Temperature increasing and decreasing adjustment instrument based on semiconductor refrigeration and heating technology

A technology of lifting adjustment, cooling and heating, applied in refrigerators, refrigeration and liquefaction, machines using electric/magnetic effects, etc., can solve problems such as long expansion time, difficult production capacity expansion, and slow heating/cooling speed , to achieve the effect of high temperature maintenance stability, easy promotion and application, and fast temperature rise and fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

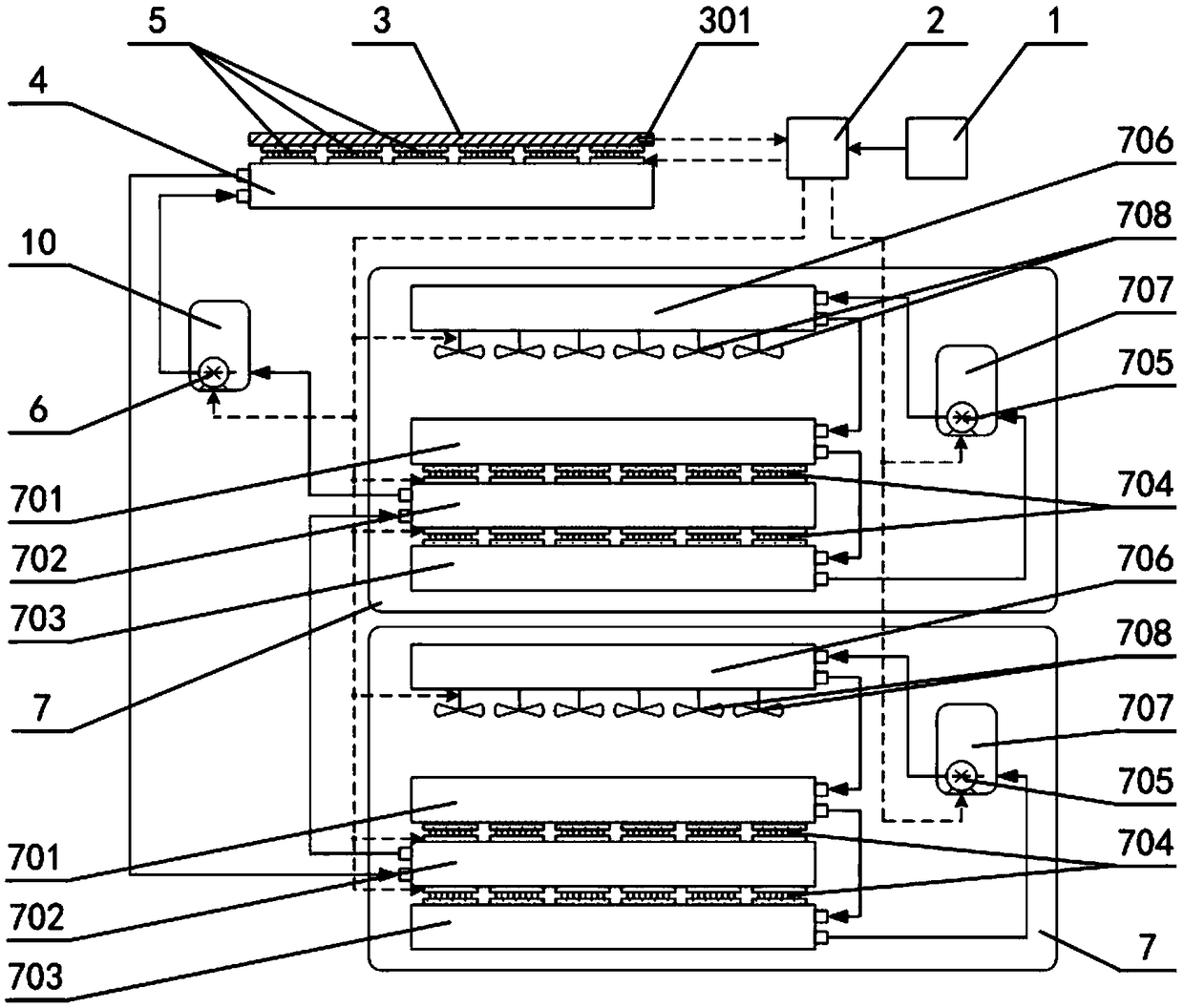

[0040] Such as figure 1 As shown, the first temperature rise and fall adjustment instrument based on semiconductor refrigeration and heating technology provided in this embodiment includes a power supply 1, a temperature rise and fall adjustment control board 2, a load heat conducting plate 3, a primary water cooling head 4, and a primary TEC device 5. The primary water pump 6 and the secondary cooling and heating interaction system 7, wherein the power supply 1 is electrically connected to the temperature rise and fall adjustment control board 2, and a temperature sensor 301 is provided in the load heat conducting plate 3; the load The heat conduction plate 3 is located directly above the primary water cooling head 4, and several primary TEC devices 5 arranged in a matrix are arranged between the load heat conducting plate 3 and the primary water cooling head 4, wherein the The N-type semiconductor plate of the primary TEC device 5 is in contact with the object heat conductin...

