Patents

Literature

239results about How to "Achieve sieving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

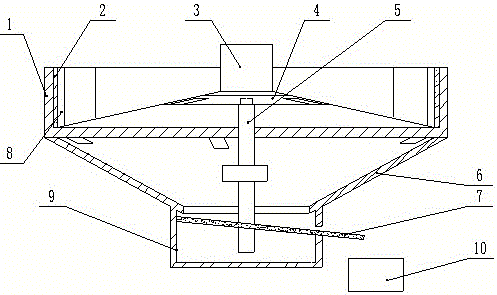

Coin separating device

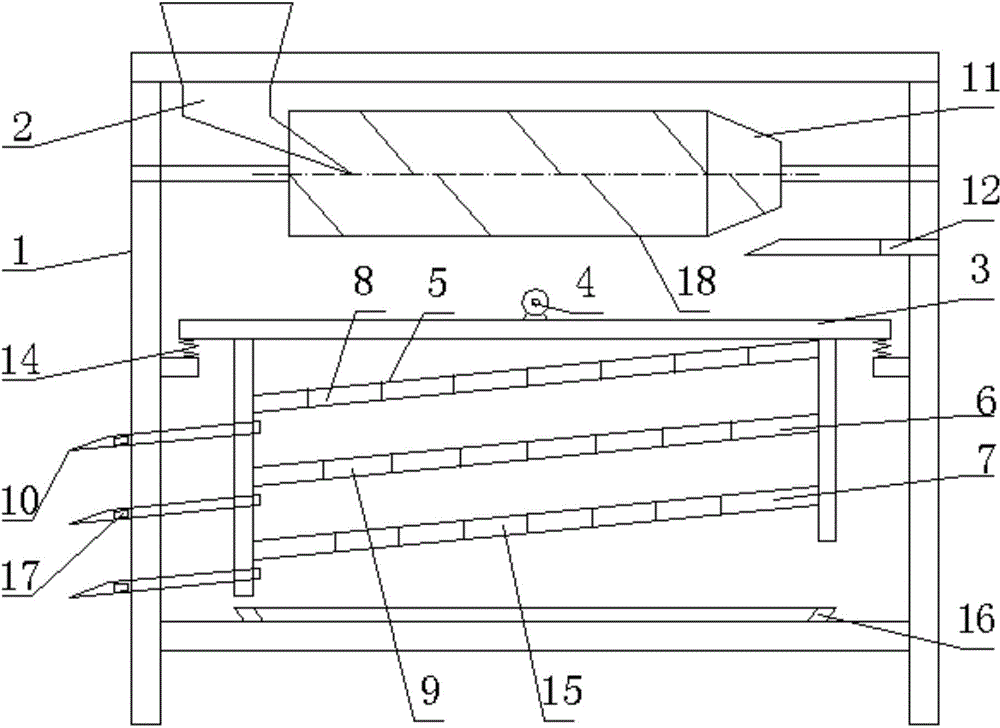

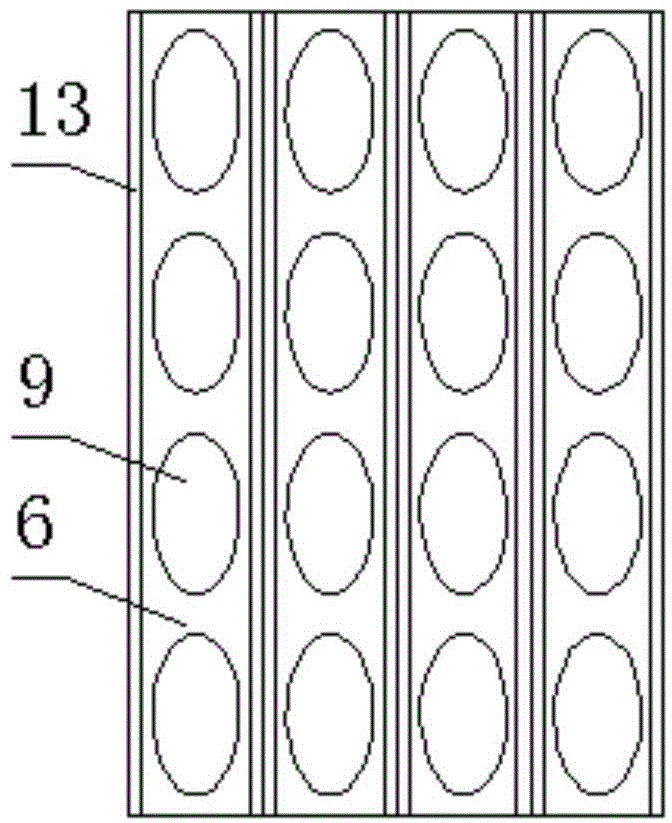

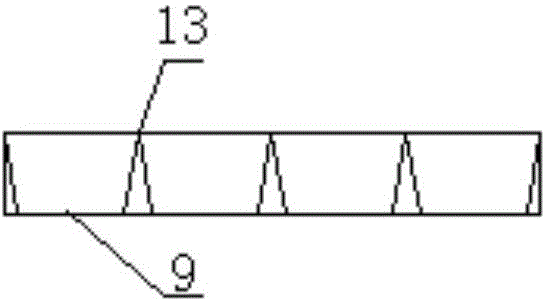

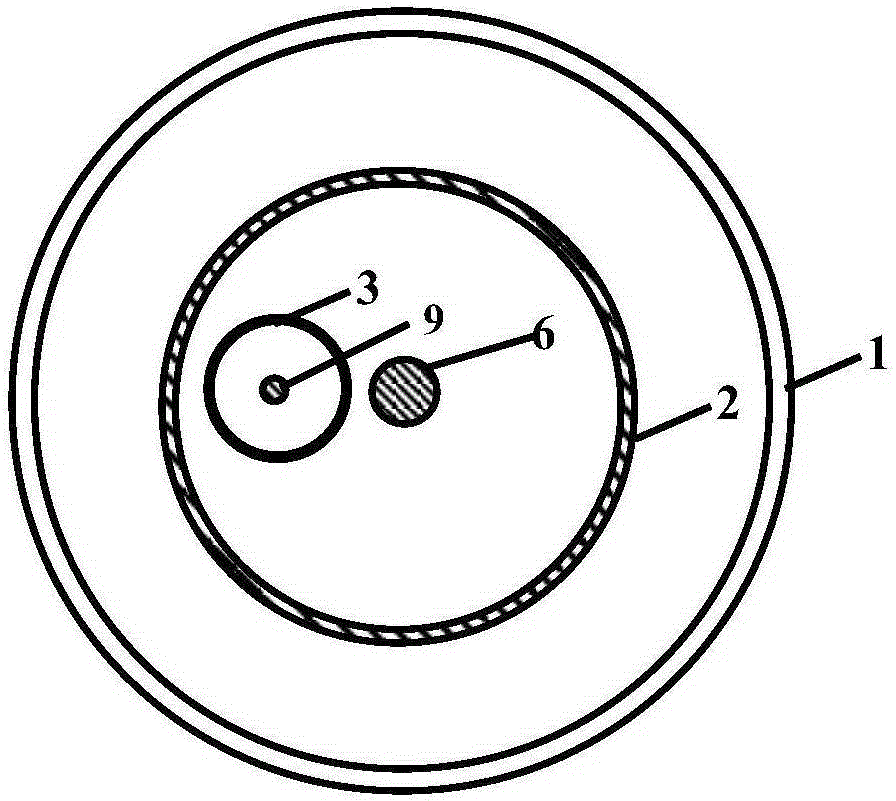

The invention relates to coin sorting equipment, and discloses a coin separating device. The coin separating device comprises a casing (1), wherein a coin inlet (2) is formed in the top of the casing (1); a baffle rack (3) is arranged inside the casing (1); a vibrating motor (4) is connected into the baffle rack (3); the end part of the baffle rack (3) is connected with the casing (1) through springs (14); a first baffle (5), a second baffle (6) and a third baffle (7) are perpendicularly lapped on the baffle rack (3); flow guide ridges (13) are arranged on the bottom surface of each of the first baffle (5) and the second baffle (6); first coin separating holes (8) are formed in the bottom of the first baffle (5); second coin separating holes (9) are formed in the bottom of the second baffle (6). The coin separating device is small and exquisite in size and compact in structure, accurate and efficient screen separation of coins in the different currency value is realized through vibrating screen separation of the coins in different size, the whole screen separation process does not need too much manual operation, and the degree of mechanization and automation is high.

