Filtering device for producing water body modifier

A technology of water conditioner and filtration device, which is applied in the fields of filtration and separation, moving filter element filter, separation method, etc., can solve the problems of accumulation of water conditioner, affecting the screening effect of water conditioner, affecting the production of finished products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

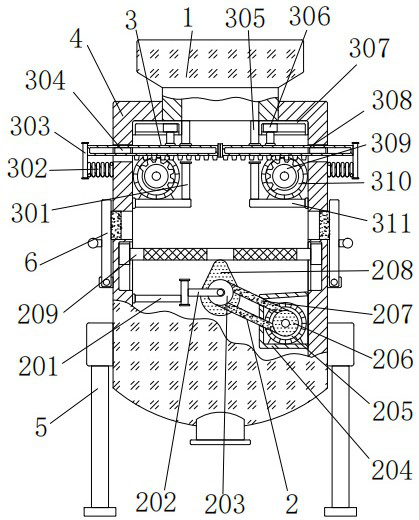

[0030] A filter device for the production of a water body improver, comprising a feed port 1, the bottom of the feed port 1 is connected to a box body 4, the left and right sides of the box body 4 are fixedly connected with long rods 5, and the long rods 5 are connected to the box body 4 To play a supporting role, the protrusions on the left and right sides of the box body 4 are rotatably connected to the bottom of the front end of the vertical plate 6 through pin shafts. Clearance fit on the inner wall of the opening.

Embodiment 2

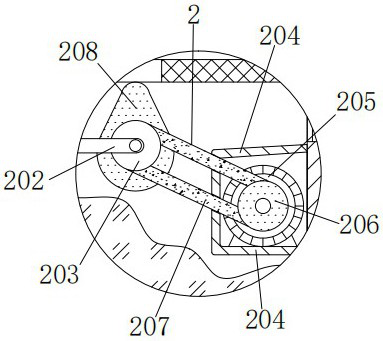

[0032] As an option, see figure 1 , 2 And 5, the filter device for water body improving agent production, the inboard of casing 4 is provided with screening device 2, and screening device 2 comprises straight rod 201, curved rod 202, first sheave 203, square box 204, first motor 205 , second sheave 206, belt 207, circular plate 208 and filter screen 209, the right end of square box 204 is fixedly connected with the bottom right side of the inner wall of casing 4, and the bottom of the inner wall of square box 204 is fixedly connected with the bottom of the first motor 205 , the model of the first motor 205 is ECMA-E11320RS, the front of the first motor 205 is provided with a second sheave 206, the rear end of the second sheave 206 is fixedly connected with the output end of the first motor 205, the first motor 205 The output shaft and the second sheave 206 are vertically arranged. When the first motor 205 starts to work, the first motor 205 can drive the second sheave 206 to ...

Embodiment 3

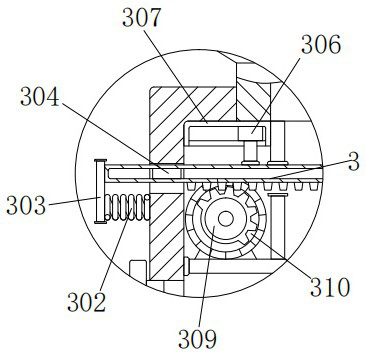

[0035] As an option, see figure 1 , 3, 4 and 6, the filter device for water body improver production, the top of the inner cavity of the box body 4 is provided with a material control device 3, the material control device 3 includes a short plate 301, a spring 302, a straight plate 303, a square 304, a long block 305, a slide Block 306, slot plate 307, rack 308, gear 309, second motor 310 and horizontal plate 311, the left end of horizontal plate 311 is fixedly connected with the upper left side of the inner wall of box body 4, and the top of horizontal plate 311 is provided with short plate 301 , the bottom of the short plate 301 is fixedly connected to the top right side of the horizontal plate 311, the second motor 310 is arranged above the horizontal plate 311, the model of the second motor 310 is SM80-D601930, the bottom of the second motor 310 is connected to the horizontal plate 311 The left side of the top of the second motor 310 is fixedly connected, the front of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com