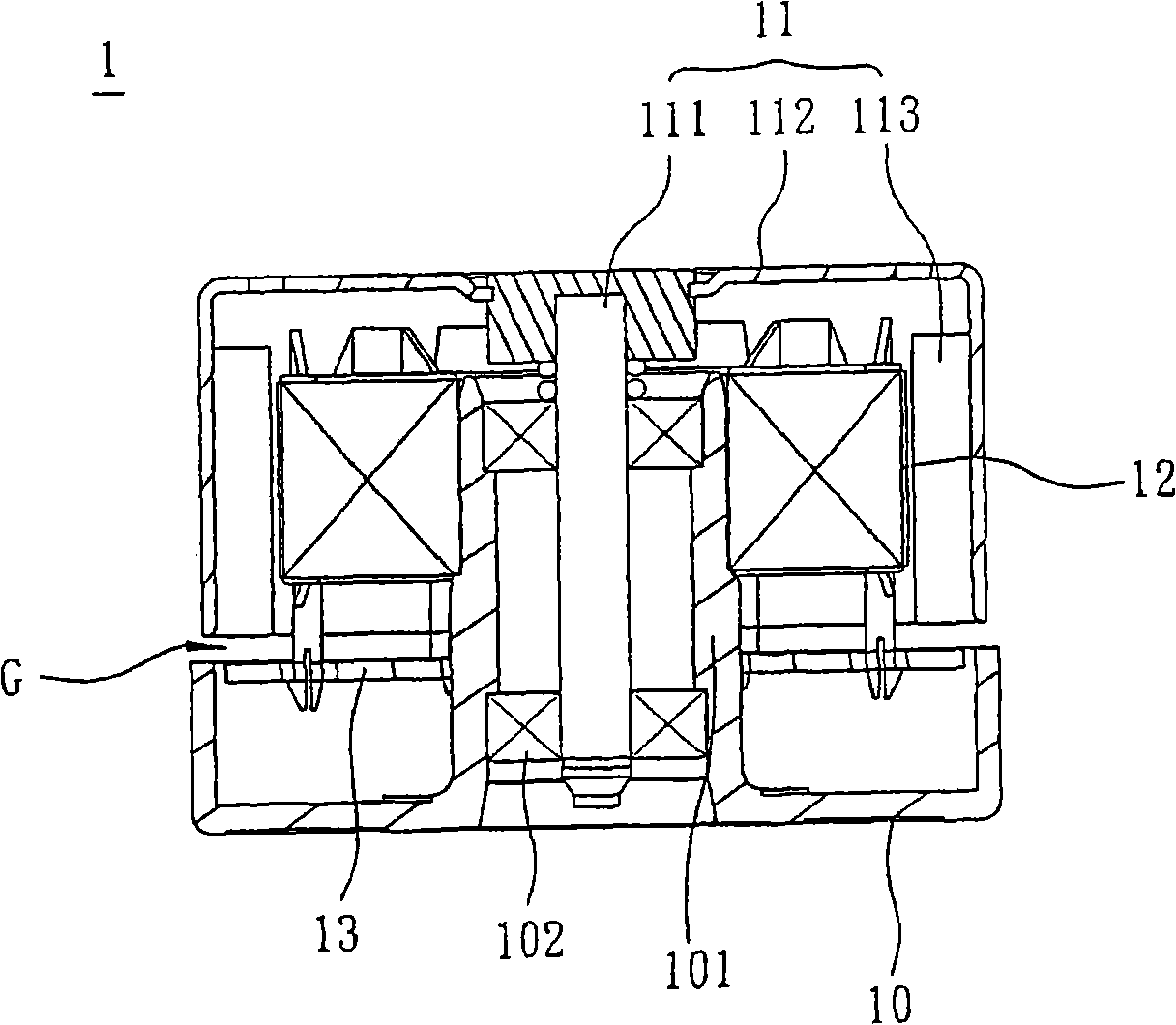

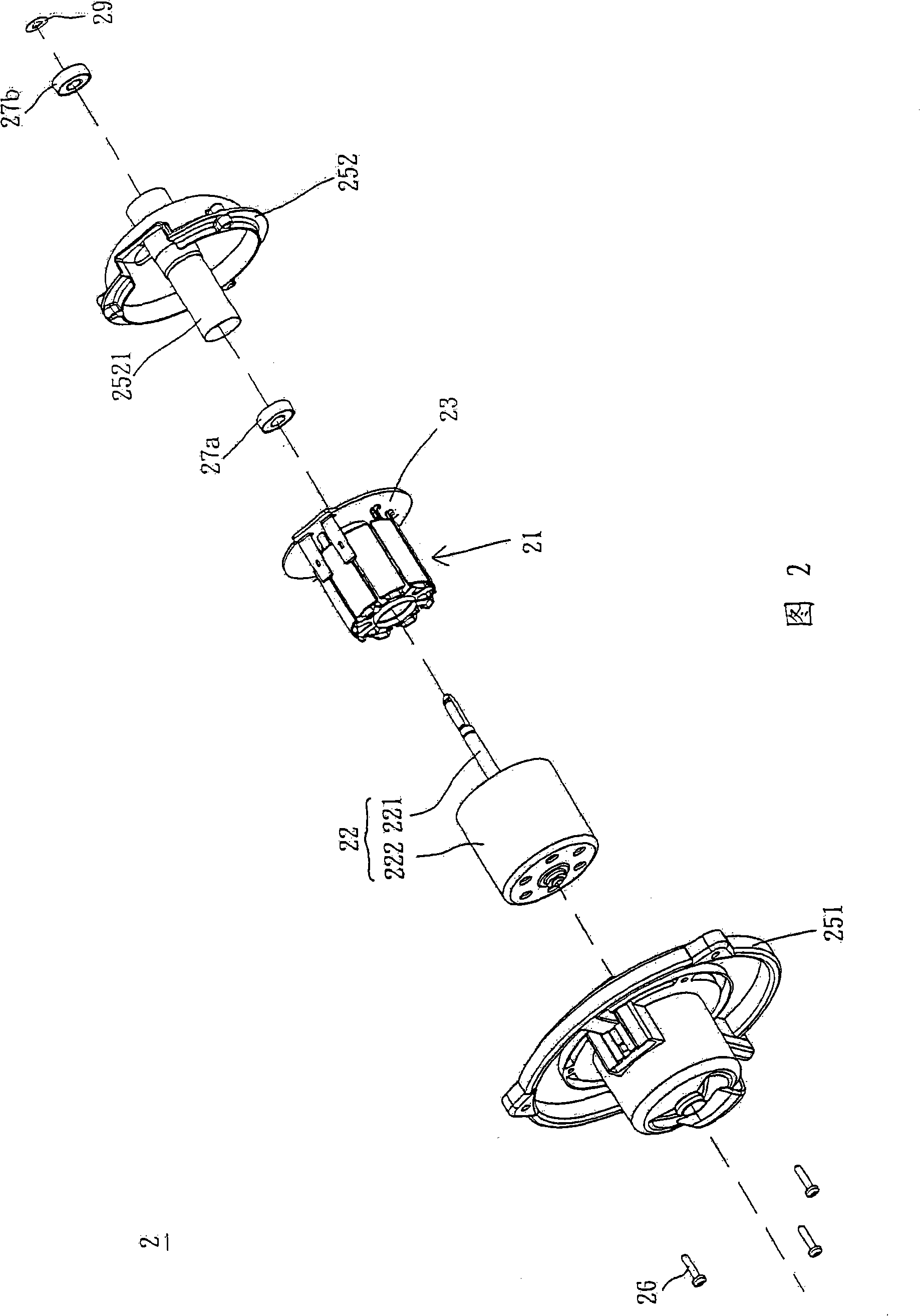

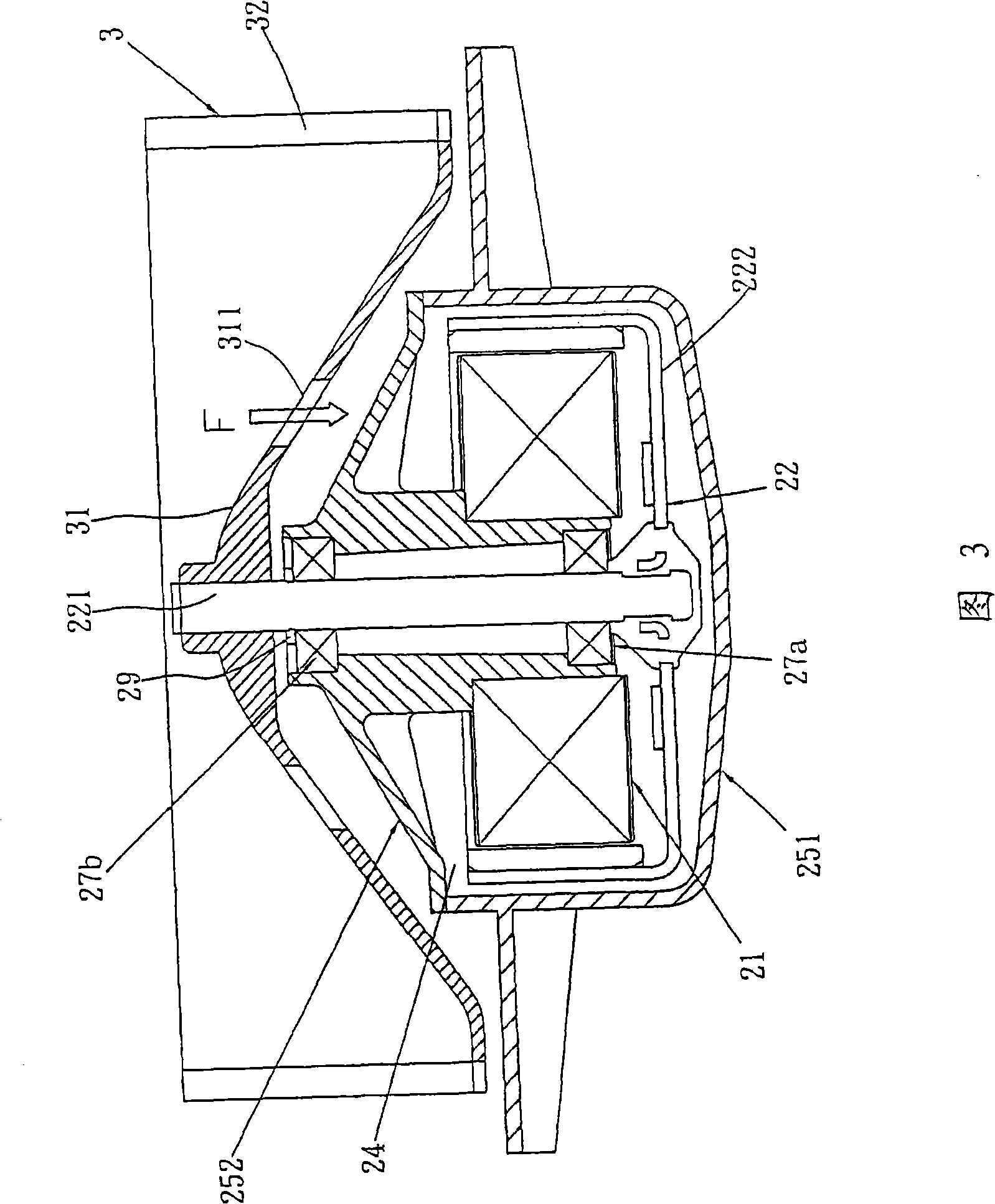

Motor and fan having dustproof and dissipating heat function

ActiveCN101494401AImprove airtightnessAchieve heat dissipationPump installationsSupports/enclosures/casingsImpellerEngineering

The invention provides a fan with dustproof and thermal discharge functions and a motor thereof. The motor comprises a shell that is provided with a closed space and composed of a heat conduction material, a stator fixed in the shell, and a rotor, which is provided with a rotating shaft and arranged through the stator and one end of which projects out of the closed space to be connected with an impeller, wherein, the stator and the rotor are contained in the closed space.