Owner:HANGZHOU NOAHS ARK NETWORK TECH

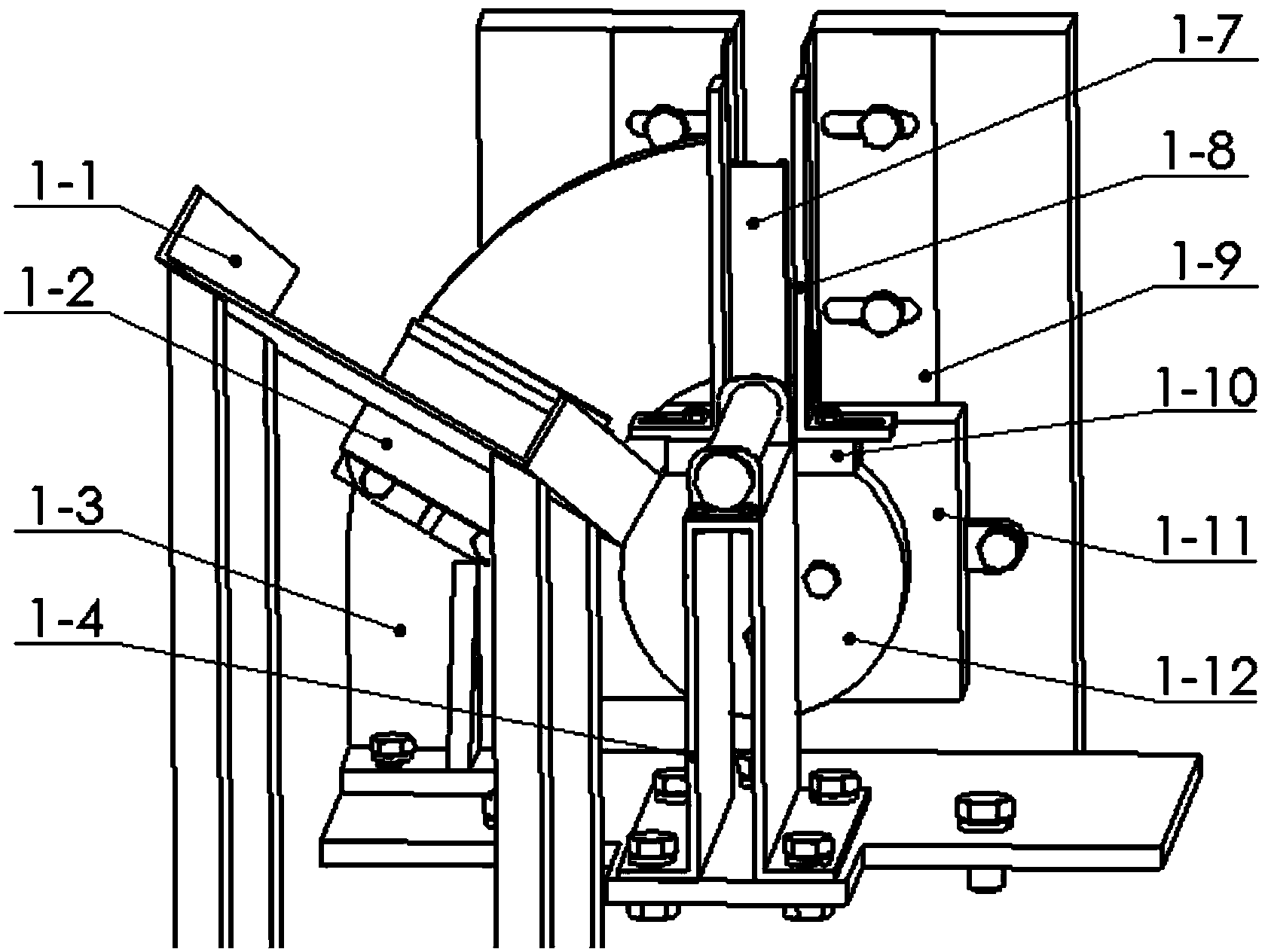

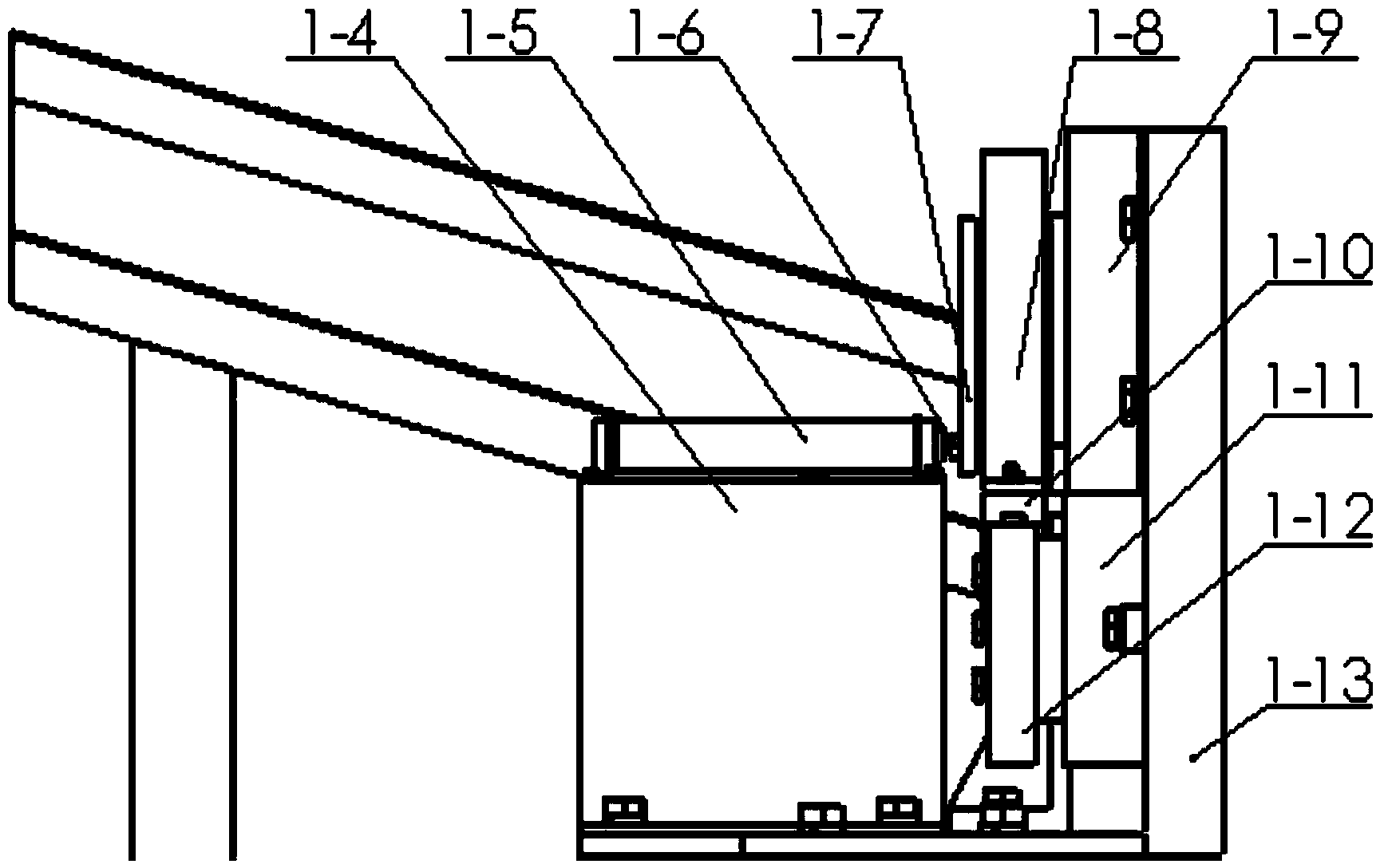

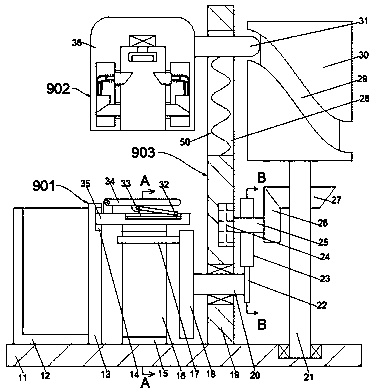

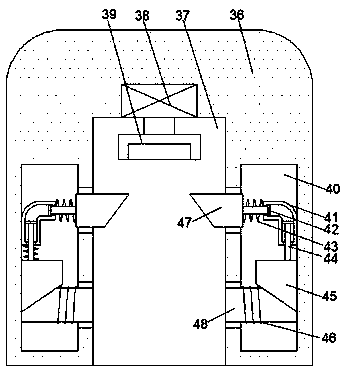

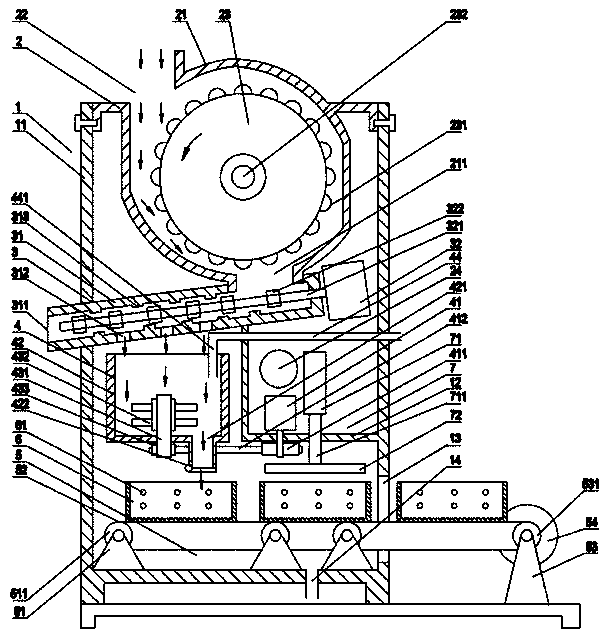

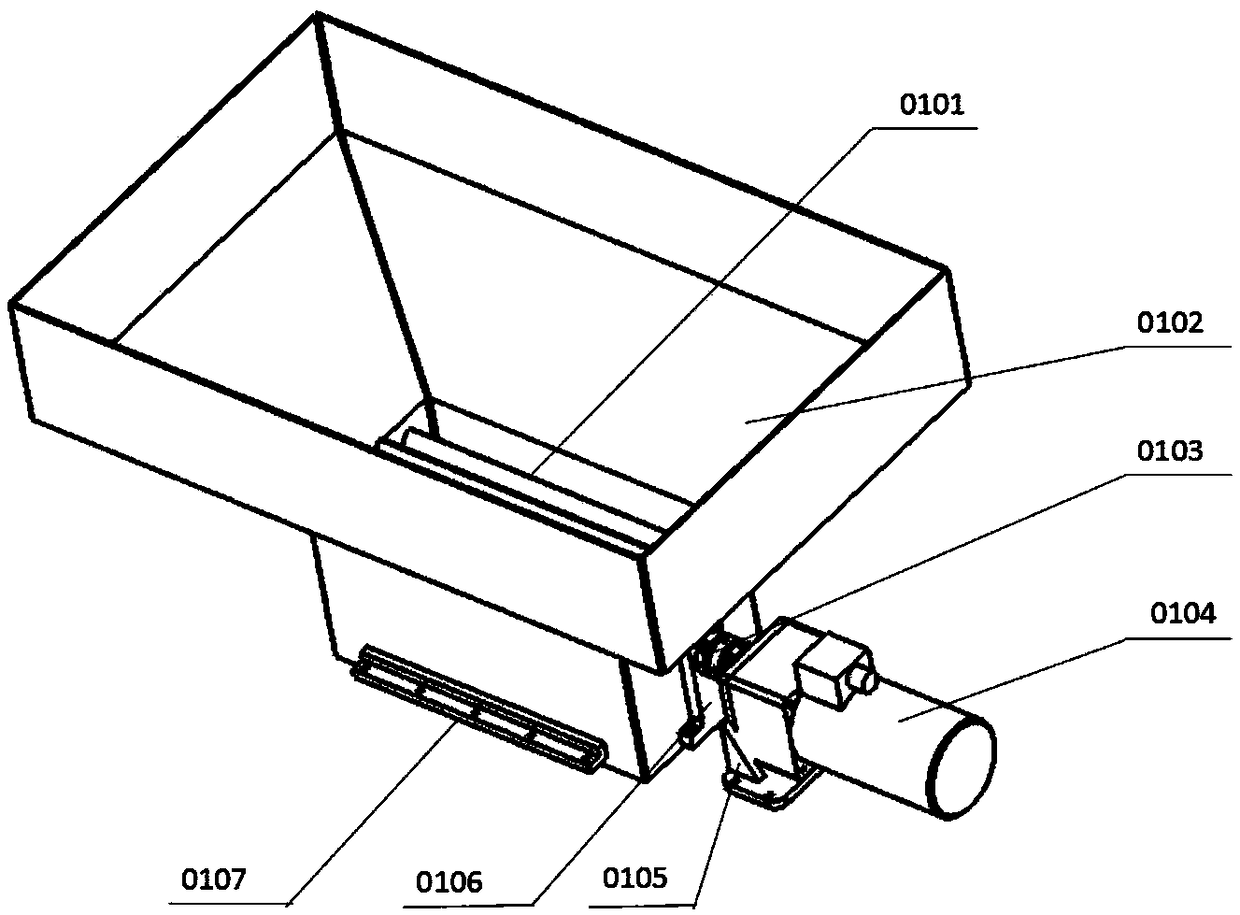

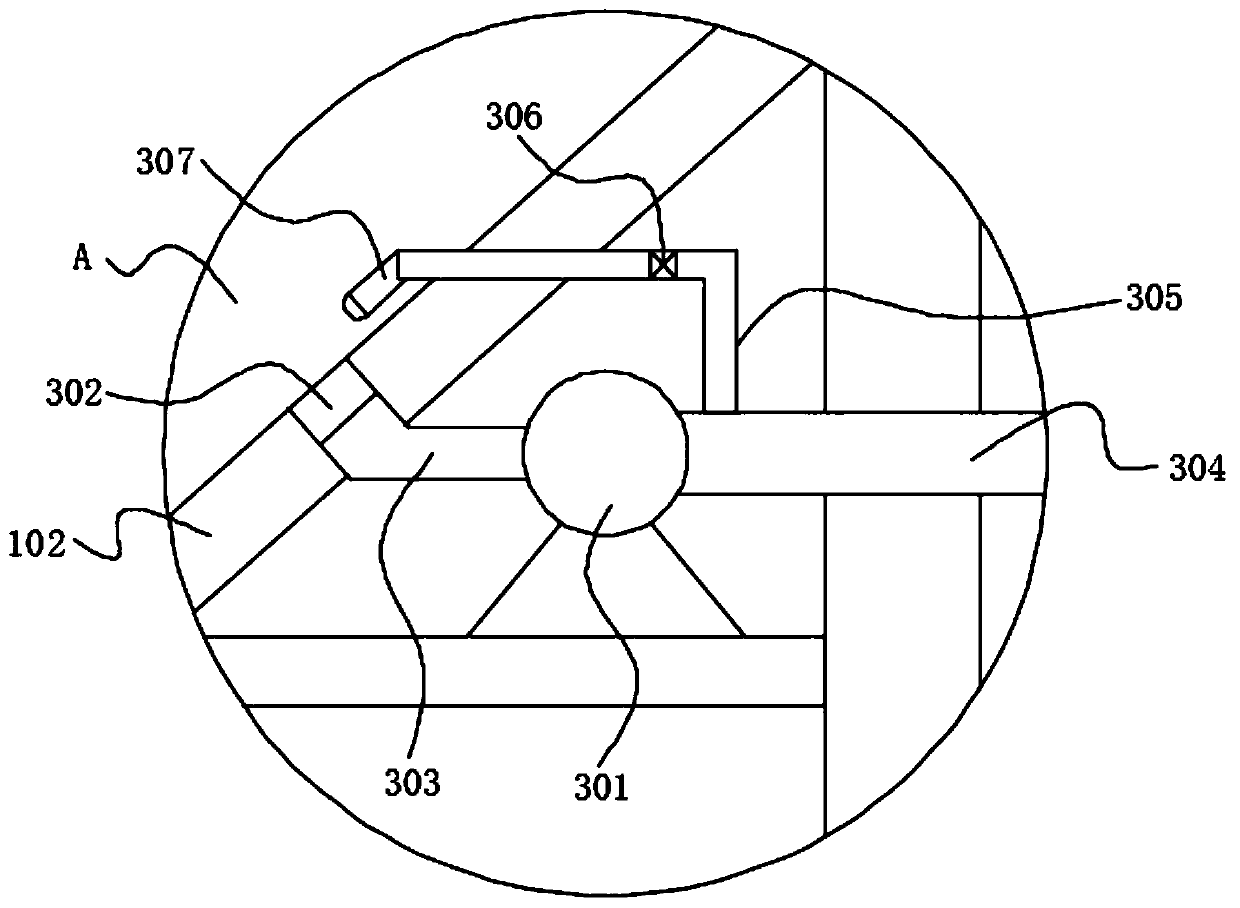

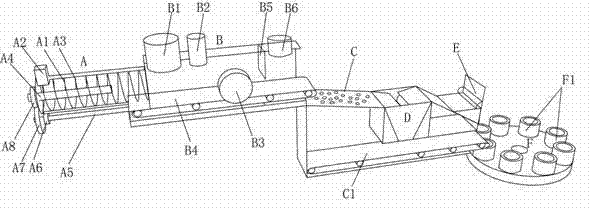

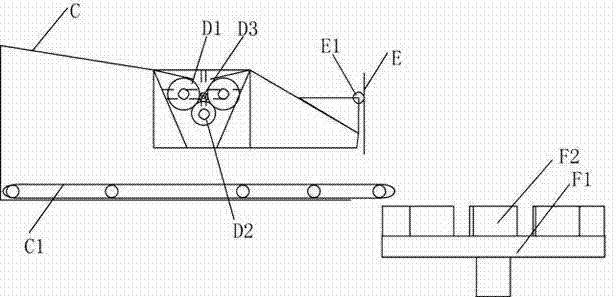

Automatic detection and screening device for hardness of bolt fastening piece

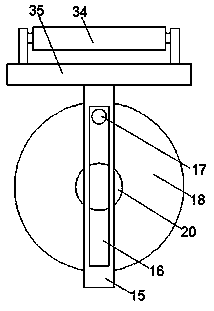

The invention discloses an automatic detection and screening device for the hardness of a bolt fastening piece. The automatic detection and screening device comprises a charging part, a rotary table, a workpiece pressing part, a discharging part, a hardness meter and a table, wherein the charging part is fixedly arranged on a swinging platform mounting base; the swinging platform mounting base and the rotary table are mounted on a base of the hardness meter. The continuous and reciprocating motion of the charging part, the workpiece pressing part, the rotary table, the discharging part and the hardness meter realizes continuous multi-point hardness detection and screening of a bolt. According to the automatic detection and screening device, a