Oxychlorination device and method

A hydrogen chloride and oxygen technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problems of over-proportion increase of by-products, formation of by-products, increase in operating costs, and over-proportion increase, and achieve high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

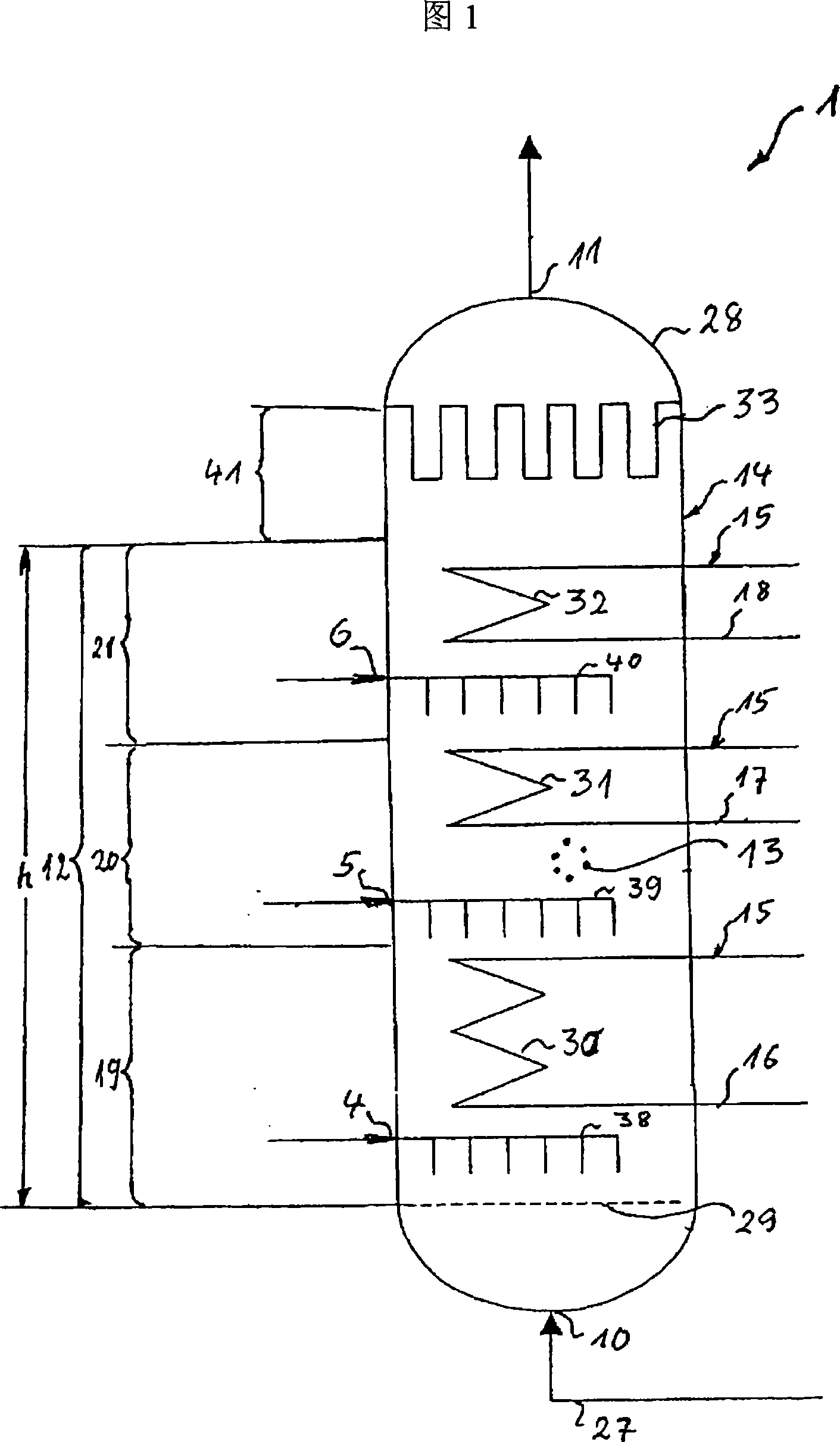

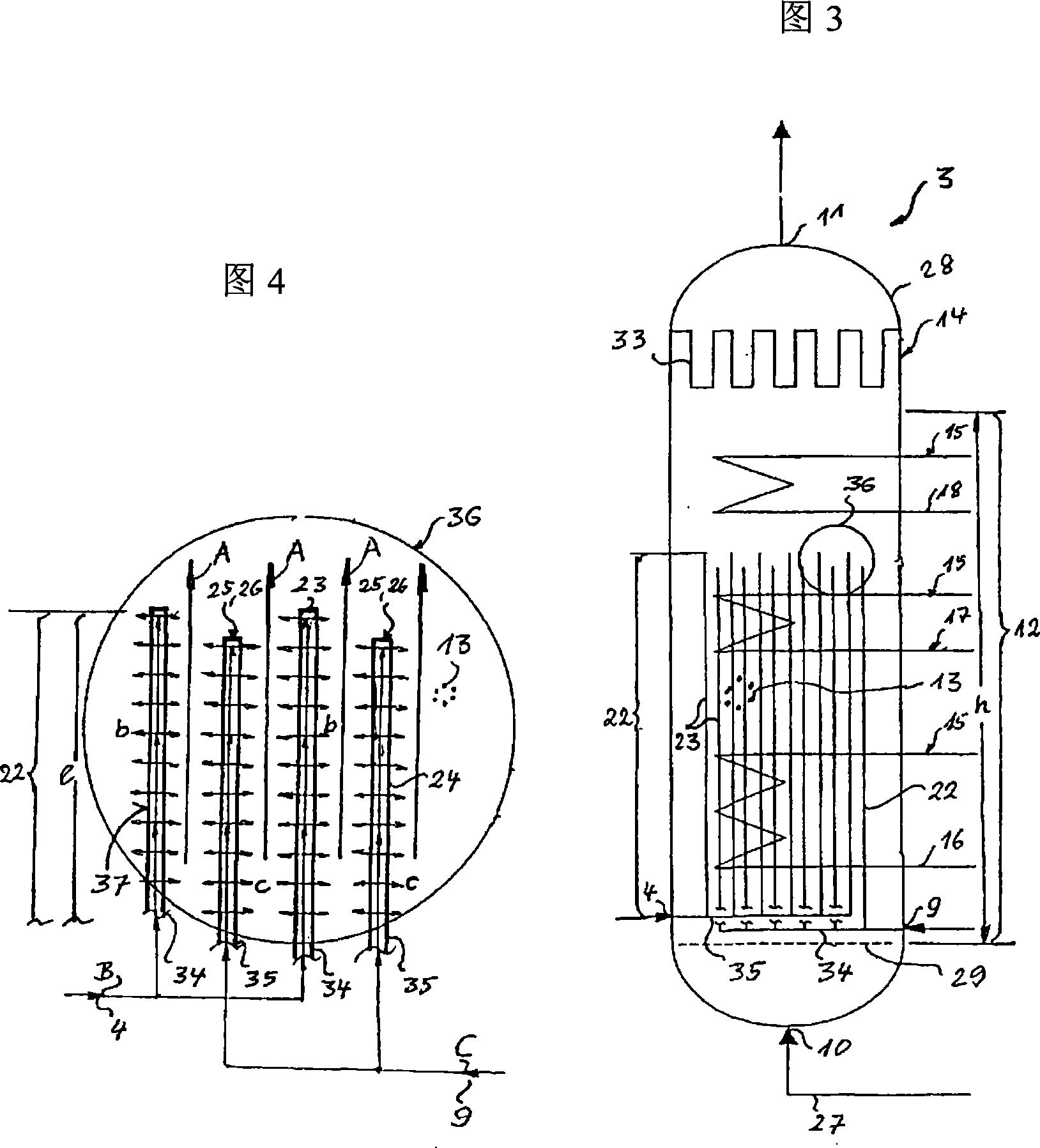

[0048] 1,2-Dichloroethane was prepared using an oxychlorination reactor 14 with a two-stage fluidized bed 12 using a catalyst of Cu(II)Cl 2 .

[0049] at 35Nm 3 / h cycle gas consumption to operate the equipment. Add 51Nm to the recirculation gas stream 3 / h ethylene that has been preheated to 160°C. The resulting gas mixture flows through distribution plate 29 into the reactor. Through the gas inlet 4 of the first gas distributor 38 located above it, 13.5 Nm 3 / h oxygen and 50Nm 3 / h of a mixture of hydrogen chloride. The starting materials react at 220°C and 0.35MPa to produce 1,2-dichloroethane and water. The reaction heat of this strongly exothermic reaction is discharged to the condensate via the cooling tube bundle 30 . The reaction temperature in the reactor is adjusted by partial evaporation of the condensate in the cooling tube bundle 30 .

[0050] Through the second gas distributor 39 between the first cooling tube bank 30 and the second cooling tube bank 31,...

