Heat storage tank and heat pump water heater

A hot water storage tank and heat storage technology, which is applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of large volume of hot water storage tanks and poor heat release capacity, and achieve large heat exchange area and enhanced heat release rate, the effect of increasing the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

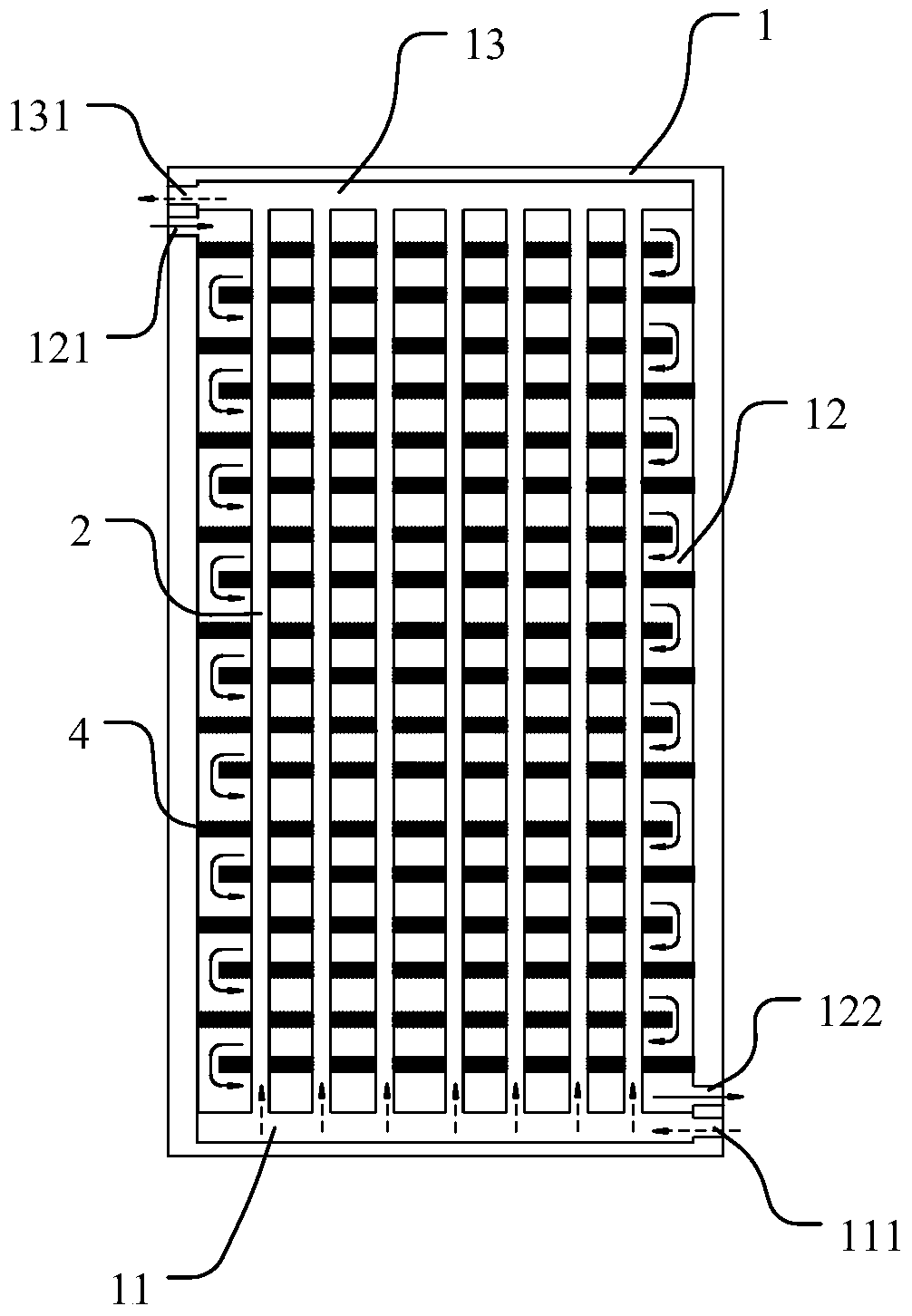

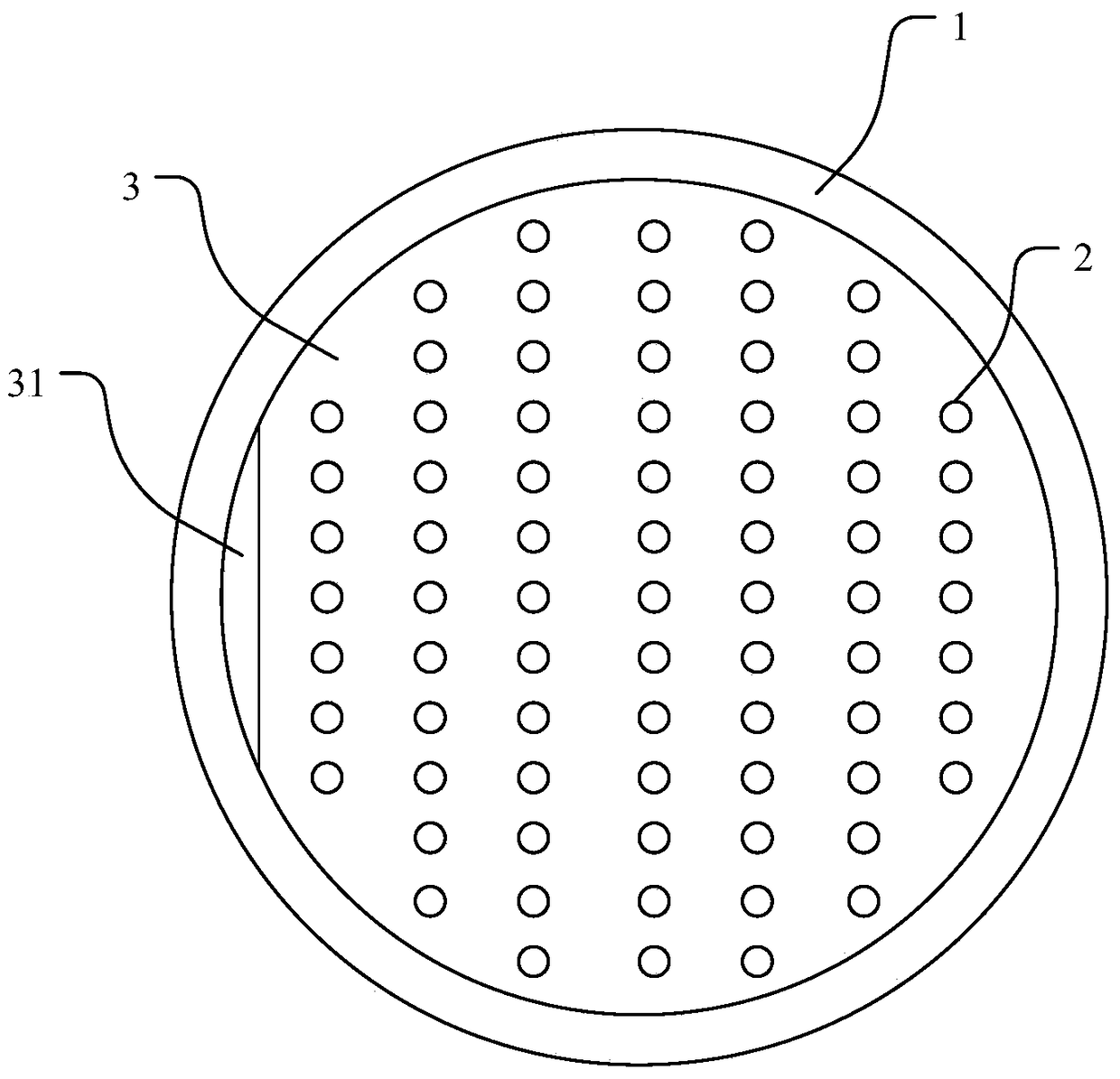

[0021] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0022] The heat storage tank provided by the invention is mainly used in heat pump water heaters, especially air heat source heat pump water heaters. Through the improvement of heat exchange components and heat storage components, the volume of the heat storage tank is reduced. At the same time, by setting special baffles , which enhances the heat release rate of the heat storage material. The heat storage tank provided by the present invention will be described in detail below in conjunction with specific embodiments.

[0023] Such as figure 1 , 2 As shown, the hot water storage tank provided by the present invention includes a shell 1, a heat exchange assembly and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com