Controller for ship equipped with thermal discharge recovery system and the ship equipped with the controller

一种废热回收、控制设备的技术,应用在辅助设备、电气控制、机械设备等方向,能够解决发动机控制没有在考虑船舶速度等问题,达到改进响应性、抑制船舶速度的变化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings. However, it is contemplated that dimensions, materials, shapes, relative positions thereof and the like will be understood as merely illustrative and not limiting the scope of the present invention if not specifically specified.

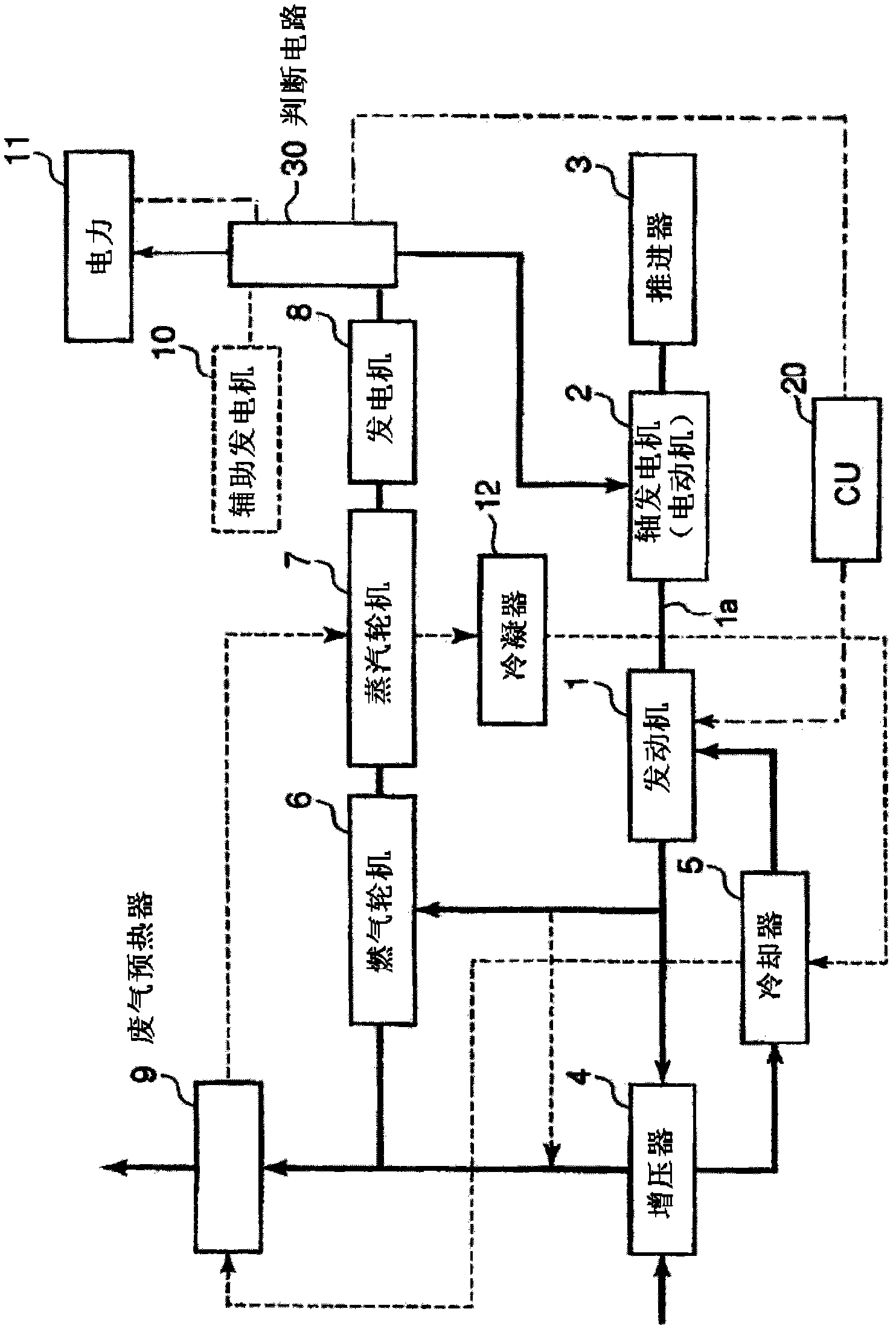

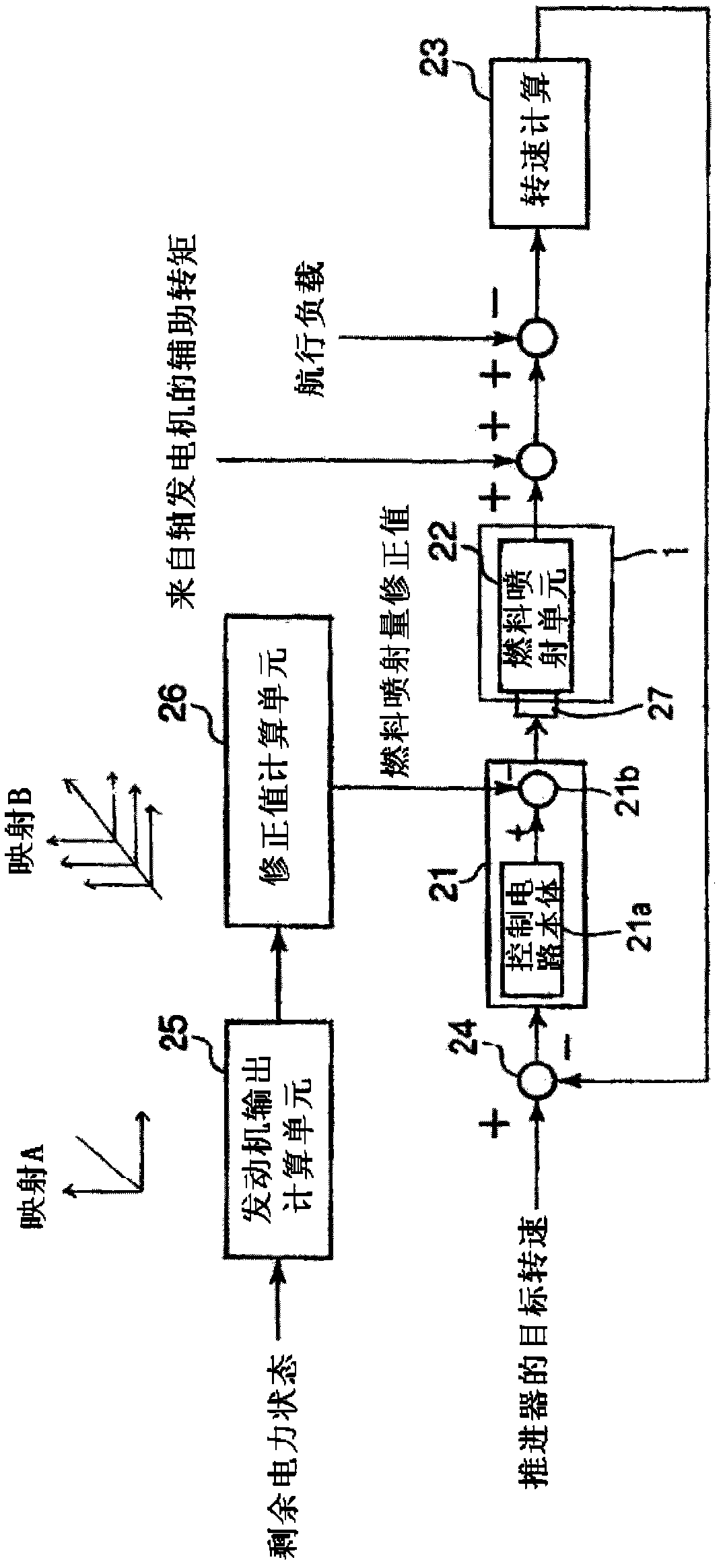

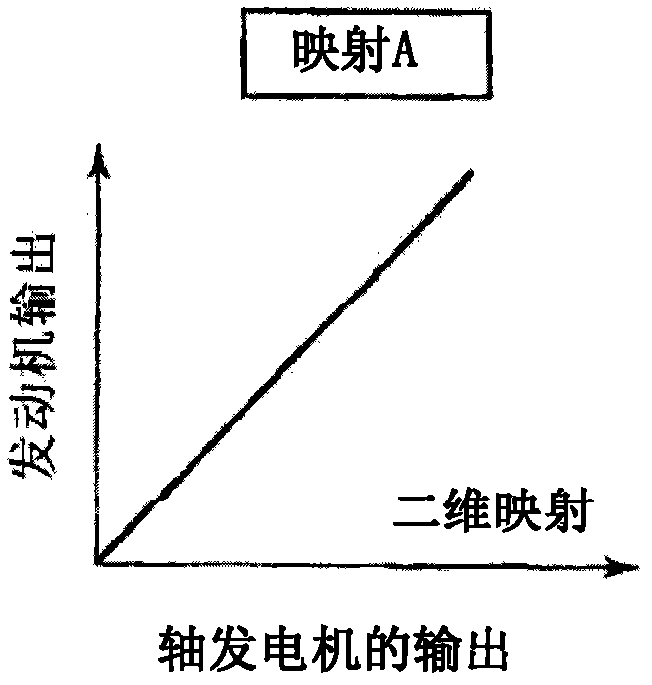

[0038] First, refer to Figure 1 to Figure 4 The control of the fuel injection amount of the ship related to the first preferred embodiment will be described. figure 1 is a block diagram showing the overall structure of a ship equipped with an exhaust heat recovery system to which the present invention is applied. figure 1 The waste heat recovery system has an engine (internal combustion engine) 1 for propelling the ship, a shaft generator 2 connected to the engine 1 through an output shaft, a propeller 3 rotated by the output of the engine 1, a compressor for compressing the air supplied to the engine 1 supercharger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com