Biomass microwave continuous pretreatment reactor

A microwave reaction system and pretreatment technology, which is applied in the field of biochemical industry, can solve problems such as limiting the optimal design of industrial application equipment, lack of theoretical basis and models for engineering amplification, and restricting the expansion of microwave technology, so as to achieve simple structure, low equipment cost, and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

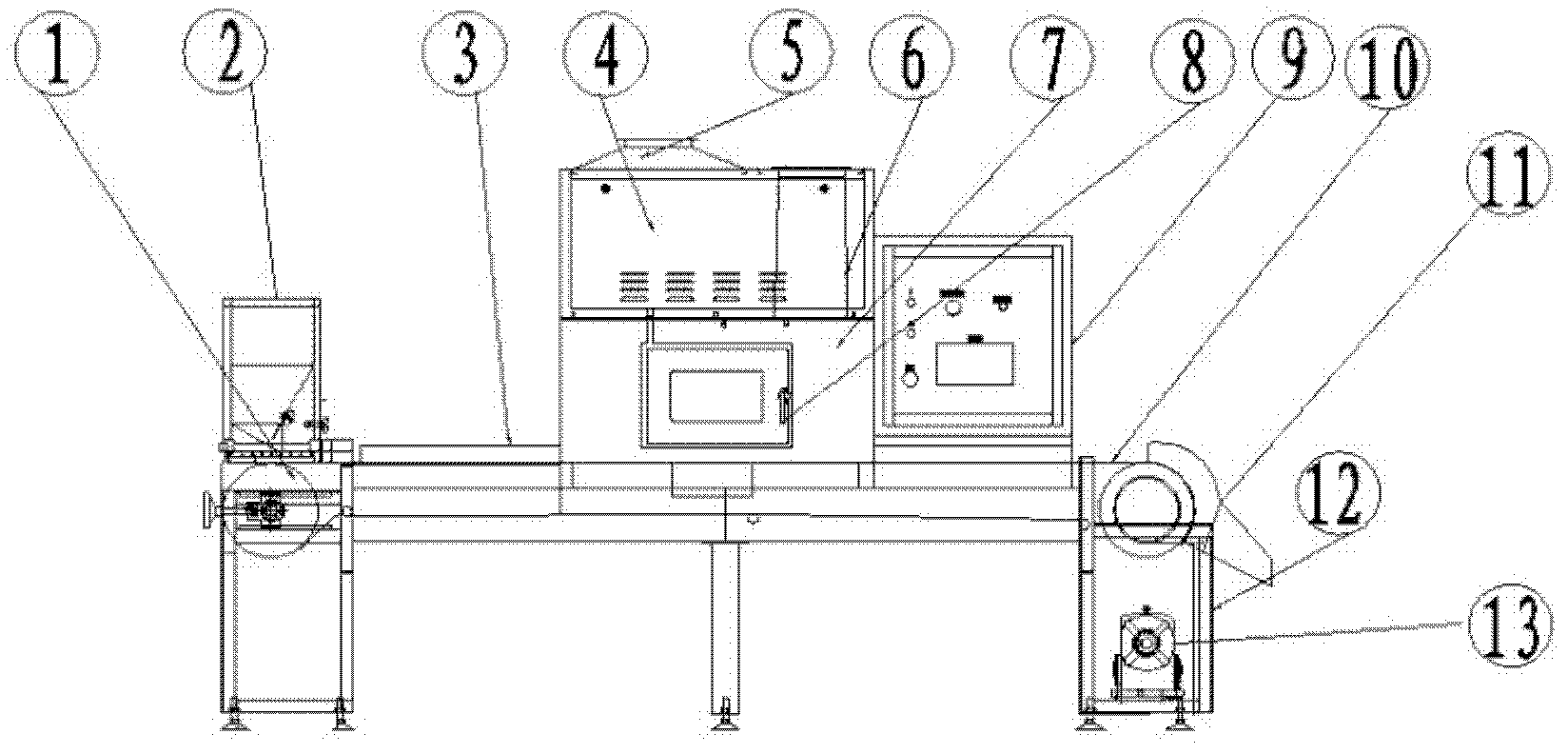

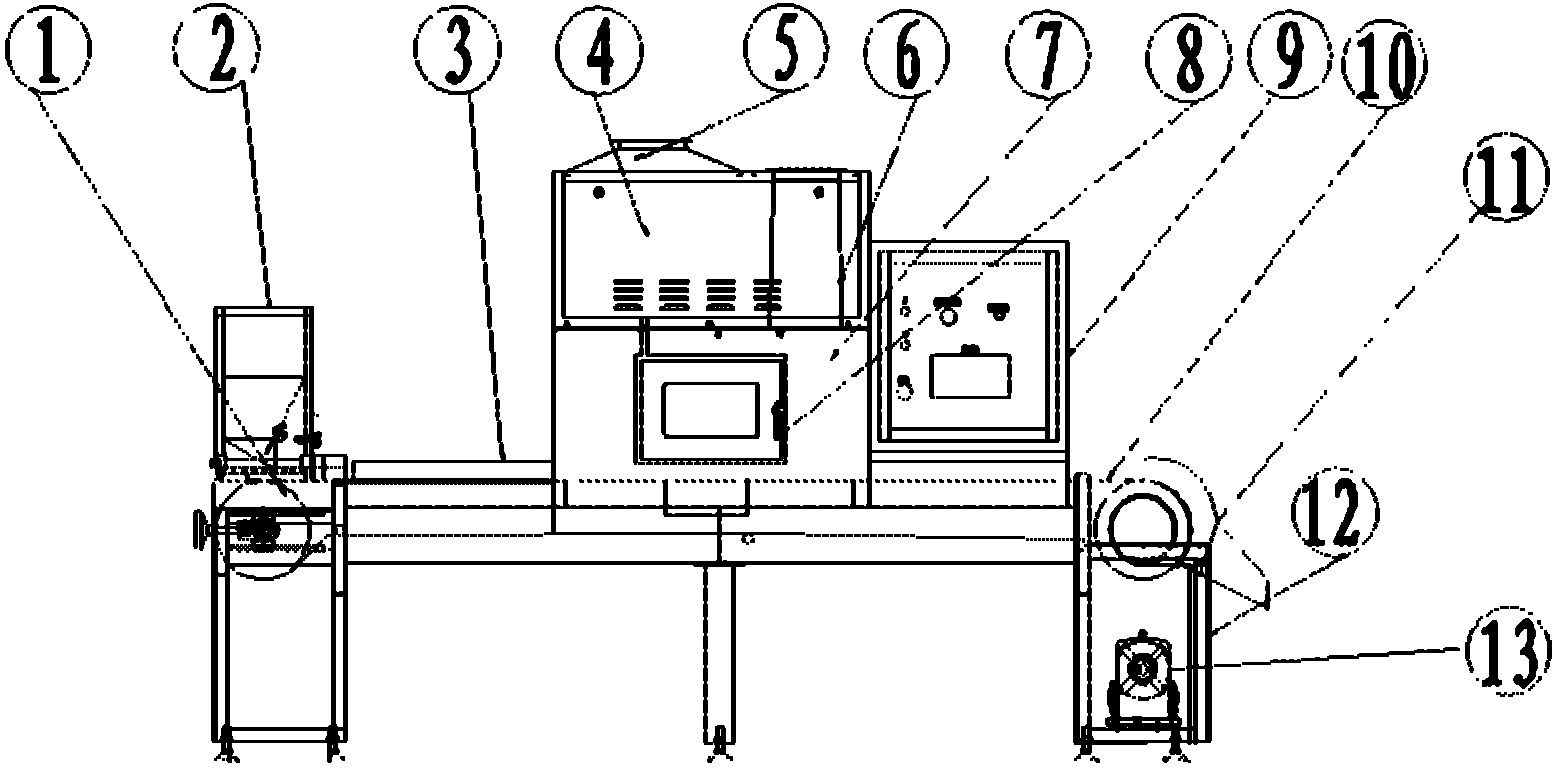

[0031] Biomass microwave continuous pretreatment reactor for processing 1kg corn stalk per hour.

[0032] as attached figure 1, the material with a solid-liquid ratio of 10% (m / v) first enters the inlet end of the conveyor belt from the feed funnel 2, and the material is transported by the conveyor belt 10. The conveyor belt is made of Teflon-coated glass wool and is equipped with a leak-proof Structure, rollers are installed at the bottom of both sides of the conveyor belt to make the conveyor belt into a 'concave' structure to prevent material leakage. After passing through the microwave suppressor 3, it is delivered to the microwave cabinet 7. The upper end of the microwave box 7 is provided with a water supply nozzle and a humidity probe, which can adjust the moisture content of the materials in the process, and detect the humidity change in the box, and at the inlet, middle, and outlet of the microwave box. A thermocouple thermometer is installed at the material inlet t...

Embodiment 2

[0035] A biomass microwave continuous pretreatment reactor that processes 3kg of fast-growing willow per hour.

