Patents

Literature

67results about How to "Avoid production impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

MC5 Steel and large-sized flattening roll prepared by using the same, and manufacturing process of MC5 steel

ActiveCN102433515ASolve burstSkip the preheating processElectric furnaceProcess efficiency improvementChemical compositionMetal

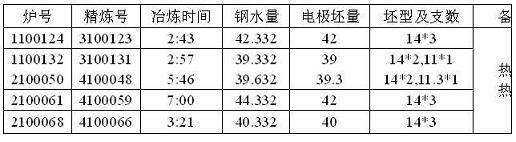

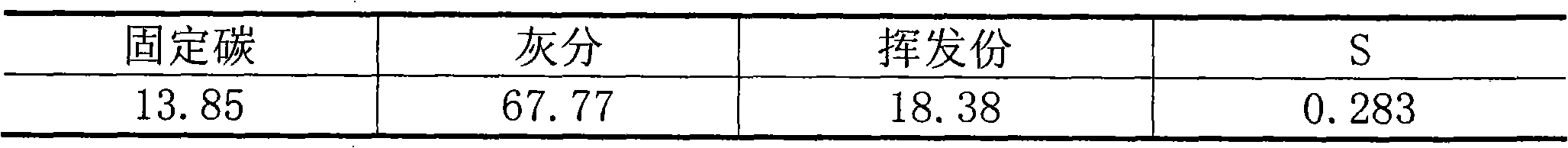

The invention relates to an MC5 steel and a large-sized flattening roll prepared by using the same, and a manufacturing process of the MC5 steel, wherein the MC5 steel comprises the following chemical components in weight percentages: 0.75%-0.90% C, 0.40%-0.80% Si, 0.20%-0.50% Mn, 4.80%-5.20% Cr, 0.30%-0.60% Ni, 0.20%-0.60% Mo, 0.10%-0.20% V, less than or equal to 0.015% P, less than or equal to 0.015% S, less than or equal to 0.20% Cu, less than or equal to 0.01% Al, less than or equal to 0.02% Pb, less than or equal to 0.02% As, less than or equal to 0.02% Sn, less than or equal to 0.02% Sb, less than or equal to 0.02% Bi, less than or equal to 2 ppm of H, less than or equal to 30 ppm of O, less than or equal to 120 ppm of N, and rest being Fe and inevitable impurities; and the MC5 steel is capable of meeting the utilization requirements of high-end metal plate rolling and long service life of the flattening roll.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Recycling treatment method for zinc-containing ironmaking and steelmaking intermediate slag

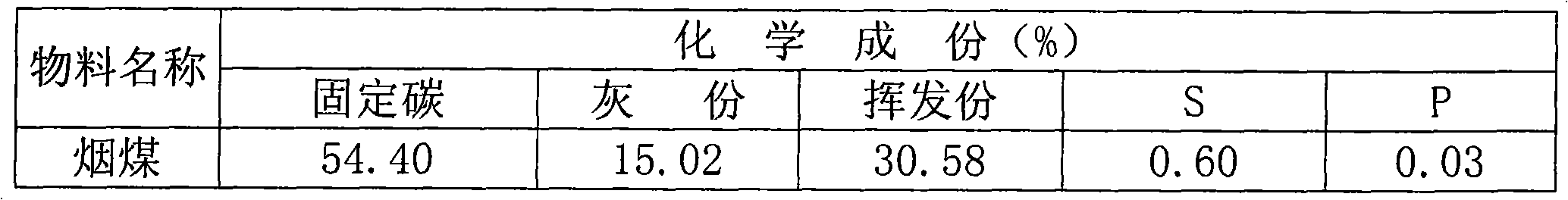

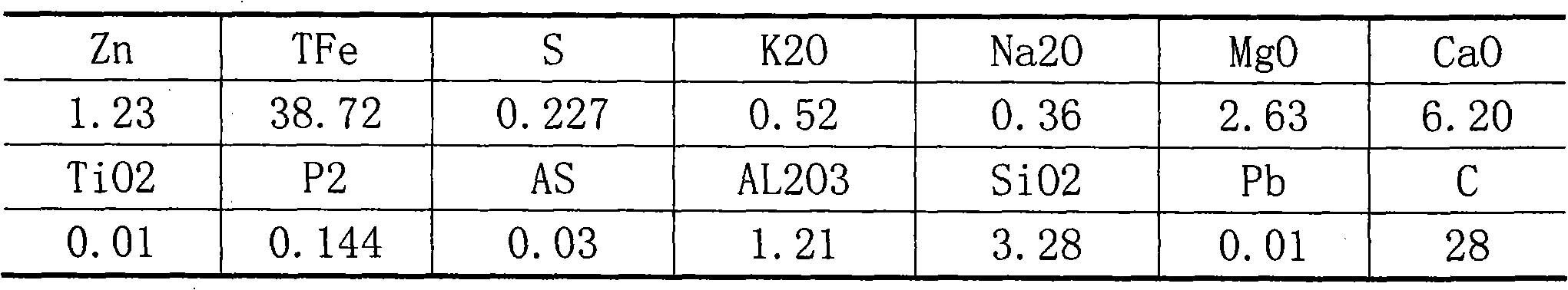

InactiveCN102634614AAvoid production impactControllable within the intervalZinc oxides/hydroxidesRecycling and recovery technologiesBrown coalAdhesive

The invention discloses a recycling treatment method for zinc-containing ironmaking and steelmaking intermediate slag, comprising the following steps of: preparing zinc-containing ironmaking and steelmaking intermediate slag into carbon-containing pellets; mixing one or more than one of soft coal, brown coal, lime powder, coal slime, coal gangue and saw powder, to prepare into cladding powder; adding an adhesive into the carbon-containing pellets and the cladding powder to prepare into composite carbon-containing pellets with the thickness of the cladding powder being 0.5-3.0mm; drying the composite carbon-containing pellets, charging into a chain belt type roasting machine to carry out reductive roasting under a high temperature; carrying out oxidation reaction on zinc steam in the chain belt type roasting machine, and finally preparing into ZnO powder; and carrying out water quenching on the dried composite carbon-containing pellets, decladding, magnetically separating, and classifying, so that semi-metalized pellets can be obtained. According to the method, the zinc-containing ironmaking and steelmaking intermediate slag which can not be directly used in the conventional blast furnace smelting technology is machined into an ironmaking high-quality raw material, i.e. the semi-metalized pellets, and the zinc in waste material can be comprehensively recovered to be prepared into the ZnO powder of the chemical additive, therefore, the waste can be changed into valuable.

Owner:陈小林 +2

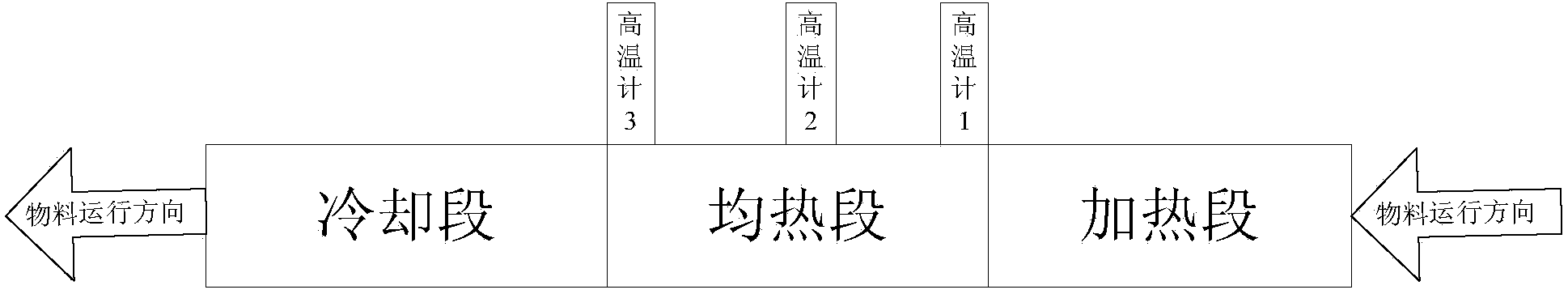

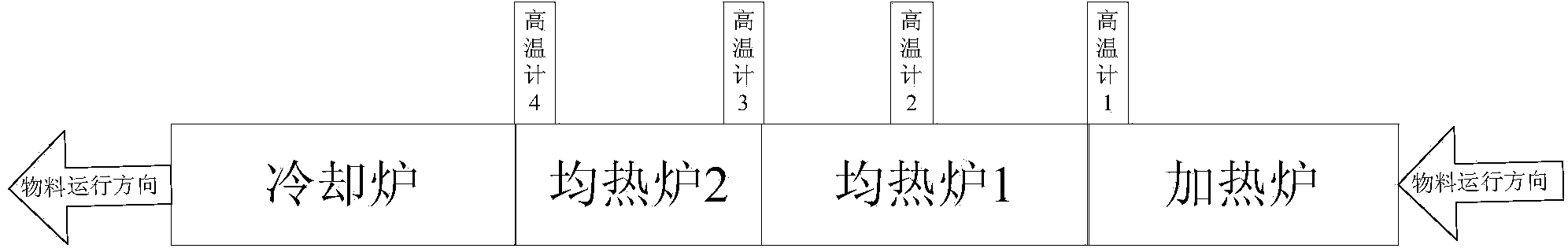

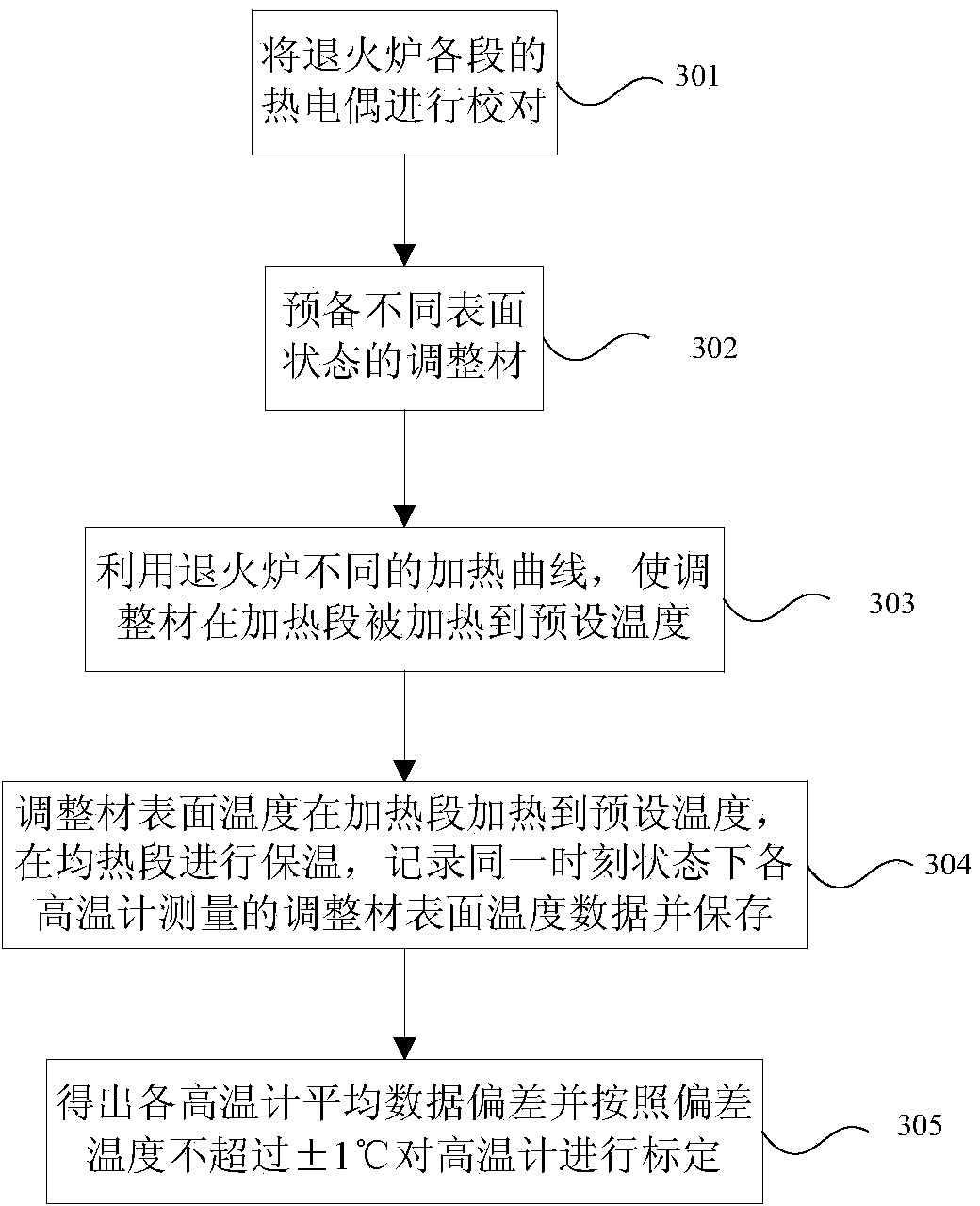

Method for online calibration of fixed type pyrometers of continuous type annealing furnace

ActiveCN103834776AAvoid production impactWith actual measurement authenticityThermometer testing/calibrationFurnace typesPyrometerLow speed

The invention discloses a method for online calibration of fixed type pyrometers of a continuous type annealing furnace and relates to the technical field of calibration of the pyrometer. The method comprises the following steps of preparing adjusting materials with different surface states, making a temperature-rising curve of the annealing furnace in the period of temperature rising before production, setting a uniform-heating section of the annealing furnace to respectively carry out insulation on preset temperature, utilizing different heating curves of the annealing furnace, enabling the adjusting materials to be heated to preset temperature at a heating section, carrying out insulation at the uniform-heating section, preparing the adjusting materials at preset low speed, and recording and storing surface temperature data of the adjusting materials measured by all the pyrometers under the same moment and state; and analyzing the acquired temperature data to obtain average data deviation of all the pyrometers, calibrating the pyrometers with the temperature deviation being not more than + / -1 DEG C, and correcting the pyrometers with the temperature deviation being more than + / -1 DEG C. The method disclosed by the invention is applicable to calibration and correction of the pyrometer under the non-stop state.

Owner:BEIJING SHOUGANG CO LTD

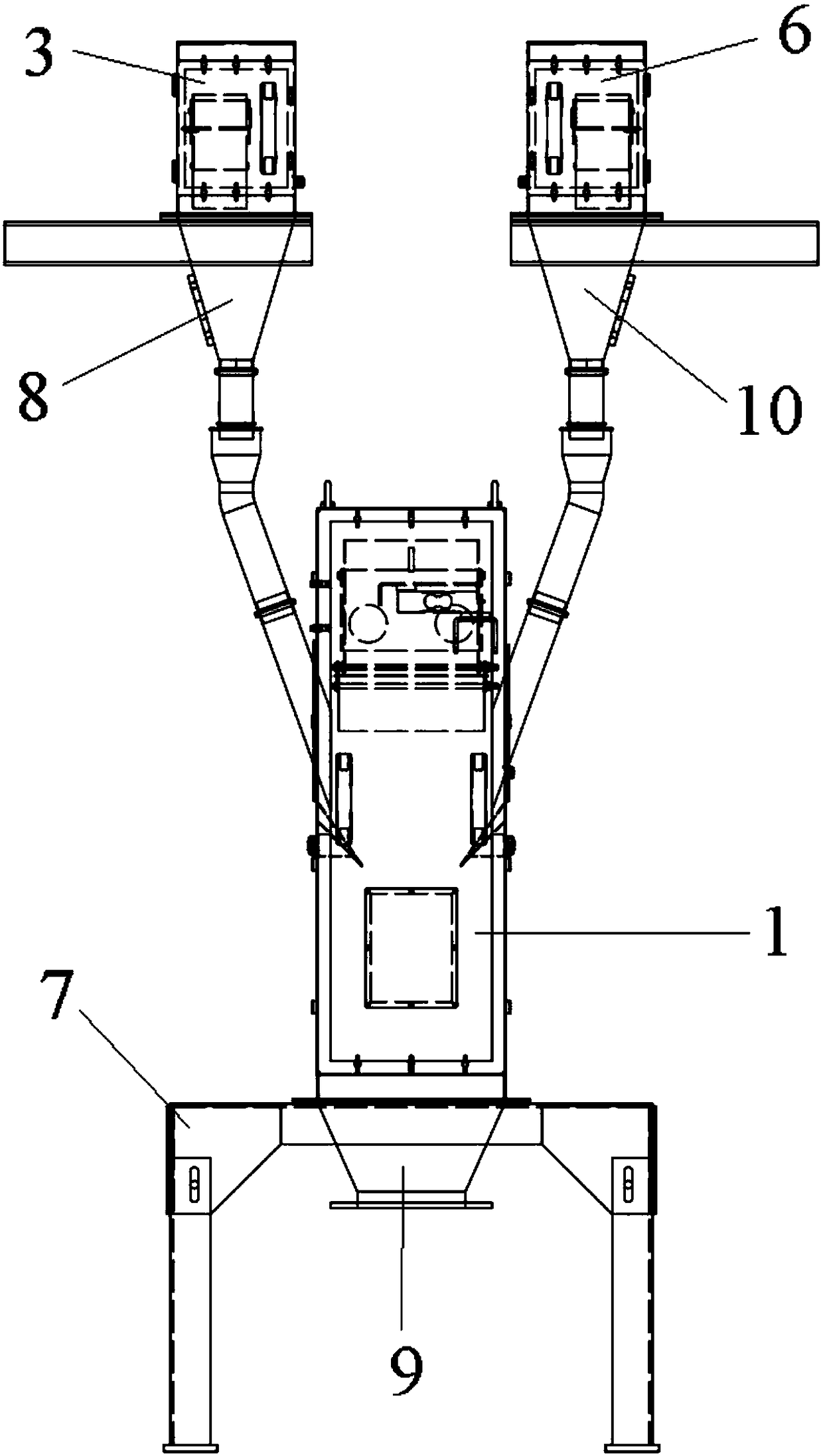

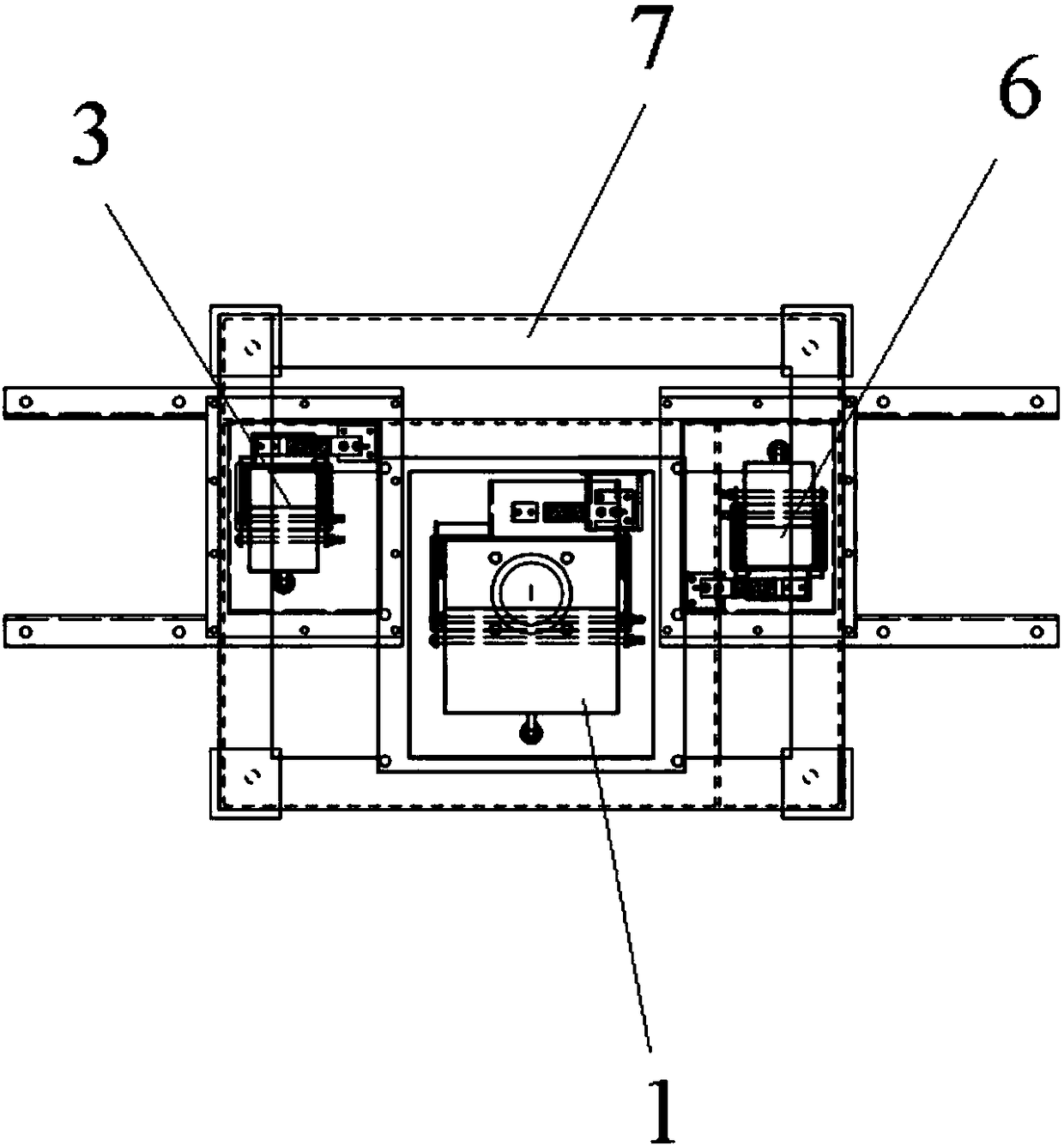

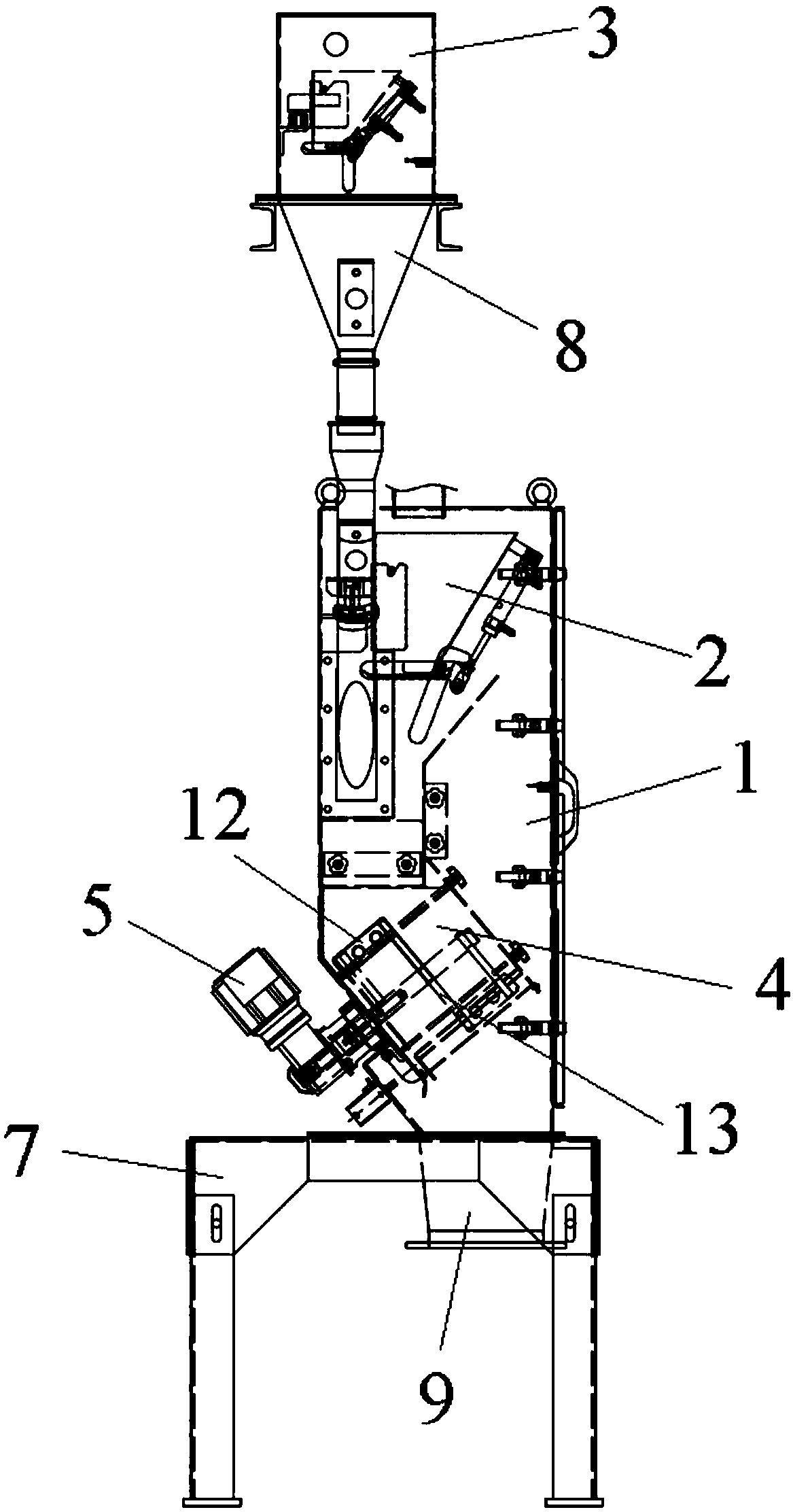

Crusher

ActiveCN102363126AEasy to driveFacilitate transmissionGrain treatmentsFluid couplingAgricultural engineering

The invention discloses a crusher, which comprises a crusher drive and transmission device, wherein the crusher drive and transmission device comprises a driver, a first flat key, a second flat key, a hydraulic coupler, a hydraulic coupler protective cover, a first spline, a gear coupling and a gearbox, wherein the driver is connected with the hydraulic coupler through the first flat key; the hydraulic coupler is connected with the gearbox through a second flat key; the hydraulic coupler protective cover covers the hydraulic coupler and is connected with the gearbox and the driver respectively; the gear coupling is connected with the gearbox through the first spline; the gearbox is connected with a gearbox suspending bracket; and the gearbox comprises a cover plate on the top, a baffle plate on the bottom, a first oil release hole formed on the side wall of the gearbox, and a second oil release hole formed on the side wall of the gearbox of the crusher. The crusher is hardly deformed, high in safety and low in cost, spare parts of the gearbox are reduced, the using state of the crusher can be monitored in real time, and special casting equipment is not needed.