Embodiment 2

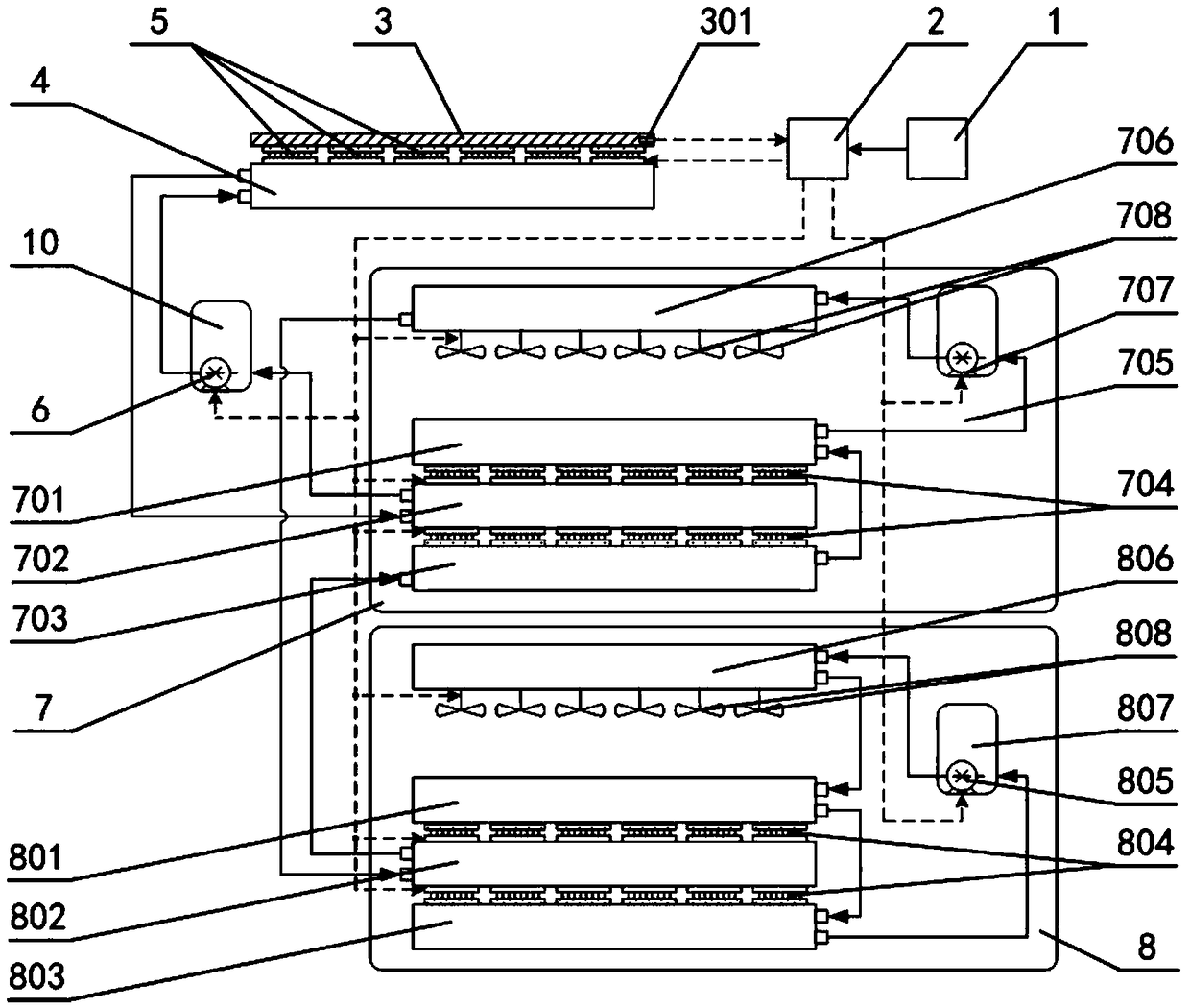

[0054] Such as figure 2 As shown, this embodiment provides another temperature rise and fall adjustment instrument based on semiconductor refrigeration and heating technology, which is different from Embodiment 1 in that it also includes an auxiliary stage cooling and heating interaction system 8, wherein the auxiliary stage The cooling and heating interaction system 8 includes a first auxiliary water cooling head 801, a second auxiliary water cooling head 802, a third auxiliary water cooling head 803, an auxiliary TEC device 804, an auxiliary water pump 805 and an auxiliary water heat exhaust pipe 806; The first auxiliary water cooling head 801, the second auxiliary water cooling head 802 and the third auxiliary water cooling head 803 are arranged sequentially from top to bottom, and between the first auxiliary water cooling head 801 and the second auxiliary water cooling head Between the two auxiliary stage water cooling heads 802 and between the second auxiliary stage wate...

