A cascaded phase change plate heat storage and heat exchange integrated device

A phase change heat storage and phase change technology, which is applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of low heat transfer efficiency of phase change materials, improve the equivalent thermal conductivity, overcome The effect of low thermal conductivity and fast heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

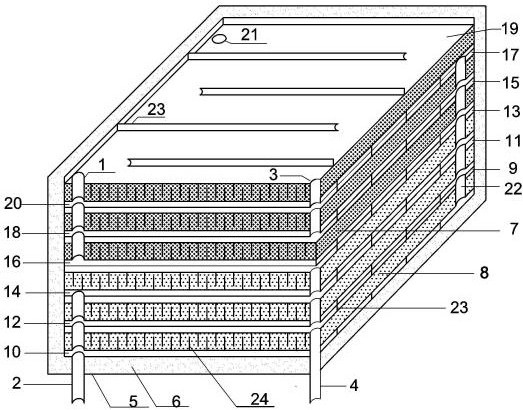

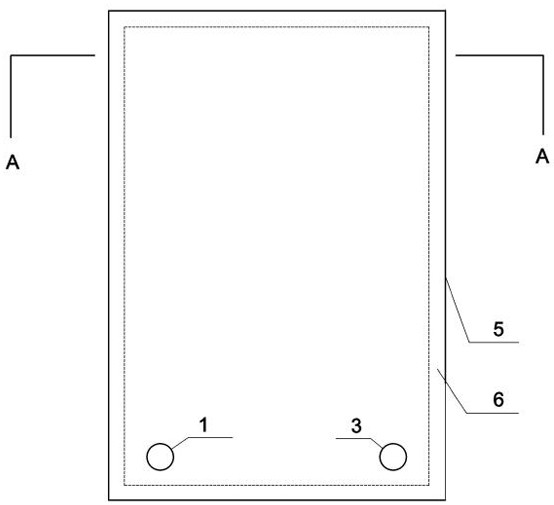

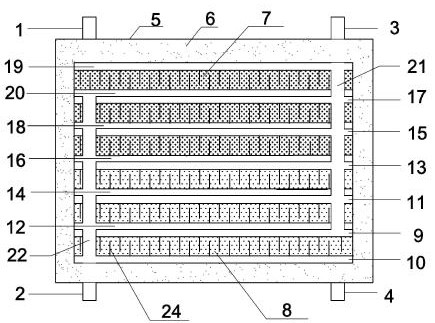

[0036]A cascaded phase change plate heat storage and heat exchange integrated device, including a phase change heat storage layer, a cold fluid horizontal channel layer is arranged on the phase change heat storage layer, a hot fluid horizontal channel layer is arranged under the phase change heat storage layer, and the hot fluid horizontal channel layer is arranged under the phase change heat storage layer. A cold fluid horizontal channel layer is arranged under the channel layer to form a set of cold fluid horizontal channel layer-phase change heat storage layer-hot fluid horizontal channel layer-cold fluid horizontal channel layer-phase change heat storage layer-hot fluid from top to bottom The basic structure of the horizontal channel layer; the phase change thermal storage layer, the cold fluid horizontal channel layer, and the hot fluid horizontal channel layer are separated by metal plates; the phase change thermal storage layer includes a phase change thermal storage laye...

Embodiment 2

[0046] A cascaded phase change plate heat storage and heat exchange integrated device, including a phase change heat storage layer, a cold fluid horizontal channel layer is arranged on the phase change heat storage layer, a hot fluid horizontal channel layer is arranged under the phase change heat storage layer, and the hot fluid horizontal channel layer is arranged under the phase change heat storage layer. A cold fluid horizontal channel layer is arranged under the channel layer to form a set of cold fluid horizontal channel layer-phase change heat storage layer-hot fluid horizontal channel layer-cold fluid horizontal channel layer-phase change heat storage layer-hot fluid from top to bottom The basic structure of the horizontal channel layer; the phase change thermal storage layer, the cold fluid horizontal channel layer, and the hot fluid horizontal channel layer are separated by metal plates; the phase change thermal storage layer includes a phase change thermal storage lay...

Embodiment 3

[0054] Compared with Example 1, the main difference between Example 3 is that each layer of phase change heat storage material is individually packaged in a sealed box, and the cold and hot fluid pipelines do not pass through the sealed box of the phase change heat storage layer. Others are consistent with Example 1. , Replacement of the phase change heat storage layer in the device can directly replace the phase change heat storage layer of each layer of the overall package, more flexible change of the heat storage capacity of the device, easy disassembly and cleaning, and easier assembly and use of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com