Owner:西安海泰科技有限公司

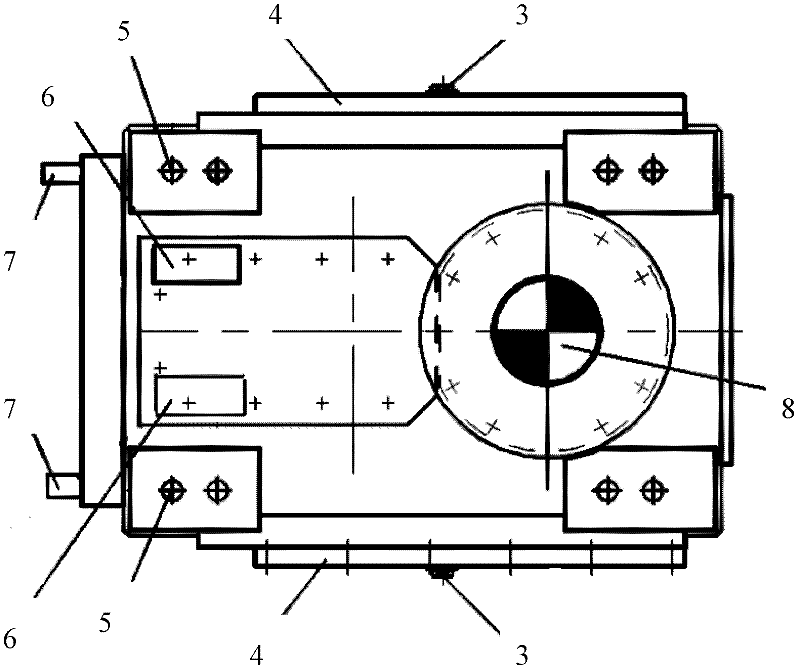

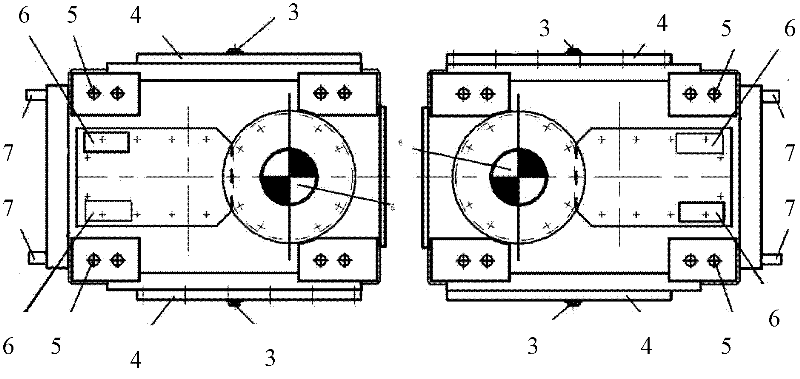

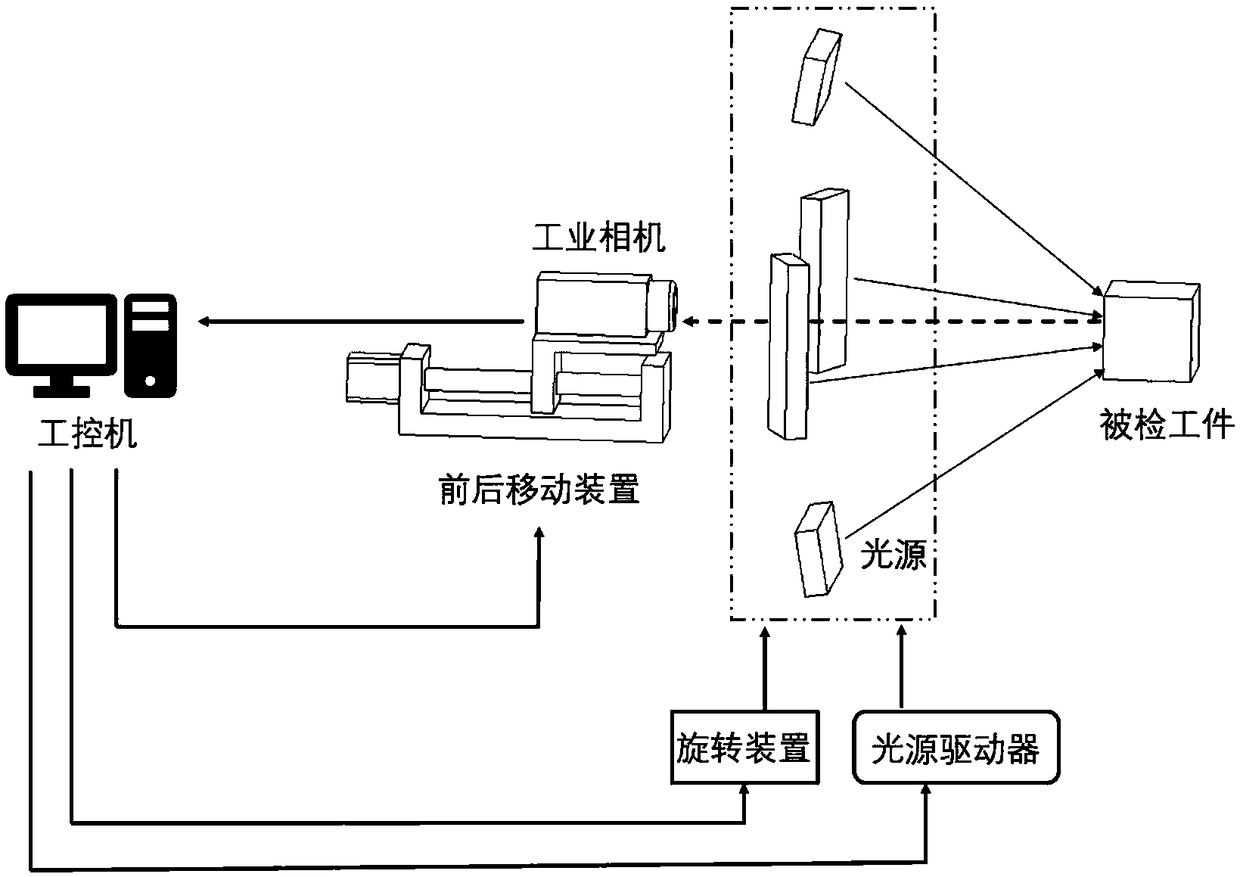

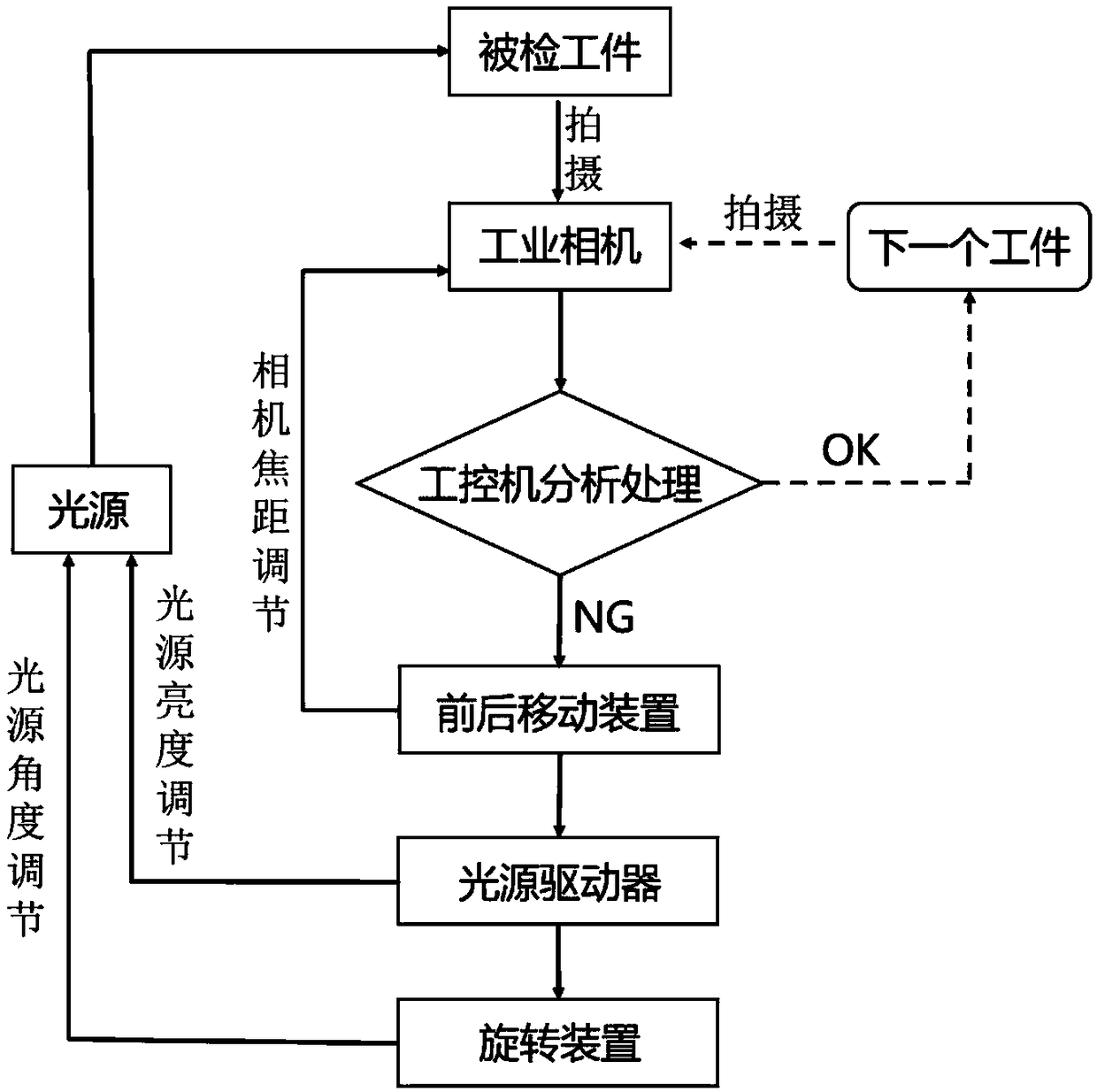

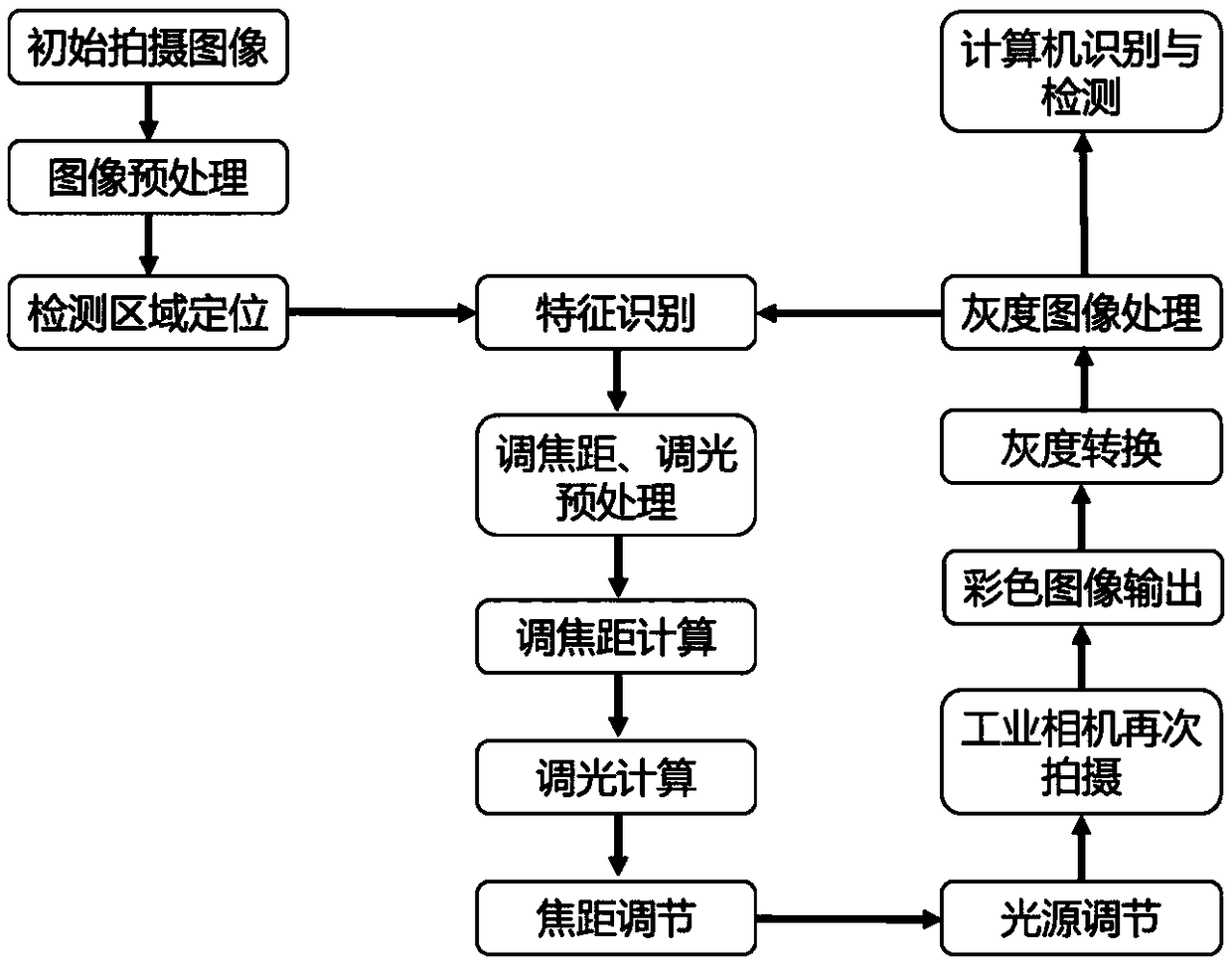

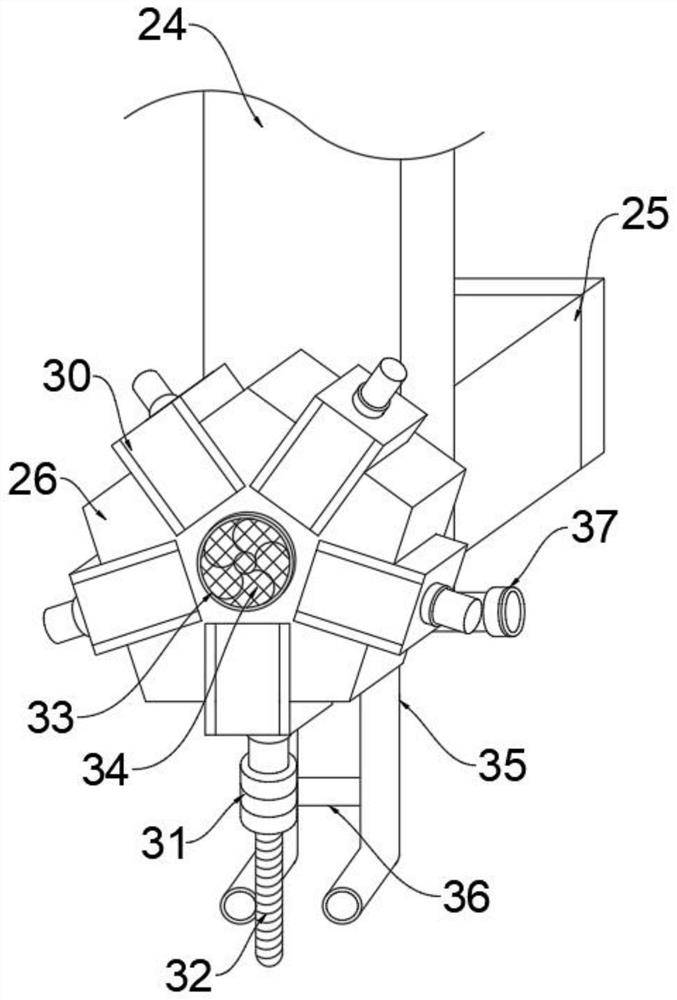

An industrial camera self-adaptive intelligent adjusting device

InactiveCN109068051AMaintain detection accuracyImprove detection accuracyTelevision system detailsColor television detailsExposureSelf adaptive

The invention discloses an industrial camera self-adaptive intelligent adjusting device, which comprises an industrial camera, a light source, a workpiece to be inspected, an industrial control computer, a back-and-forth moving device, a rotating device and a light source driver. The industrial camera collects images of the workpiece to be inspected and transmits data back to the industrial control computer. The back-and-forth moving device can control that backward and backward movement of the industrial camera to adjust the focal length of the camera, the rotating device adjusts the angle atwhich the light source irradiates the workpiece to be inspected, the light source driver adjusts the brightness of the light source, controls the exposure of the workpiece to be inspected when the image is collected, the industrial control computer analyzes and processes the image data to give a processing signal, and controls the back-and-forth moving device, the rotating device, and the light source driver. As that intelligent adjust device is adopted, real-time adjustment can be realize during production, high detection accuracy can be maintained, machine stoppage caused by unqualified detection due to product replacement or machine vibration and environmental change can be avoided, manual operation can be reduced, the degree of intelligence is high, and the use is convenient.

Owner:方汝松

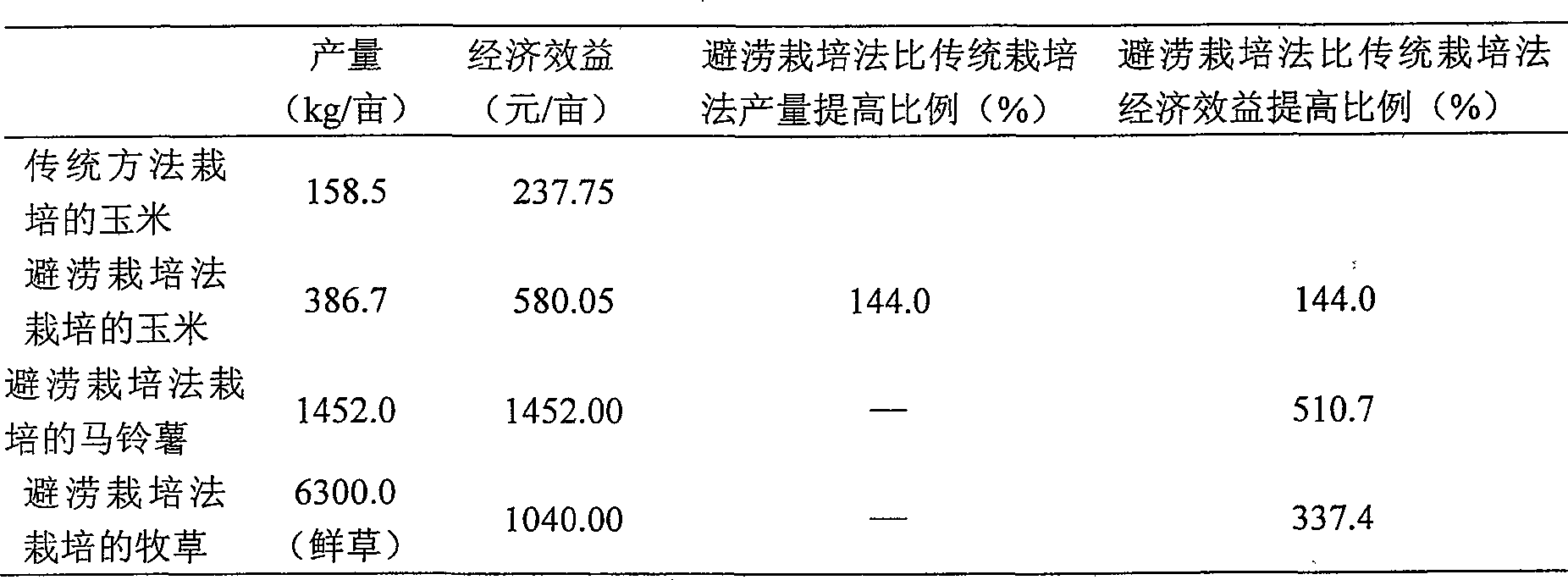

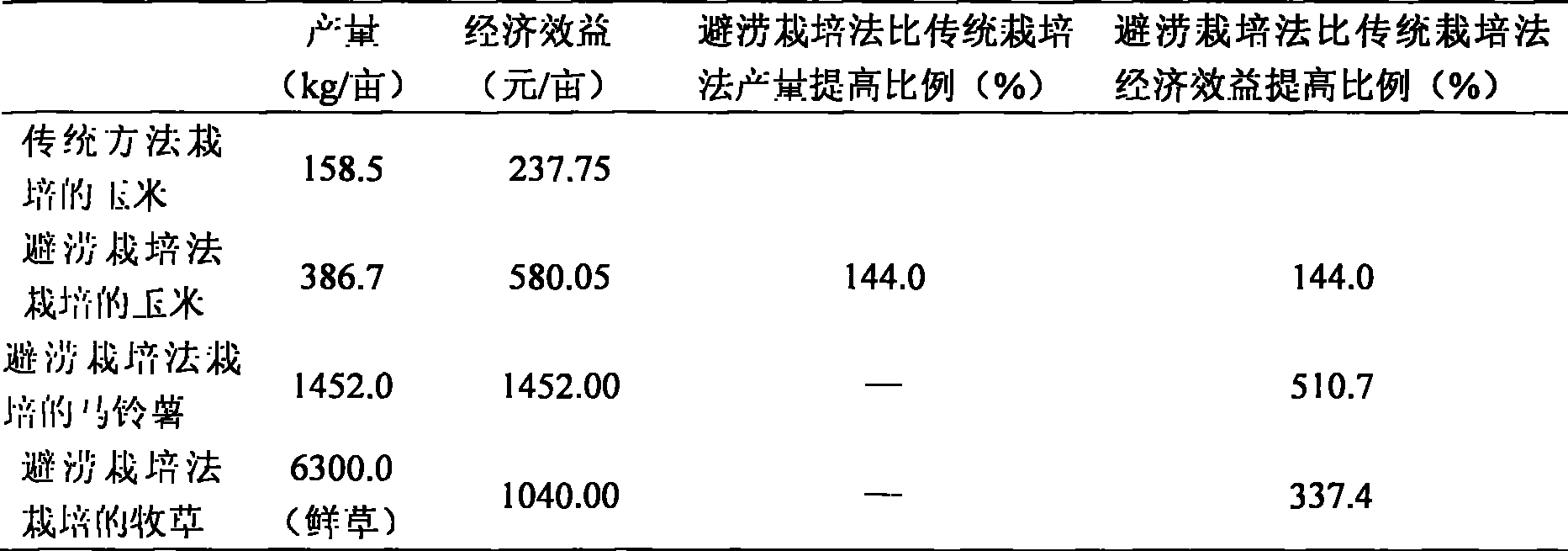

Method for cultivating flood-refuge crops in hollow of southwest karst peak cluster