movable part is driven by an air cylinder and an electromagnet; the control manner is simple and the work is reliable and easy to realize; an adjusting bolt on a driving piece, a gasket on a spring material stopping part, a workpiece positioning sleeve and a rotary baffle are adjusted simply so as to realize hardness detection of the bolts with different specifications and the flexibility is good; meanwhile, the multi-point hardness detection can be carried out on the bolt by controlling the rotary angle of the rotary table so as to meet the requirements of the use of the hardness meter and the hardness detection; the charging part and the discharging part are mounted on a hardness meter worktable and the structure space of the whole machine is compact.

Owner:SHANGHAI JIAO TONG UNIV

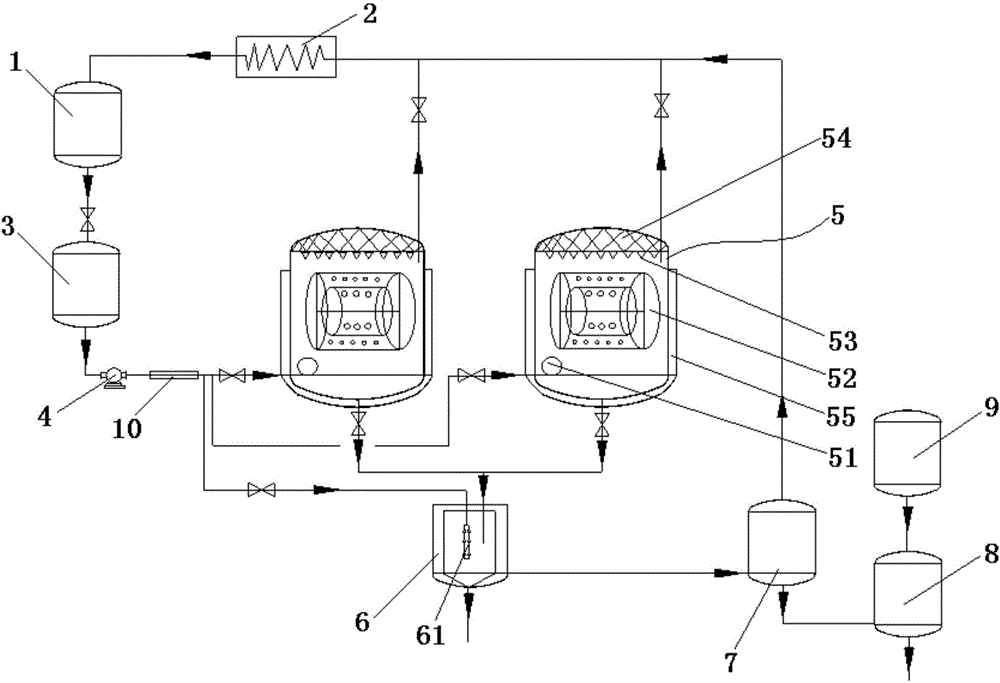

Asphalt pavement material recycling device and asphalt pavement material recycling method

The invention relates to an asphalt pavement material recycling device and an asphalt pavement material recycling method. The asphalt pavement material recycling device is characterized by comprising a solvent storage tank, wherein the inlet of the solvent storage tank is connected with a condenser by a pipeline, the outlet of the solvent storage tank is connected with the inlet of a solvent tank by a pipeline, the outlet of the solvent tank is connected with the inlet of a solvent pump by a pipeline, the outlet of the solvent pump is connected with the inlets of two washing chambers and a flushing device arranged in a high-speed centrifugal machine by three parallel-connected pipelines respectively, the outlet pipelines of two washing chambers are connected with the inlet of the high-speed centrifugal machine, the outlet of the high-speed centrifugal machine is connected with the inlet of a solvent evaporating pot by a pipeline, the outlet of the solvent evaporating pot is connected with one inlet of a blending tank by a pipeline, the other outlet of the solvent evaporating pot and pipelines of steam outlets at the tops of the two washing chambers are converged by pipelines so as to be connected with the condenser, and the other inlet of the blending tank is connected with a fresh asphalt storage tank by a pipeline. According to the asphalt pavement material recycling device and the asphalt pavement material recycling method, aggregates and old asphalts in the old asphalt mixture can be screened and recycled, and besides, a secondary flushing device is arranged, so that the mixture can be effectively separated and filtered.