Owner:DELTA ELECTRONICS INC

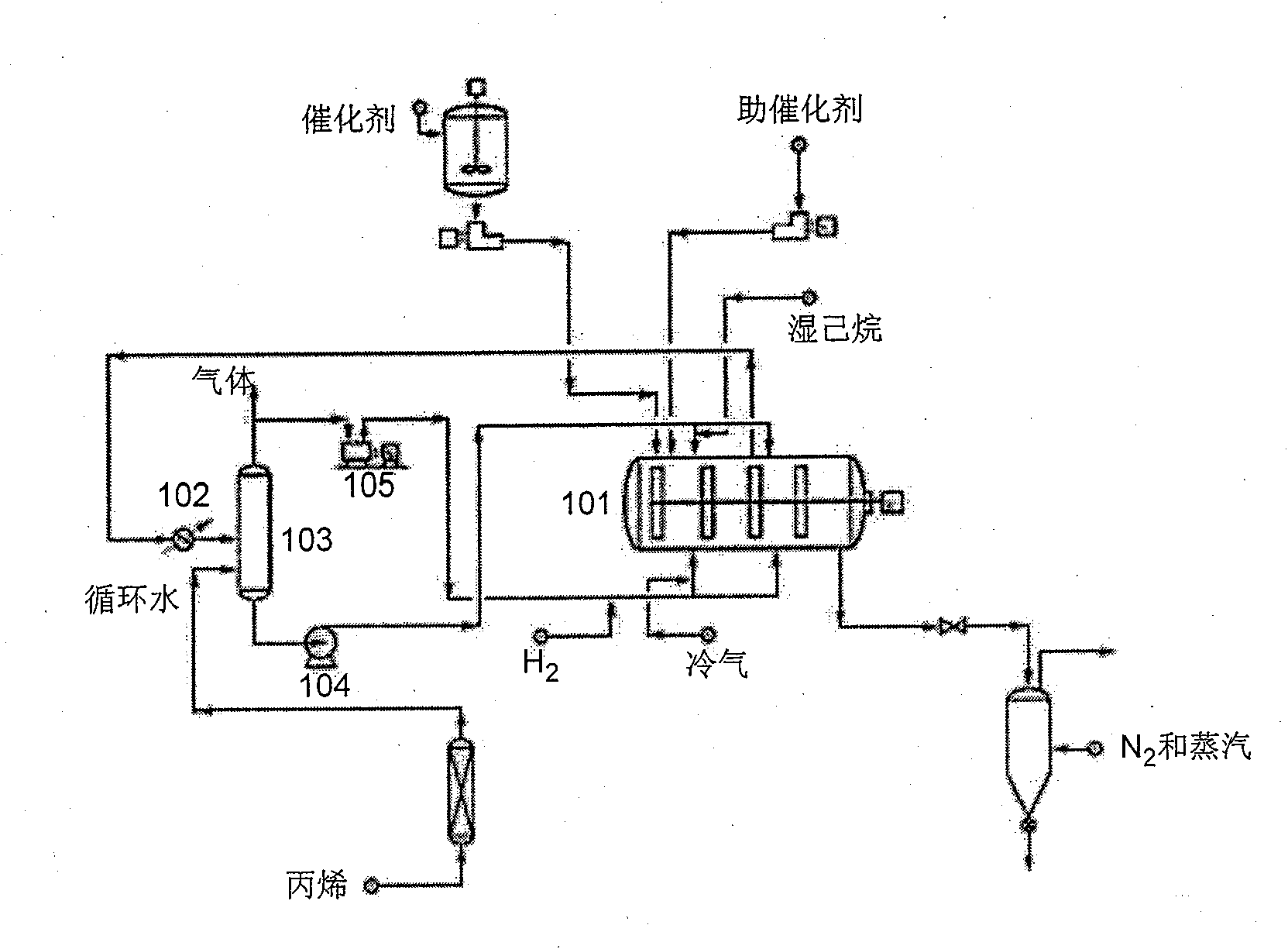

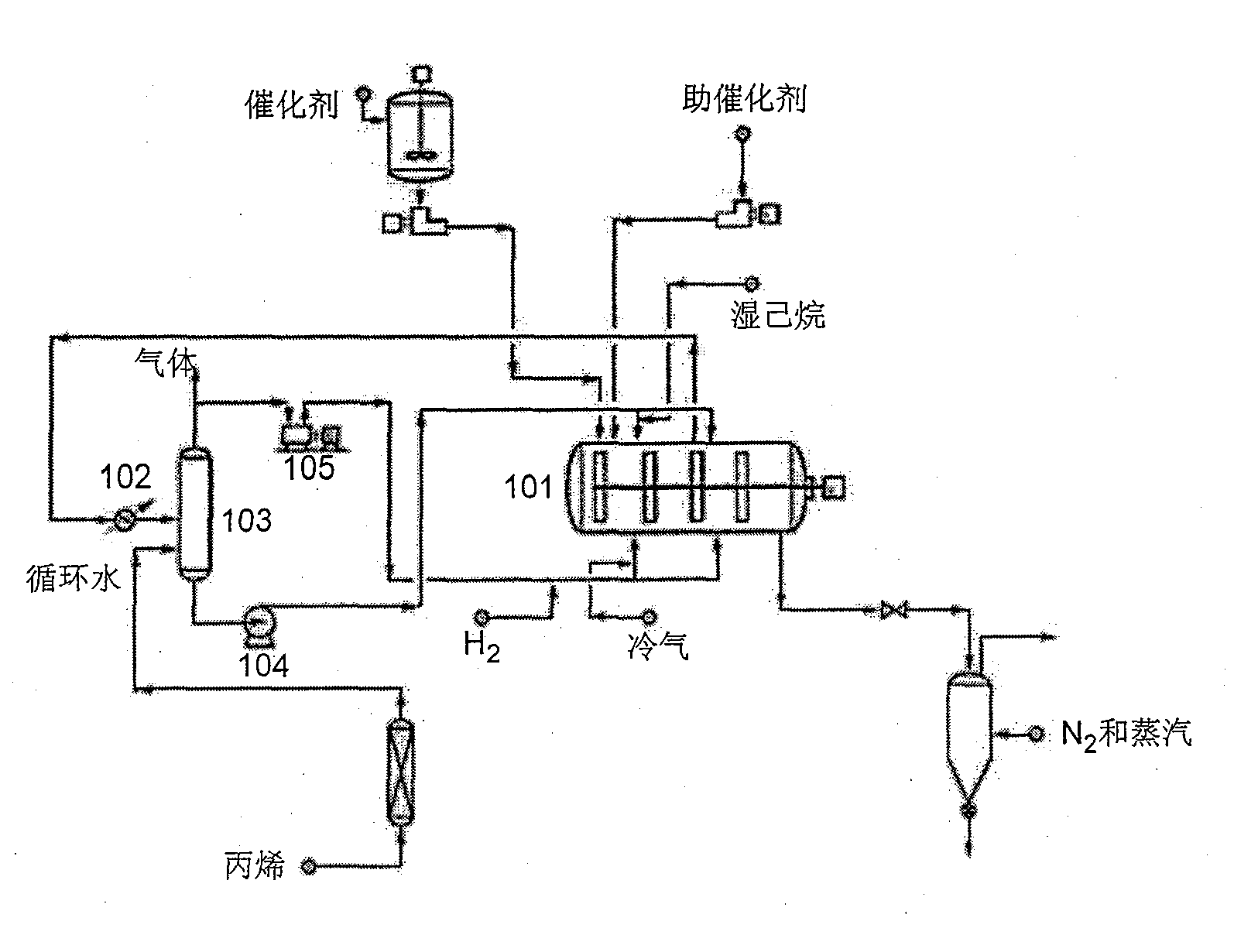

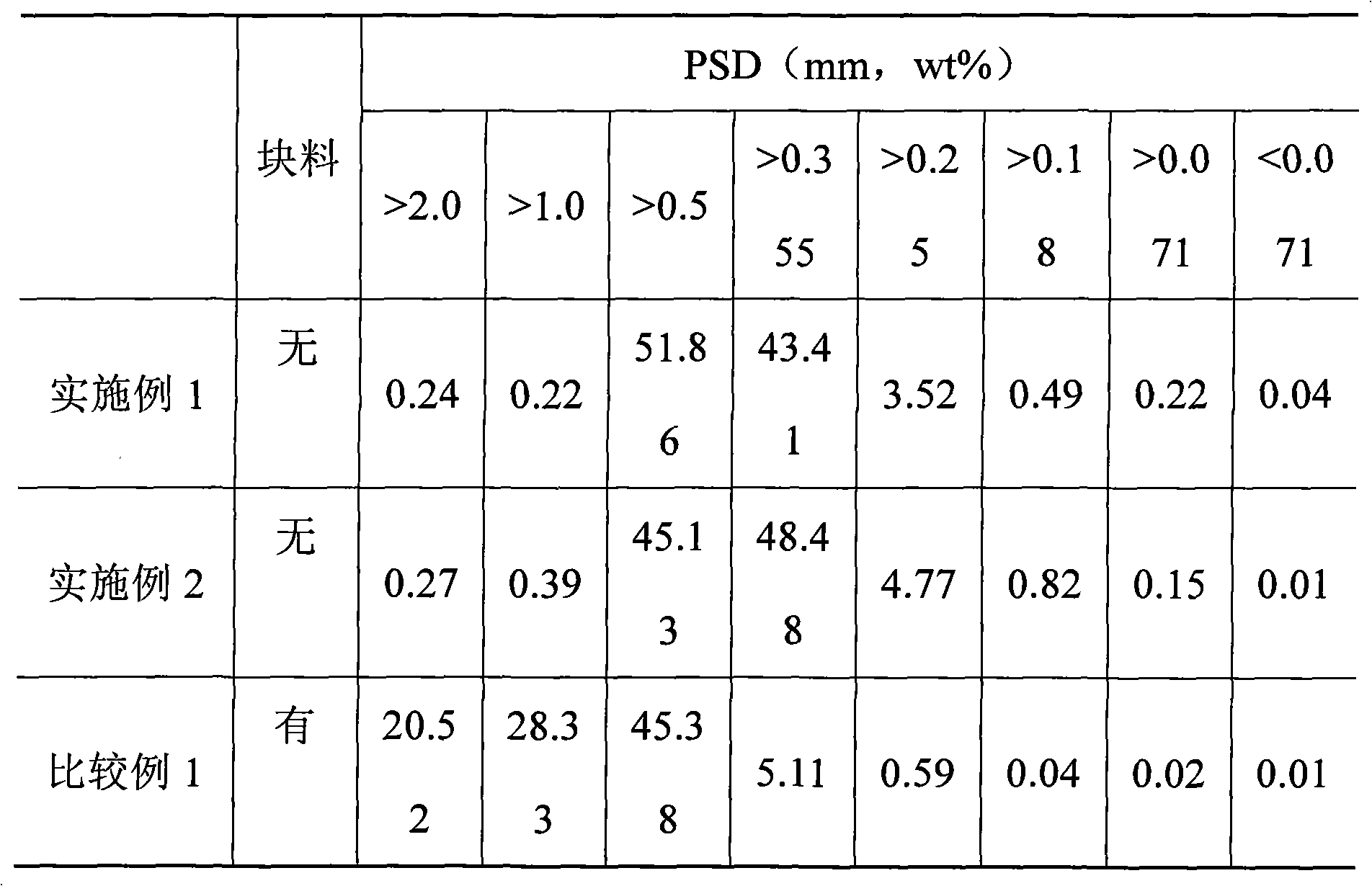

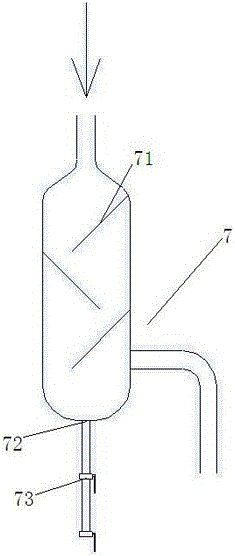

Method for avoiding agglomeration of continuous gas phase polymerization

The invention provides a method for avoiding the agglomeration of a continuous gas phase polymerization. In the method, an activity inhibitor is added in an initial stage of the continuous gas phase polymerization so as to avoid local agglomeration caused by the relative concentration of a catalyst in the initial stage of the reaction and the relatively high thermal discharge of the polymerization reaction. The method is particularly suitable for producing random copolymers of propylene / ethane, propylene / butylene or propylene / ethane / butylenes in a horizontal gas-phase reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