InactiveCN101411282AAvoid production impactAchieve economySeed and root treatmentClimate change adaptationEcological environmentPlastic mulch

The invention discloses a waterlogging-avoiding crop cultivation method for karst peak-cluster depression area. The method comprises: a. arrangement of a crop planting system, which is to plant pasture; and b. waterlogging-avoiding cultivation method for crop in the depression area: A. waterlogging-avoiding potato cultivation which comprises the steps of potato seed selection and germination, land preparation and fertilizer application, seeding, management and harvest, wherein potato blocks with dedicate, bright and smooth skin are selected as potato seeds and are stored in stacks before seeding, fertilizer application is carried out before land preparation, seeding is carried out after rain when soil contains enough water; B. waterlogging-avoiding corn cultivation which comprises the steps of introducing a new corn variety, planting corn seeds and covering a plastic film in the early growth period of the corn to advance the maturation period of the corn, and top dressing; and C. depression area pasture cultivation which comprises seedling and fertilizer application, field care and fertilizer application, intertillage and weeding, wherein intertillage is carried out together with fertilizer application to improve the resistance of the pasture and to accelerate the growth of the pasture after waterlogging. The method is easy to implement and operation, increases economic income and avoids damages to ecological environment.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

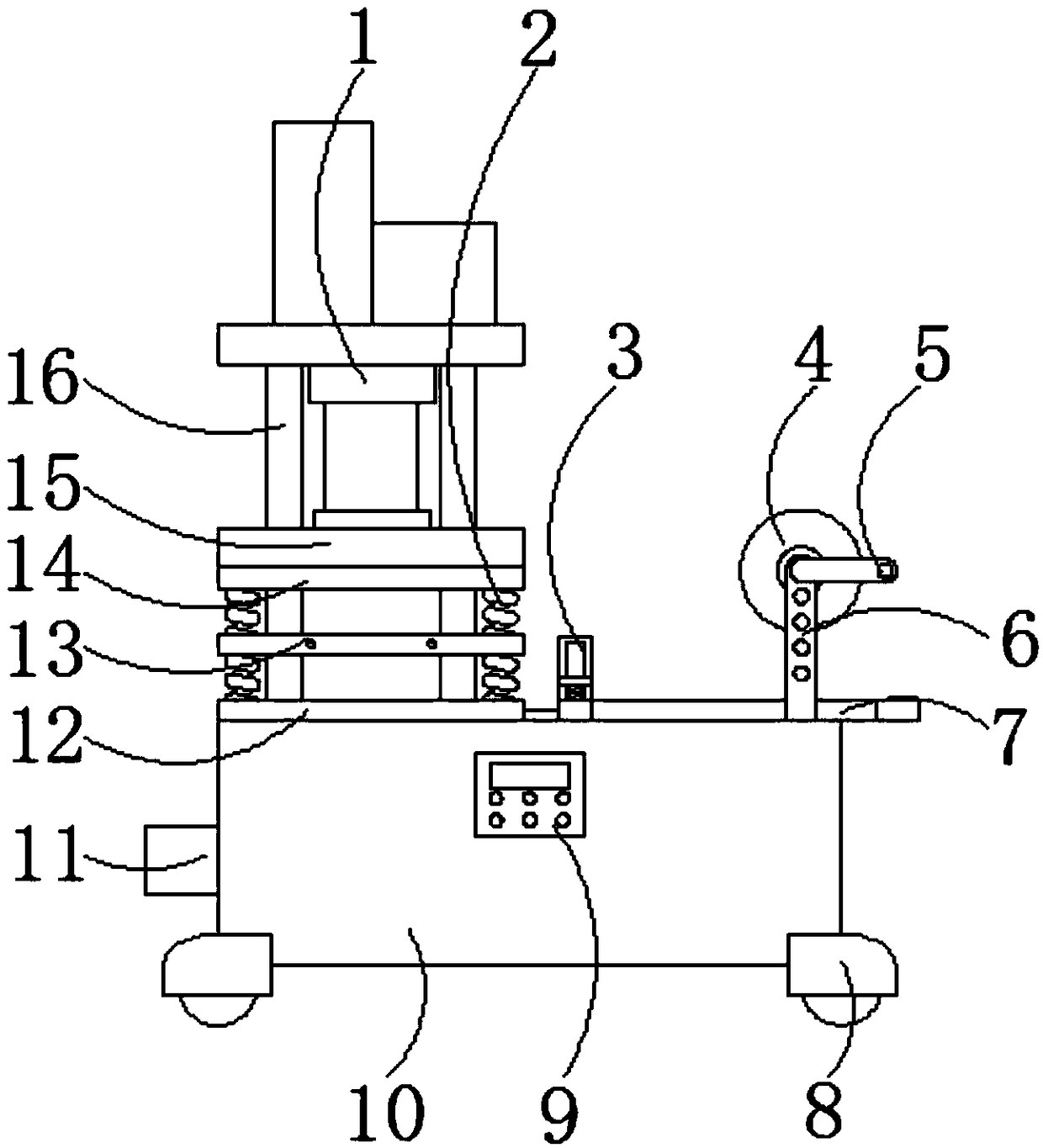

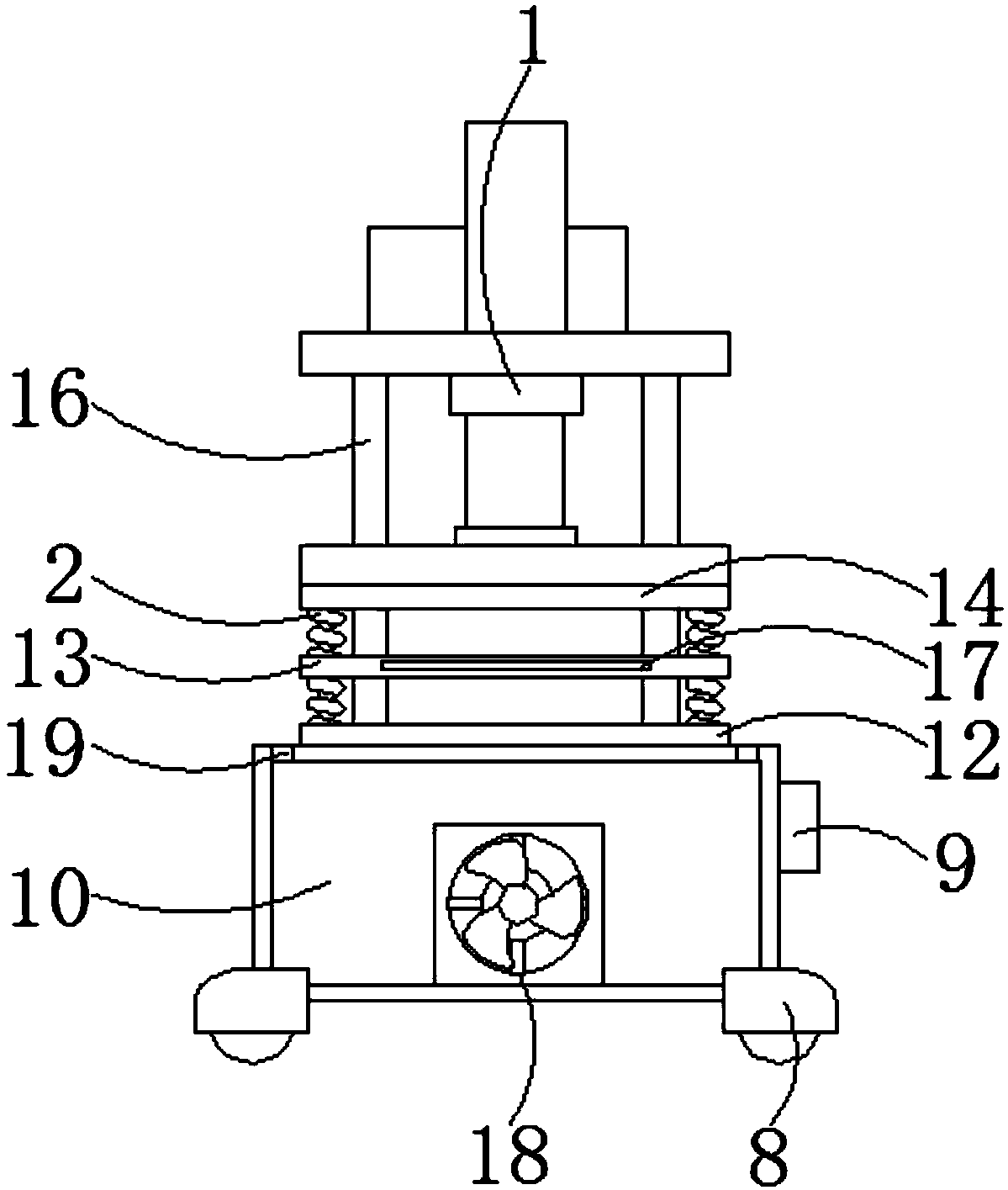

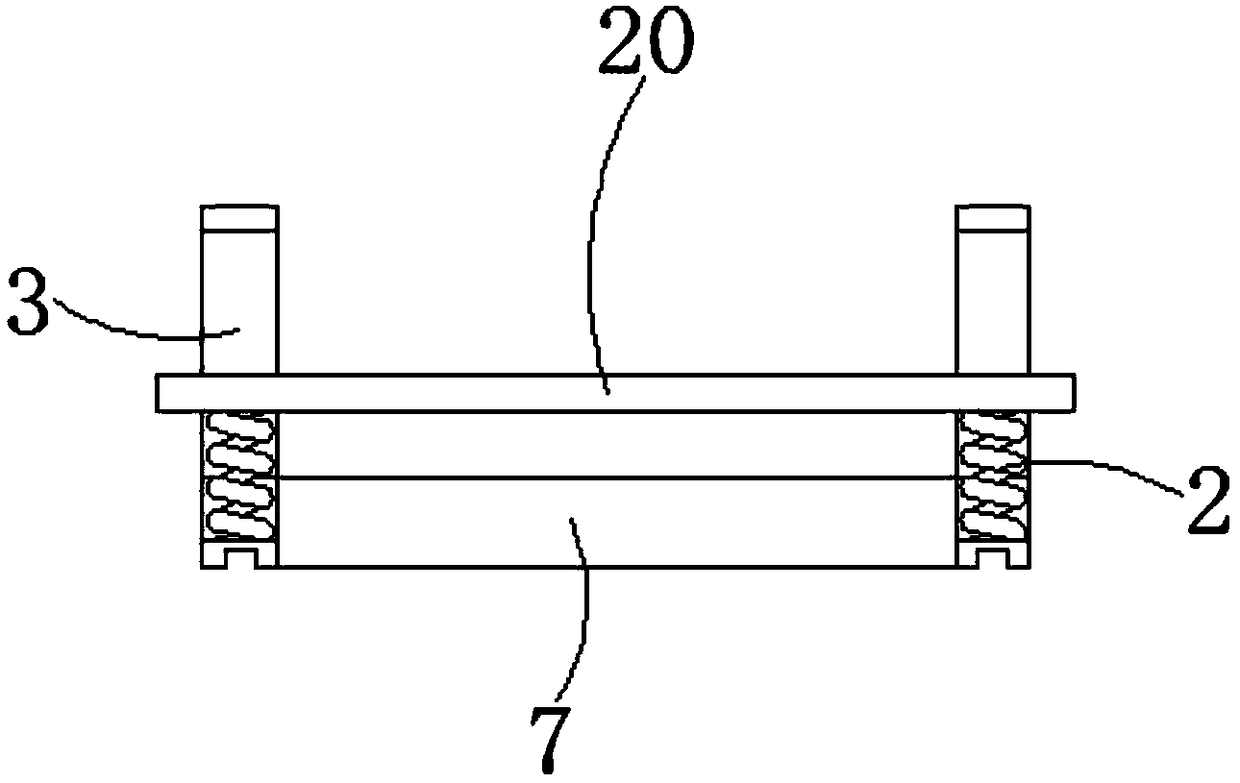

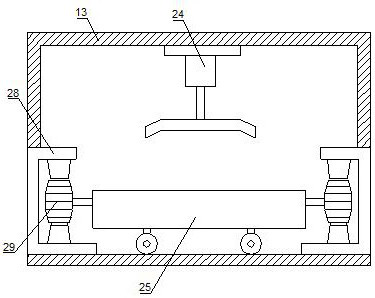

Downward-pressing-type production equipment for multilayer gum dipping paper laminated board

InactiveCN108528004APrevent movementStickyLaminationLamination apparatusProduction effectEngineering

The invention discloses downward-pressing-type production equipment for a multilayer gum dipping paper laminated board. The equipment comprises a workbench, a mobile plate is slidingly connected to the top of the workbench through a sliding groove, and a fixing rack is installed at the exterior of the mobile plate; clamping racks are arranged at the two sides of the mobile plate, a clamping plateis slidingly connected into the clamping racks through sliding grooves, and springs are installed at the bottom of the clamping plate; a press wheel is rotatably connected into the fixing rack througha rotation shaft, a handwheel is installed at the exterior of the fixing rack, and a baseplate is installed at one side of the mobile plate; a limit rod is installed at the top of the baseplate. According to the downward-pressing-type production equipment, through arrangement of the press wheel, the mobile plate and the clamping plate, a user can use the clamping plate to fix one edge of a woodenboard and one edge of gum dipping paper, the mobile plate is moved, the press wheel is used for rolling on the gum dipping paper, the gum dipping paper can fit the wooden board preliminarily and is prevented from moving during pressing, the gum dipping paper can be flattened, and the situation is avoided that the production effect is influenced by wrinkles generated on the gum dipping paper.

Owner:ZHEJIANG YIJIA NEW MATERIAL CO LTD

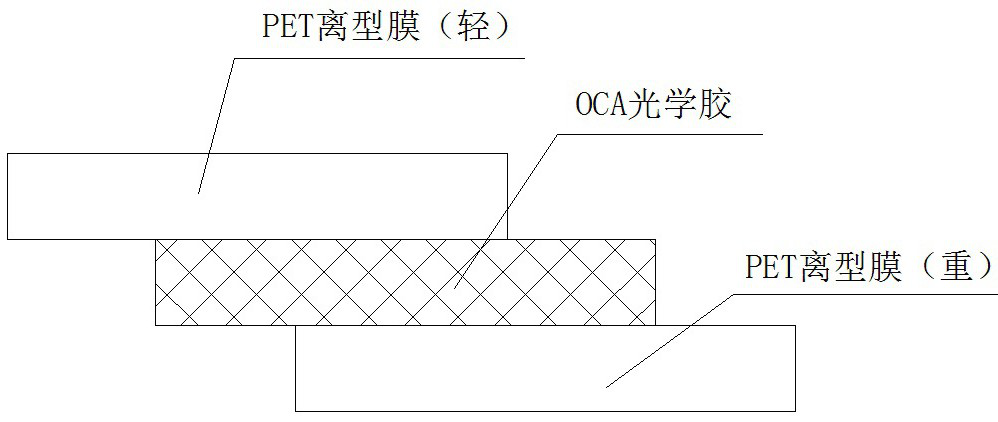

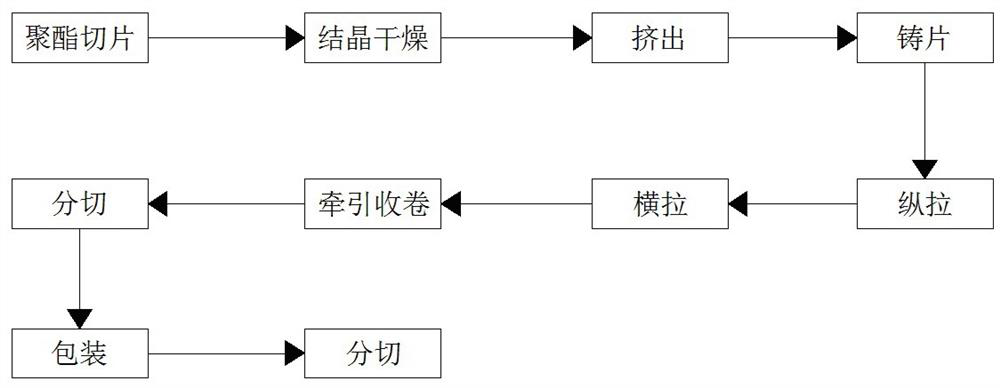

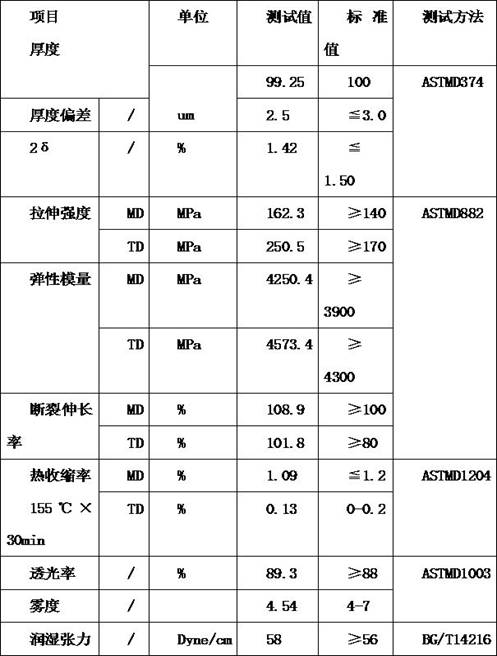

Preparation process of high-end release protection polyester base film for OCA

PendingCN112322208AReduce the impactImprove antistatic propertiesFilm/foil adhesivesFlat articlesPolyesterPolymer chemistry

The invention discloses a preparation process of a high-end release protection polyester base film for an OCA, which comprises the OCA. The OCA is produced by adopting an ABA three-layer structure, when the OCA is laminated, the thickness of a light release film is generally required to be 25-55 mum, the release force is 5-20 mm / g, and the thickness of a heavy release film is 50-100 mum, and the release force is 30-110 mm / g, the thickness of the adhesive layer is 45-100 mum, the shore hardness is 40-50 D, when a customer needs electrostatic treatment, the viscosity of one surface of the film before coating is about 5500 mps.s, and the solid content is about 95%, and by compounding and superposing the multiple adhesive layers, the obtained OCA has a better effect on the basis of ensuring complete curing of each adhesive layer, and has excellent optical apparent performance, excellent transparency and good haze, is free of crystal points, white points and other impurities and foreign matters, and can realize observation of bubbles, foreign matters and other defects in OCA under the condition of not removing the protective film.

