Molten salt thermal storage heater

A heater and resistance heater technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of small heat transfer coefficient and low heat storage efficiency, and achieve high heat storage capacity and system thermal efficiency. The effect of improving and reducing the size of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

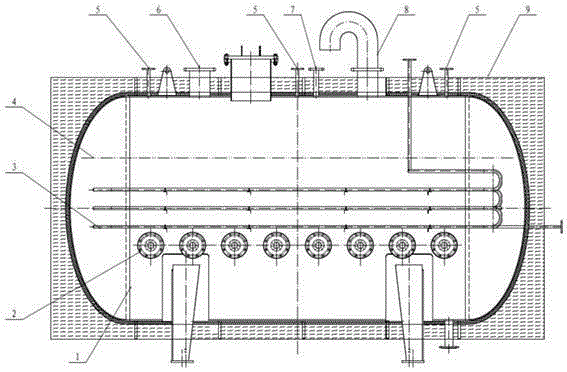

[0015] As shown in the figure, a molten salt thermal storage heater includes a tank body 1, which is formed by butt welding of a cylinder body and an elliptical head, a molten salt temperature measuring device 5, a molten salt inlet 6, a molten salt The liquid level measuring device 7 and the air vent 8 are welded on the top of the tank body 1, and the tank body 1 has a built-in molten salt 4, and the molten salt 4 is composed of potassium nitrate, sodium nitrite and sodium nitrate, wherein the mass content of potassium nitrate is 53 %, the mass content of sodium nitrite is 40%, and the mass content of sodium nitrate is 7%. is 0.34Kcal / Kg; the resistance heater automatic control system 2 is built in the molten salt 4, and the resistance heater automatic control system 2 includes a high-sensitivity molten salt temperature detection element, a PLC programmable controller, frequency conversion control of the feed water pump and molten salt storage The automatic switching element ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com