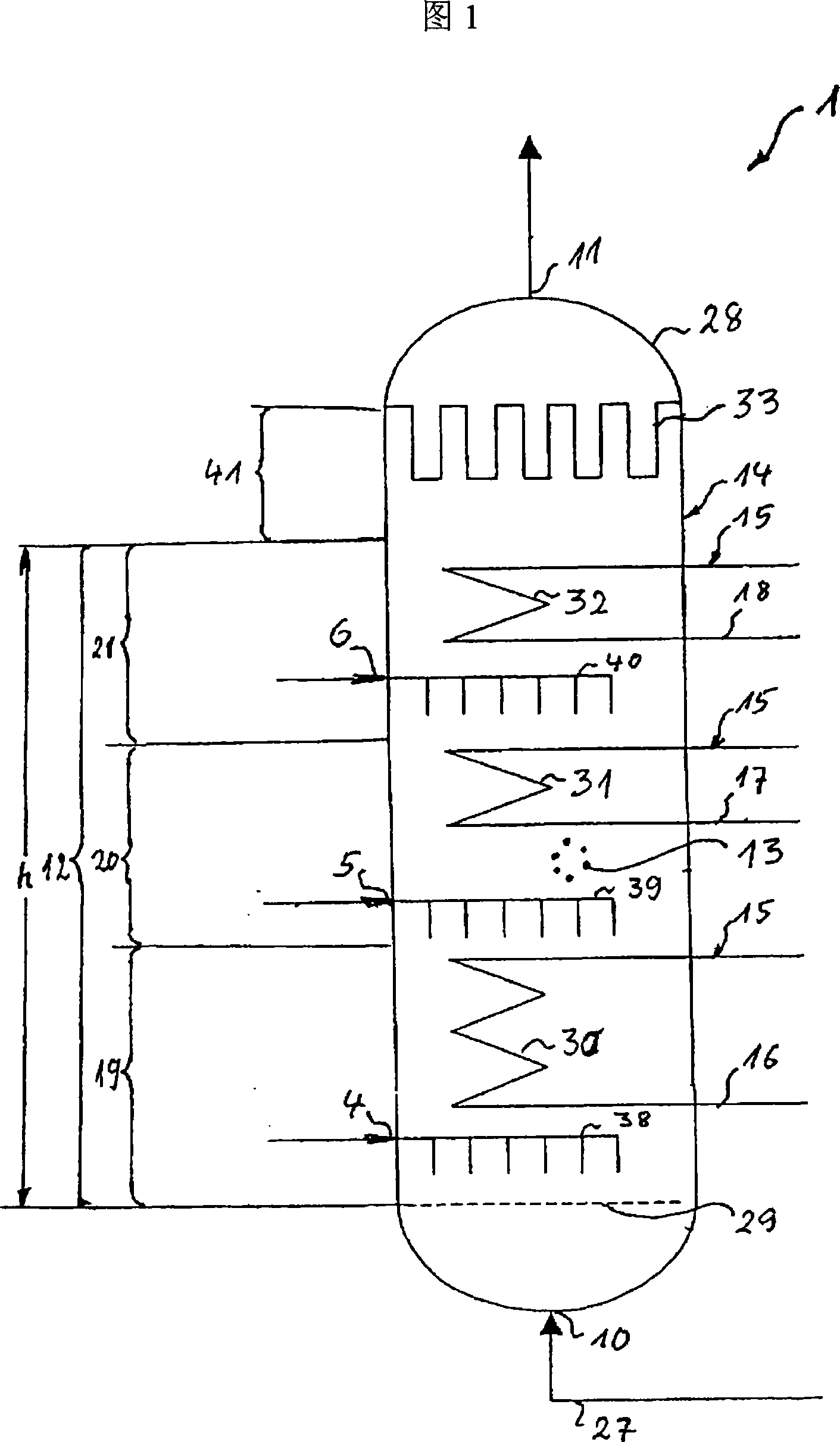

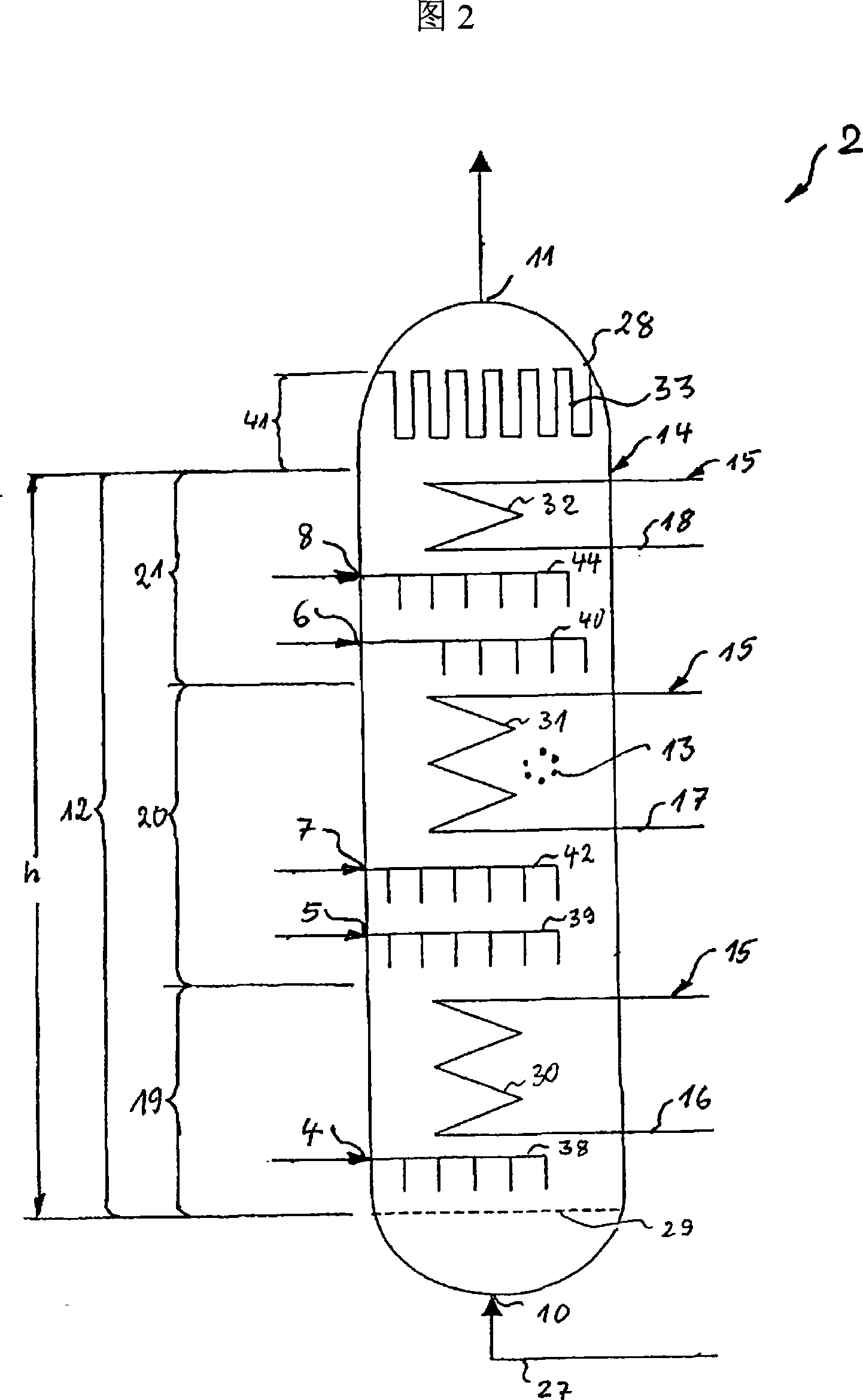

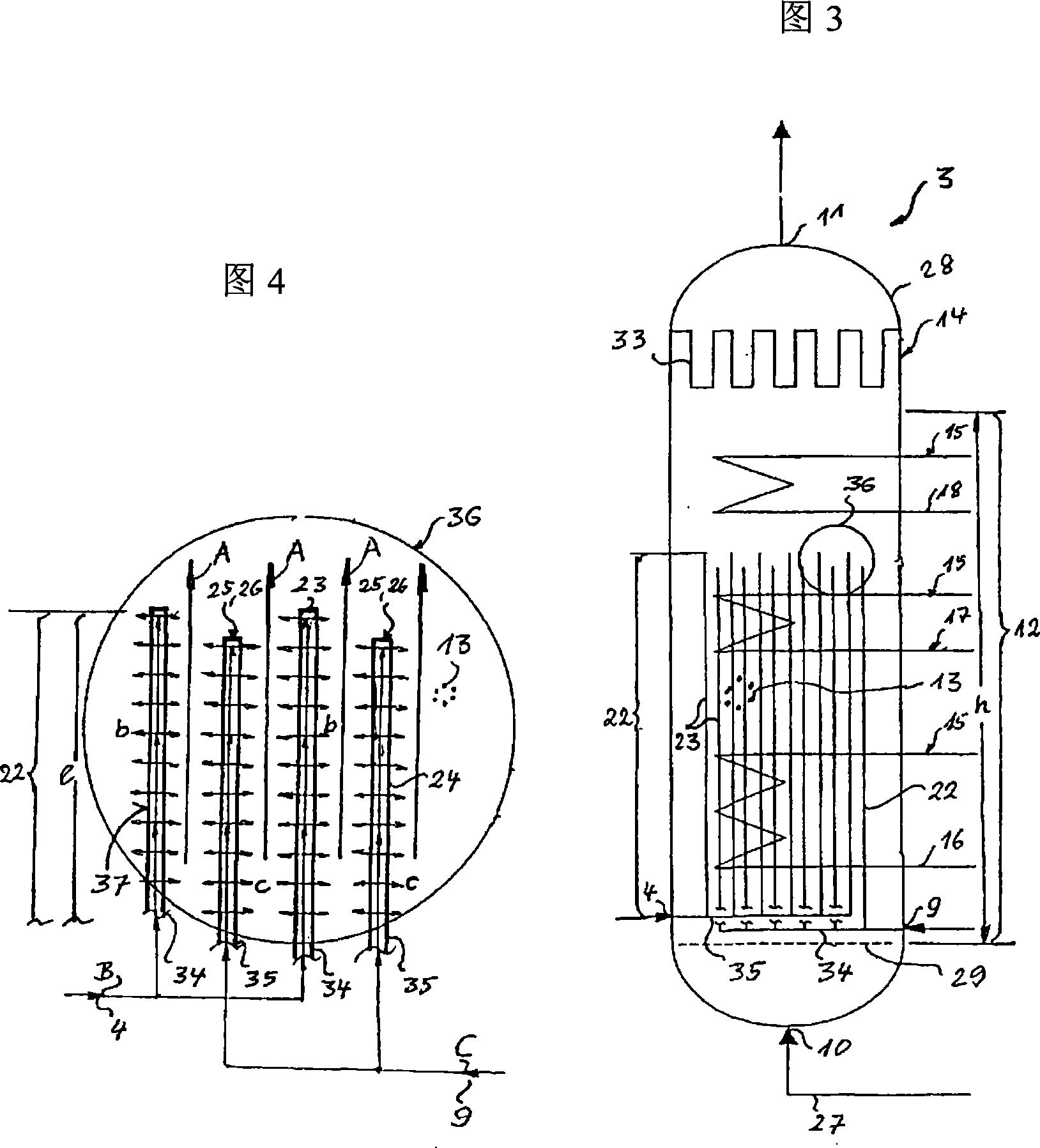

Oxychlorination device and method

InactiveCN101165032AHigh purityIncrease loadHalogenated hydrocarbon preparationChemical/physical processesFluidized bedProduct gas