Owner:SHANDONG SNTON OPTICAL MATERIALS TECH CO LTD

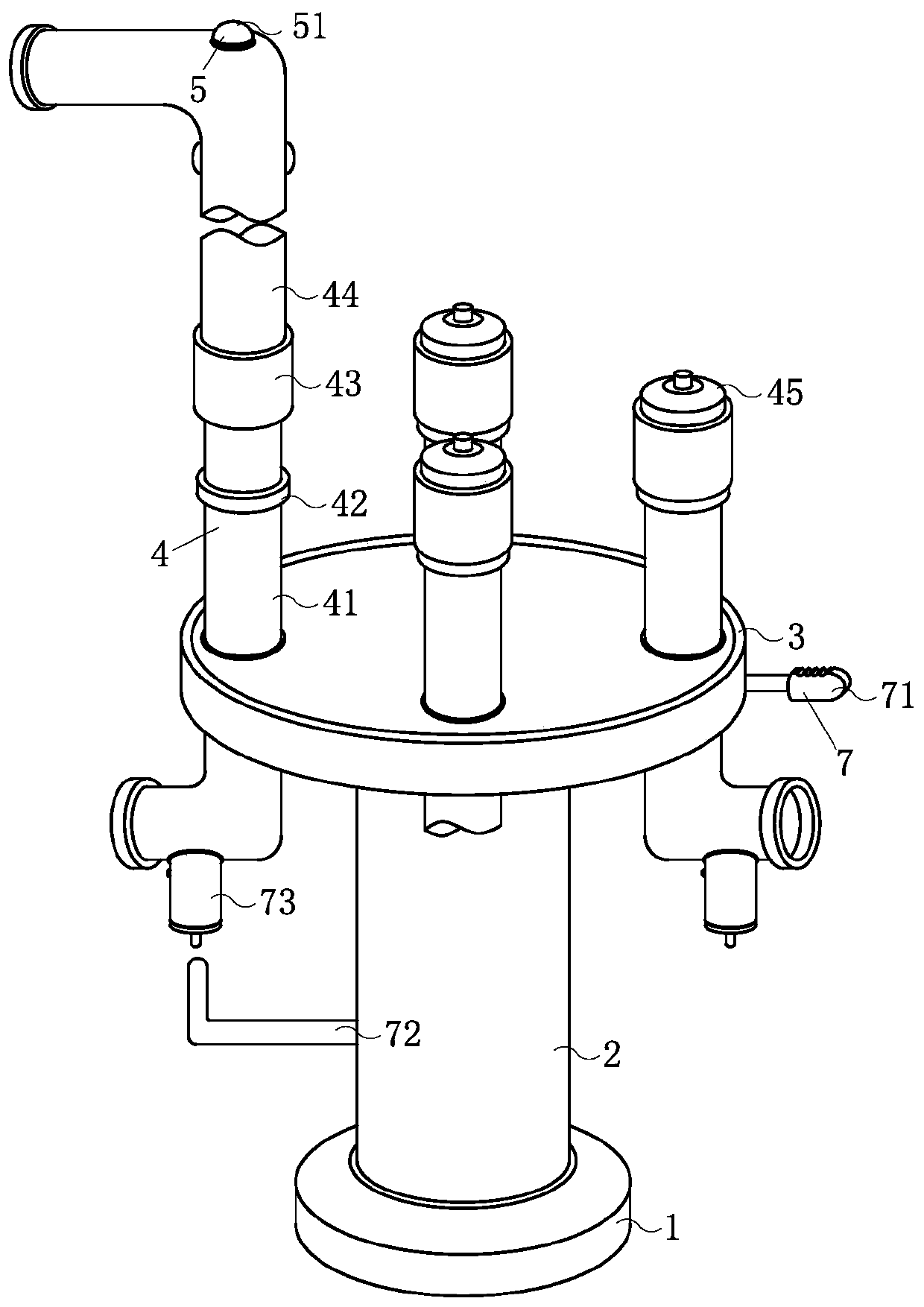

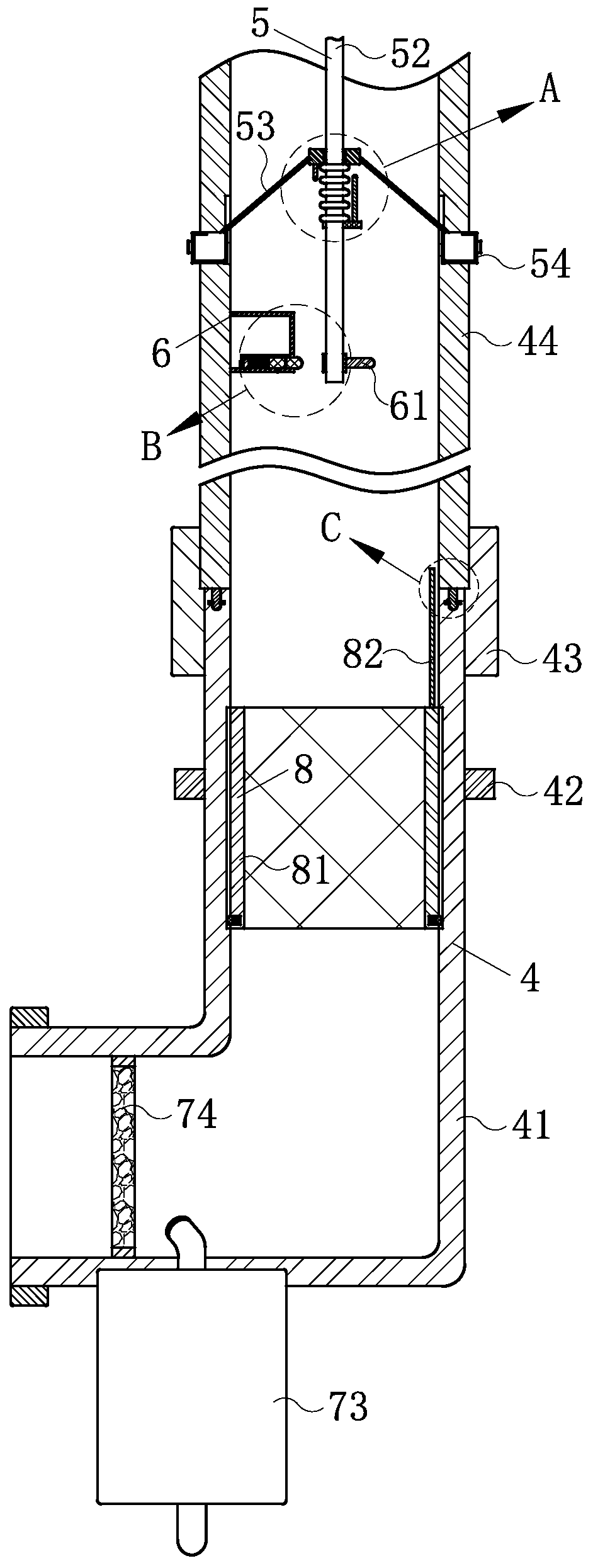

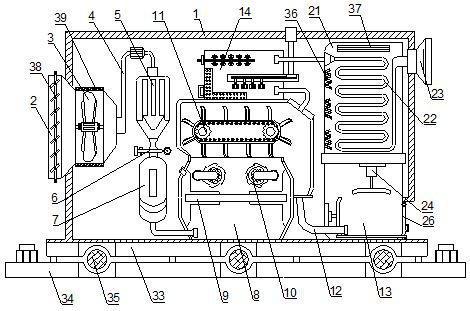

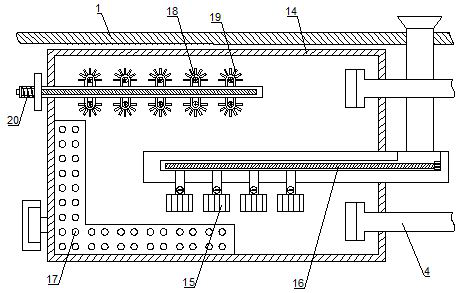

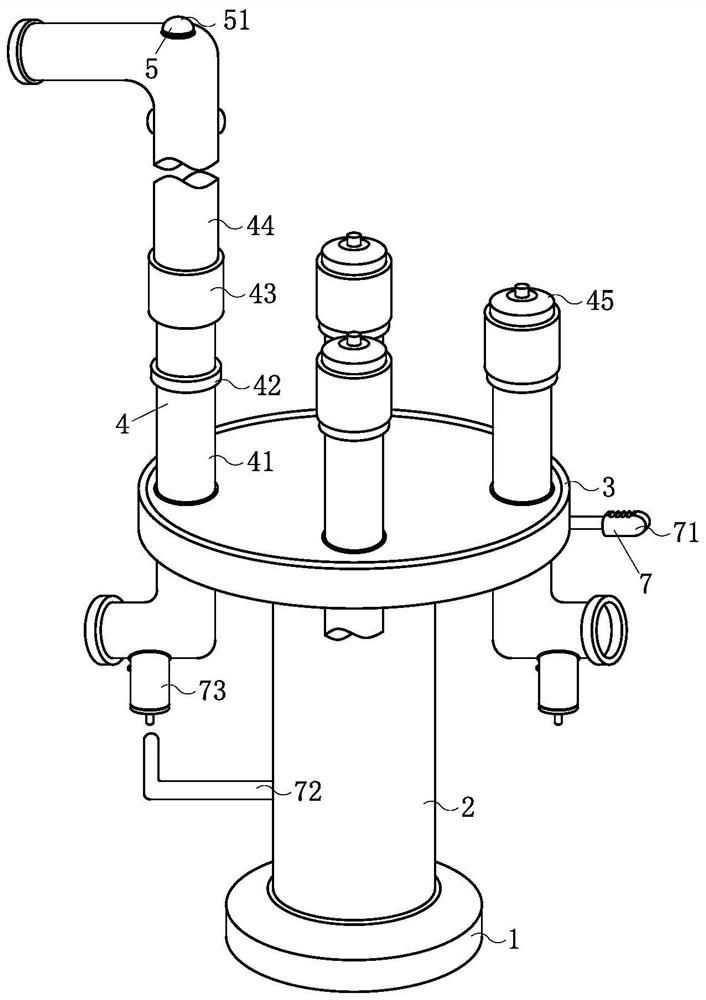

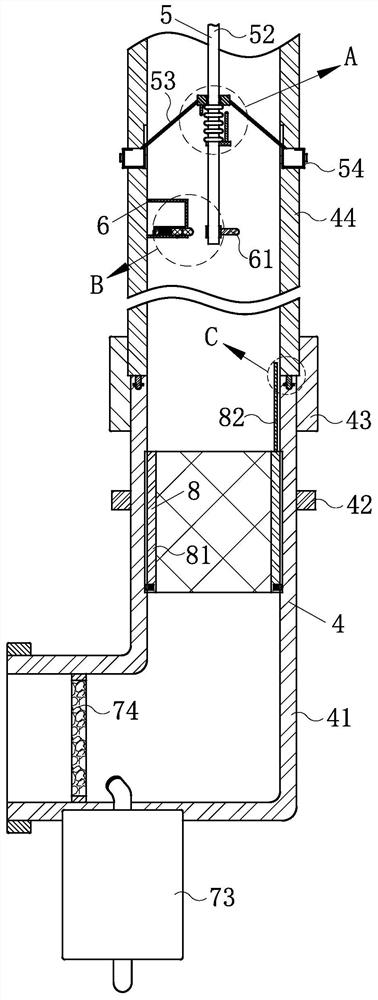

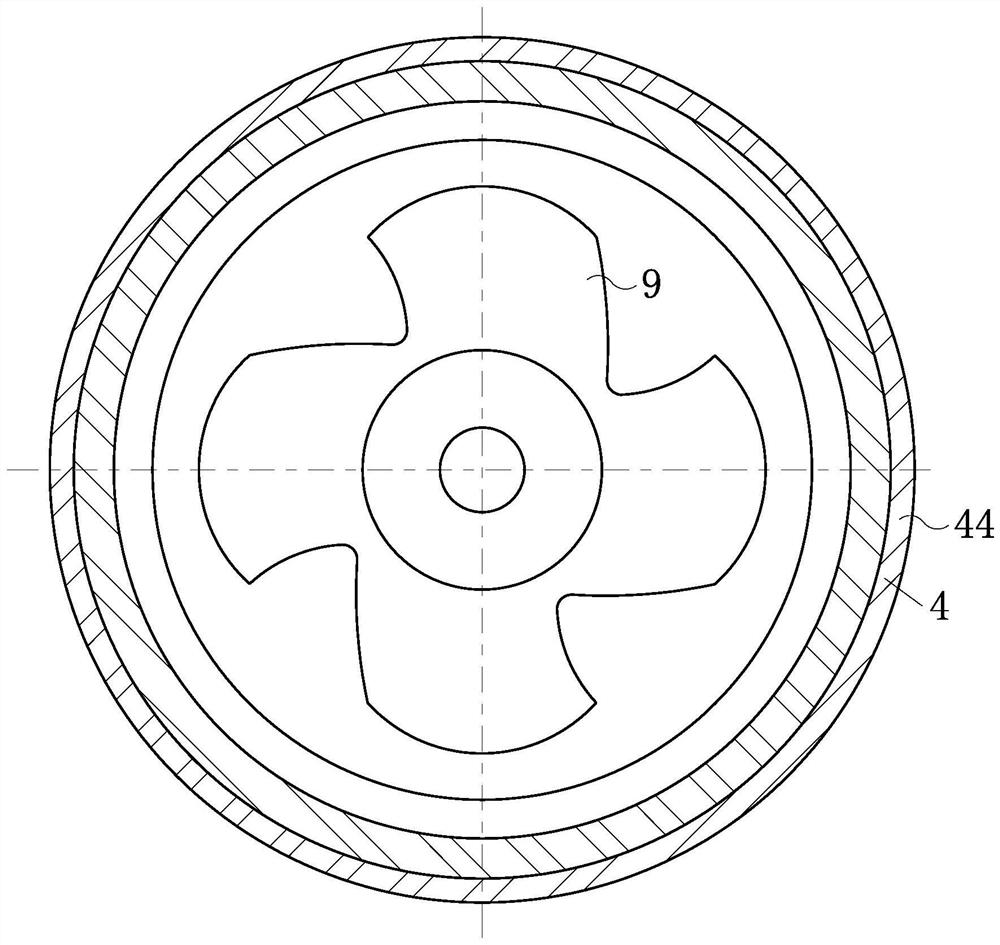

Air purification equipment for factories

ActiveCN111365777AImprove the use effectEasy to collectDucting arrangementsMechanical apparatusAir cleaningProcess engineering

The invention relates to the field of air purification, in particular to air purification equipment for factories. The air purification equipment comprises a base, a supporting rod, an installation table, a through pipe mechanism, a purification mechanism, a feeding mechanism, a humidifying mechanism, a filter element mechanism and a fan main body. According to the air purification equipment, thepurification mechanism rotates inside the through pipe mechanism, and a large amount of impurities adsorbed for the first time can be conveniently shaken off, so that the purification mechanism can beprevented from being blocked; under the rotation of the purification mechanism, the feeding mechanism can automatically and continuously add decomposition agents of harmful substances to a filter element inside the through pipe mechanism in the use process, so that the equipment has a better purification effect on harmful components in gas; the humidifying mechanism is rotated, the humidity of the filtered gas is conveniently adjusted under the matching of the through pipe mechanism, and the influence of the dry air on production is avoided; and the filter element mechanism is arranged in themiddle of an inner cavity of the through pipe mechanism, and through the matched operation with the humidifying mechanism, the rapid replacement of the filter element in the equipment is convenientlyrealized.

Owner:南通安强工程科技有限公司

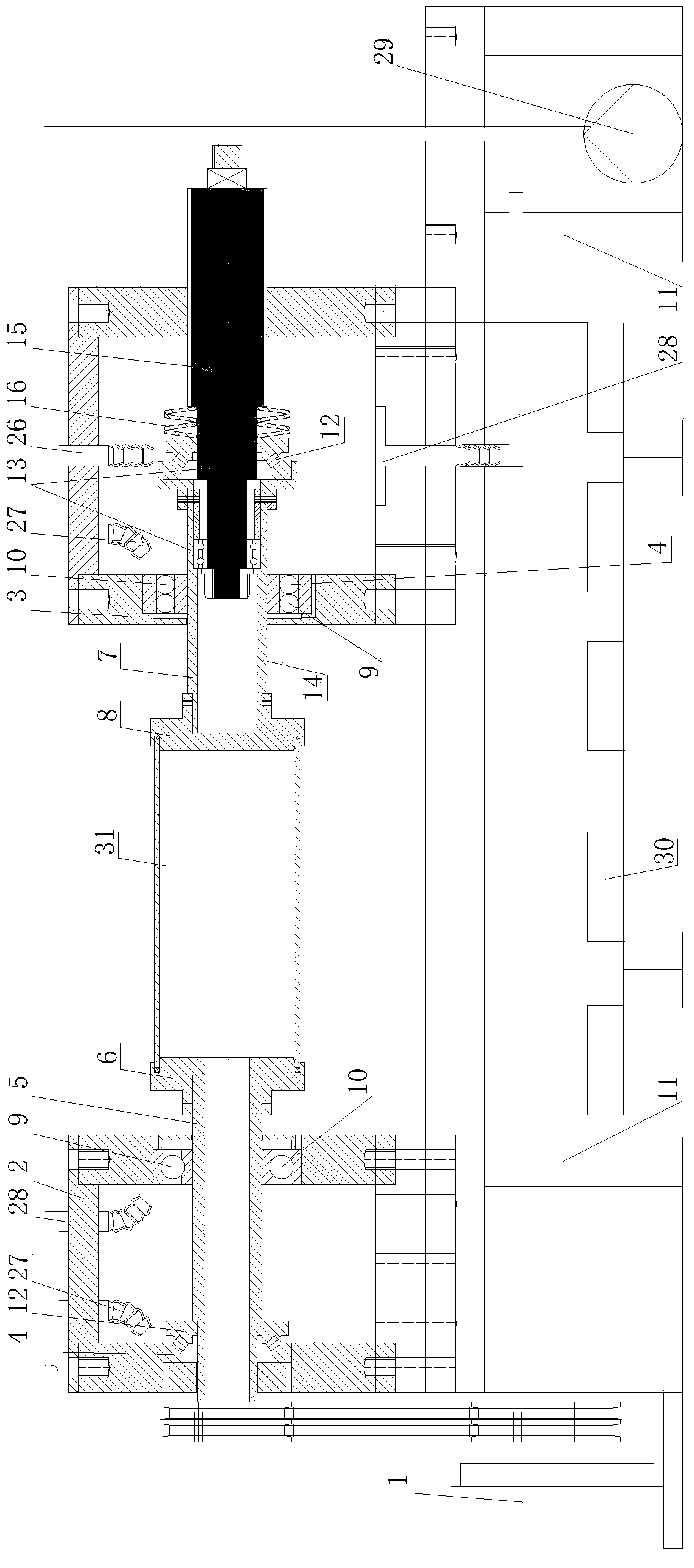

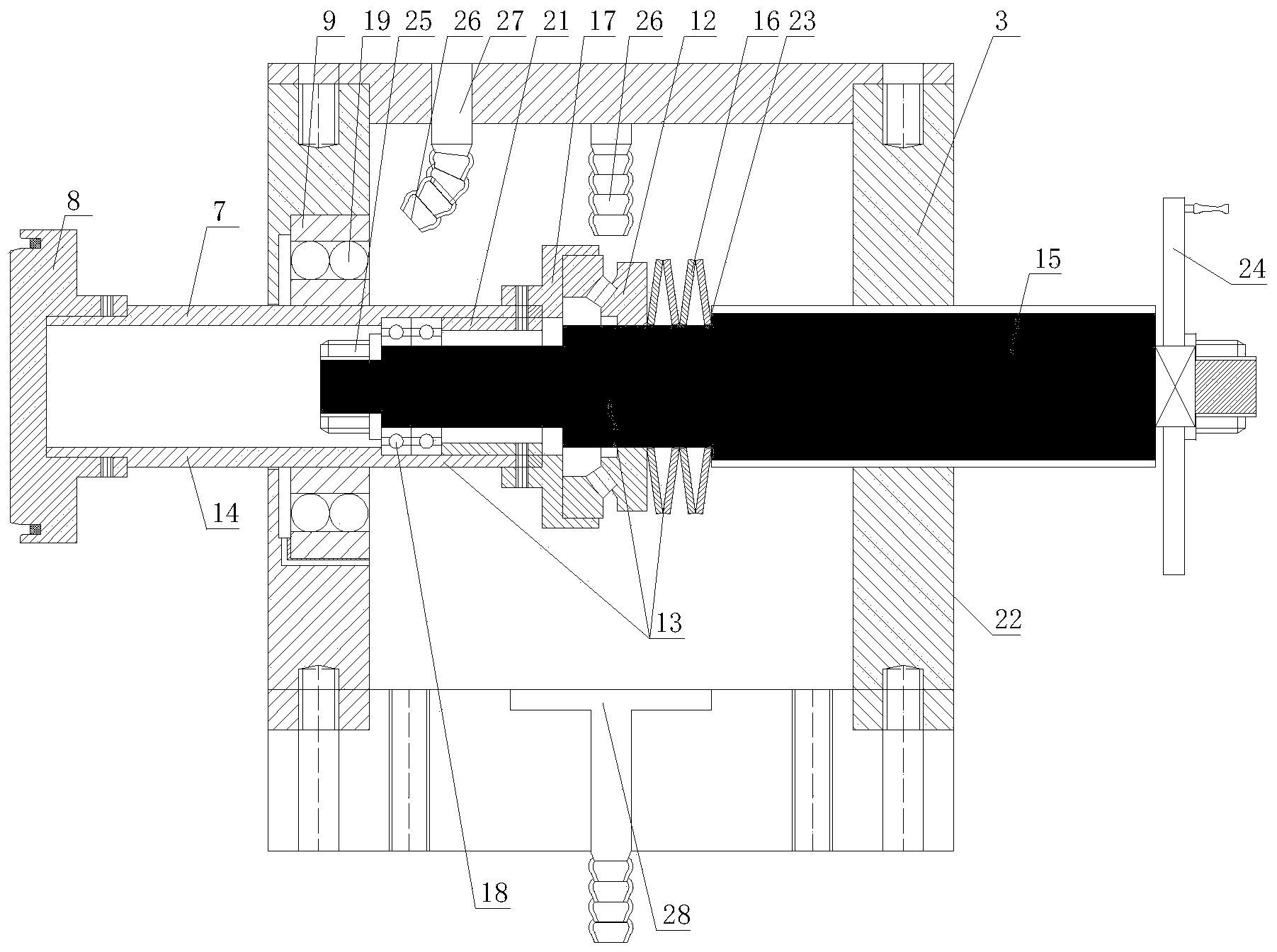

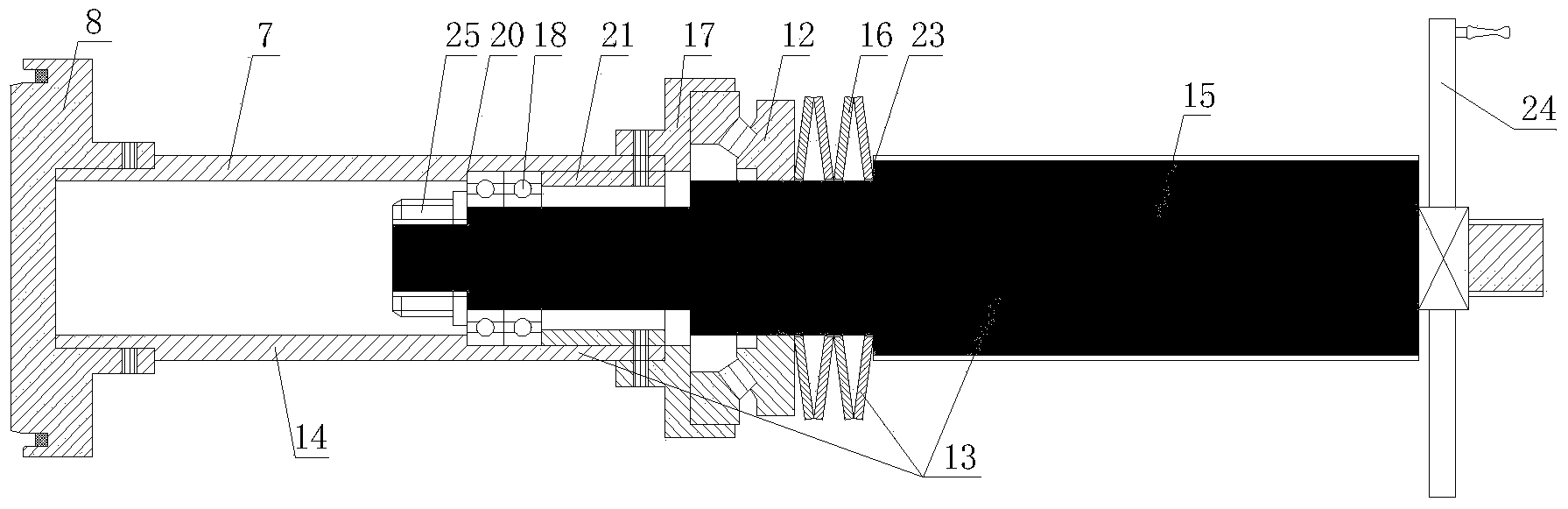

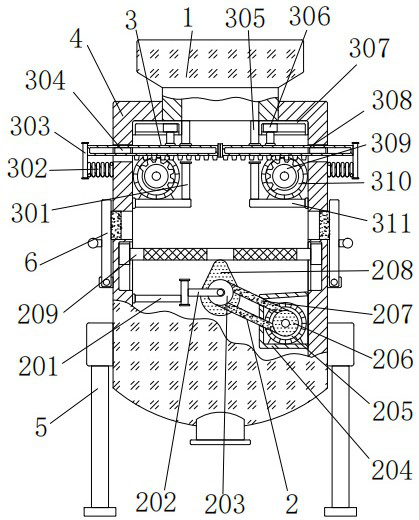

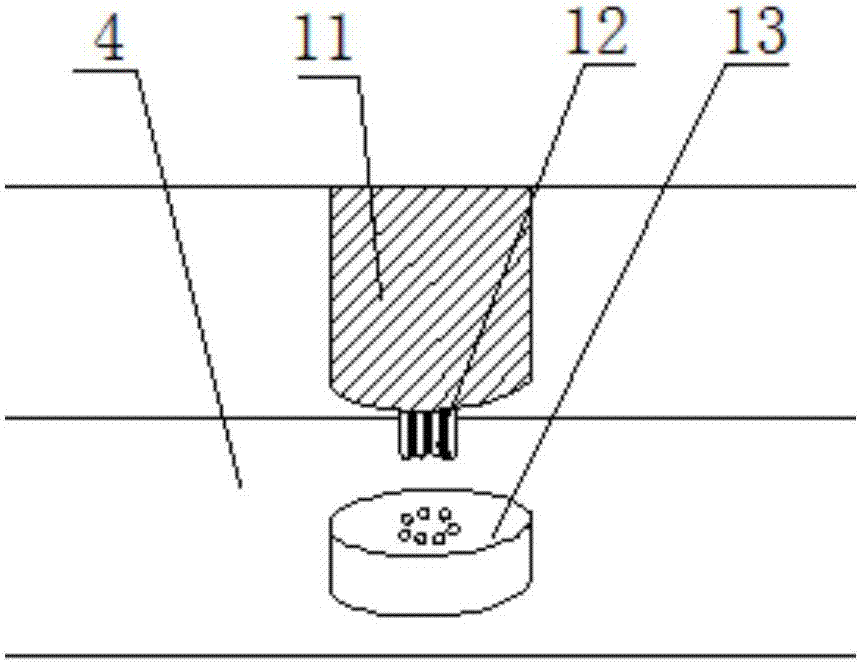

Centrifuge

ActiveCN103480509AGuaranteed performanceExtended service lifeCentrifugesEngineeringMechanical engineering

The invention relates to a centrifuge which comprises a drive device, a rear seat case and a front seat case. Each of the rear seat case and the front seat case is provided with a rotary shaft. Each rotary shaft penetrates a bearing disposed on a case body of the rear seat case and the front seat case to be connected with the case body. A drive device is disposed at the rear end of the rear seat case rotary shaft. A die mounting base is disposed at the front end of the rear seat case rotary shaft. A die mounting base is disposed at the rear end of the front seat case rotary shaft. A centrifuge eccentricity correcting device is disposed on the front seat case rotary shaft or / and the rear seat case rotary shaft. By the arrangement, even axis deviation of the front rotary shaft and the rear rotary shaft exists or axis deviation of a die and the rotary shafts during die mounting, the centrifuge eccentricity correcting device can be used for adjusting as long as the deviation is in a certain range, so that performance of the centrifuge is guaranteed. Due to the fact that eccentricity can be adjusted, the centrifuge does not need to operate under centrifuge eccentricity, and the service life of the centrifuge is prolonged.