Owner:CHINA NAT OFFSHORE OIL CORP +3

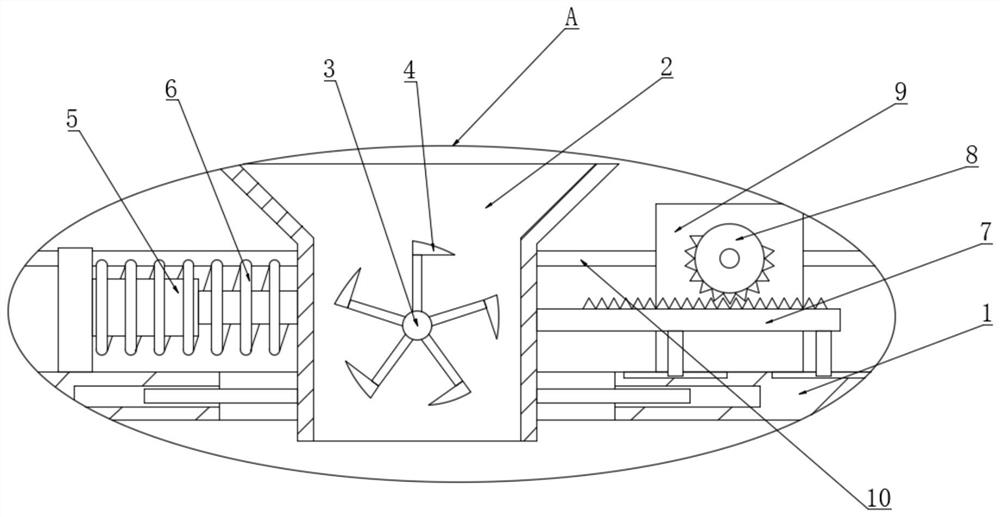

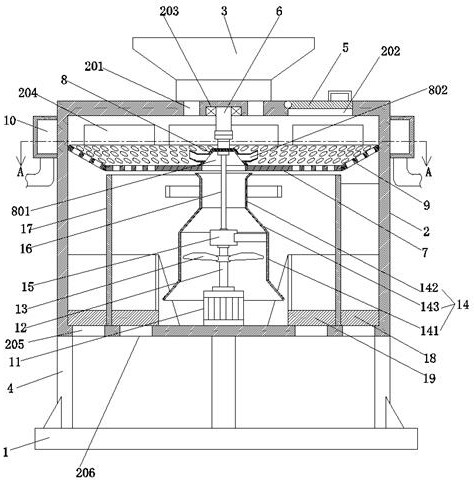

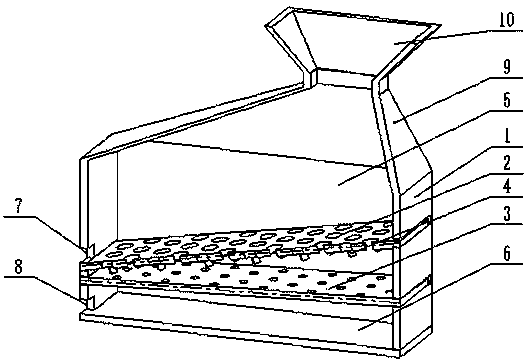

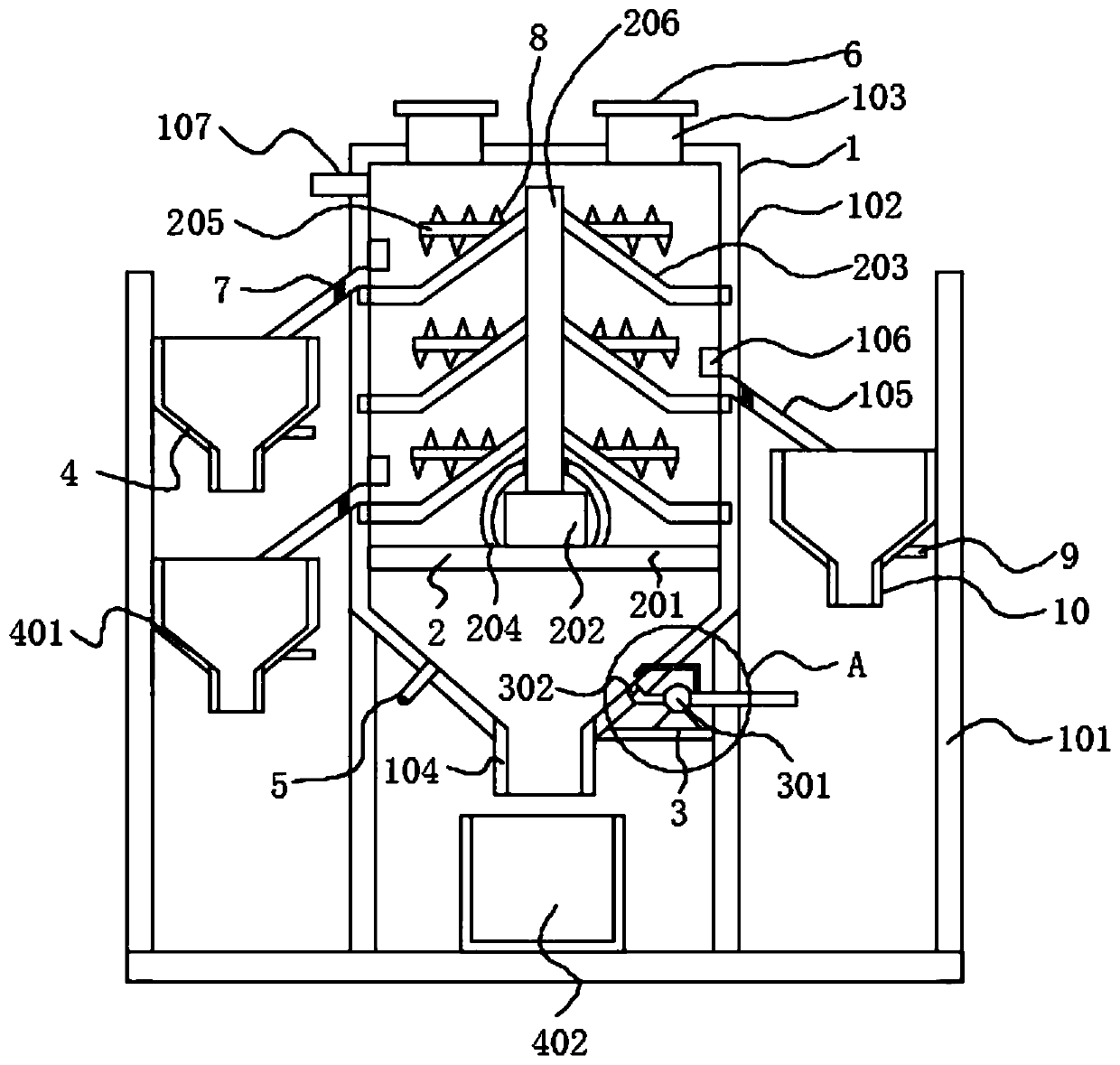

Efficient mixing device for water-soluble fertilizer processing

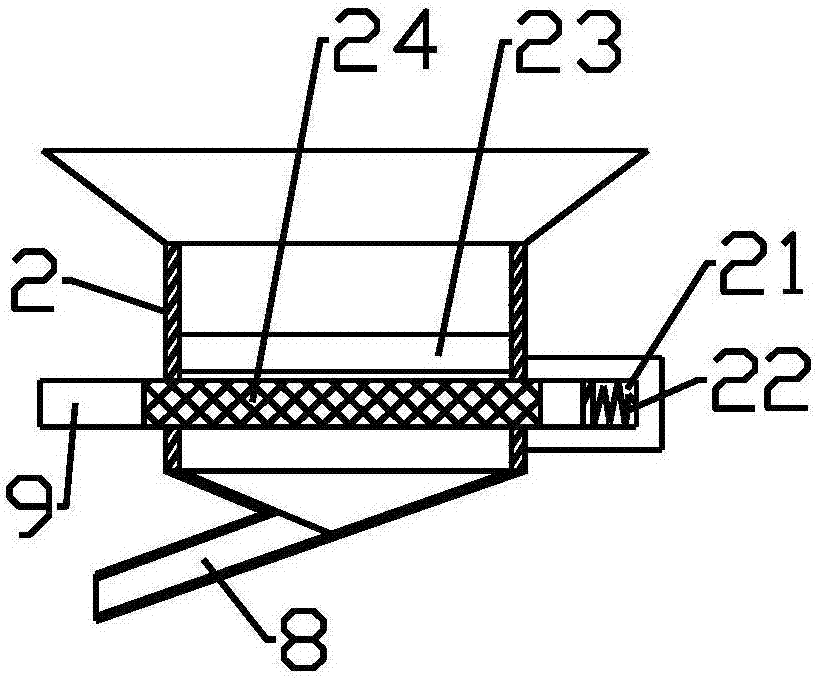

InactiveCN107224909AAchieving stirringAchieve sievingSievingTransportation and packagingPush pullEngineering

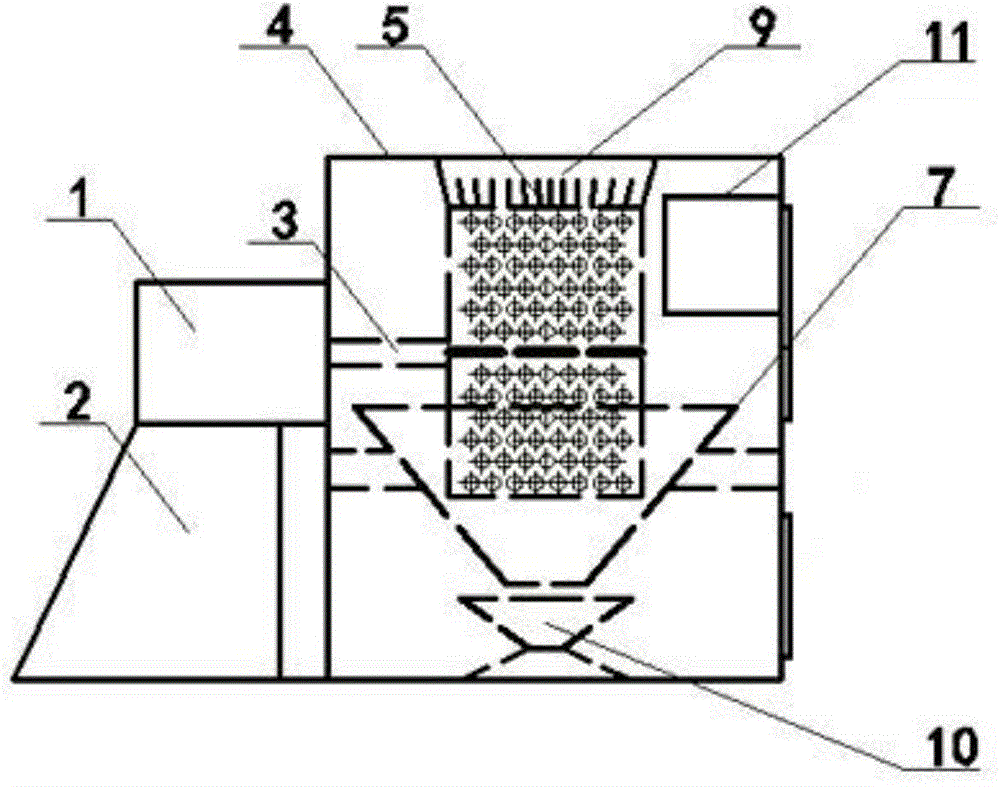

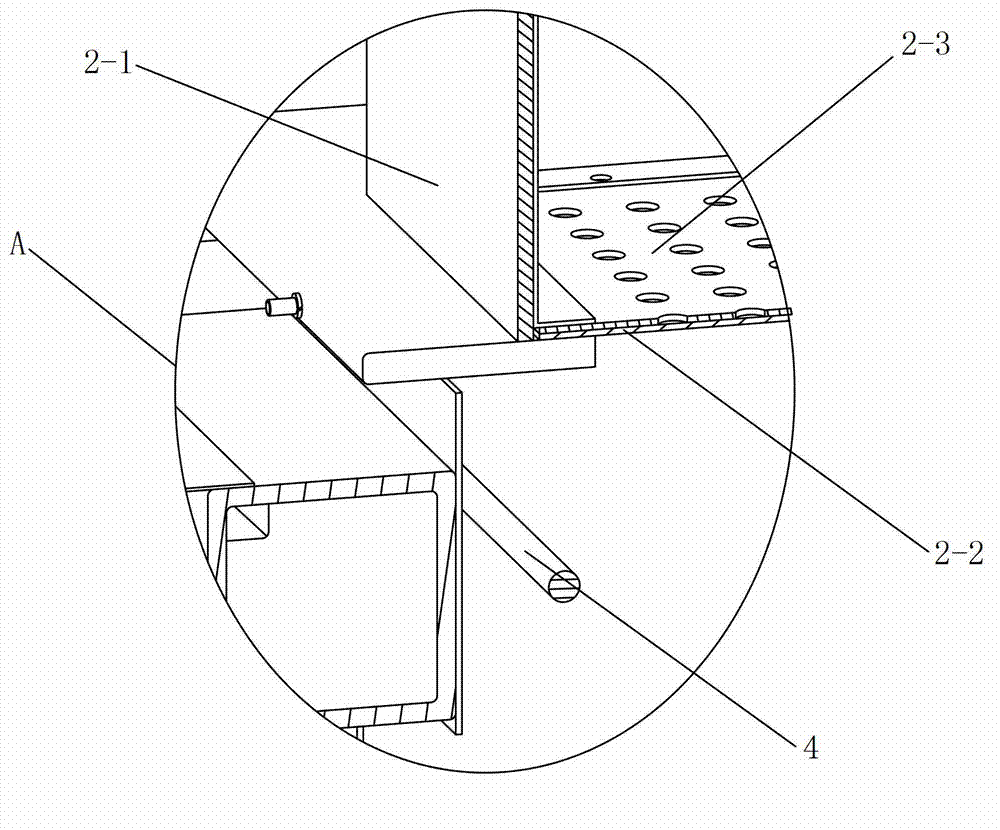

The invention discloses an efficient mixing device for water-soluble fertilizer processing. The efficient mixing device comprises a mixing box, feeding boxes and guide sliding sleeves, wherein a rotating rod is rotationally arranged in an inner cavity of the mixing box; a spiral stirring rod is fixedly arranged at the outer ring of the rotating rod; a stirring blade is arranged and erected on the bottom end of the rotating rod; two guide sliding sleeves are symmetrically and fixedly welded and erected on the upper surface of a top plate of the mixing box; guide sliding holes are formed in the guide sliding sleeves; the guide sliding holes are internally connected with push-pull rods in a left-right sliding way; an eccentric wheel is fixedly arranged on the outer ring of the top end of the rotating rod in a sleeving way; an annular guiding sleeve is arranged on the outer ring of the eccentric wheel in a sliding and sleeving way; two mutually-parallel side plates on the annular guiding sleeve are respectively and fixedly arranged on the end parts of the two push-pull rods; the other ends of sieve plates are fixedly connected with the end parts of the push-pull rods. The efficient mixing device disclosed by the invention is simple in structure, convenient in operation, good in dissolution effect of fertilizer granules, fast in dissolution speed and high in transmission efficiency, is energy-saving and environment-friendly and is suitable for being popularized and used.