The invention relates to a device (1) which can oxidize and chloridize the olefin into chloralkane through chlorine hydride and oxygen, as well as a method thereof. The device (1) is provided with air inlets (4, 5 and 6) of the fluidized bed (12) which enters into a fluidized bed reactor (14) and includes catalyst grains (13), and at least one reacted air outlet (11) positioned above the fluidized bed (12), and a cooling arrangement (15) which is used for controlling the thermal of the thermal discharge reaction. The plurality of air inlets (4, 5 and 6) which are used for the same inlet air are arranged along the fluidized bed (12) vertically. The cooling arrangement (15) is provided with cooling loops (16, 17 and 18) which are arranged vertically to each other and are inserted into the fluidized bed (12). The device (1) can produce industrial dichloroethane in mass by utilizing the raw material ethylene maximally.

Owner:VINNOLIT GMBH & CO KG

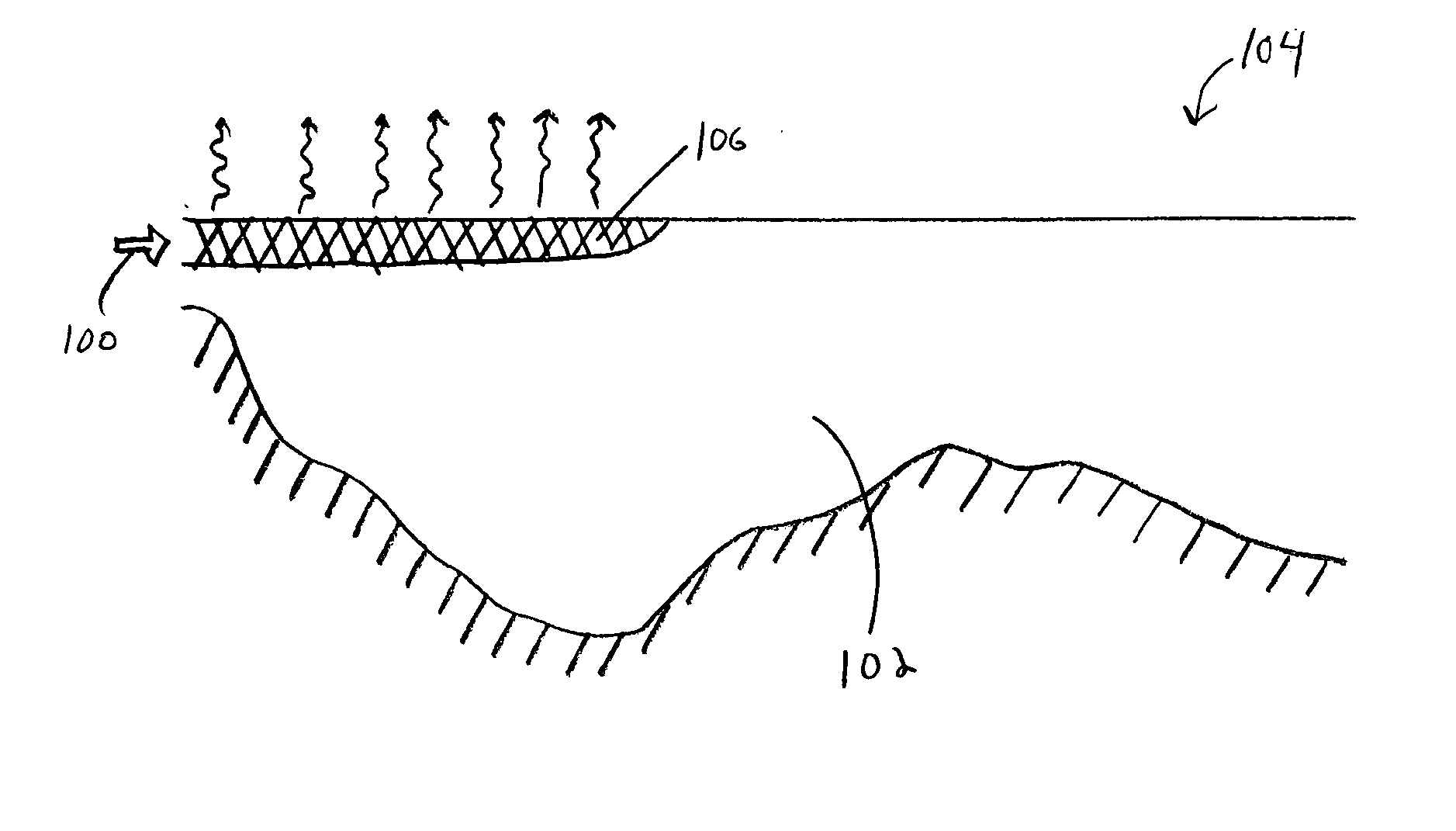

