Motor and fan having dustproof and dissipating heat function

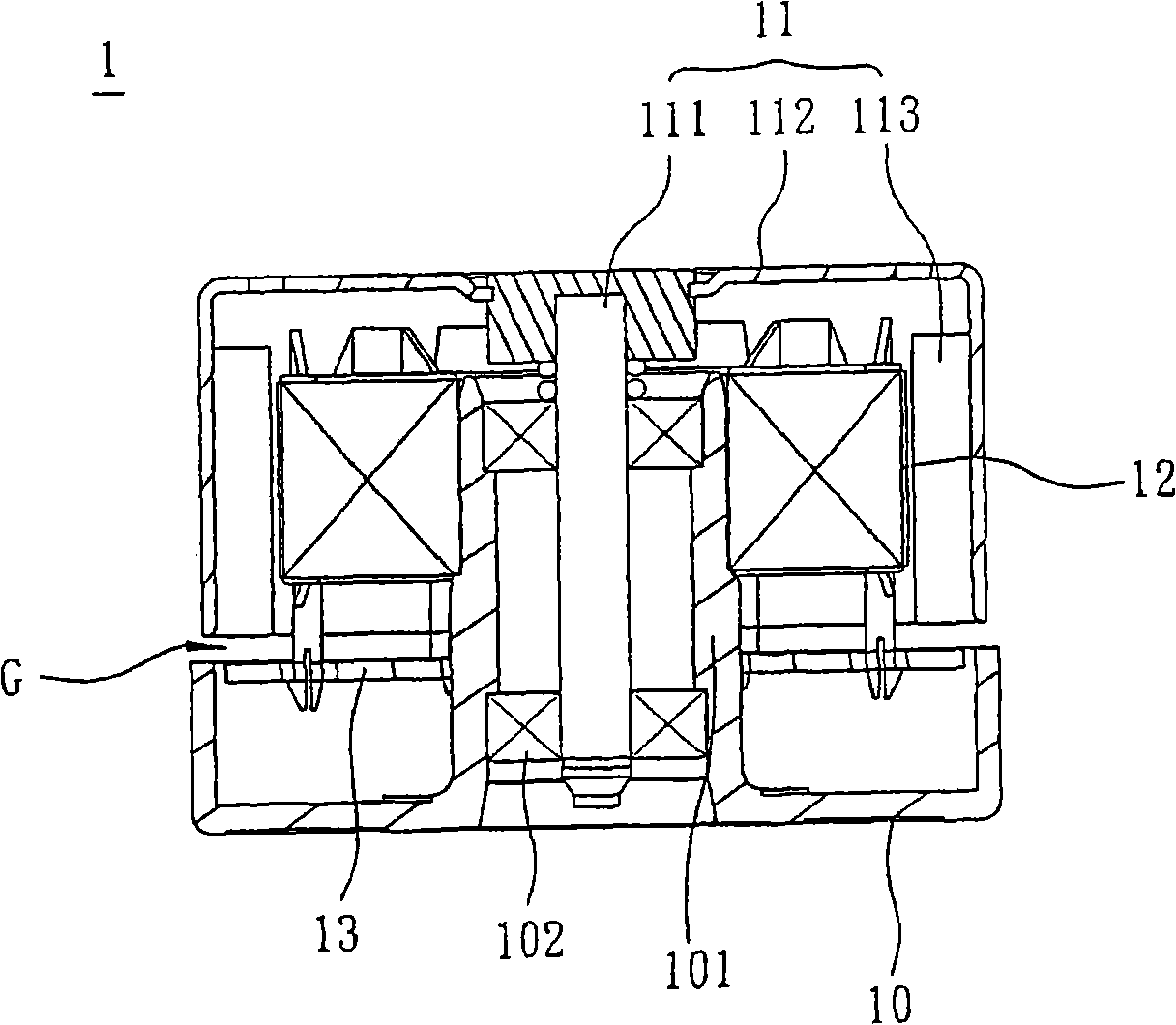

A motor and fan technology, applied in the direction of casing/housing/support, non-variable pumps, pumps, etc., can solve problems such as insufficient sealing, reduced reliability and service life of the outer rotor motor 1, and many gaps. , to increase the heat dissipation surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A motor and a fan using the motor according to preferred embodiments of the present invention will be described below with reference to related drawings. The same elements will be described with the same reference symbols.