Owner:汪辉

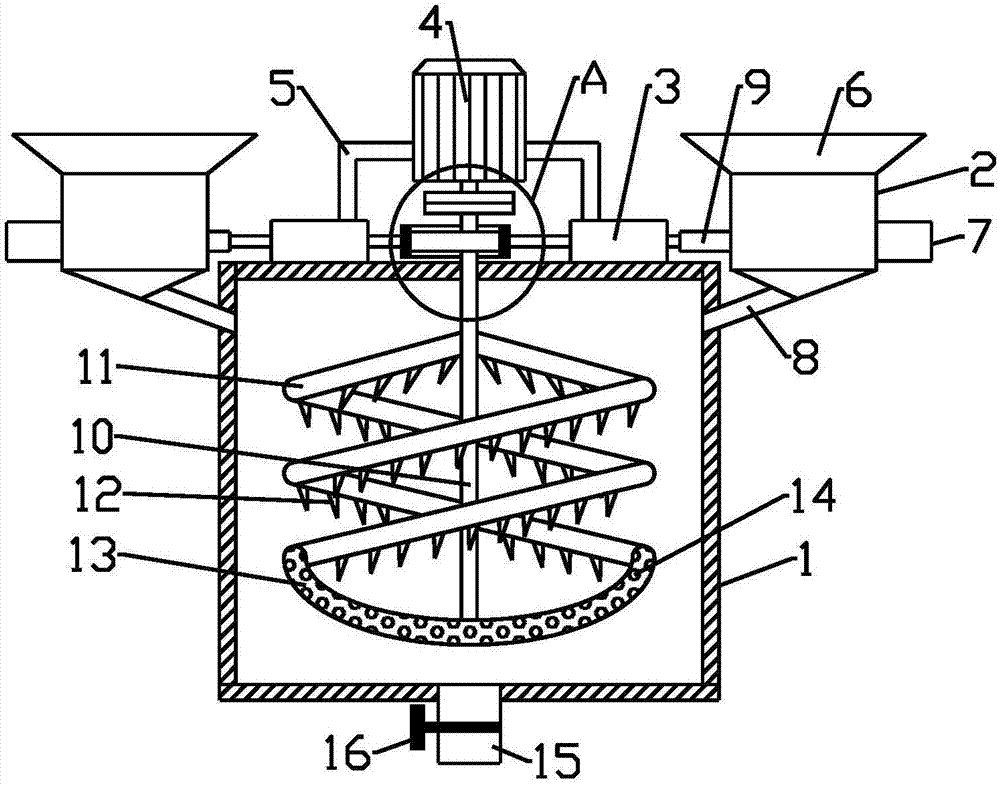

Soil crushing and fertilizer mixing device

InactiveCN112403376AAchieve sievingImprove crushing effectShaking/oscillating/vibrating mixersTransportation and packagingAgricultural scienceSoil mixing

The invention discloses a soil crushing and fertilizer mixing device, belongs to the technical field of soil, solves the problems of poor soil crushing effect and poor fertilizer mixing effect of an existing soil crushing device, and has the technical key points that the soil crushing and fertilizer mixing device comprises a crushing box, soil is placed in a feeding hopper, and a first motor is started to drive the incomplete gear to rotate, so that the feeding hopper moves reciprocatingly; then the stirring turning plate rotates to stir, and the first crushing roller and the second crushing roller rotate to crush; the unscreened soil enters the conveying bin, and the auger blade conveys materials to guide out the soil for continuous crushing; finally, the fertilizer is placed on the thirdscreen to be screened and refined, wherein a crushing cutter on the stirring shaft rotates to stir the fertilizer; finally, a first cam rotates to enable the second screen and the third screen to vibrate and screen, the fertilizer and the soil are mixed and enter the mixing frame, the second motor is started to enable the mixing frame to reciprocate, and the crushing cutter on the threaded sleeverod rotates forwards and backwards to stir and mix. The device has the advantages of being good in soil crushing effect and fertilizer mixing effect.