Owner:湖南恒科新材料有限公司

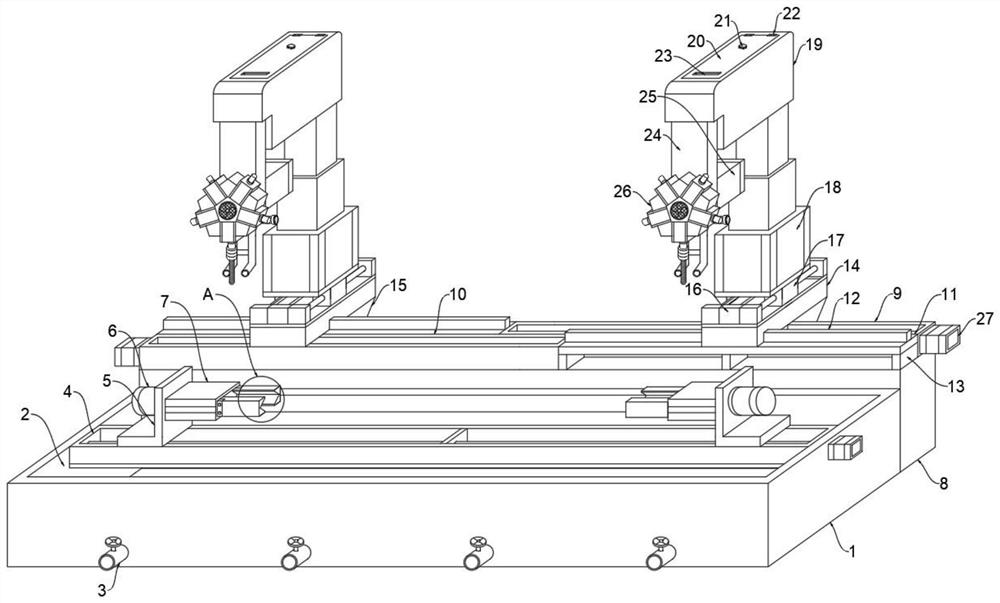

Punching device for colored aluminum sectional material machining and punching method of punching device

ActiveCN113579285AHigh continuity of operationImprove stabilityFeeding apparatusDriving apparatusPunchingWater storage tank

The invention discloses a punching device for colored aluminum sectional material machining and a punching method of the punching device, and relates to the technical field of colored aluminum sectional material machining. The punching device and the punching method aim at solving the problems that an existing punching device for colored aluminum sectional material machining cannot flexibly adjust the size of a drilled hole in the machining process, only one specification of hole site can be formed in an aluminum sectional material through one-time machining, and if a plurality of through holes with different specifications need to be formed in the same sectional material, a drill rod on the punching device needs to be replaced many times, and the process is tedious. A water storage tank is arranged in a clamping table, a bidirectional lead screw guide rail is installed in the water storage tank, L-shaped sliding blocks are installed on the two sides of the upper surface of the bidirectional lead screw guide rail correspondingly, a pneumatic clamping jaw is installed on one sides of each L-shaped sliding block, and a first stepping motor is installed on the other side of each L-shaped sliding block. The output end of each first stepping motor is in transmission connection with the corresponding pneumatic clamping jaw, two clamping arms are installed at the output end of each pneumatic clamping jaw, and a V-shaped groove is formed in the inner side of each clamping arm.

Owner:HUBEI SHIMEI TECH

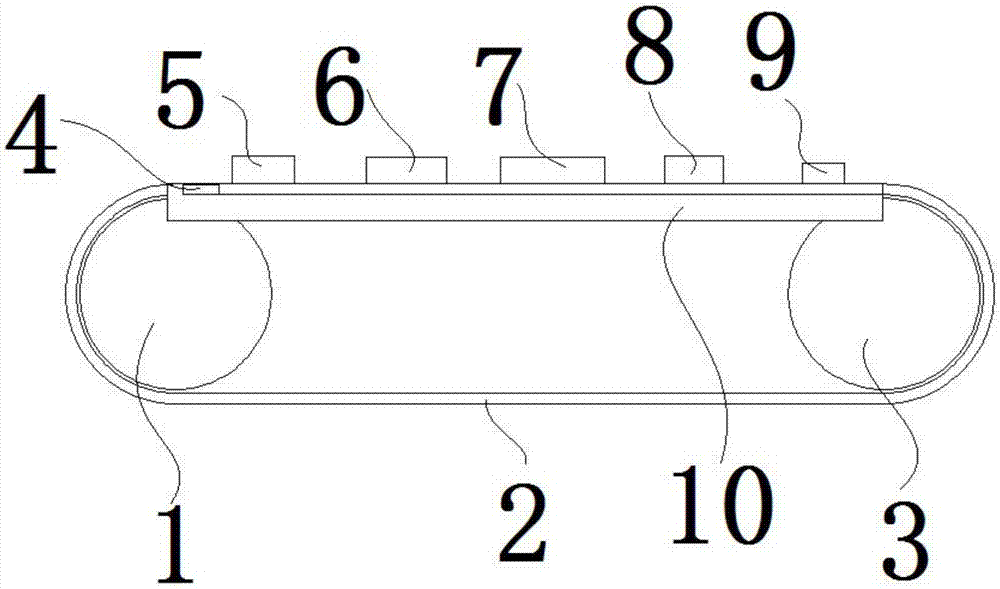

Self-adjusting type automatic production line

InactiveCN107399582ADamage reductionExtended service lifeConveyorsMeasurement devicesEngineeringMaterial supply

The invention discloses a self-adjusting type automatic production line, and relates to the technical field of automatic production lines. The self-adjusting type automatic production line comprises a material supply unit, a numerical control machining part, an automatic conveying unit, a sorting unit, a driving unit and a production main processing controller; the material supply unit and the numerical control machining part and the sorting unit are sequentially arranged on one side of a conveying belt according to the machining process and the machining procedures of products; the automatic conveying unit comprises a driving wheel, a driven wheel and a conveying belt; and the sorting unit comprises a color recognizer and a material pushing pneumatic rod. According to the self-adjusting type automatic production line, a temperature sensor, a camera, the material pushing pneumatic rod, an electrostatic detector, an infrared sensor and the color recognizer are arranged so that the self-adjustment of the automatic production line can be realized, the situation that a fire occurs due to the fact that the conveying belt works in a high-temperature and electrostatic environment for a long time can be avoided, the service life of the conveying belt can be prolonged, the use safety of the conveying belt can be ensured, the phenomena that the products are accumulated or are too few on the conveying belt can be avoided, and therefore high-efficiency production can be realized.

Owner:合肥星袖机械科技有限公司

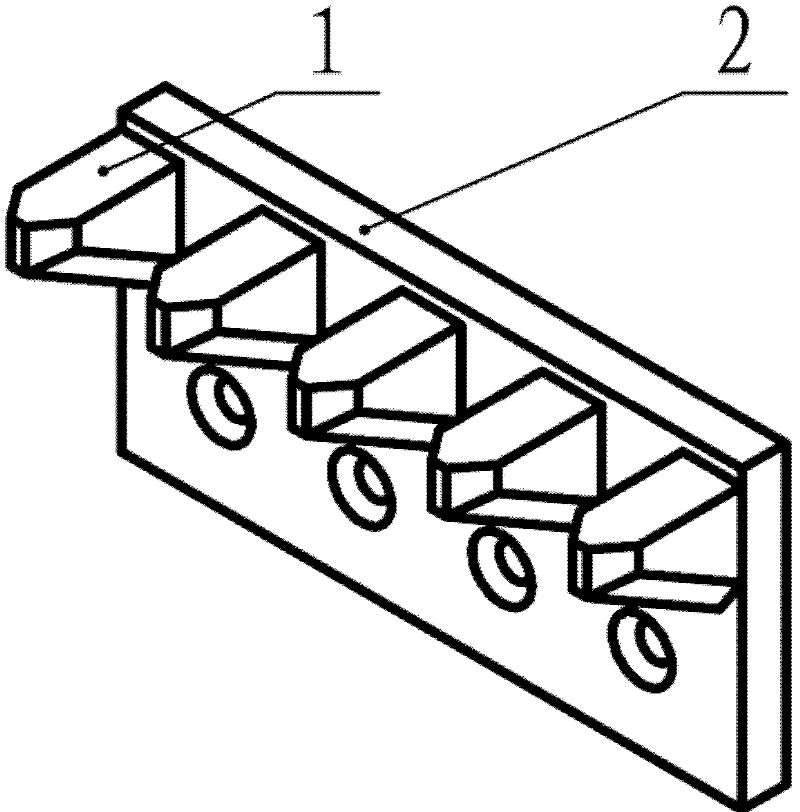

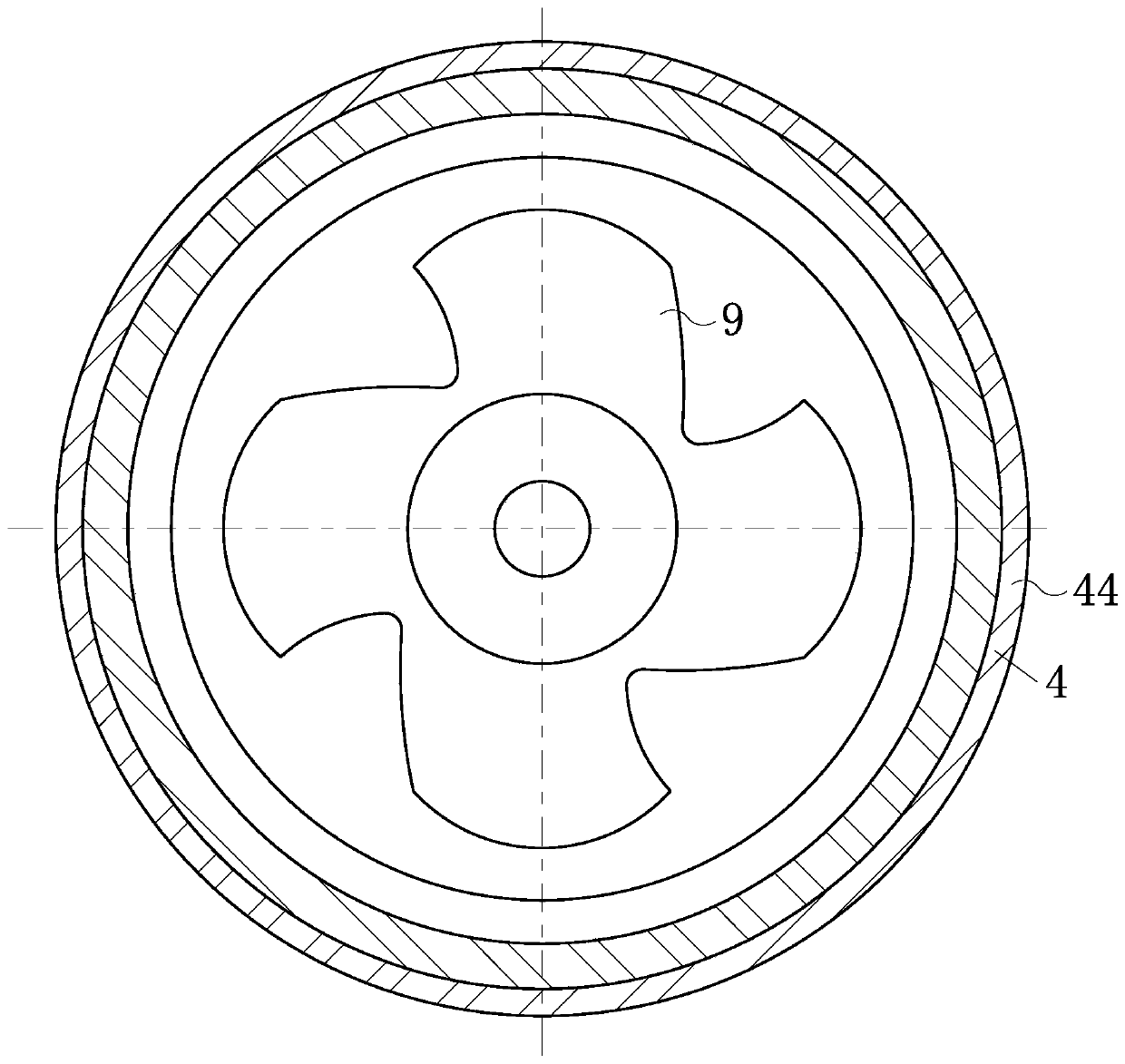

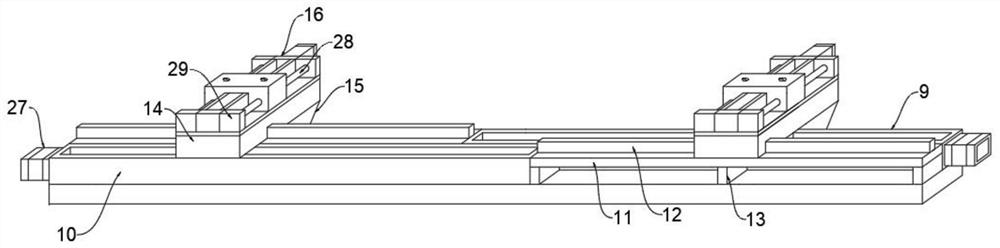

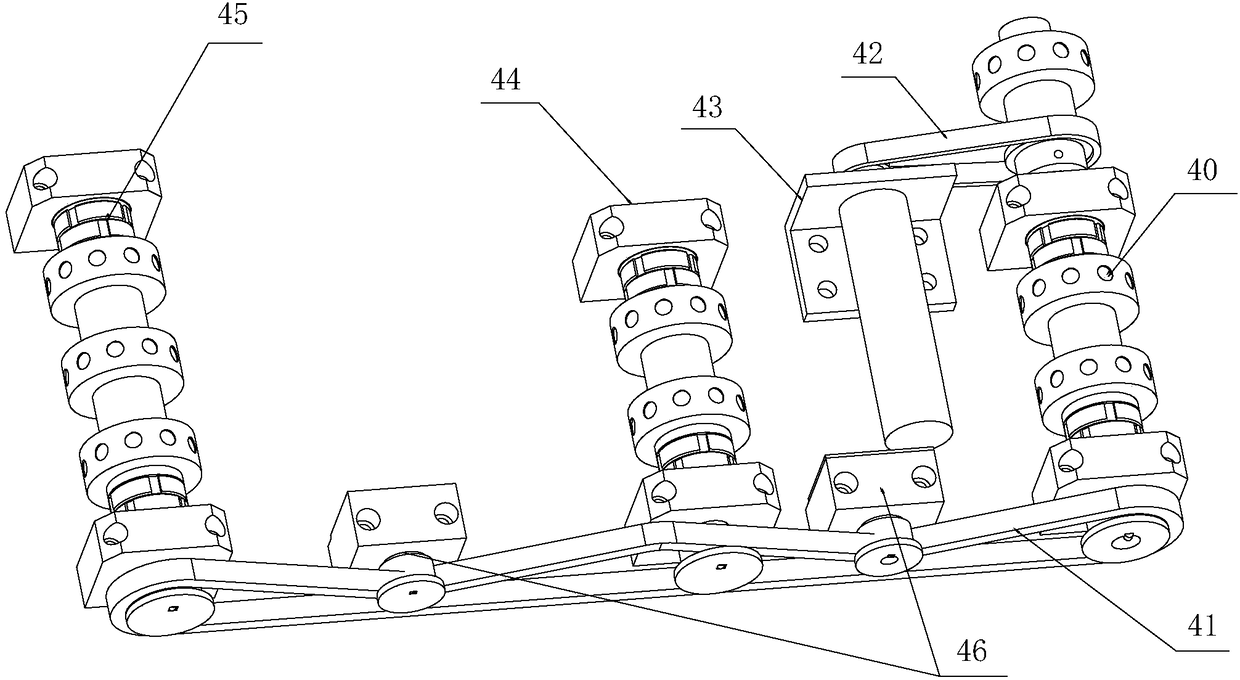

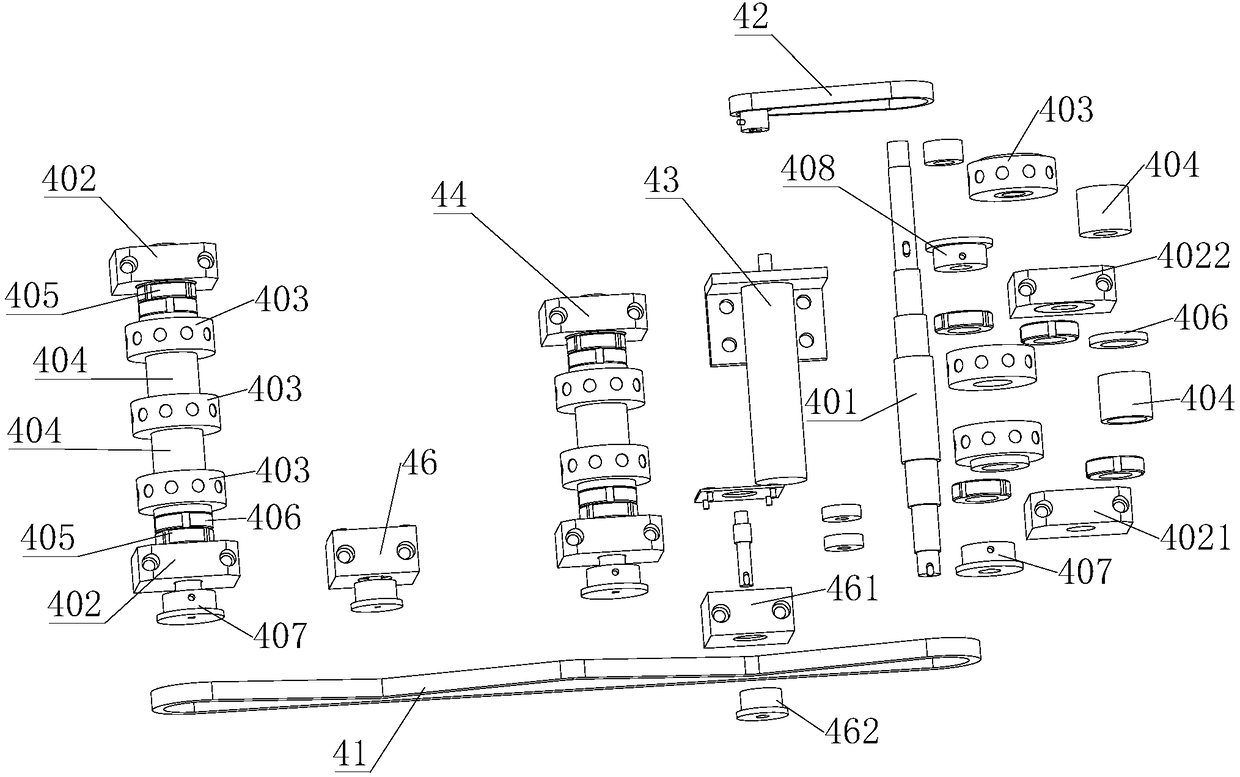

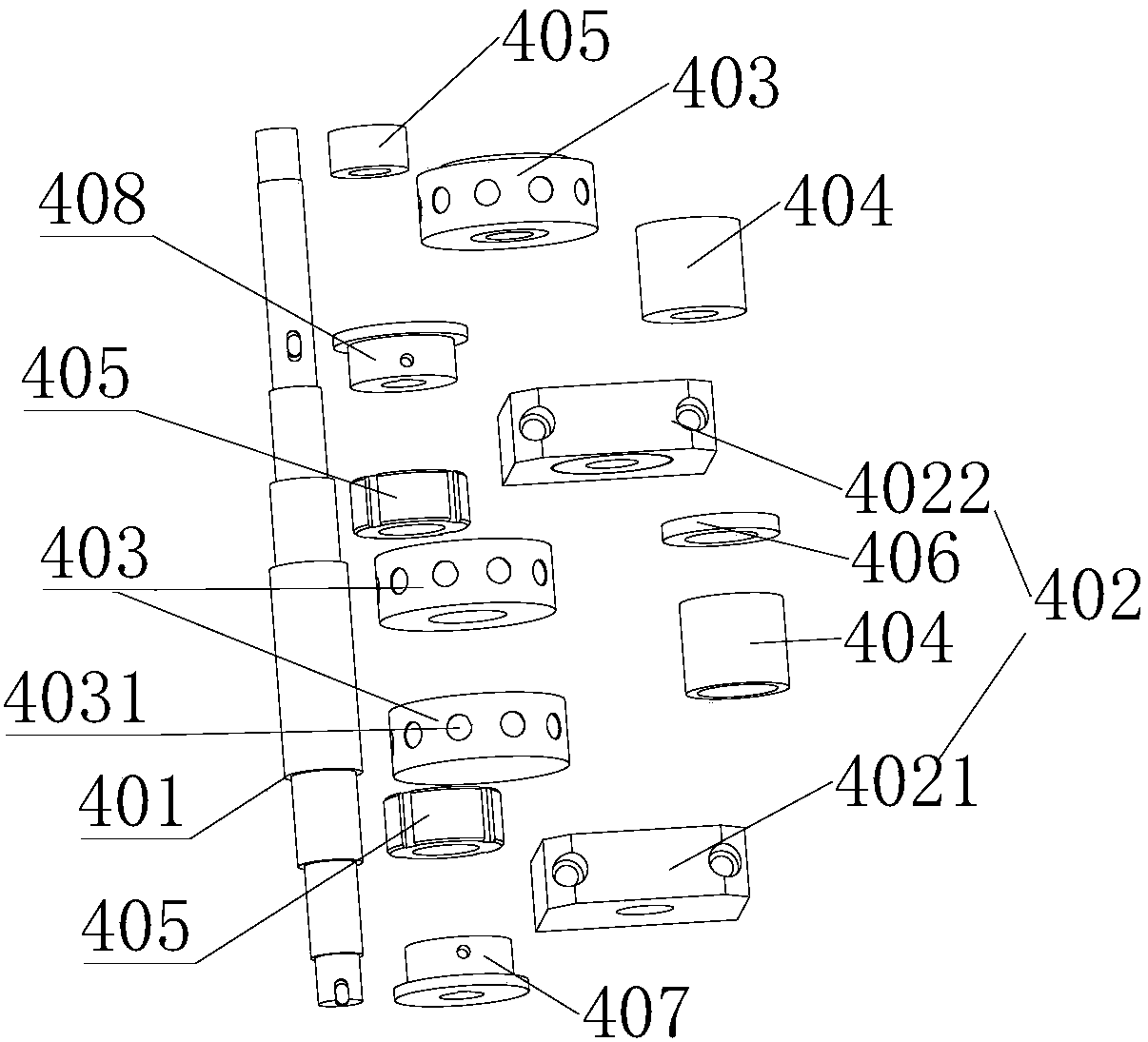

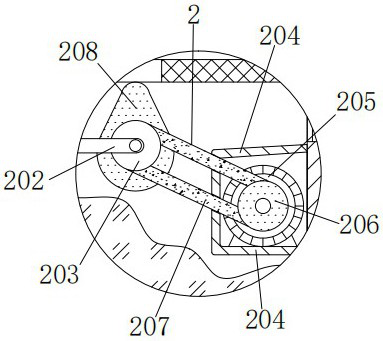

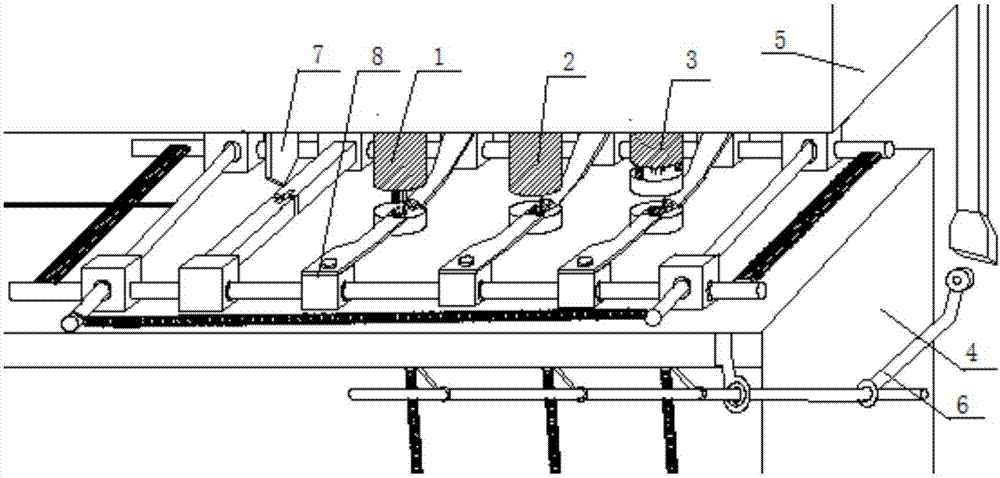

Conveying system of uncoiling blanking die

InactiveCN108465744ASmooth transmissionAvoid production impactMetal-working feeding devicesPositioning devicesMagnetLinkage concept

