A pretreatment method for purifying supernatant impurities in zinc hydrometallurgy

A technology of zinc hydrometallurgy and pretreatment, applied in the field of zinc hydrometallurgy, can solve the problems of less than 20wt%, out-of-control manganese ions, excessive addition of iron, etc., saving manpower, easy controllability and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Using 800 tons of high-impurity complex zinc ore from Yunnan Luoping Zinc Electric Co., Ltd., mixed evenly and sampled for analysis, its zinc was 42.36wt%, arsenic 0.22wt%, antimony 0.013wt%, germanium 0.010wt%, lead 4.26wt%, di Silicon oxide 5.23wt%, iron 3.07wt%.

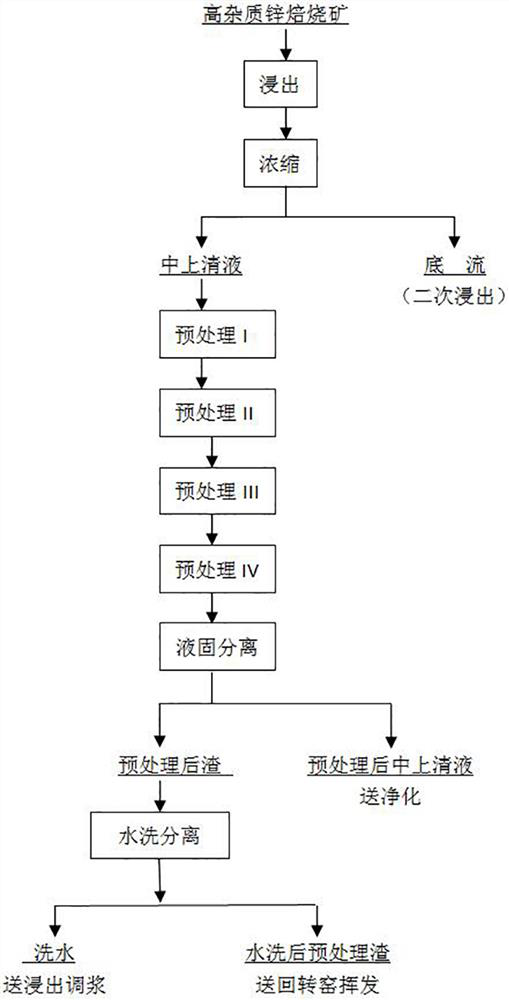

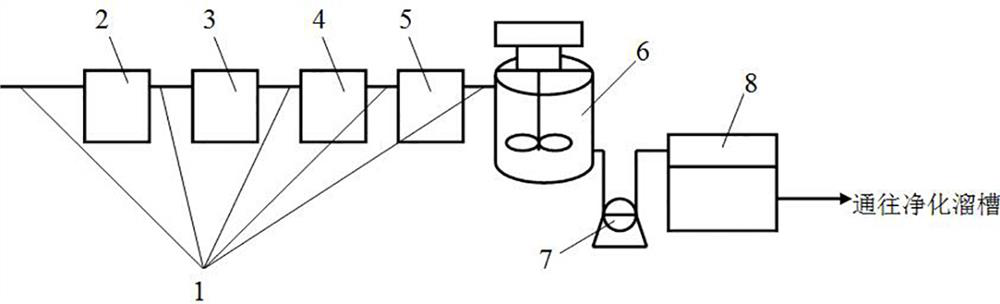

[0045] like figure 2 As shown, on the chute between the supernatant leaching and purification in the existing transportation, add 4 additional volumes of about 0.5~1.0m 3 Each buffer tank is 1.5~2.0m apart and connected by a chute. A stirring device with a volume of about 5.0~10.0m is installed at the end of the chute 1.0~1.5m behind the last buffer tank. 3 One end of the stirring storage tank is connected to the chute, and the other end is connected to the filter press through the filter press pump, which is the liquid-solid separation equipment. After the pretreated high-impurity supernatant is separated from the liquid-solid by the filter press, the output The low-impurity, clear middle supernatant di...

Embodiment 2

[0059] Using 880 tons of high-impurity complex zinc ore from Yunnan Luoping Zinc Electric Co., Ltd., mixed evenly and sampled for analysis, its zinc was 43.08wt%, arsenic 0.24wt%, antimony 0.015wt%, germanium 0.009wt%, lead 4.58wt%, di Silicon oxide 5.47wt%, iron 3.24wt%. The pretreatment device in Example 1 is used.

[0060] S100, leaching: due to the continuous leaching and continuous purification, after starting the leaching, adjust the flow rate to 50~60m 3 / h, control liquid-solid ratio 8~9:1, process temperature 85~90℃, leaching time 40~50min, add manganese powder at 55kg / h during the leaching process, end point pH=5.0, leaching pulp is input into thickening tank for concentration Settling, producing high-impurity medium supernatant and underflow for secondary leaching, the output rate of medium supernatant is 87.06 wt% after calculation; Sampling and testing once every 2 hours, with a total of 28 hours of monitoring; the average composition of the supernatant produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com