Embodiment 2

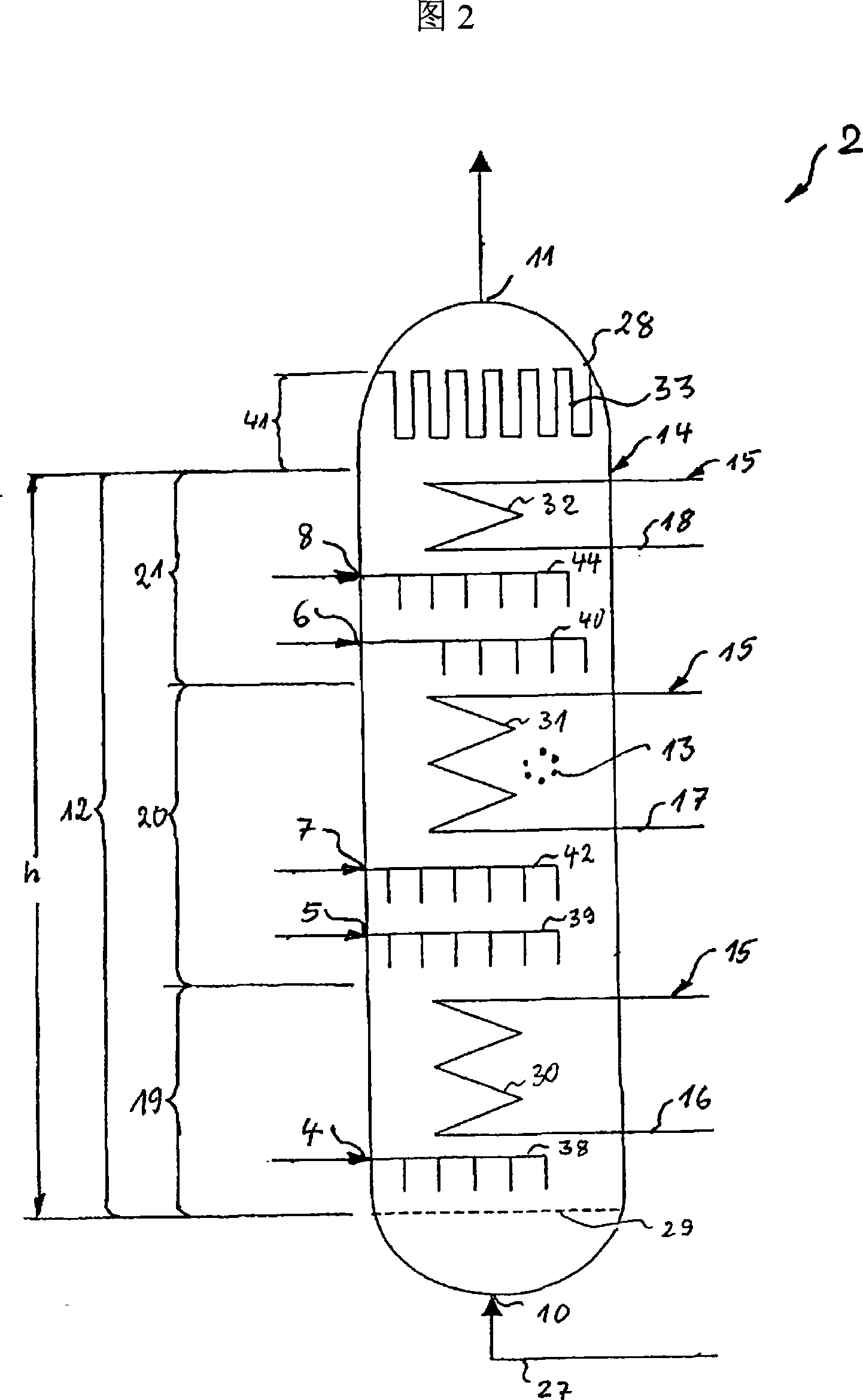

[0071] 1,2-Dichloroethane was prepared using an oxychlorination reactor 1 with a fluidized bed 12, the catalyst used was CuCl 2 .

[0072] at 35Nm 3 / h cycle gas consumption to operate the equipment. Add 28Nm to the recirculation gas stream 3 / h ethylene that has been preheated to 160°C. The resulting gas mixture flows through the distribution plate 29 into the reactor. 27Nm 3 / h of oxygen and 100Nm 3 / h of a mixture of hydrogen chloride. The starting materials react at 220°C and 3.5 bar absolute to form 1,2-dichloroethane and water. The reaction heat of this strongly exothermic reaction is discharged to the condensate via the cooling tube bundle 16 . The reaction temperature in the reactor is adjusted by partial evaporation of the condensate in the cooling tube bundle 30 .

[0073] Through the gas distributor 42 between the first cooling tube bank 30 and the second cooling tube bank 31, feed 23 Nm in the fluidized bed reactor 14 through the gas inlet 7 3 / h of ethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com