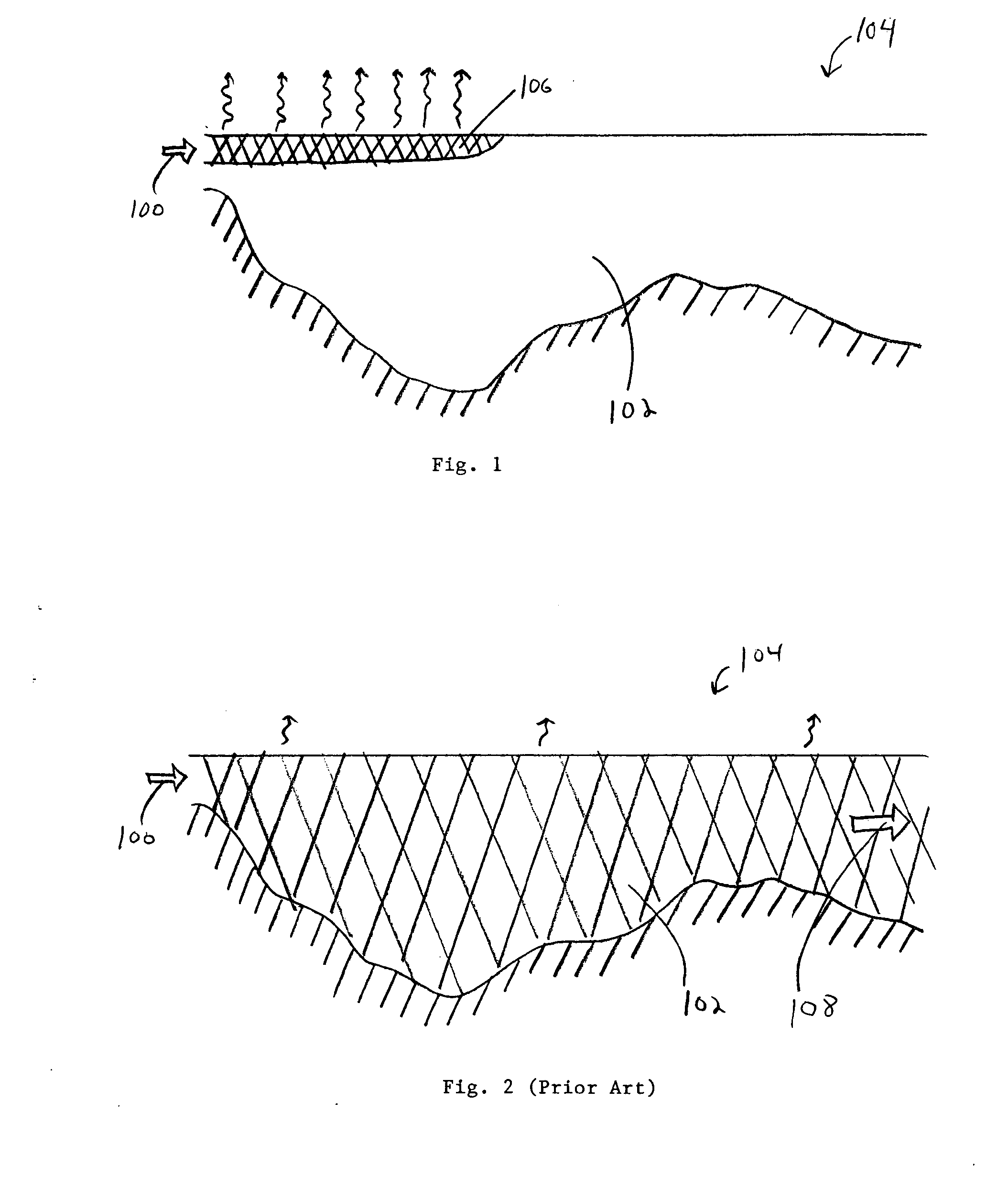

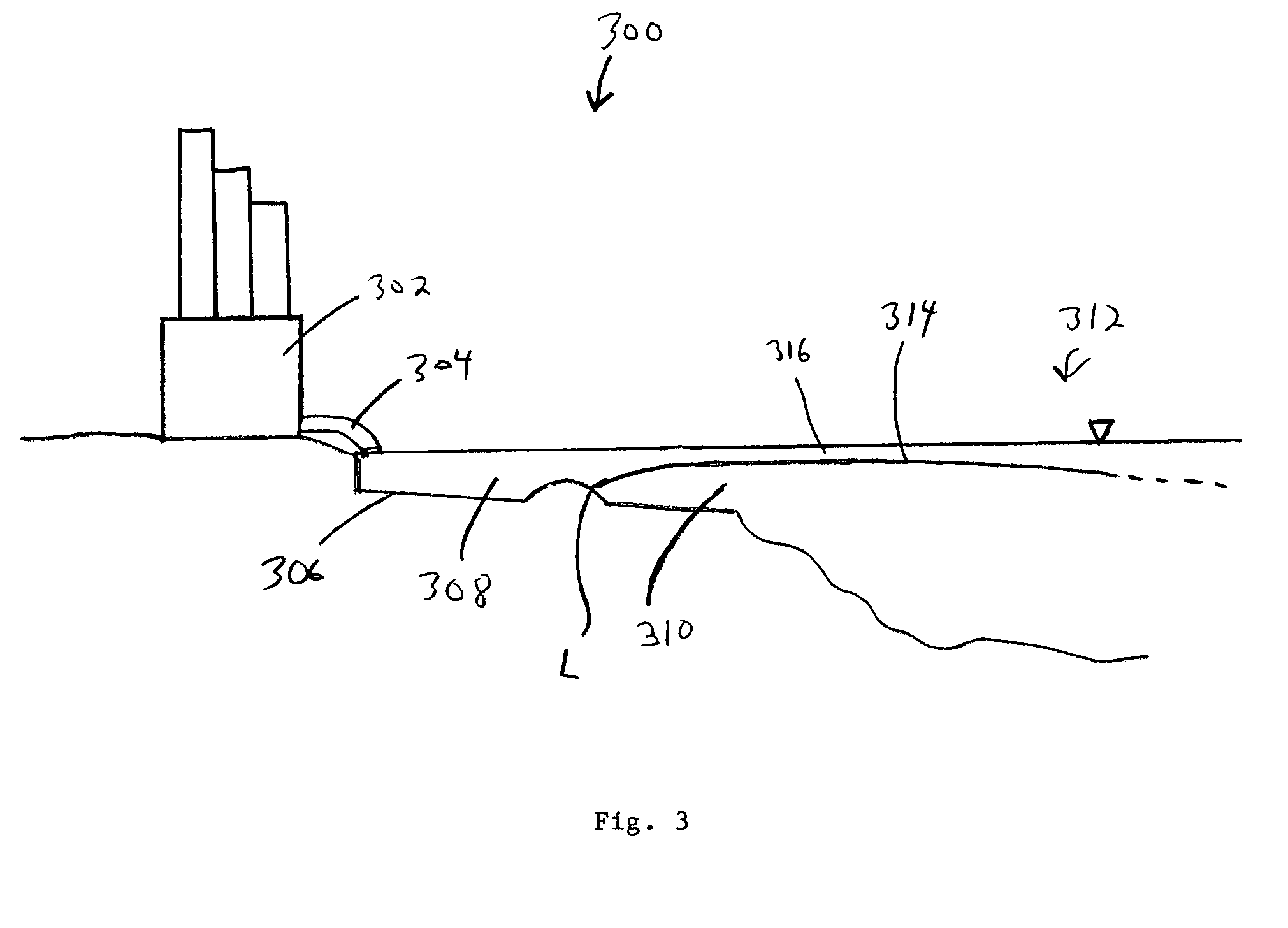

Enhanced surface cooling of thermal discharges

InactiveUS20110011556A1Improve heat transfer performanceFine surfaceOther heat production devicesHydraulic engineering apparatusAmbient waterSurface cooling

A water discharge system enhances heat transfer to the atmosphere by limiting the mixing of heated discharge water with the ambient water of a receiving water body. The heated water is maintained near the top surface of the receiving water body which increases the transfer of heat to the atmosphere as compared to a system where the discharge water is mixed quickly with the ambient water.

Owner:UNIV OF MASSACHUSETTS

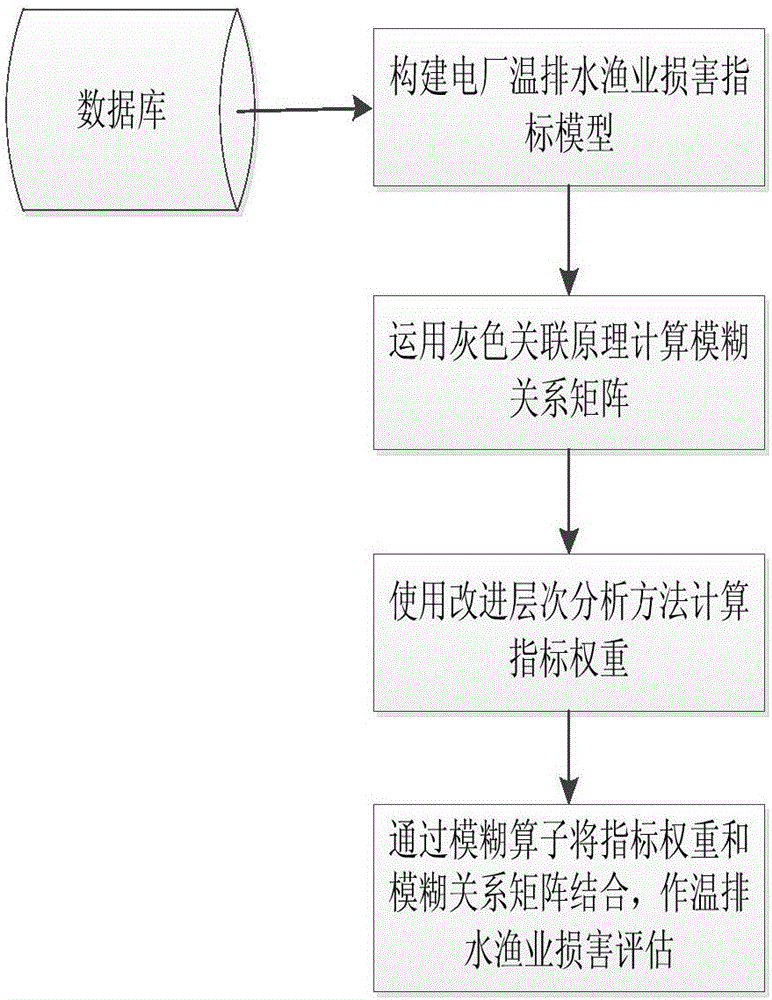

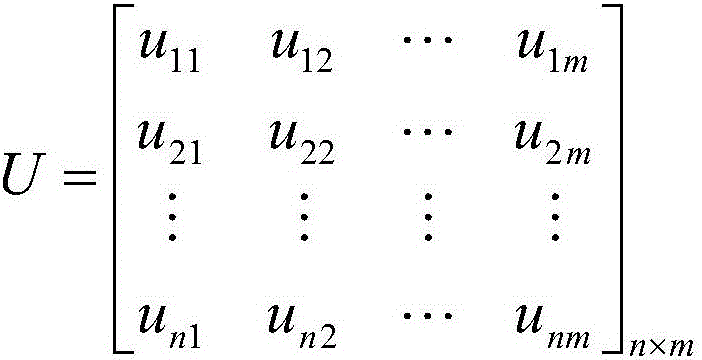

Grey correlation based fuzzy hierarchy estimation method for damages to fishery by thermal discharge of power plant

ActiveCN106845870AError probability controlSimple calculationResourcesSynthesis methodsCorrelation factors

