Method for avoiding agglomeration of continuous gas phase polymerization

A technology of polymerization reaction and gas phase polymerization, applied in the field of olefin polymerization, can solve the problems of polymer agglomeration, reduction of comonomer content, and unsatisfactory effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

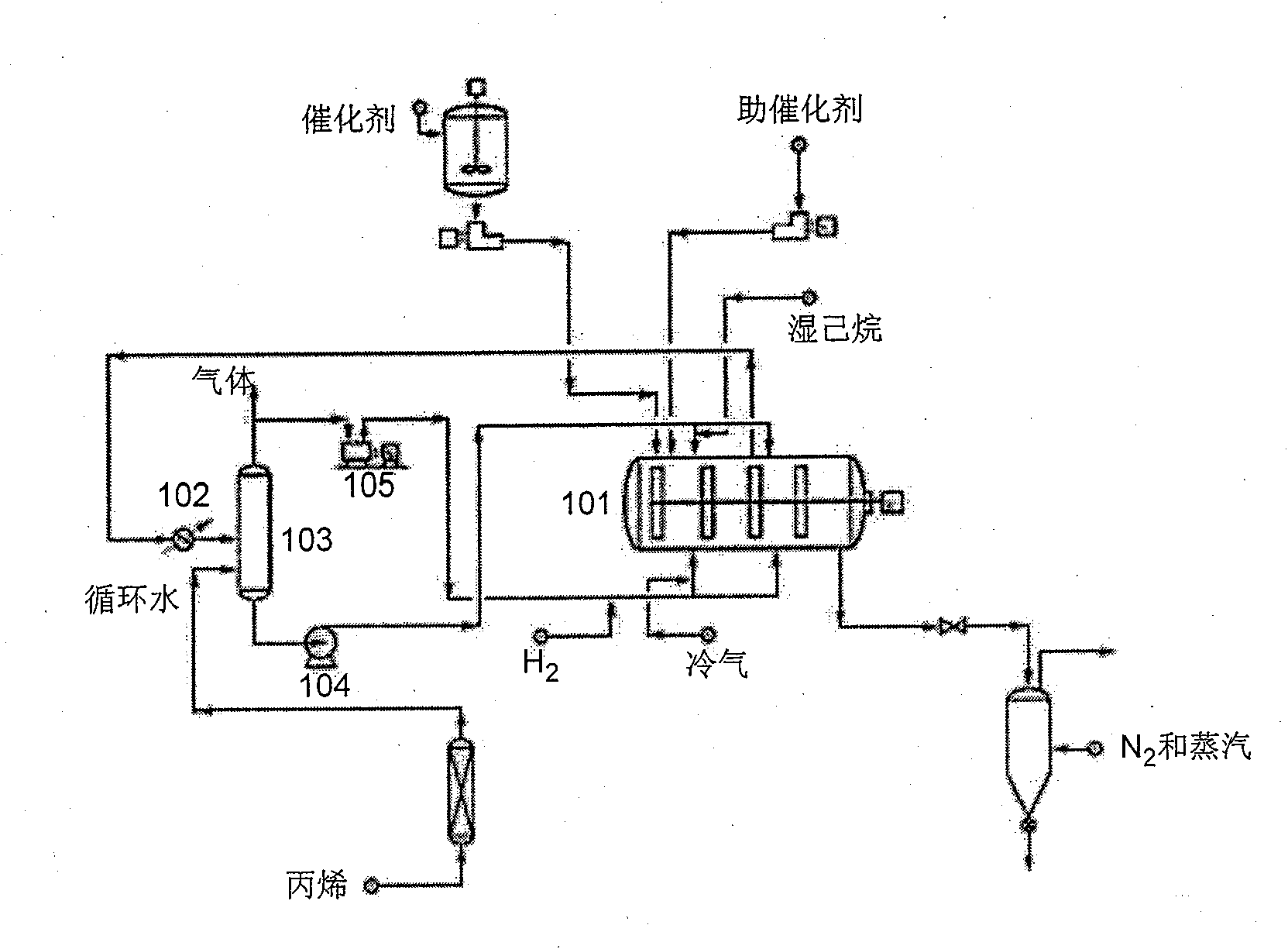

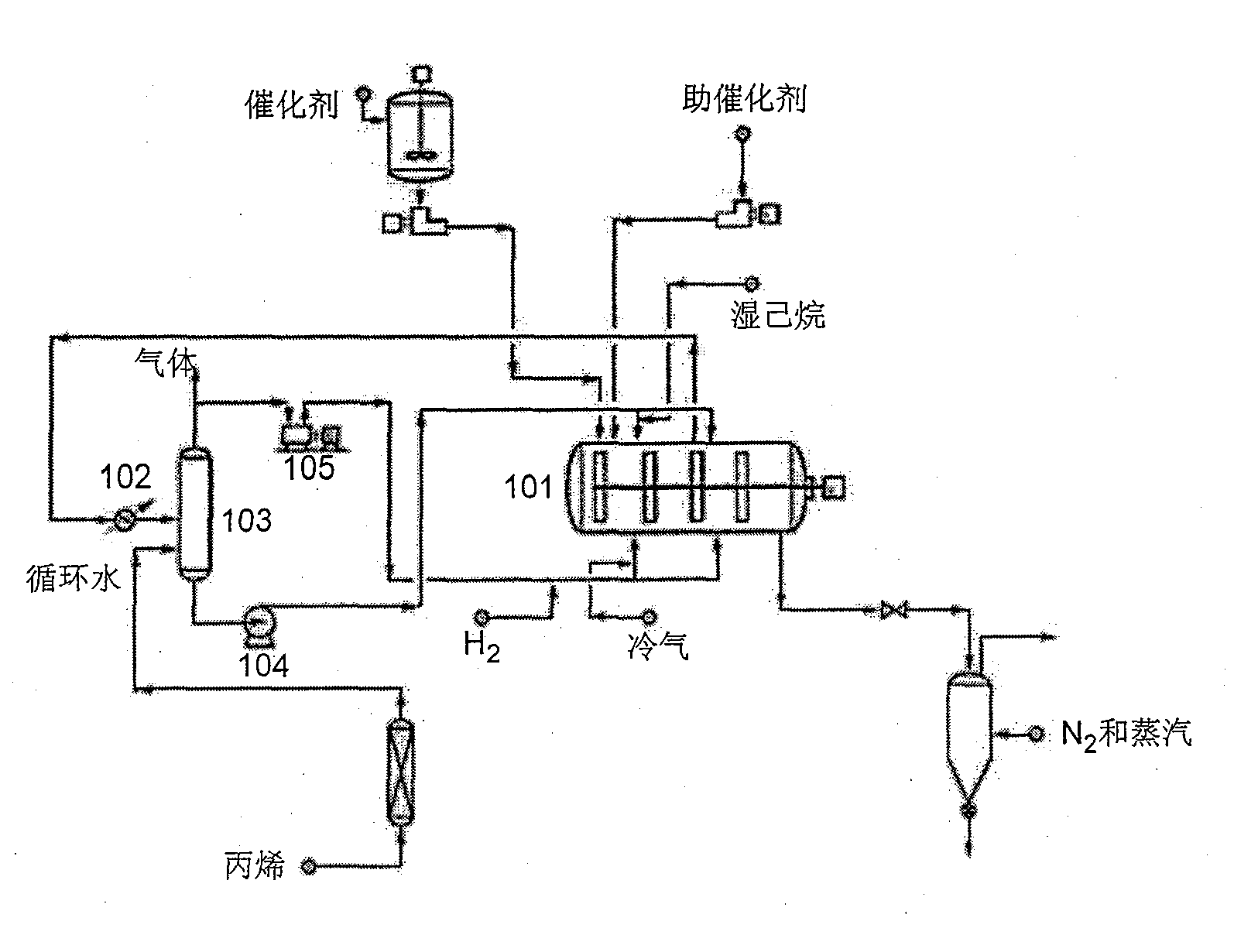

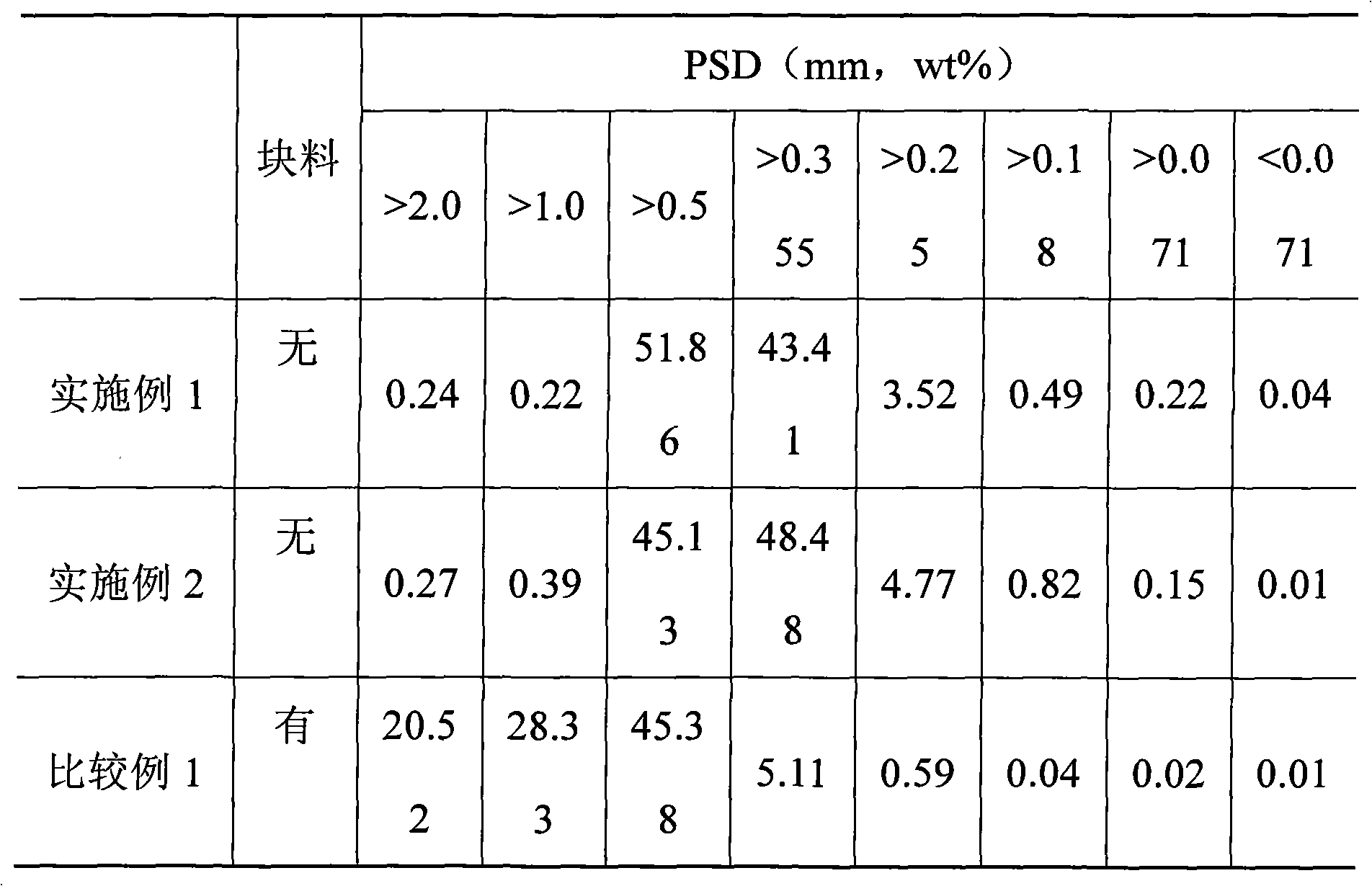

[0021] Carry out the random copolymerization of propylene / ethylene / butene-1 in the device shown in accompanying drawing, catalyst active component is prepared by the embodiment 1 that CN98111780.5 describes, cocatalyst is triethylaluminum, and external electron donor is Diisobutyldimethoxysilane. The pressure of the polymerization reactor was controlled at 2.3MPa, and the temperature was controlled at 66°C. Nitrogen containing 4.5% oxygen was added to the gas phase feed in the area where the catalyst feed position of the reactor was located, and the concentration of oxygen in the gas phase feed was controlled to be 5 ppmV. Adjust the feed amount of propylene and butene-1 according to the composition set by the process target to achieve the structure of the target polymer. The data of the particle size distribution of the obtained polymer powder is shown in Table 1, and other analytical data are shown in Table 2.

Embodiment 2

[0023] Same as Example 1, but no oxygen is added to the gas phase feed of the reactor, and the oxygen content measured by the online water oxygen analyzer is less than 0.5ppm. Hexane containing 2 wt% water was added to the liquid-phase sprayed propylene feed in the catalyst feed zone of the reactor, and the water content measured by the online water analyzer was 6 ppm.

[0024] The data such as size distribution and composition, melting point of the obtained polymer of analysis test are listed in Table 1 and Table 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com