[0036] as attached figure 1 , the material with a solid-liquid ratio of 10% (m / v) first enters the inlet end of the conveyor belt from the feed funnel 2, and the material is transported by the conveyor belt 10. The conveyor belt is made of wave fiber plus PTFE, and has a leak-proof Structure, rollers are installed at the bottom of both sides of the conveyor belt to make the conveyor belt into a 'concave' structure to prevent material leakage. After passing through the microwave suppressor 3, it is sent to the microwave box 7. The upper end of the microwave box 7 is provided with a water supply nozzle and a humidity probe, which can adjust the moisture content of the materials in the process and detect the humidity in the box. changes, and infrared thermometers are installed at the inlet, middle, and outlet of the microwave box respectively to detect the temperature...

Embodiment 3

[0039] Biomass microwave continuous pretreatment reactor for processing 6kg miscanthus per hour.

[0040] as attached figure 1 , the material with a solid-liquid ratio of 10% (m / v) first enters the inlet end of the conveyor belt from the feed hopper 2, and the material is transported by the conveyor belt 10. The conveyor belt is made of polyamide and is equipped with a leak-proof structure. Both sides of the conveyor belt Rollers are installed at the bottom to make the conveyor belt into a "concave" structure to prevent material leakage. After passing through the microwave suppressor 3, it is sent to the microwave box 7. The upper end of the microwave box 7 is provided with a water supply nozzle and a humidity probe, which can adjust the moisture content of the materials in the process and detect the humidity in the box. change, and thermal resistance thermometers are respectively installed at the inlet, middle, and outlet of the microwave cabinet to detect the temperature in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com