Embodiment 3

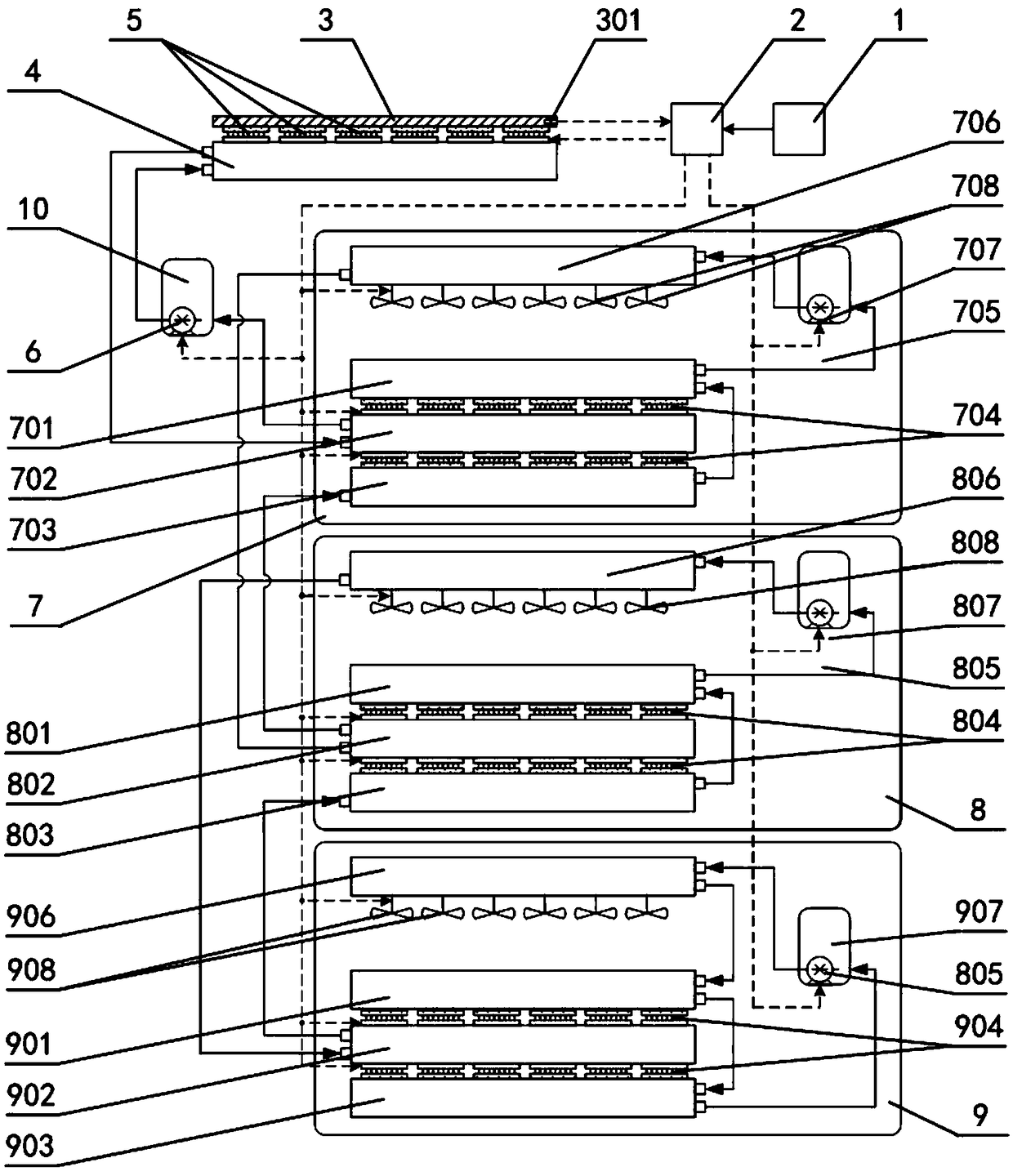

[0062] Such as image 3 As shown, this embodiment provides a third temperature rise and fall adjustment instrument based on the semiconductor refrigeration and heating technology on the basis of the second embodiment, which is different from the second embodiment in that it also includes the final cooling and heating interaction system , wherein, the final cooling and heating interaction system 9 includes a first final water cooling head 901, a second final water cooling head 902, a third final water cooling head 903, a final TEC device 904, a final water pump 905 and a final Waterway heat removal pipe 906; the first final stage water cooling head 901, the second final stage water cooling head 902 and the third final stage water cooling head 903 are arranged sequentially from top to bottom, and at the first final stage Between the water-cooling head 901 and the second final-stage water-cooling head 902 and between the second-stage final-stage water-cooling head 902 and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com