The invention discloses a conveying system of an uncoiling blanking die. The conveying system comprises a main rolling wheel device, a motor and at least one driven roller device, wherein the motor isused for driving the main rolling wheel device; the driven rolling wheel devices and the main rolling wheel device are arranged side by side and generate linkage through a conveying part; each of themain rolling wheel device and the driven rolling wheel devices comprises a rotating shaft, supporting bases and wheel hubs, wherein the supporting bases are used for supporting the rotating shaft torotate, and the wheel hubs are used for driving blanks; the multiple wheel hubs are arranged; and magnets enabling the blanks to move stably are uniformly distributed on the side walls of the wheel hubs. Compared with the prior art, the conveying system has the advantages that the multiple sets of rolling wheel devices are arranged and are driven for synchronous transmission through the conveyingpart, the magnets for adsorbing the blanks are arranged on the side walls of the wheel hubs, so that the conveying process can be more stable, and the influence on the production after the blanks falloff can be avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

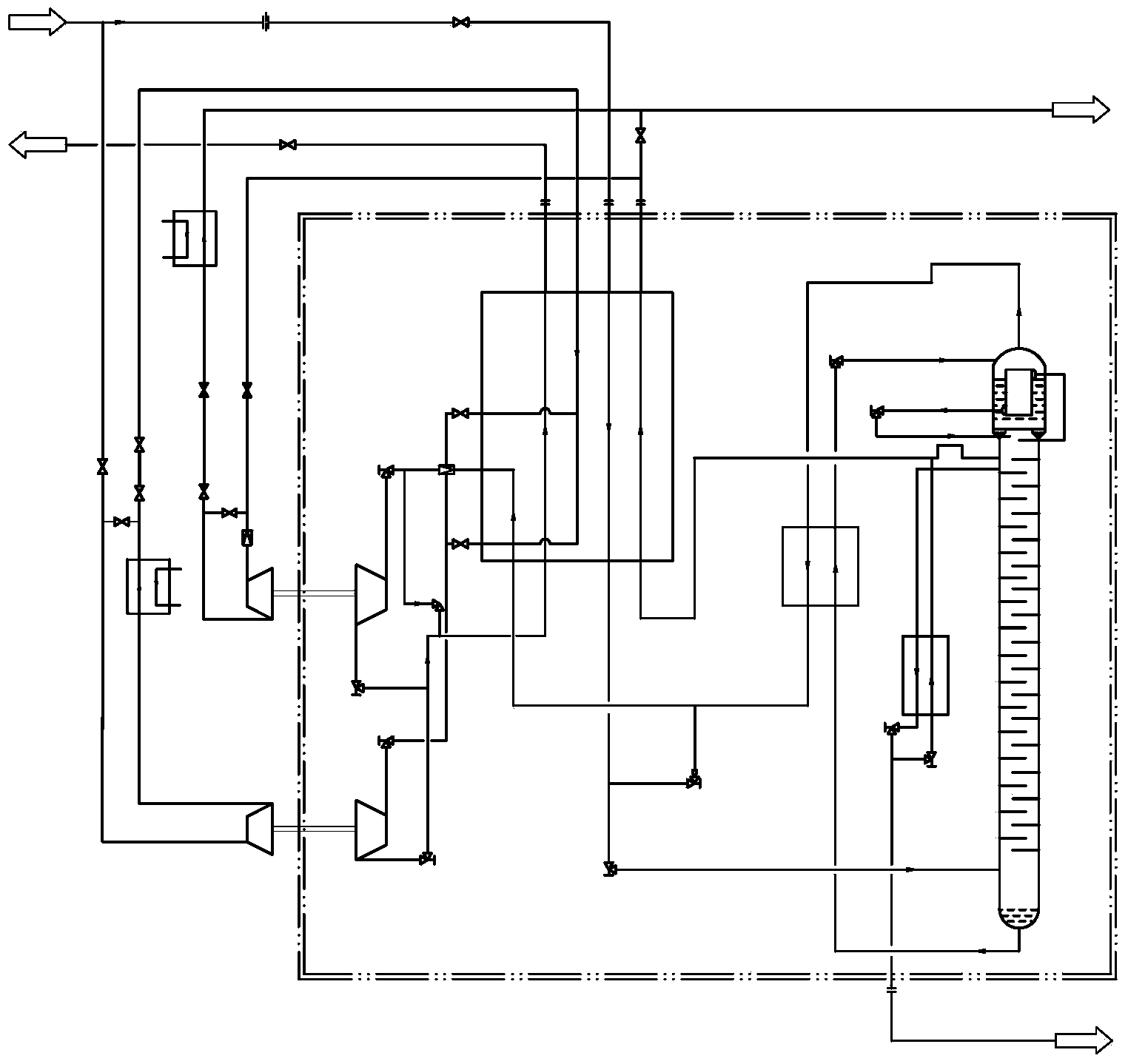

Multifunctional nitrogen making device

ActiveCN103776239AOutstanding and Beneficial Technical EffectsRelieve pressureSolidificationLiquefactionOxygenNitrogen gas

The invention relates to the technical field of nitrogen making, and relates to a multifunctional nitrogen making device. A part of purified air is fed to the bottom of a rectifying tower after heat exchange is carried out through a main heat exchanger, the other part of the purified air is pressurized through a supercharger, is cooled after heat exchange is carried out through the main heat exchanger and then is fed into an ET2 expansion machine to be refrigerated and fed into a waste nitrogen pipe network, oxygen-enriched liquid air is obtained at the bottom of the rectifying tower and is fed to the top of a condensing evaporator after passing through a liquid air subcooler and after throttling, liquid nitrogen in the condensing evaporator flows back to the top of the rectifying tower to serve as backflow liquid of the rectifying tower, waste nitrogen obtained on the top of the a lower pressure side of the condensing evaporator is fed into an ET1 expansion machine for expansion refrigeration, the reheated waste nitrogen is fed into a purifying system, high-purity nitrogen is obtained on the top of the rectifying tower, the high-purity nitrogen is output externally after being reheated by the main heat exchanger or after being reheated by the main heat exchanger and passing through the supercharger in sequence, and liquid nitrogen is output externally after high-purity liquid nitrogen passes through a liquid nitrogen subcooler. The multifunctional nitrogen making device has the advantages of being low in energy consumption, high in extraction ratio, good in economic benefit, flexible and reliable in adjustment and suitable for gas making industries.

Owner:浙江海畅气体股份有限公司

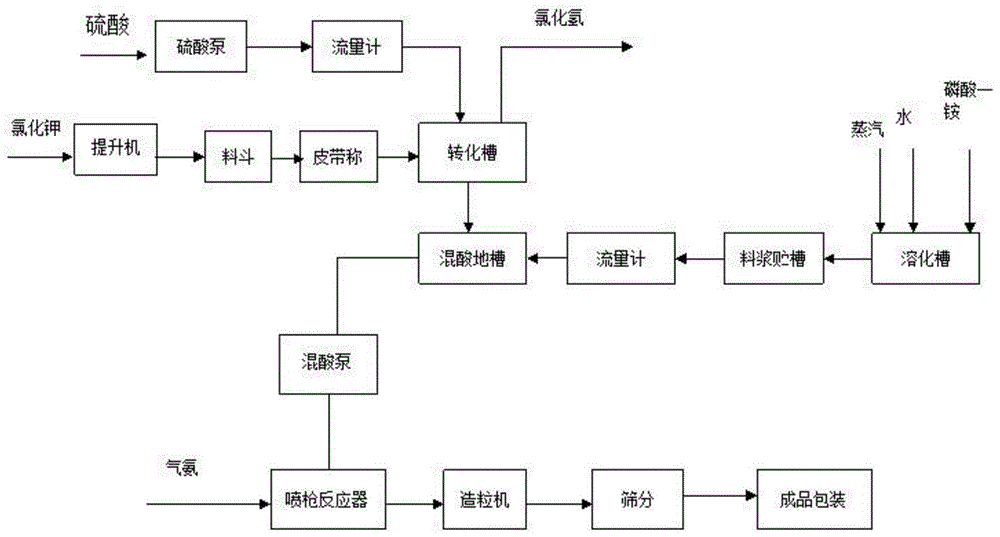

Method for producing sulfur-based composite fertilizer by using monoammonium phosphate instead of phosphoric acid

InactiveCN104418626AAvoid it happening againAvoid environmental hazardsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersHydrogen SulfatePhosphate

The invention discloses a method for producing a sulfur-based composite fertilizer by using monoammonium phosphate instead of phosphoric acid, which comprises the following steps: 1) preparing monoammonium phosphate slurry, that is, dissolving monoammonium phosphate with water or composite fertilizer tail gas washing liquid, and heating with low-pressure steam; 2) preparing mixed acid, that is, reacting sulfuric acid with potassium chloride in a conversion groove to generate a solution containing potassium hydrogen sulfate and excessive sulfuric acid, controlling the reaction in the conversion groove at 100-150 DEG C, transferring the solution into an acid mixing trough, mixing the solution with the monoammonium phosphate slurry in the acid mixing trough; 3) further performing a neutralization reaction of the mixed acid and gas ammonia in a neutralization reactor to generate neutralized slurry; 4) spraying the neutralized slurry into a pelletizer to produce the sulfur-based composite fertilizer. The concentration of the sulfuric acid is 98%. The advantages of the invention are that the composite fertilizer is produced by monoammonium phosphate, the generation of phosphogypsum is prevented, about 0.98 tons of phosphogypsum are decreased when one ton of the composite fertilizer is produced, and the environmental protection hidden trouble caused by phosphogypsum is prevented.

Owner:山东聊城鲁西化工第五化肥有限公司

Steel industry waste residue contaminant comprehensive treatment method

InactiveCN106957956AHigh energy costIncrease profitProcess efficiency improvementPelletizingBrown coal

The invention discloses a steel industry waste residue contaminant comprehensive treatment method. The method comprises following steps: steel slag is broken to 5 meshes to 10 meshes and is washed through distilled water and dried, and standby application is carried out; a composite is flatly laid in a container and is put into a high-temperature resistance furnace to be roasted to obtain an absorbing material; the absorbing material is ground according to the weight ratio to powder, and a carbon-bearing pellet is manufactured; one or multiple of soft coal, brown coal, lime powder, coal slime, coal gangue and saw powder are mixed to obtain cladding powder, the carbon-bearing pellet and the cladding powder are put into the other pelletizing disc, a bonding agent is added, then, continuous pelletizing is carried out, the composite carbon-bearing pellet enters a chain belt type roasting machine to be subject to high-temperature reduction roasting, and in the chain belt type roasting machine, the temperature rises to 1450 DEG C to 1650 DEG C within 7 to 15 minutes, the carbon-bearing pellet is subject to 2.5-hour roasting, and the pellet is obtained. The method is economical, applicable, small in material loss, good in effect, low in energy consumption and low in production cost and facilitates environment friendliness.

Owner:王冰

CNC shot blasting machine for continuous shot blasting operation

InactiveCN112192451AConvey evenlyAvoid cloggingBlast gunsAbrasive feedersMachine partsTransmission belt

The invention relates to the field of shot blasting machines, in particular to a CNC shot blasting machine for continuous shot blasting operation. The CNC shot blasting machine comprises a box body, wherein a conveying mechanism is arranged in the box body. The CNC shot blasting machine has the beneficial effects that when the CNC shot blasting machine is used, a driving motor drives a driving rodand a conveying blade to rotate, the conveying blade conveys shots in a storage box into a conveying cavity and meanwhile drive a first bevel gear to rotate through a sealing ring, the first bevel gear meshes with a second bevel gear to drive a transmission rod to rotate, meanwhile, the transmission rod drives a second transmission wheel and a third transmission wheel to rotate through cooperation of a first transmission wheel and a transmission belt, the second transmission wheel drives a rotating rod to rotate, the rotating rod drives a rotating disc and conveying tanks to convey all the shots entering the conveying cavity into a shot blasting pipe, the shots are conveyed more uniformly without being blocked inside through whole-process pushing and conveying, and the phenomenon that shot blasting strengthened operation on the surface of a machined part is not uniform is avoided.

Owner:程群

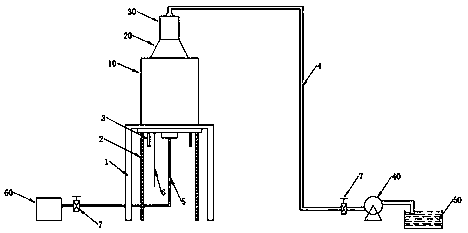

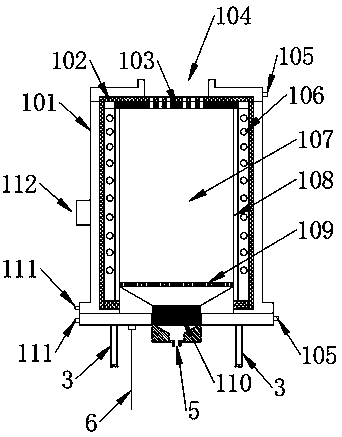

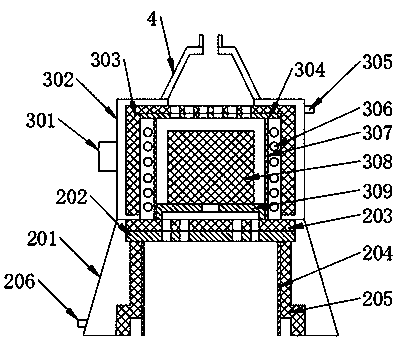

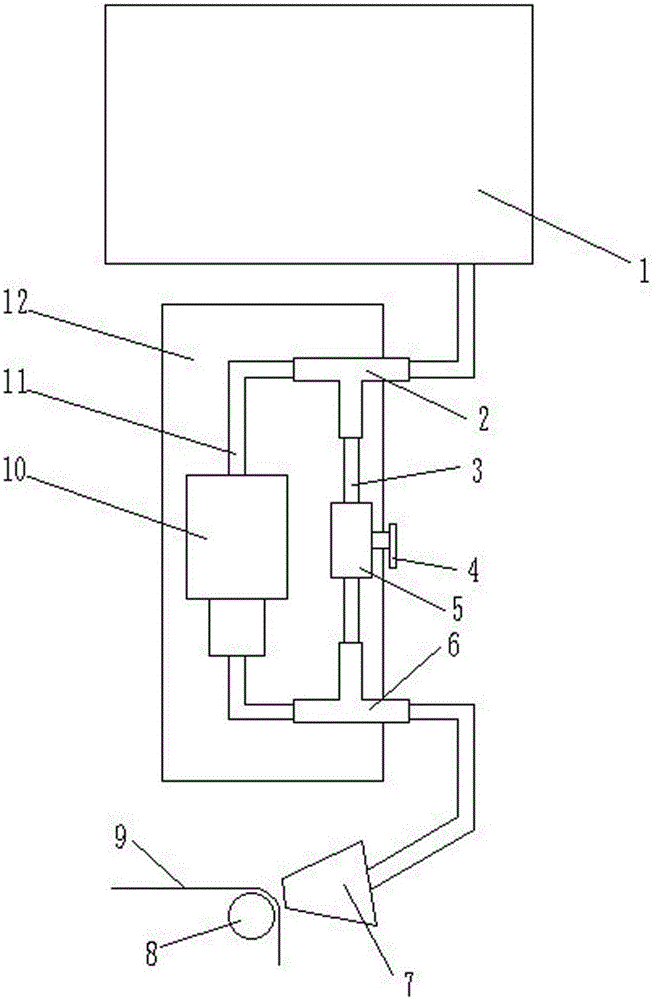

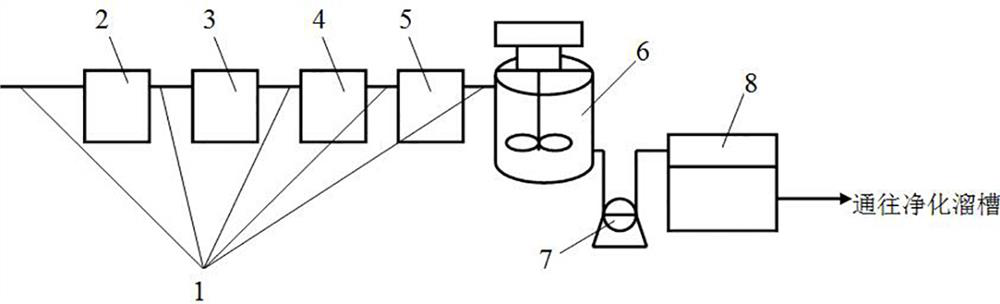

Vertical double-furnace-body chemical vapor deposition equipment

InactiveCN109487235AInto the uniformAvoid production impactChemical vapor deposition coatingCALCIUM HYDROXIDE SOLUTIONGas phase

The invention relates to vertical double-furnace-body chemical vapor deposition equipment. The vertical double-furnace-body chemical vapor deposition equipment is characterized that a support base, alifting system, a lower furnace body, a buffer system, an upper furnace body, a source gas system, a gas inlet pipe, a vacuum valve, a gas exhaust pipe, a vacuum pump and a filter tank are included. The lower furnace body is installed on the support base, the lower end of the lower furnace body is connected with the lifting system, and the lower furnace body is connected with the source gas systemthrough the gas inlet pipe. The buffer system is installed at the upper end of the lower furnace body, and the upper furnace body is installed above the buffer system. The upper furnace body is connected with the vacuum pump through the gas exhaust pipe, the vacuum pump and the filter tank are connected through the gas exhaust pipe, and solution in the filter tank is calcium hydroxide solution. According to the vertical double-furnace-body chemical vapor deposition equipment, the reaction lower furnace body and the tail gas treatment upper furnace body are vertically and integratedly distributed, no superfluous pipeline is connected, and tail gas in the chemical vapor deposition production process can be treated in time and effectively; and zero exhaust emission, safe and green productionare achieved, and production efficiency is improved.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

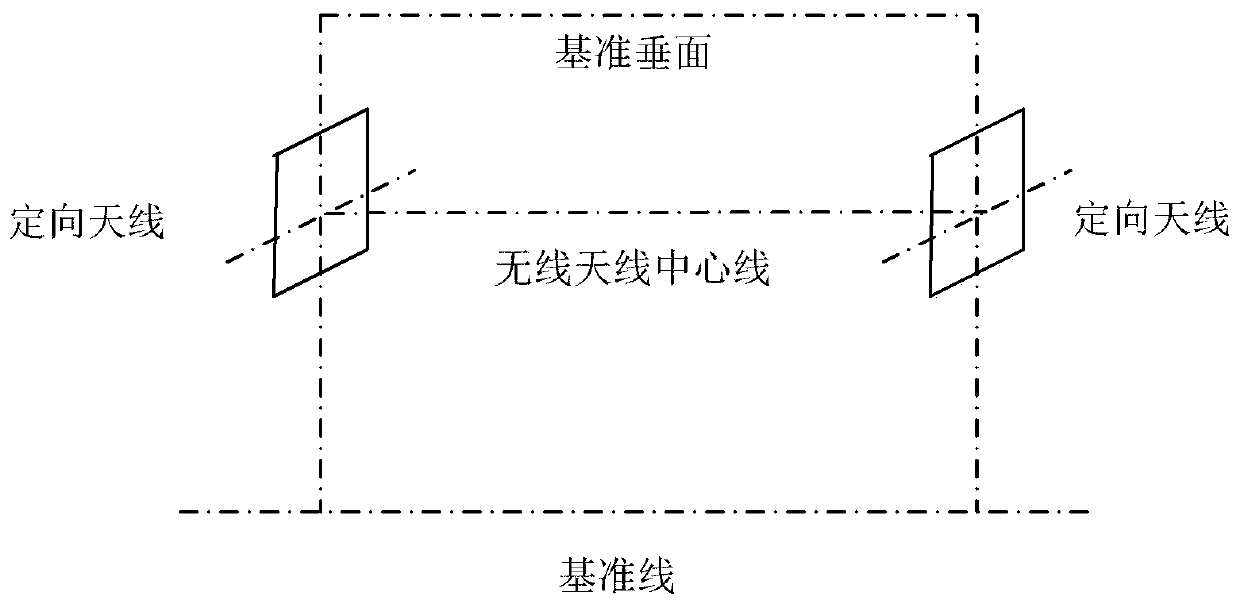

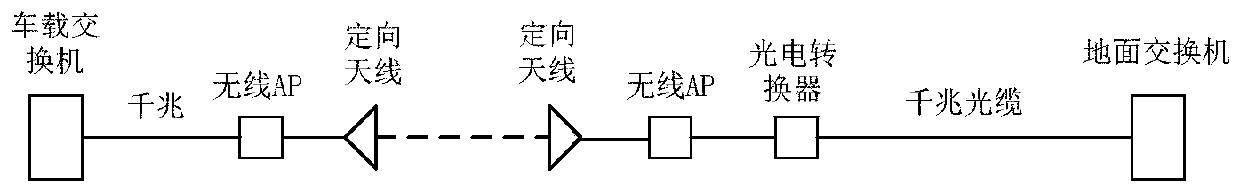

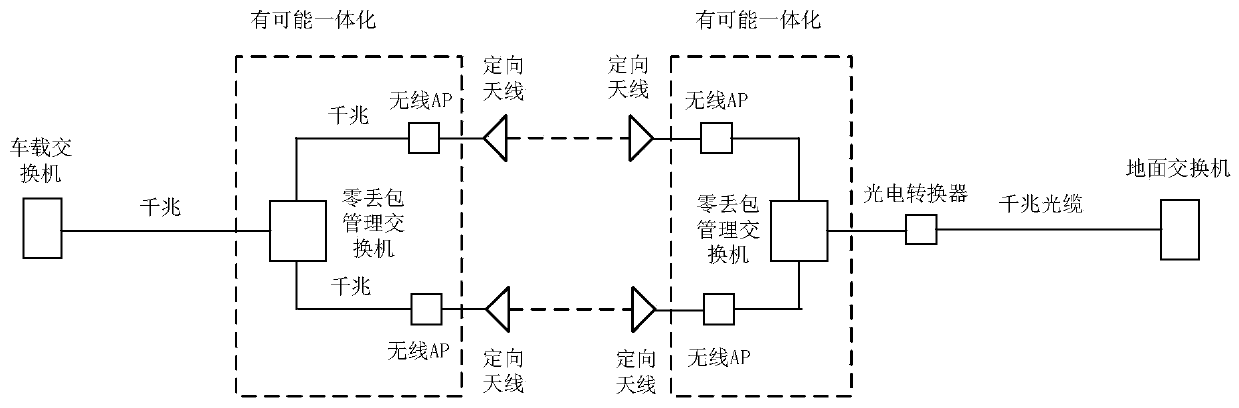

Directional antenna alignment system and method for wireless communication system of stacker-reclaimer

ActiveCN111326861AIncrease speedImprove stabilitySurveying instrumentsIncline measurementCommunications systemDirectional antenna

The invention discloses a directional antenna alignment system and method for a wireless communication system of a stacker-reclaimer, and relates to the field of Ethernet communication. The directional antenna alignment system for the wireless communication system of the stacker-reclaimer comprises an antenna support, a ground calibration platform, a bidirectional vertical laser beam projection component, a perpendicularity measuring component and a reflector alignment assembly, wherein the antenna support is used for fixing a directional antenna at the appropriate position of the stacker-reclaimer and the ground; the ground calibration platform is used for providing a ground benchmark reference; the bidirectional vertical laser beam projection component is used for projecting bidirectional laser beams which are perpendicular to each other to form laser surfaces which are perpendicular to each other; the perpendicularity measuring component is used for adjusting the directional antennaplane to be perpendicular to the horizontal plane; and the reflector alignment assembly is used for displaying a laser projection line, enhancing a visual effect of the bottom edge of the directionalantenna plane and prolonging the bottom edge line of the directional antenna plane to improve the alignment precision. According to the technical scheme, accurate alignment of the directional antennais achieved, and the alignment method has the advantages of being high in alignment accuracy, simple in operation procedure, low in cost and easy to master by the field maintenance personnel.