The invention provides a grey correlation based fuzzy hierarchy estimation method for damages to fishery by thermal discharge of a power plant and belongs to a field of environment protection. The method includes steps of analyzing strong correlation factors of damages to fishery by thermal discharge of the power plant and establishing a fishery damage estimation indicator system; utilizing a grey correlation principle to calculate indicator correlation degree and to further construct a fuzzy relation matrix of fishery damage indicators; employing an improved analytic hierarchy model to obtain fishery damages caused by thermal discharge and weight vectors of the indicators corresponding to the different factors; combining the obtained indicator weight vectors with the fuzzy relation matrix of the fishery damage indicators via blurring operators by using a fuzzy synthesis method and performing comprehensive estimation on fishery damages caused by thermal discharge of the power plant. According to the invention, three mathematic estimation methods including grey correlation, fuzzy mathematics and analytical hierarchy process are combined together organically, so that the three estimation methods complement each other and also enhance the reliability of the estimation of fishery damages caused by thermal discharge of the power plant.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

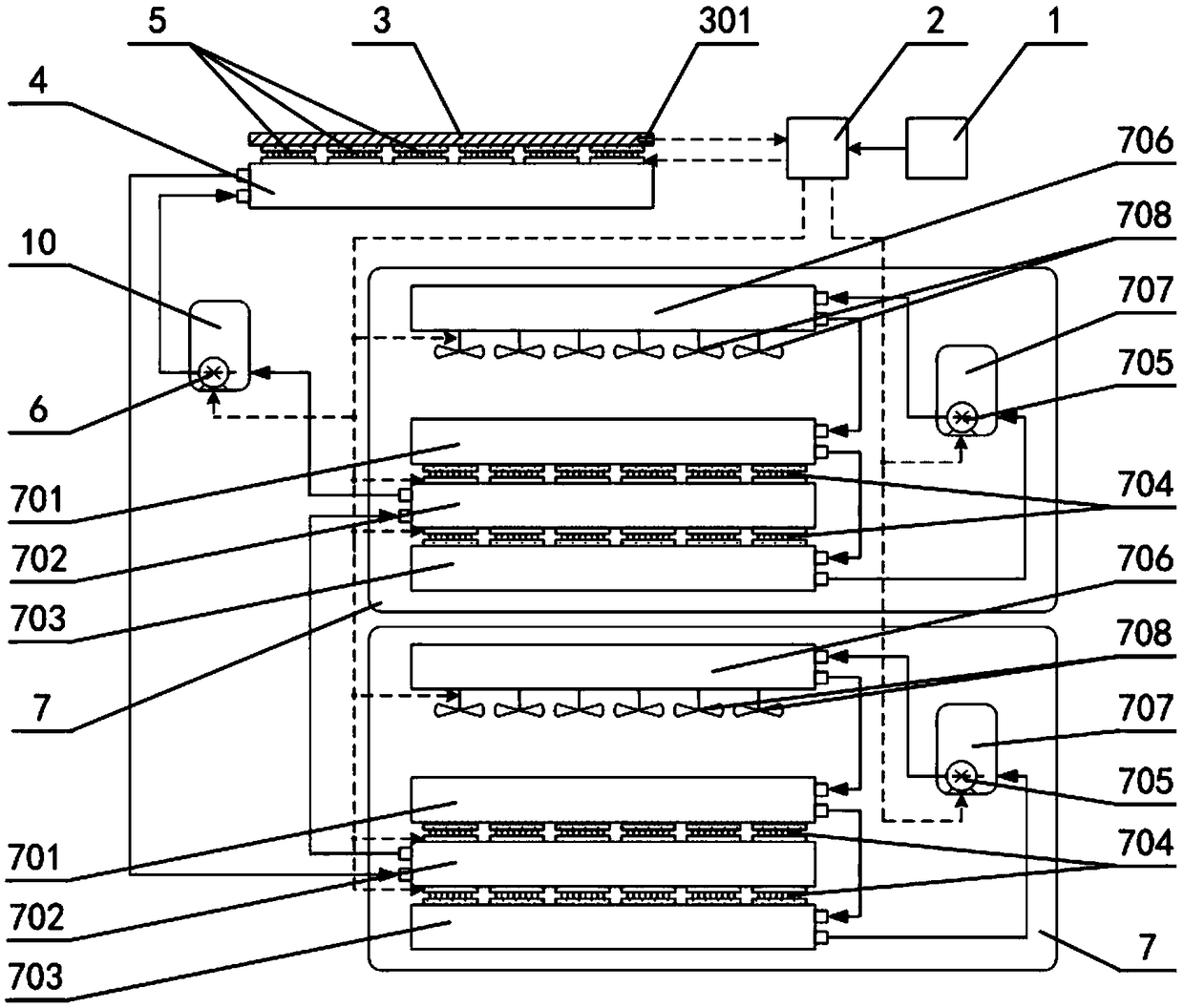

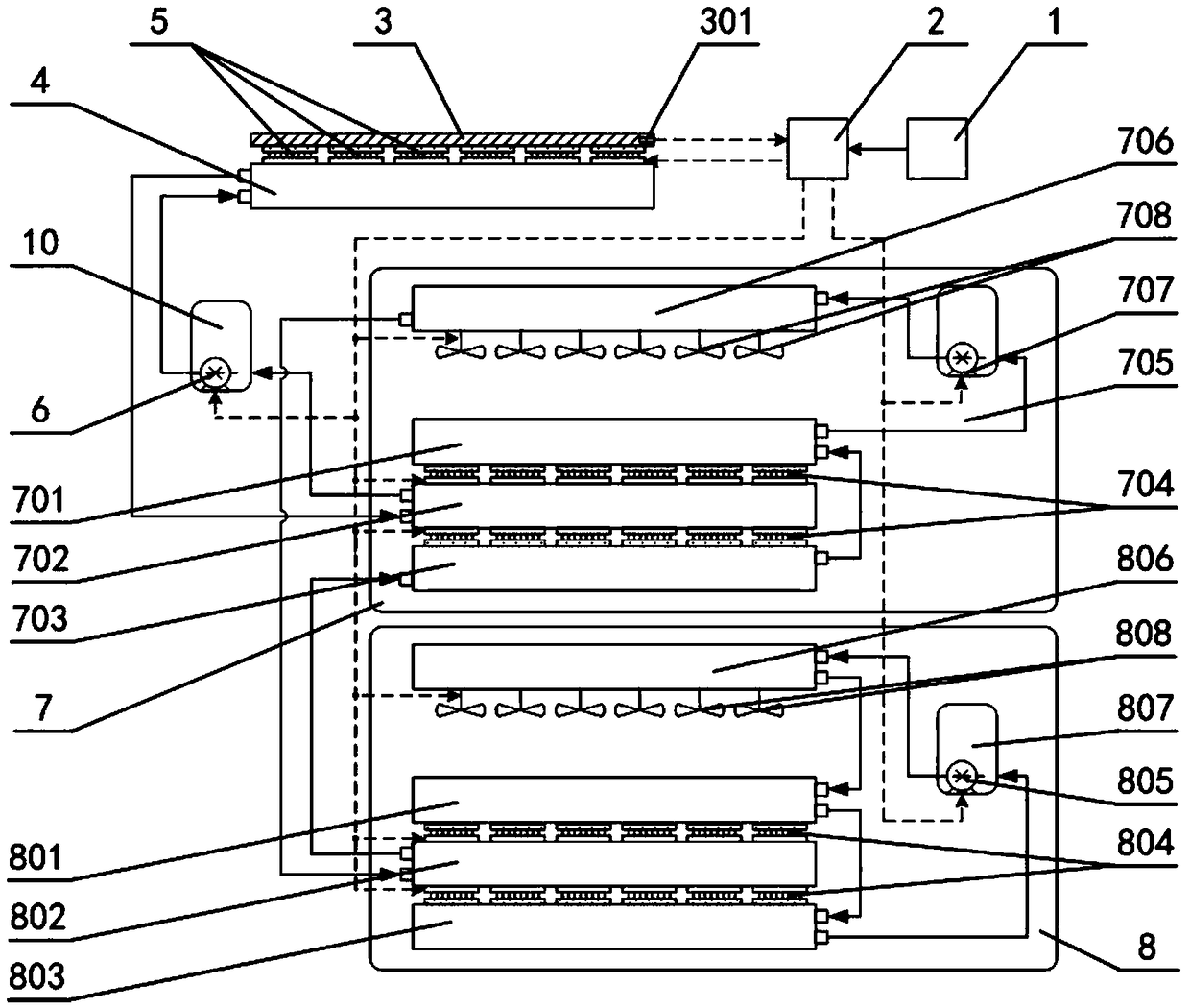

Intelligent control system for coal mine water chilling unit

ActiveCN103529798ASave power resourcesEfficient mine coolingTotal factory controlProgramme total factory controlEngineeringCoal

The invention discloses an intelligent control system for a coal mine water chilling unit and relates to a coal mine control system. The control system consists of a mine water chilling unit intelligent control operation platform (4), a mine water chilling unit operating parameter visualization and economization display platform (5), a mine movable air cooler energy efficiency analysis and operating parameter visualization platform (6), a mine movable water cooler energy efficiency analysis and operating parameter visualization platform (7) and an underground thermal pollution control effect feedback platform (8). The intelligent control system disclosed by the invention is used for controlling the water chilling unit to realize the launch of the intelligent and economical control system, so that the problem that the deep thermal pollution control difficulty is high can be effectively solved, and the thermal pollution control cost is reduced. Meanwhile, the use ratio of a cold source is effectively increased, the problem that the thermal discharge efficiency of a deep mine is low is effectively solved, the water chilling unit is economically and intelligently controlled, economical mine cooling is implemented, and energy sources are fully utilized.

