CFD-based floating nuclear power station thermal discharge water heat diffusion numerical simulation method

A numerical simulation, warm drainage technology, applied in CAD numerical modeling, CAD technology, electrical digital data processing and other directions, to achieve the effect of saving time and cost, high speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

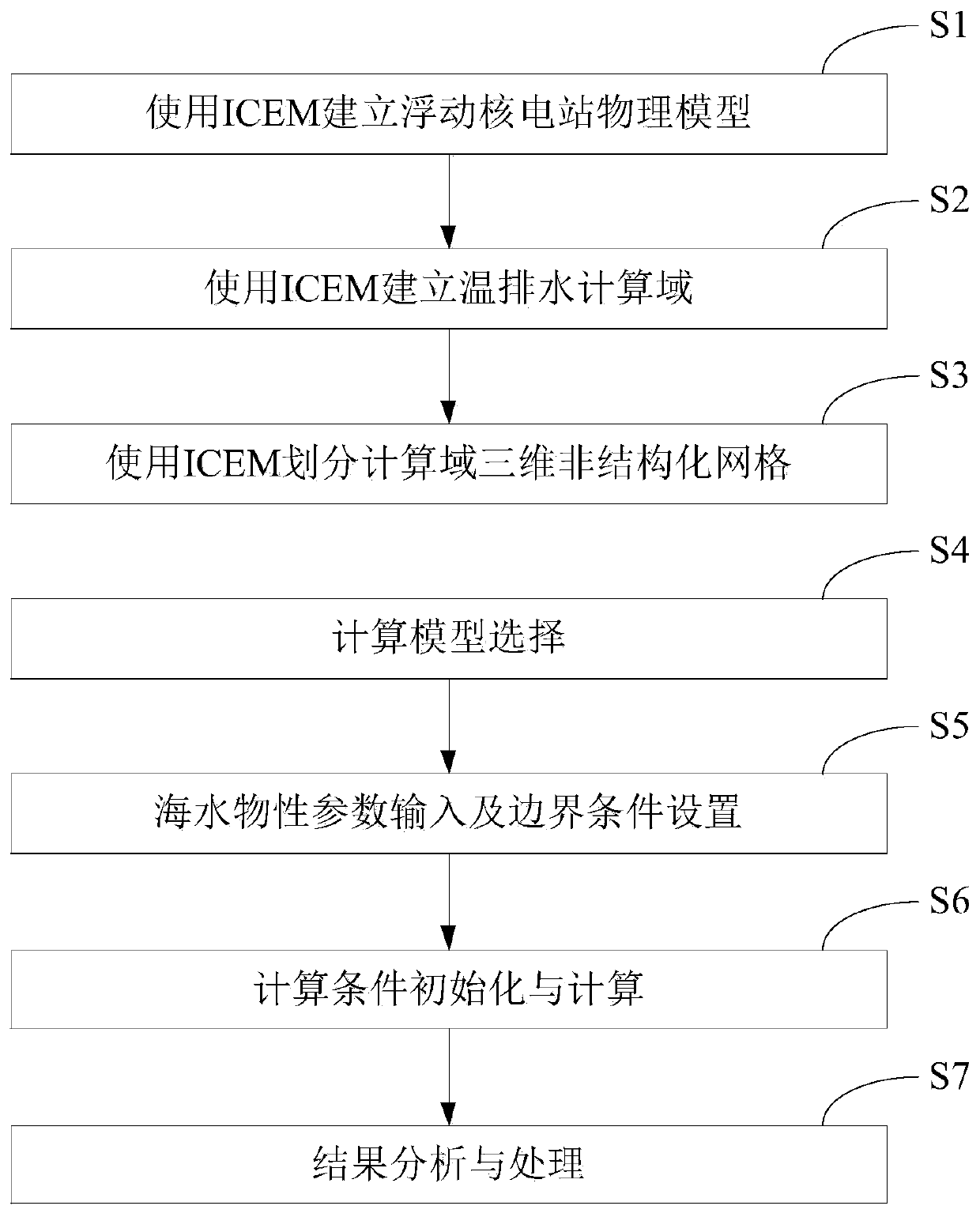

[0018] like figure 1 As shown in the figure, the numerical simulation calculation method for the thermal diffusion of warm water drainage in a floating nuclear power plant based on the CFD technology of the present invention includes the following steps:

[0019] S1. Use ICEM to build a physical model of a floating nuclear power plant

[0020] This example is based on the "Academician Lomonosov", using ICEM software to build a 1:1 physical model of a floating nuclear power plant; the overall length of the ship is 140m, the width of the ship is 30m, and the draft is 5.5m; the circulating cooling water intake is initially selected to be arranged at the bottom of the ship The position is 25m from the bow and 6m from the side of the ship; the drainage outlets are arranged at a position of 1m from the bottom on both sides of the ship and 38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com