Owner:BEIJING DEBAI LITAI TECH

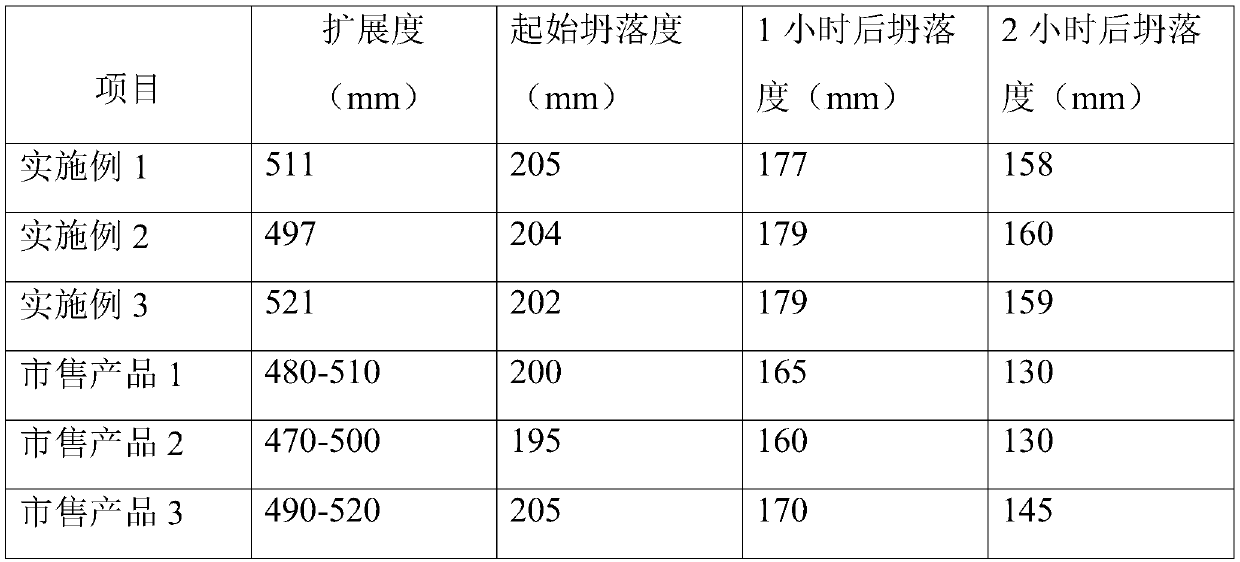

Preparation method of polycarboxylic acid water reducer

The invention discloses a preparation method of a polycarboxylic acid water reducer, which comprises the steps of: step I, pouring 32-38wt% of polyethylene glycol methacrylate monomer into a reactionkettle, adding 56-62wt% of water into the reaction kettle for stirring, and uniformly mixing the monomer and the water, step II, adding 0.2-0.6wt% of triethylene tetramine, 3.5-5.2wt% of acrylic acid,0.1-0.3wt% of vitamin C into a mixing kettle, and uniformly stirring triethylene tetramine, acrylic acid and the vitamin C in the mixing kettle, and step III, keeping working states of stirring shafts in the mixing kettle and the reaction kettle within 2h, gradually and uniformly adding a mixture from the mixing kettle into the reaction kettle, performing continuous stirring in the reaction kettle till a reaction is finished, and cooling a temperature of a material to a room temperature.

Owner:张家港市嘉成新材料有限公司

Filtering device for producing water body modifier

InactiveCN112546702AAchieve sievingAvoid production impactMoving filtering element filtersGear driveMotor drive

The invention discloses a filtering device for producing a water body modifier. The device comprises a feeding port, the bottom of the feeding port is communicated with a box body, convex blocks on the left side and the right side of the box body are rotationally connected with the lower portions of the front end faces of vertical plates through pin shafts, and a screening apparatus is arranged onthe inner side of the box body. According to the filtering device for producing the water body modifier, through cooperation of the feeding port, the box body, long rods, the vertical plates and thescreening apparatus, a first motor drives a second groove wheel to rotate, a first groove wheel drives a circular plate to rotate, the circular plate enables a filter screen to move up and down, thenscreening of the water body modifier is achieved, impurities are prevented from being mixed in the water body modifier, second motors drives gears to rotate, the gears drive racks to move outwards, springs drive straight plates to move inwards, and the straight plates drive the racks to move inwards, so that the two racks are attached to and separated from each other, the putting amount of the water body modifier is controlled, the water body modifier is prevented from being accumulated above the filter screen, and the screening effect of the water body modifier is improved.

Owner:伍保国

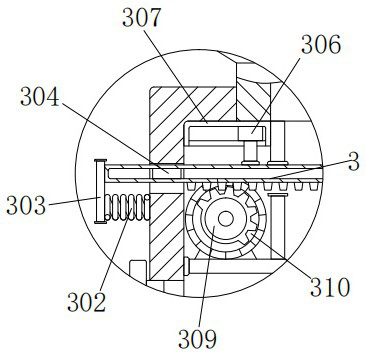

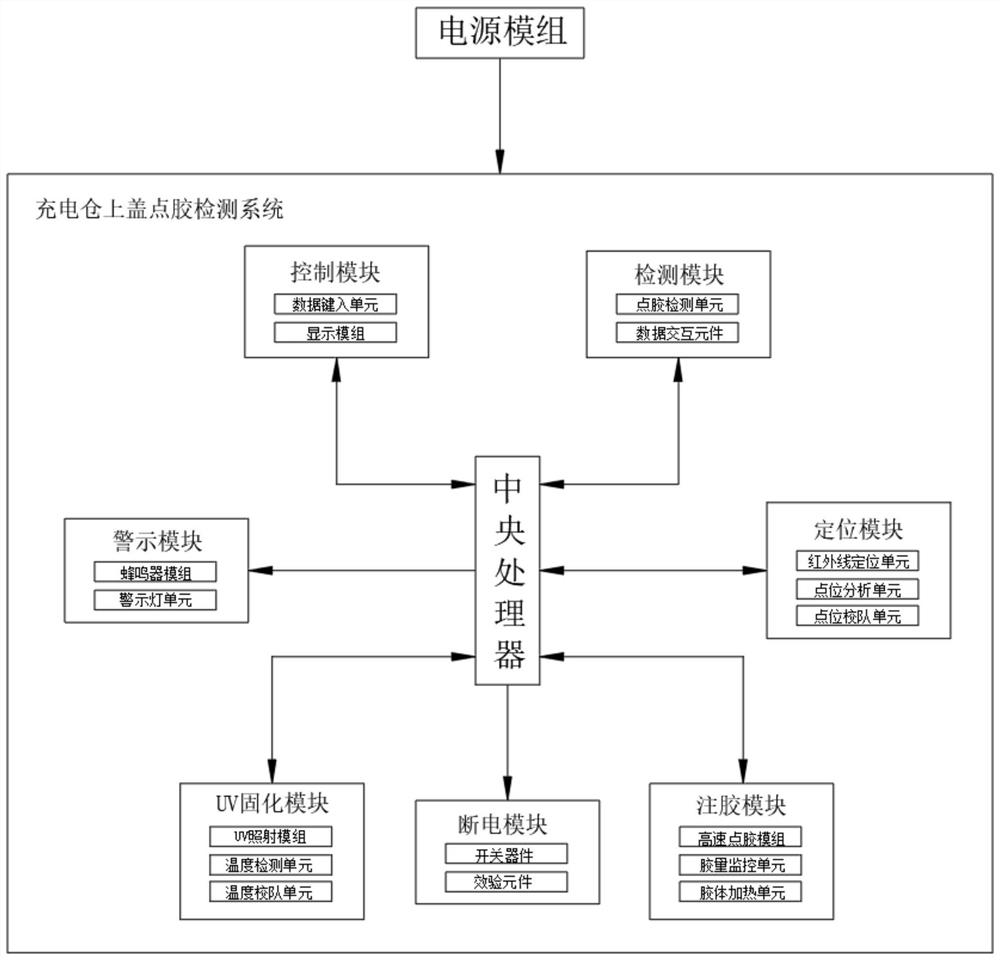

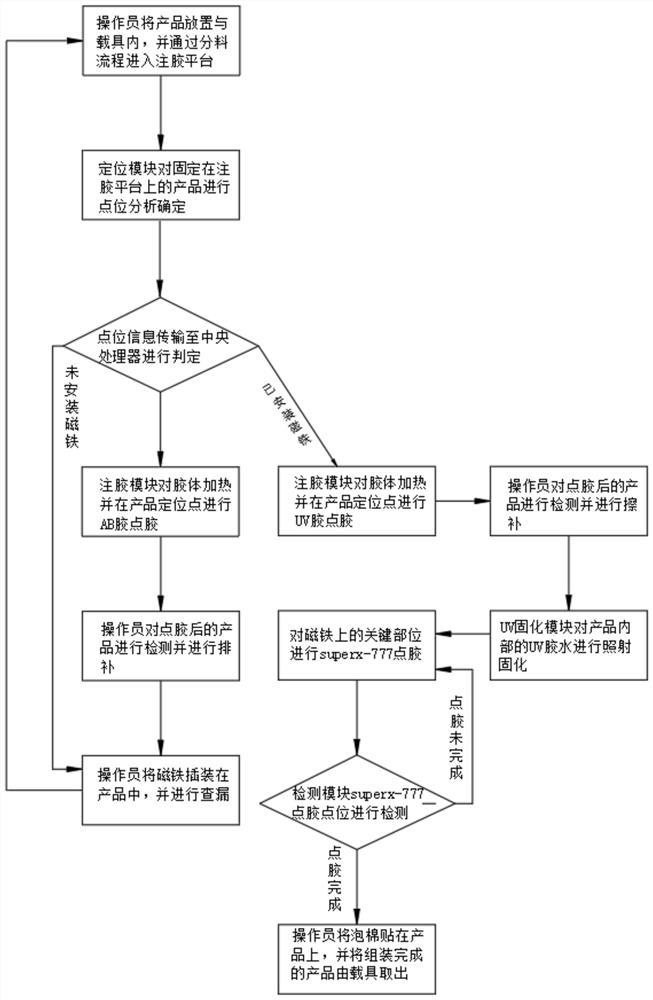

Bluetooth earphone charging bin upper cover dispensing process based on super-precision automation

PendingCN113304954AQuality improvementReduce labor pressurePretreated surfacesAlarmsElectrical connectionProcess engineering

The invention relates to the technical field of dispensing processes, and discloses a Bluetooth earphone charging bin upper cover dispensing process based on super-precision automation. The process comprises a charging bin upper cover dispensing detection system, wherein the input end of the charging bin upper cover dispensing detection system is electrically connected with the output end of a power supply module, the charging bin upper cover dispensing detection system comprises a central processing unit, the input end of the central processing unit is electrically connected with the output end of a control module, the input end of the control module is electrically connected with the output end of the central processing unit, the system can work for a long time, the influence of human factors on production can be well avoided, rapid dispensing is realized, the dispensing quality is good, various instructions can be realized, product dispensing is stable, various high-difficulty dispensing processes can also be realized, the production cost is low, multi-manual operation can be replaced, the labor pressure of workers is reduced, the quality of the dispensing processes is ensured, the production efficiency of charging bin products is improved, and the reliability and stability of the quality of the process are ensured.

Owner:LUXSHARE ELECTRONICS TECH (KUNSHAN) LTD

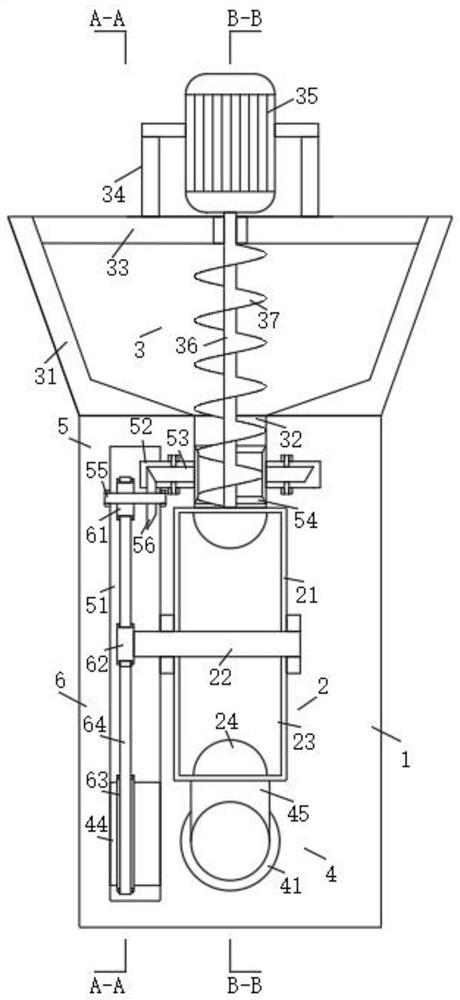

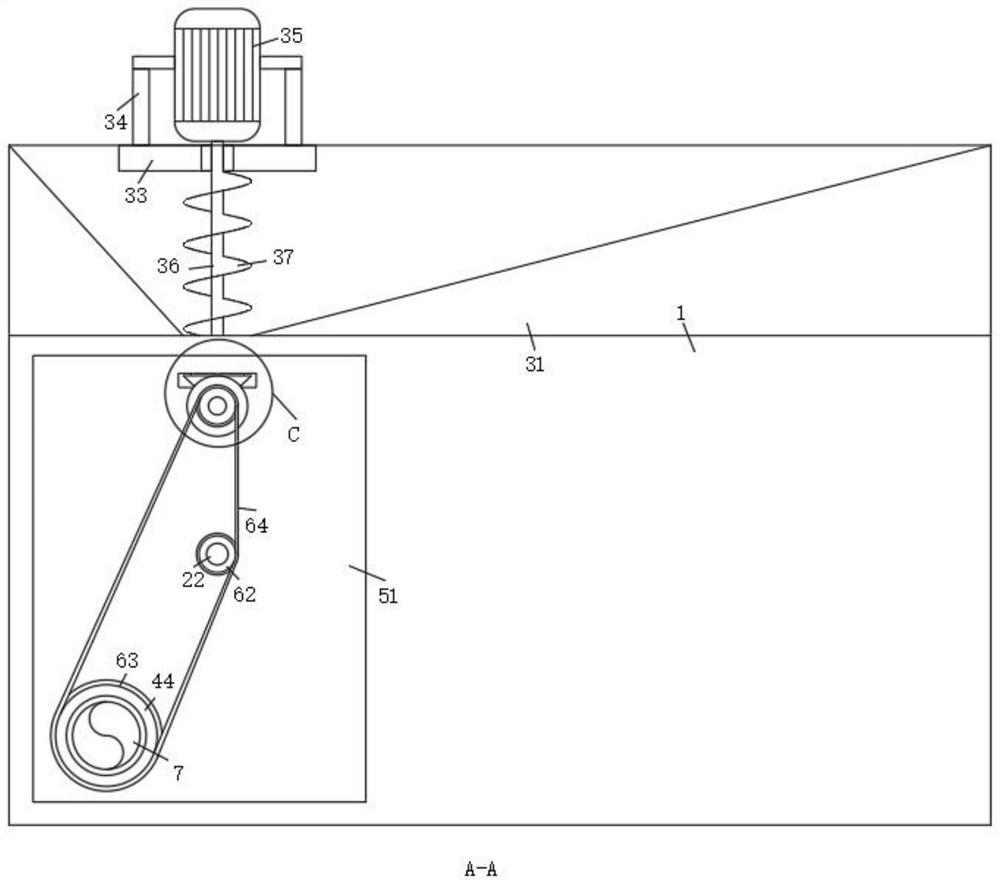

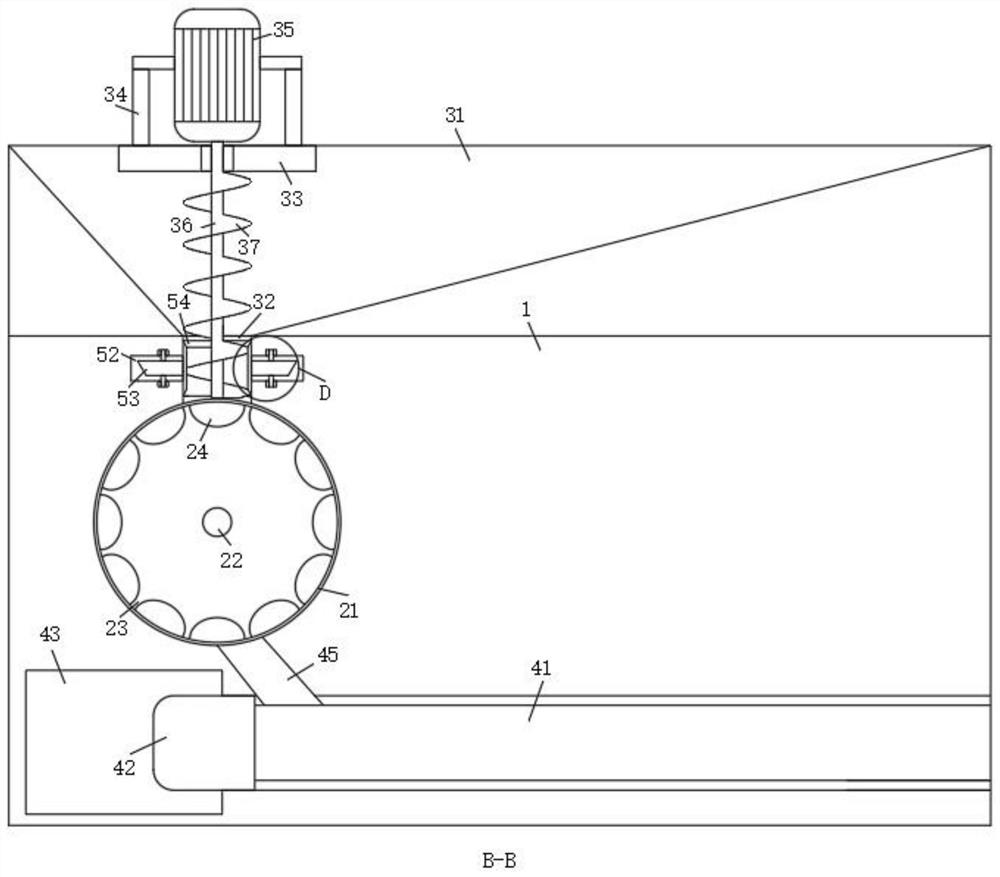

Mixing and metering device

PendingCN108311002AGuaranteed safe operationOperation impactTransportation and packagingRotary stirring mixersMechanical engineering

Owner:KAWATA MASCH MFG (SHANGHAI) CO LTD

Method for cultivating flood-refuge crops in hollow of southwest karst peak cluster

InactiveCN101411282BAvoid production impactPromote growth and developmentSeed and root treatmentClimate change adaptationEcological environmentPlastic mulch