Owner:CCTEG SHENYANG RES INST

Temperature increasing and decreasing adjustment instrument based on semiconductor refrigeration and heating technology

PendingCN108716787AReduce volumeReduce weightMachines using electric/magnetic effectsTemperature controlCelsius Degree

The invention relates to the field of temperature increasing and decreasing devices, and discloses a temperature increasing and decreasing adjustment instrument based on semiconductor refrigeration and heating technology. The temperature increasing and decreasing adjustment instrument uses a thermoelectric refrigeration sheet as the base of a cold and hot source, is constructed through a loading heat conduction board, a water-cooling head, a water pump, a waterway thermal discharge pipe and a temperature increasing and decreasing adjustment control board, and has the advantages of small size,light weight, being convenient to move, fast temperature increasing and decreasing speed, high temperature control accuracy, low manufacturing cost and the like. The temperature increasing and decreasing adjustment instrument can further provide a refrigeration heating loading plane with any temperature environment from -65-120 degrees Celsius, and has high load capacity, that is, when the refrigeration heating loading plane bears small and medium-sized micro-electronic products, the external temperature of the small and medium-sized micro-electronic products or the monitoring temperature of chips can be optionally adjusted between -50-100 degrees Celsius, and the temperature increasing and decreasing adjustment instrument can create a variety of different temperature environments or required continuous temperature cycle environment for the production and manufacture of various commercial and industrial electronic products and scientific experimenters.

Owner:胡晓

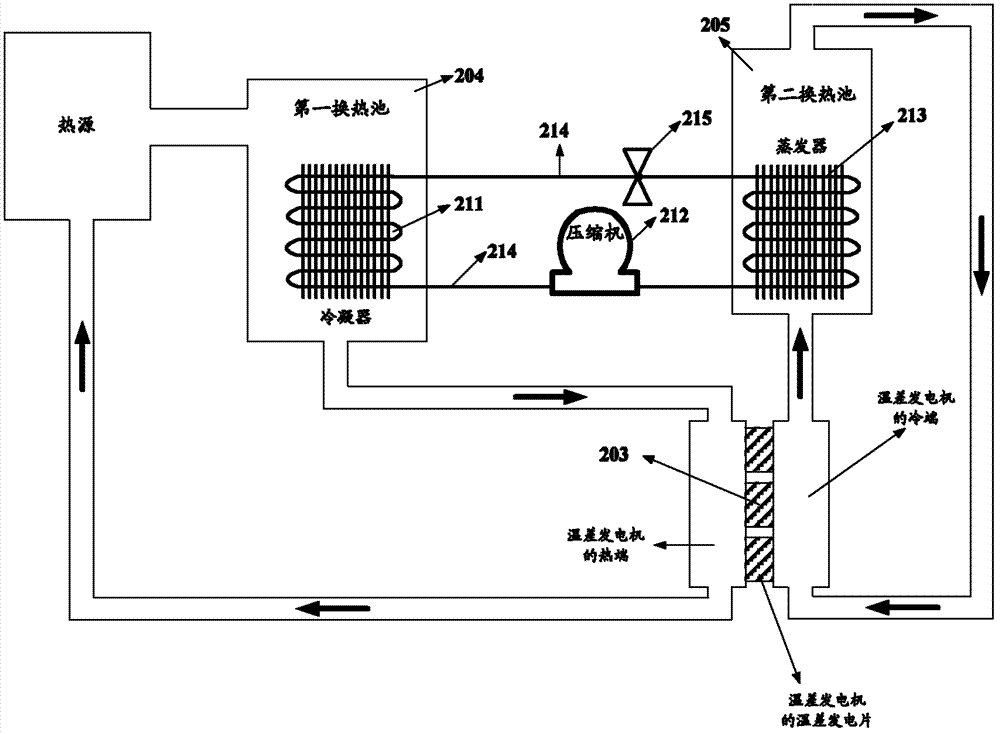

Semiconductor condensation heat energy power system utilizing thermal discharge water of nuclear power station

InactiveCN106246270AImprove conversion efficiencyPrevent backflowSteam/vapor condensersStationary conduit assembliesNuclear powerHydraulic pump

The invention discloses a semiconductor condensation heat energy power system utilizing thermal discharge water of a nuclear power station. The semiconductor condensation heat energy power system comprises a heat collecting device, a gasification device, a turbine, a condensation device and a one-way hydraulic pump, all of which cyclically communicate with one another through a circulation pipeline in sequence. Circulation working media are contained in the circulation pipeline. The heat collecting device and the gasification device are arranged in a thermal discharge channel of the nuclear power station. The condensation device is arranged in a deep water low temperature area. The condensation device comprises a condensation pipe and a heat dissipation fan, and the condensation pipe is made of temperature difference power generation sheets. The semiconductor condensation heat energy power system utilizing the thermal discharge water of the nuclear power station has a high condensation rate, can reduce condensation energy dissipation, improve the heat energy conversion efficiency and is stable in running and adjustable in power.

Owner:郭远军

Remote non-thermal atmospheric plasma treatment of temperature sensitive particulate materials and apparatus therefore

The present invention relates to a novel process for the remote plasma surface treatment of substrate particles at atmospheric pressure. The invention is motivated by the urge to overcome major drawbacks of particle treatment in low pressure plasmas and in-situ particle treatment at atmospheric pressure. The former requires complex and mostly expensive vacuum installations and vacuum locks usually prohibiting continuous processing. Independent of the system pressure, in-situ plasma treatment causes particle charging and therefore undesirable interaction with the electric field of the discharge, which is seen to contribute to the process of reactor clogging. Additionally, the filamentary discharges modes of atmospheric pressure plasmas are inflicted with inhomogeneous surface treatment. Furthermore, short radical lifetimes at elevated pressures complicate a remote plasma treatment approach as widely used in low pressure applications. The key-element of the invention is that by reducing the dimension of the atmospheric discharge arrangement to the micrometer range, transonic flow conditions can be achieved in the discharge zone while maintaining moderate flow rates. The resulting superimposition of high drift velocity in the gas flow and the inherent diffusion movement is to prolong the displacement distance of activated species, thus making a remote plasma treatment of substrate particles feasible and economically interesting. The circumferential arrangement of e.g. micro discharge channels around the treatment zone of variable length allows a remote plasma treatment independently of the discharge mode and benefits additionally from the aerodynamic focusing of a particle-gas stream to the center, reducing reactor clogging. Furthermore, taking advantage of non-thermal discharges, there is no restriction of the concept of the outlined invention in the material properties of the particulate solids especially not with regard to the treatment of temperature sensitive materials as often encountered in polymer or pharmaceutical industries. In conclusion, atmospheric pressure plasma treatment close to ambient gas temperature as well as continuous processing is a specialty of the invention disclosed here.

Owner:ETH ZZURICH

Small and medium size boiling type ready-packaged organic carrier heating furnace

ActiveCN106642092ABurn fullyImprove thermal efficiencyCombination devicesFluidized bed combustionAir preheaterProtection system

The invention discloses equipment comprising a feeding device, a hearth, a waste heat device, a tail gas treatment device and a chimney connected in sequence, wherein the lower portion in the hearth is a fuel combustion area connected with a quartz sand circulating system; a hot oil heater is arranged at the upper portion in the hearth, and connected with an oil feeding and draining device via an oil pipe; the outlet of the hot oil heater is connected with a steam generator of the waste heat device, and the outlet of the steam generator is connected with the inlet of an air preheater; the steam generator and a steam pipe forms a fluidized bed circular protection system arranged between the hot oil heater and the fuel combustion area; and the tail gas treatment device comprises a multi-pipe dust remover and circular cleaning equipment connected in sequence. The hearth, the waste heat device, the tail gas treatment device and the chimney are connected in sequence, so that ash generated during a combustion process in the hearth can be effectively deposited under the effect of the waste heat device and the tail gas treatment device, the thermal discharge temperature of the chimney can also be further reduced, and emission pollution generated by the heating furnace is reduced, and environment protection is facilitated.

Owner:JIANGSU JINCHENZHEN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com