Temperature-difference power generation system

A technology of thermoelectric power generation and temperature difference, which is applied in the direction of generators/motors, electrical components, etc., can solve the problems that thermoelectric generators cannot communicate with tap water or well water through pipelines, cannot use thermoelectric generators to generate electricity, and have limited application occasions, etc., to achieve Improve reusability and economy, reduce environmental heat emissions, and improve the effect of reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

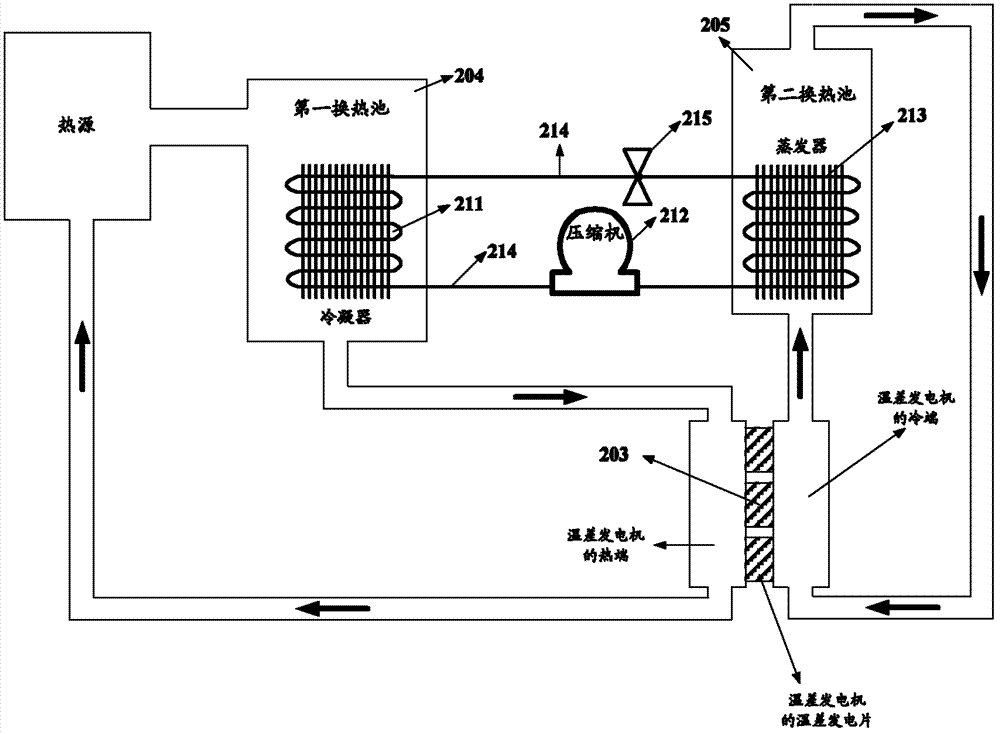

[0052] Referring to FIG. 2 , the thermoelectric power generation system according to Embodiment 1 of the present invention includes: a thermoelectric generator 203 , a heat pump device (not marked in the figure), a first heat exchange pool 204 , and a second heat exchange pool 205 . Wherein, the heat pump device specifically includes: a condenser 211 , a compressor 212 , an evaporator 213 , a refrigerant circulation pipeline 214 , and a throttle valve 215 .

[0053] The condenser 211 is disposed in the first heat exchange pool 204 ; the evaporator 213 is disposed in the second heat exchange pool 205 .

[0054] The hot flow medium flowing out from the heat source passes through the first heat exchange pool 204 and flows through the hot end 203 of the thermoelectric generator. Specifically, one end of the first heat exchange pool 204 is connected to the heat source, and the other end is connected to the inlet of the hot end of the thermoelectric generator 203 . The heat source ...

Embodiment 2

[0068] Furthermore, waste heat can also be recycled for power supply. Another thermoelectric power generation system provided by Embodiment 2 of the present invention can be found in image 3 As shown, it includes: a waste heat accumulation subsystem 301 , a first heat pump device 302 , a high calorific value energy output subsystem 303 , a thermoelectric generator 203 , a third heat exchange pool 305 , and a second heat pump device 304 .

[0069] Wherein, both the first heat pump device 302 and the second heat pump device 304 include a condenser 211 , a compressor 212 , an evaporator 213 , a refrigerant circulation pipeline 214 , and a throttle valve 215 . The functions and working principles of the condenser 211, compressor 212, evaporator 213, refrigerant circulation pipeline 214, and throttle valve 215 of the first heat pump device 302 and the second heat pump device 304 are the same as those of the first heat pump device in the above-mentioned embodiment. I won't repeat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com