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

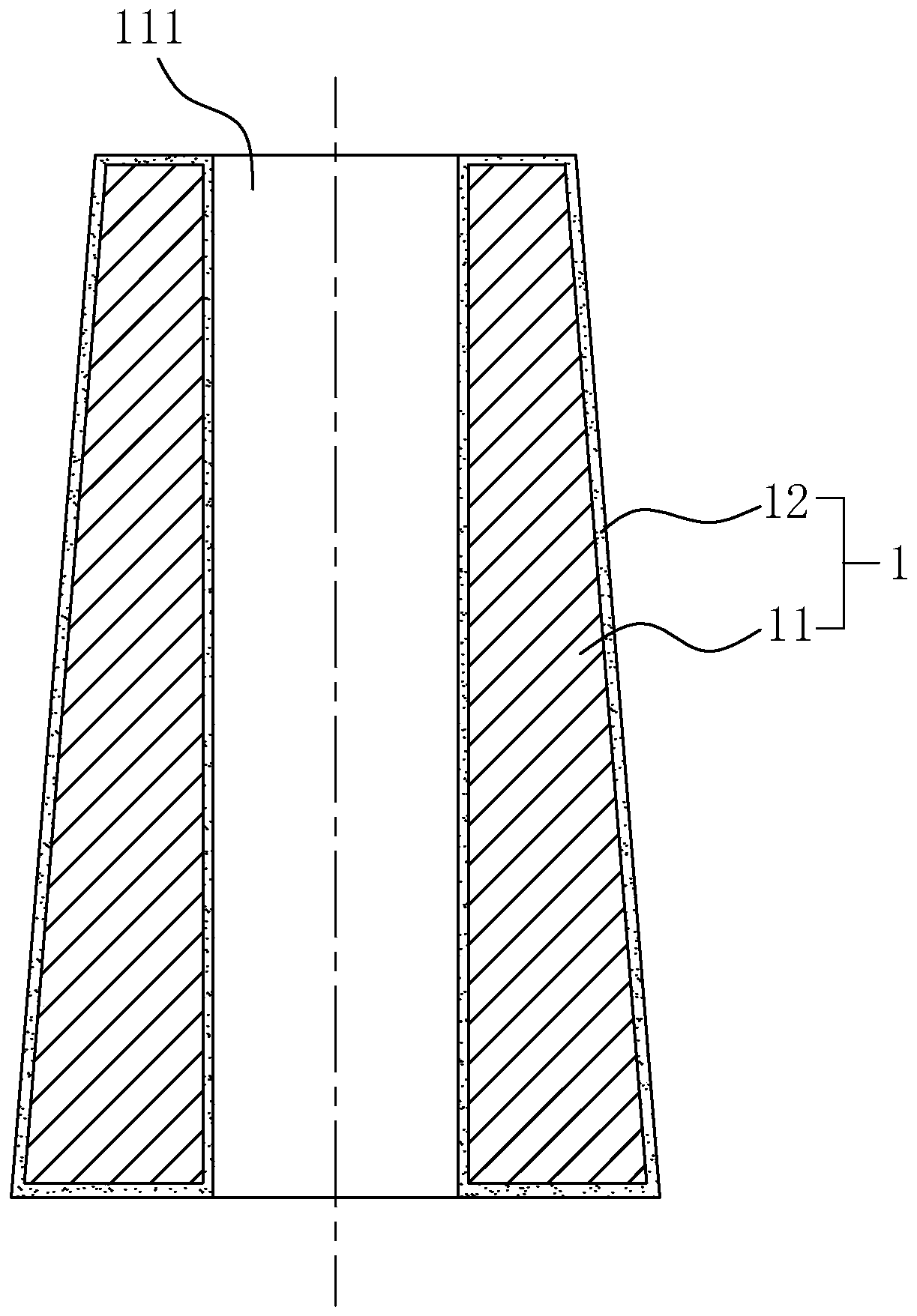

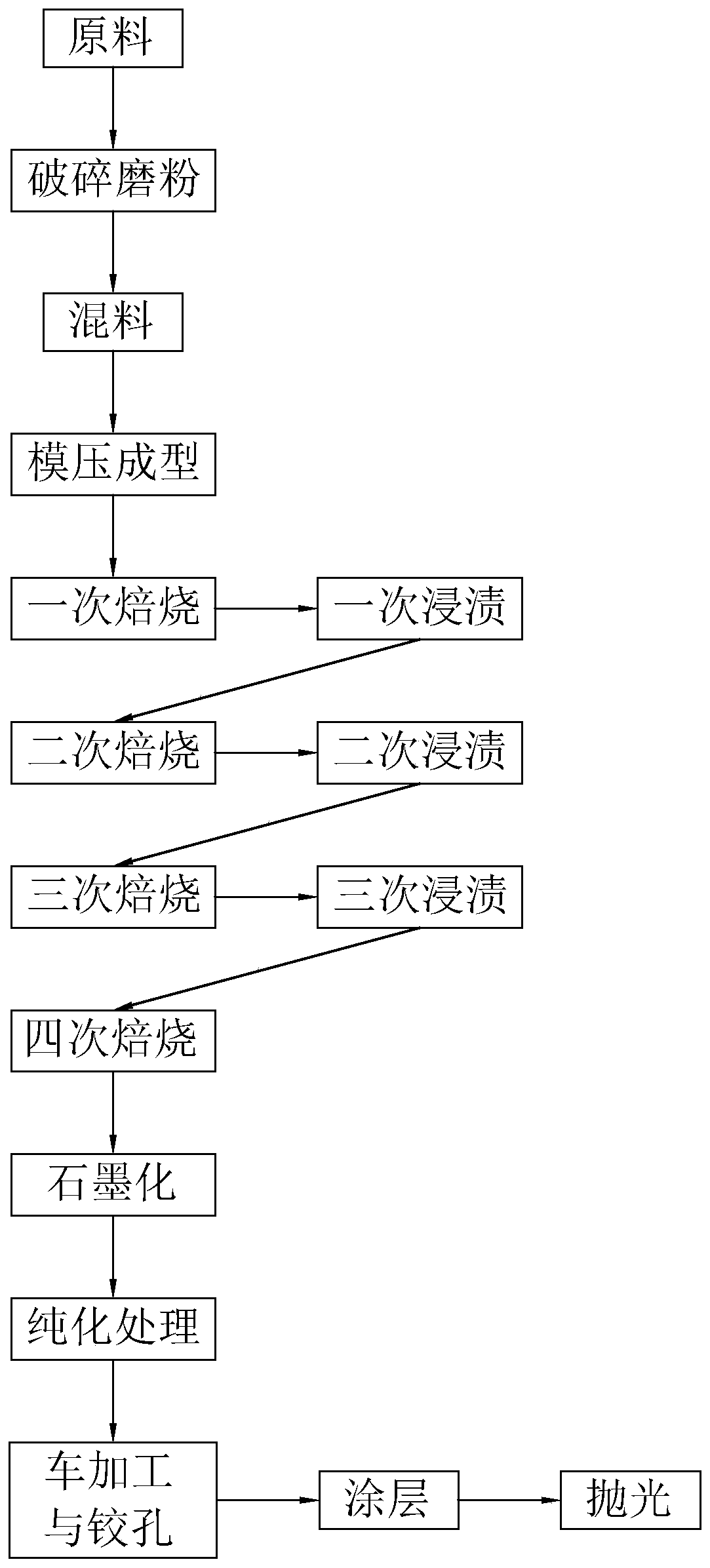

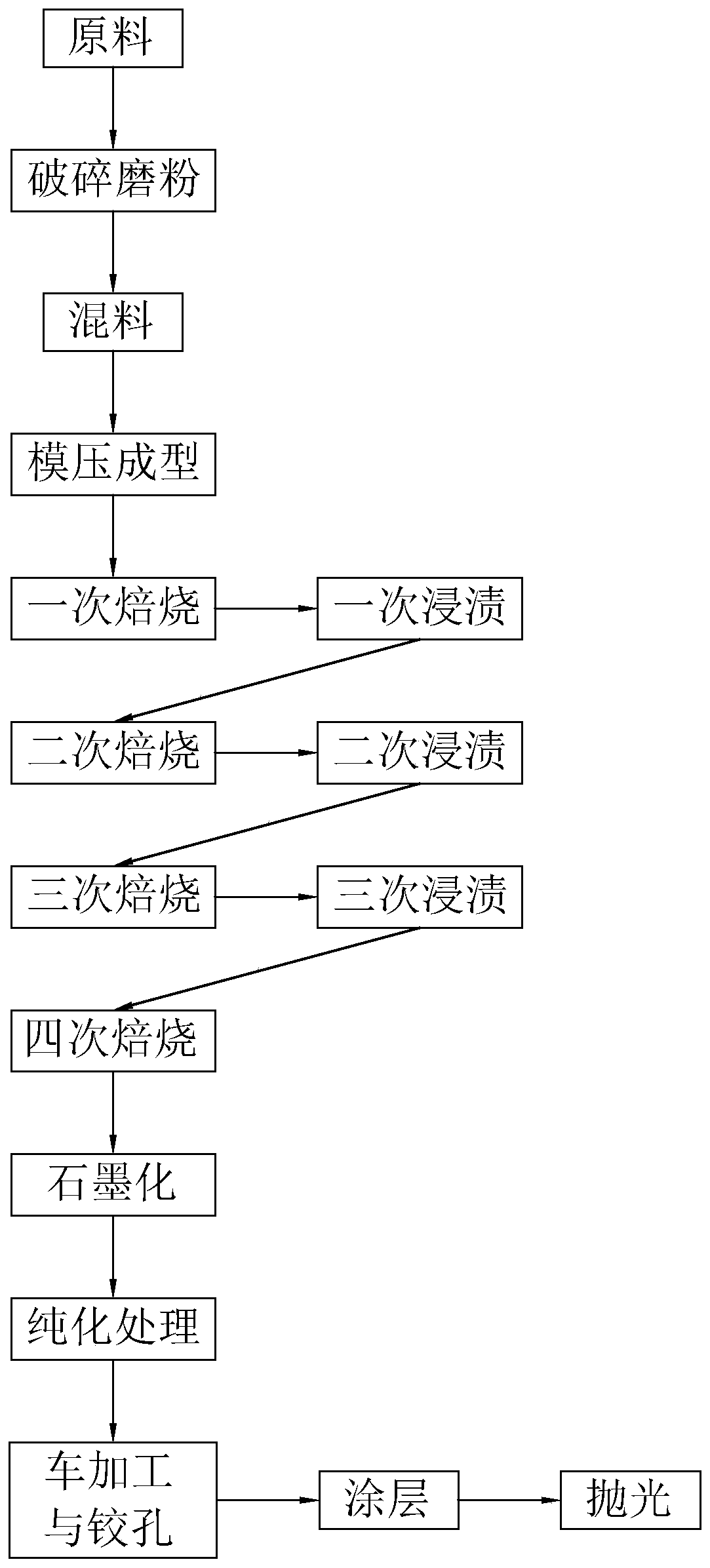

High-speed rail wire alloy copper rod continuous casting crystallizer and production process thereof

ActiveCN109702156AStable lifeEasy to change regularlyFoundry mouldsFoundry coresSurface roughnessGraphite

The invention discloses a high-speed rail wire alloy copper rod continuous casting crystallizer and a production process thereof, and relates to the technical field of crystallizers. According to thetechnical scheme, the crystallizer is characterized by comprising a graphite tube body, wherein the fixed carbon content of the graphite tube body is not lower than 99.95%, the density of the graphitetube body is 1.80-1.88 g / cm<3>, a through hole penetrating through the graphite tube body is formed in the axis, the roughness of the inner surface of the through hole is at least Ra 0.8, and a pyrolytic carbon coating with the thickness of 4-6 microns is coated on the side wall of the through hole of the graphite tube body. According to the high-speed rail wire alloy copper rod continuous casting crystallizer, the problem that due to the fact that the service life of an existing crystallizer for copper rod continuous casting is not stable, the production of a copper rod for the high-speed rail is affected is solved, three times of immersion, four times of baking and purification treatment are carried out on graphite, so that the service life of the graphite crystallizer is prolonged, andthe stability of the graphite crystallizer is improved.

Owner:青岛卓越碳素制品有限公司

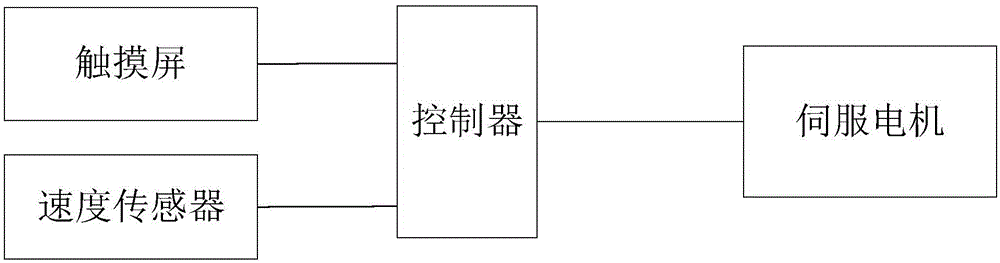

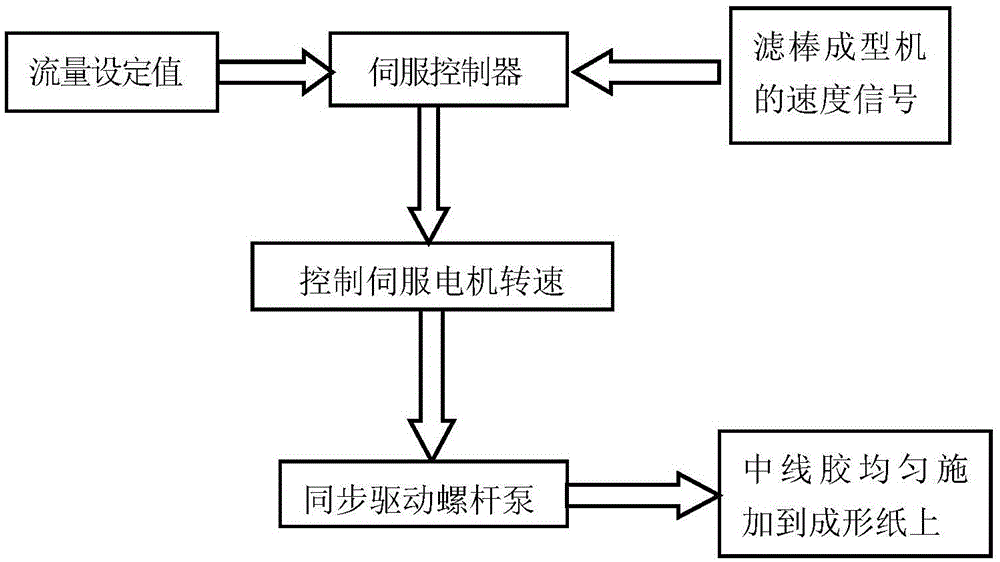

Filter stick forming machine

ActiveCN105029703ANot prone to cloggingPrevent glue phenomenonCigarette manufactureControl mannerElectric machinery

The invention relates to a filter stick forming machine which comprises a speed sensor and a glue supply device, wherein the speed sensor is used for detecting conveying speed of forming paper for cigarettes, the glue supply device comprises a first glue supply branch circuit and a second glue supply branch circuit which are arranged in parallel, the first glue supply branch circuit is provided with a switching valve in series, the second glue supply branch circuit is provided with a glue supply pump in series, the glue supply device further comprises a controller and a motor, the controller is connected with a speed sensor in a sampling way, and connected with a motor in a controlling manner, and the motor is in mechanical driving connection with the glue supply pump. According to the filter stick forming machine, firstly, the controller controls the rotation speed of the glue supply pump correspondingly according to the collected conveying speed of the forming paper, and then controls the flow ratio of the glue, so that the glue can be conveyed out practically according to requirements, the glue accumulation phenomenon caused by overlarge flow ratio of the glue is prevented, and the problem of low quality of filter sticks caused by too low flow ratio of the glue is also solved; in addition, when the glue supply pump or the motor has faults, the first glue supply branch circuit can be used for carrying out glue conveying operation continuously, so that great influences caused by machine halt to the production is avoided.

Owner:CHINA TOBACCO HENAN IND

A multi-stage air purification device for a workshop

ActiveCN109099508BWith self-cleaning functionWith secondary pollutionMechanical apparatusLighting and heating apparatusAir cleaningElectric machinery

The invention discloses a multi-stage air purification device for a workshop. The multi-stage air purification device comprises a box body, and an air inlet pipe is fixedly connected to the left sideof the box body. A gas collecting fan is rotatably connected to the inner portion of the left side of an air guide duct, and the lower end of a layering purifier is fixedly connected with a pressure dissolved air tank. A culture medium table is fixedly connected to the middle portion of a purifying pond, and a sediment scraper is arranged above the purifying pond. An ion purifying box is arrangedabove the sediment scraper, and negative ion poles are fixedly connected to the middle portion of the ion purifying box. The upper ends of the negative ion poles are fixedly connected with ionizationrods, and deposition storage bins are fixedly connected to the inner walls of the left side and the lower side of the ion purifying box. The upper left inner wall of the ion purifying box is fixedly connected with positive charge poles, and adsorption strips are fixedly connected to the outer sides of the positive charge poles. A drying box is arranged on the right side of the ion purifying box, and the left end of a U-shaped tube is fixedly connected with the air guide duct. The right end of the U-shaped tube is fixedly connected with an exhaust pipe, and a small electromotor and the ionization rods are electrically connected with an external power source. The multi-stage air purification device has the advantages of low consumption, high efficiency, multi-stage thorough purification, simple operation and no secondary pollution.

Owner:SHANDONG BOCHEN HYDRAULIC MASCH CO LTD

A kind of air purification equipment for factory

ActiveCN111365777BAvoid cloggingEasy to shake offDucting arrangementsMechanical apparatusHazardous substanceProcess engineering

The present invention relates to the field of air purification, specifically an air purification equipment used in factories, including a base, a support rod, a mounting platform, a pipe mechanism, a purification mechanism, a feeding mechanism, a humidification mechanism, a filter element mechanism and a fan body; Make the purification mechanism rotate inside the pipe mechanism, so that it is convenient to shake off a large amount of impurities adsorbed for the first time, so as to prevent the purification mechanism from being blocked; under the rotation of the purification mechanism, the feeding mechanism can be automatically cleaned during use. Continuously add some decomposing agents of harmful substances to the filter element inside the pipe-passing mechanism, so that the equipment has a better purification effect on harmful components in the gas; by rotating the humidifying mechanism, with the cooperation of the pipe-passing mechanism, it is convenient to adjust the after-filtering The humidity of the gas avoids the impact of dry air on production; by setting the filter element mechanism in the middle of the inner cavity of the pipe mechanism, and through the cooperation with the humidification mechanism, it is convenient to quickly replace the filter element in the equipment.

Owner:南通安强工程科技有限公司

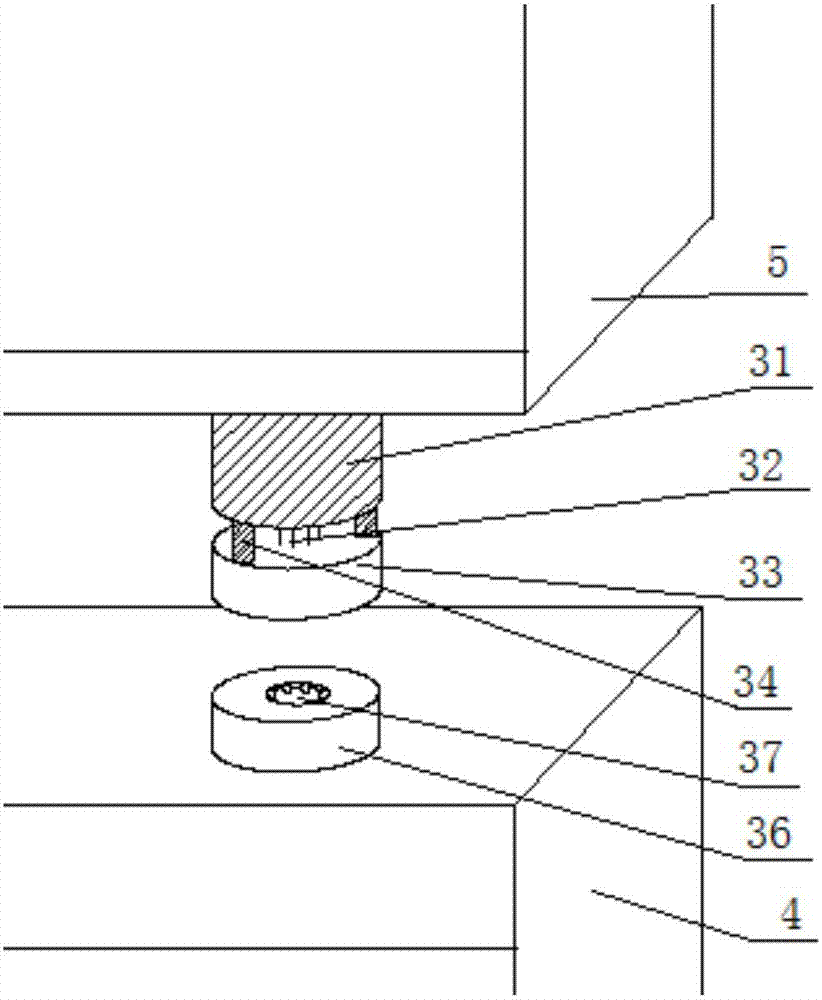

Automatic displacement production device of silent bearing cage

ActiveCN105107993BAchieve shiftReduce breakage rateShaping toolsPerforating toolsHydraulic cylinderPunching

The invention provides an automatic shifting producing device for a silent bearing retainer. The device comprises a feeding assembly, a shifting assembly, a forming die, a shaping die and a punching die, wherein the feeding assembly comprises a feeding hydraulic cylinder, a position fixing plate and a pushing plate; the shifting assembly comprises a first transverse guide rod, a second transverse guide rod, a left longitudinal guide rod, a right longitudinal guide rod, a transverse returning spring and a longitudinal returning spring; the forming die comprises an upper forming die and a lower forming die; the shaping die comprises an upper shaping die and a lower shaping die; the punching die comprises an upper punching die and a lower punching die; the upper punching die comprises a punching propping plate, punching pins and a guide plate, wherein the punching pins are arranged as a circle; a plurality of guide holes through which the punching pins pass are formed in the guide plate; a circular clamping groove is formed in the bottom part of the guide plate; a circular supporting groove for storing the silent bearing retainer is formed in the top part of the lower punching die. The device is reasonable in structural design, enables automatic shifting of a workpiece in processing, is high in processing accuracy, produces few wastes, and is beneficial for production and application.

Owner:宁波优斯凯精密机械有限公司

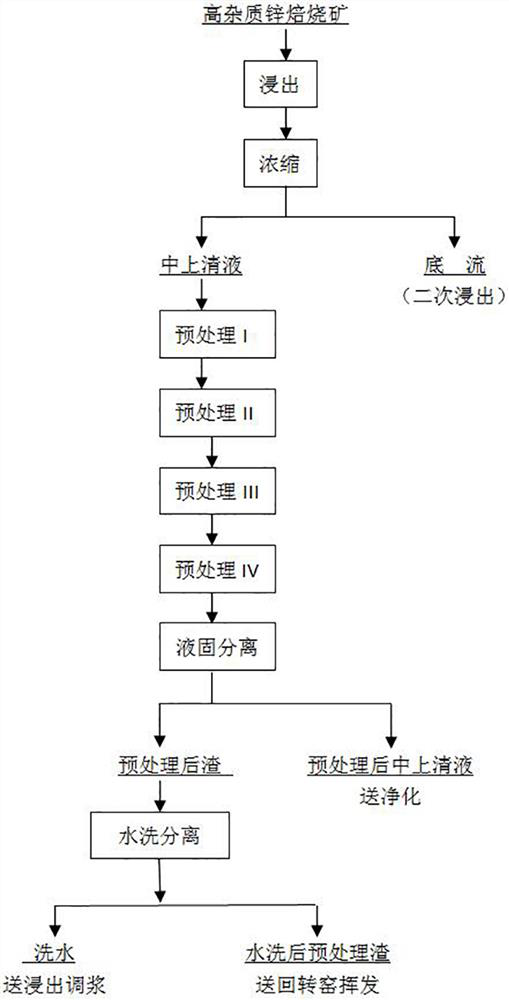

A pretreatment method for purifying supernatant impurities in zinc hydrometallurgy

The invention discloses a pretreatment method for purifying impurities in the supernatant liquid in zinc hydrometallurgy, which comprises adding manganese powder into the acidic leaching pulp of zinc hydrometallurgy for leaching and concentrating; introducing the obtained supernatant liquid with high impurities into buffer tank I And add ferrous sulfate to fully mix and dissolve; import the mixed and dissolved solution into buffer tank II and add hydrogen peroxide to fully mix and undergo a chemical reaction; introduce the mixed and chemically reacted solution into buffer tank III and add milk of lime to adjust the acidity of the solution; The solution with adjusted acidity is introduced into the buffer tank IV, and silicon purification and filter performance improver are added; the treated solution is input into the storage tank with a stirrer, and the liquid and solid are separated while stirring to obtain the pretreated supernatant and the pretreated scum. The present invention adopts the method of combining chemistry and physics to pretreat the supernatant liquid with high impurities leached from high-impurity raw materials of zinc hydrometallurgy, realize the opening of harmful impurities and suspended matter in advance, and reduce the pressure and pressure of directly using zinc powder for replacement and purification. Zinc powder is saved.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com