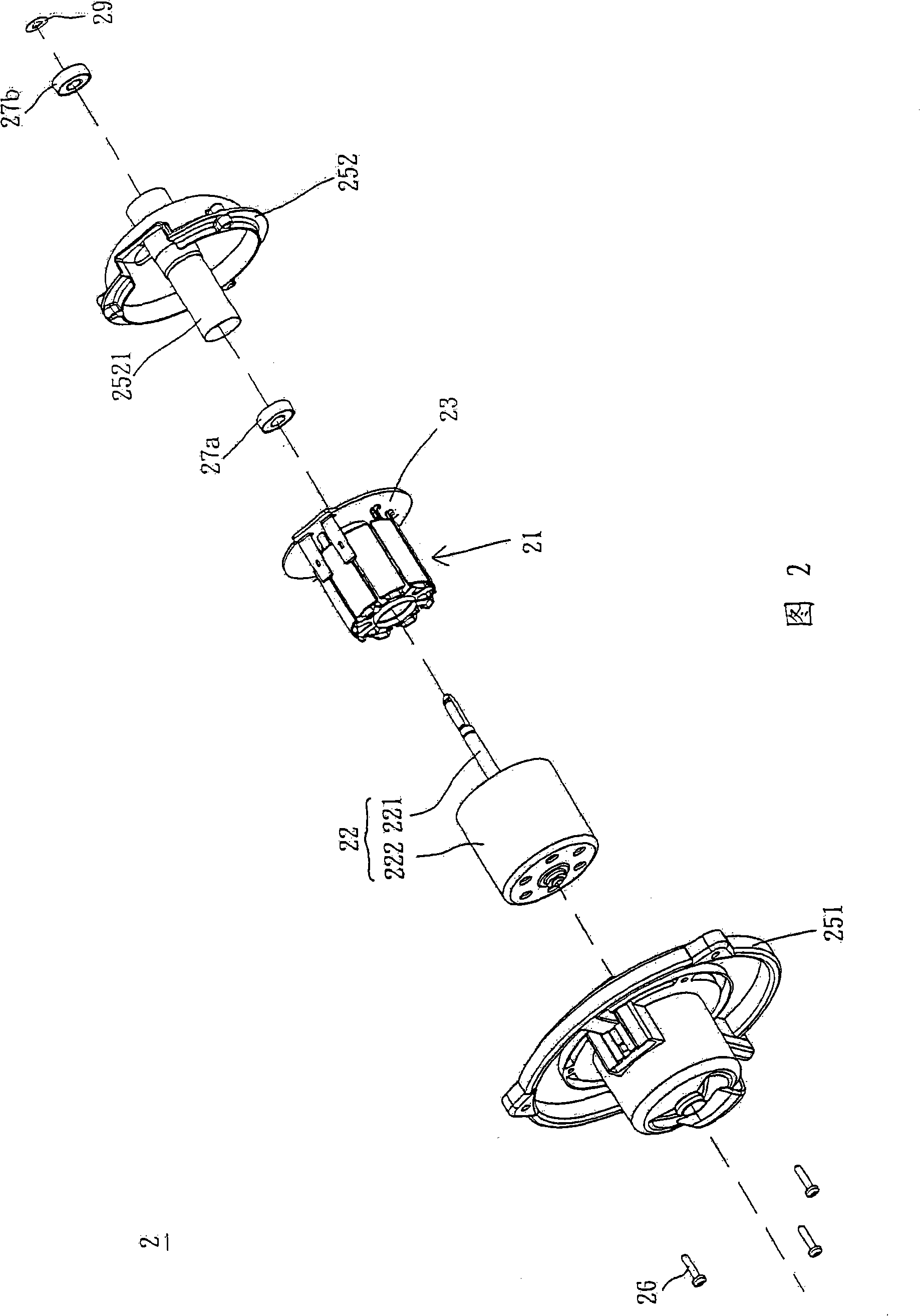

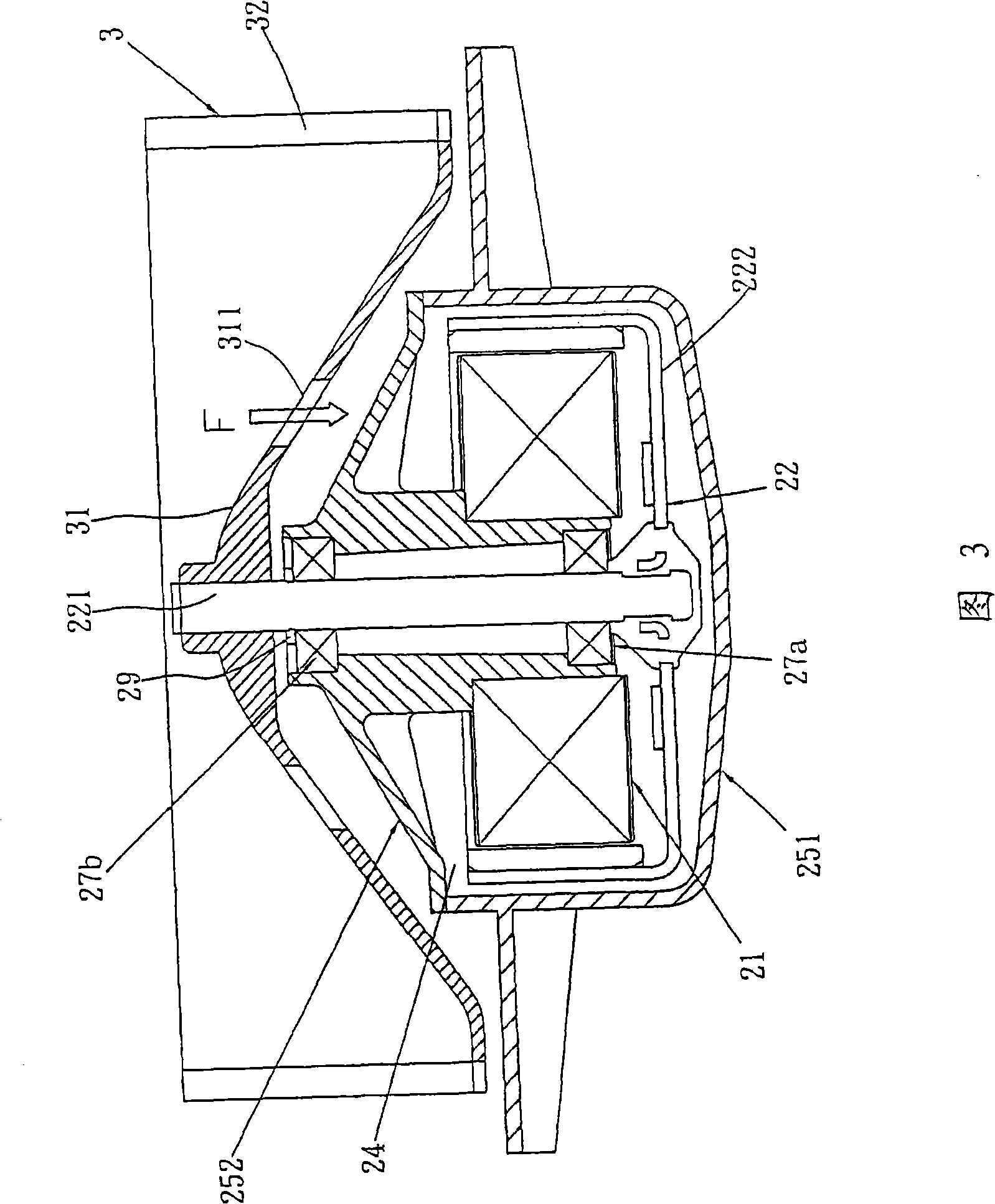

[0034] FIG. 2 is an exploded perspective view showing a motor of a preferred embodiment of the present invention. The motor 2 includes a stator 21 , a rotor 22 and a driving device 23 .

[0035] The driving device 23 is electrically connected to the stator 21, and the driving device 23 has a circuit board. In addition, the rotor 22 includes a rotating shaft 221 and a magnetically permeable shell 222 , and the rotating shaft 221 is connected or embedded in the magnetically permeable shell 222 . The stator 21 is composed of silicon steel sheets and coils.

[0036] The motor 2 further includes a first housing 251 and a second housing 252, the material of the first housing 251 and the second housing 252 can be copper, aluminum, metal or heat conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com