Owner:袁加衡

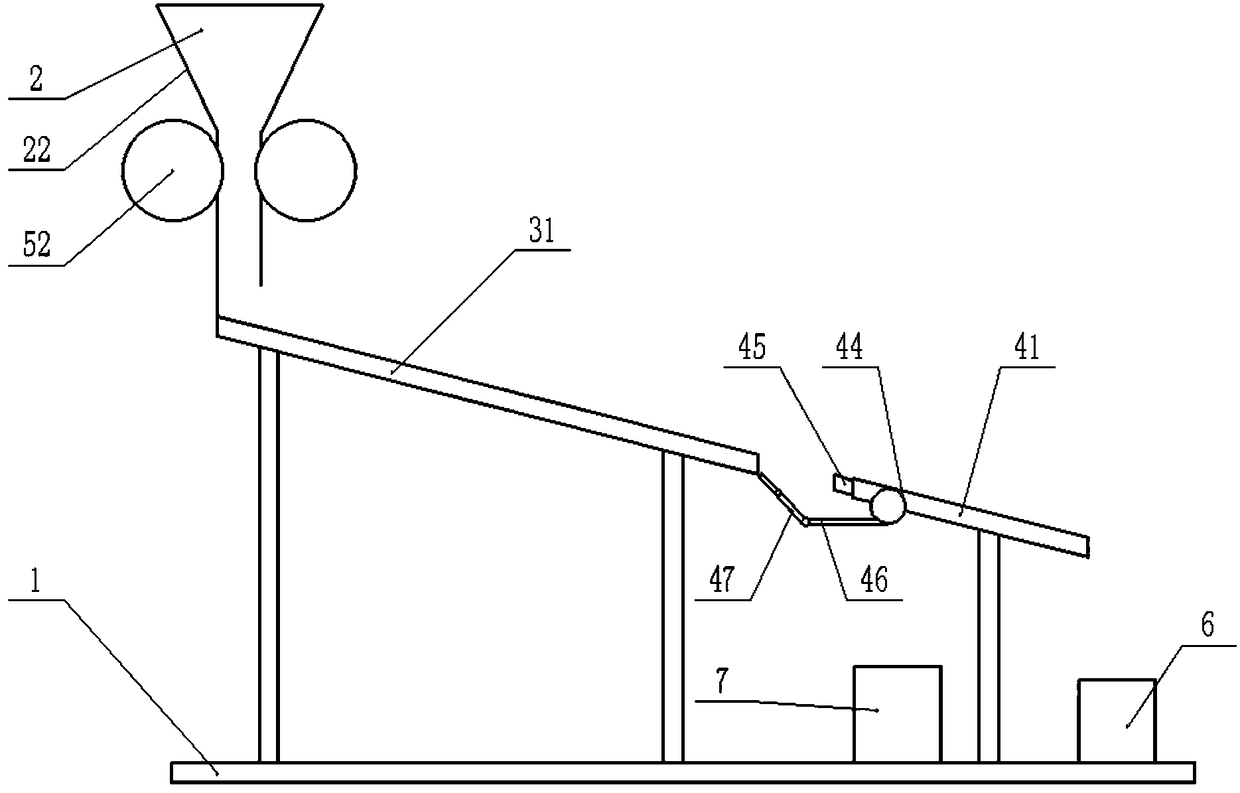

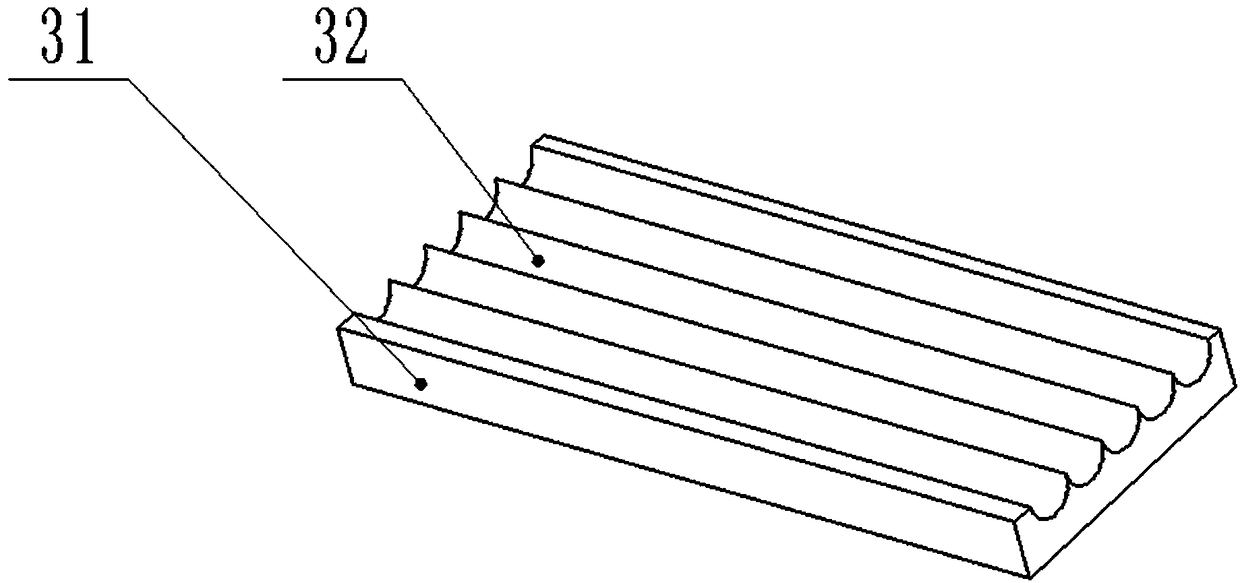

Bio-fuel particle screening device

The invention belongs to the technical field of production devices of bio-fuels, and particularly discloses a bio-fuel particle screening device. The bio-fuel particle screening device comprise a machine frame, a funnel and a first sliding path, the first sliding path communicates with the funnel, a plurality of guiding barrels are arranged on the lower portion of the funnel, and the first slidingpath is provided with a plurality of sliding channels. The machine frame is further provided with a second sliding path aslant, and a gap is reserved between the first sliding path and the second sliding path. The second sliding path is provided with a plurality of toggle mechanisms, the toggle mechanisms comprise cavities, the cavities are internally provided with torsional springs, the torsional springs are provided with a rotary table in a concentric mode, an elastic block is connected to the upper end of the rotary table in a hinged mode, a first pushing plate is connected to the lower end of the rotary table in a hinged mode, the first pushing plate is connected with a second pushing plate in a hinged mode, and the second pushing plate is rotatably connected to the machine frame. Thebio-fuel particle screening device solves the problem of the existence of powders, circular particles and impurities in bio-fuel particles.

Owner:遵义双河生物燃料科技有限公司

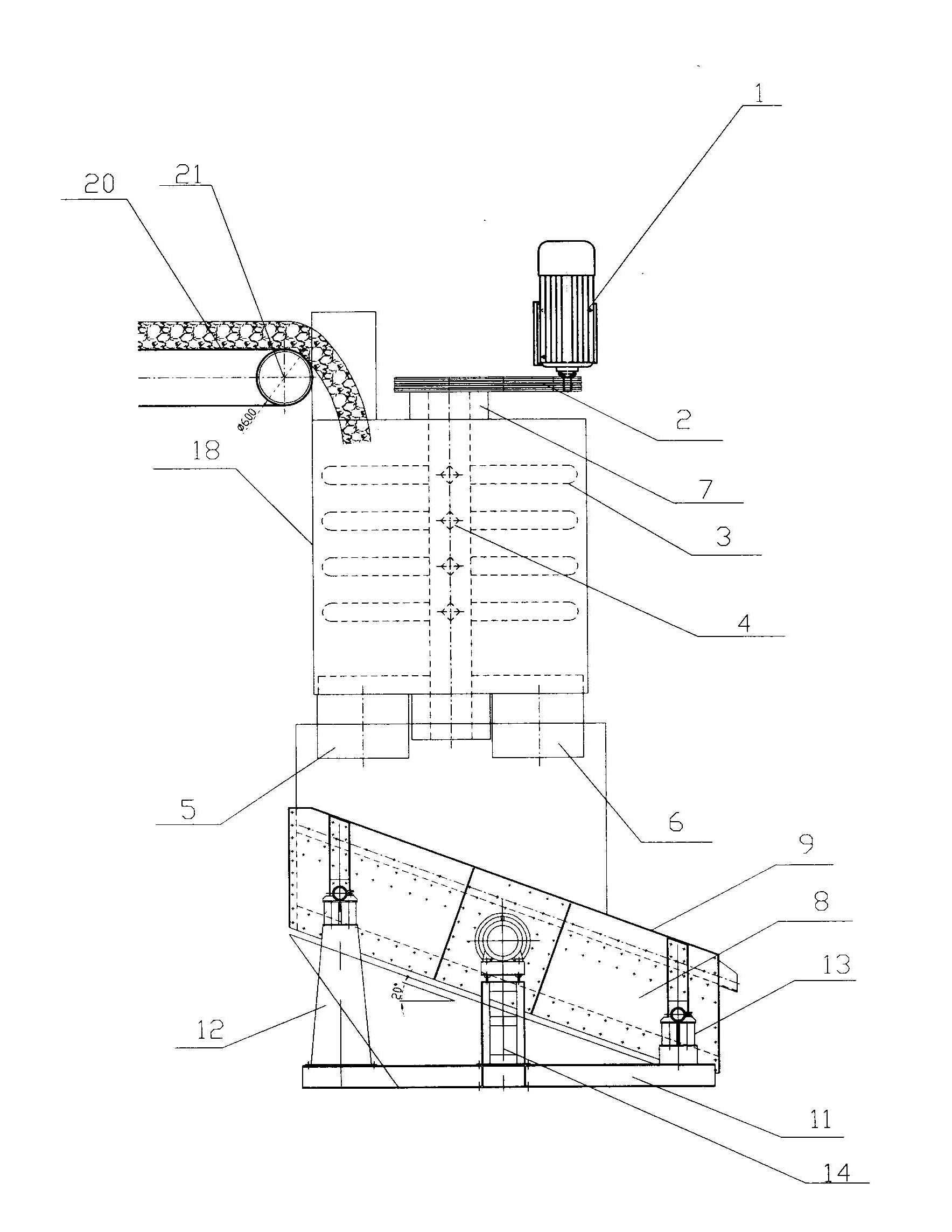

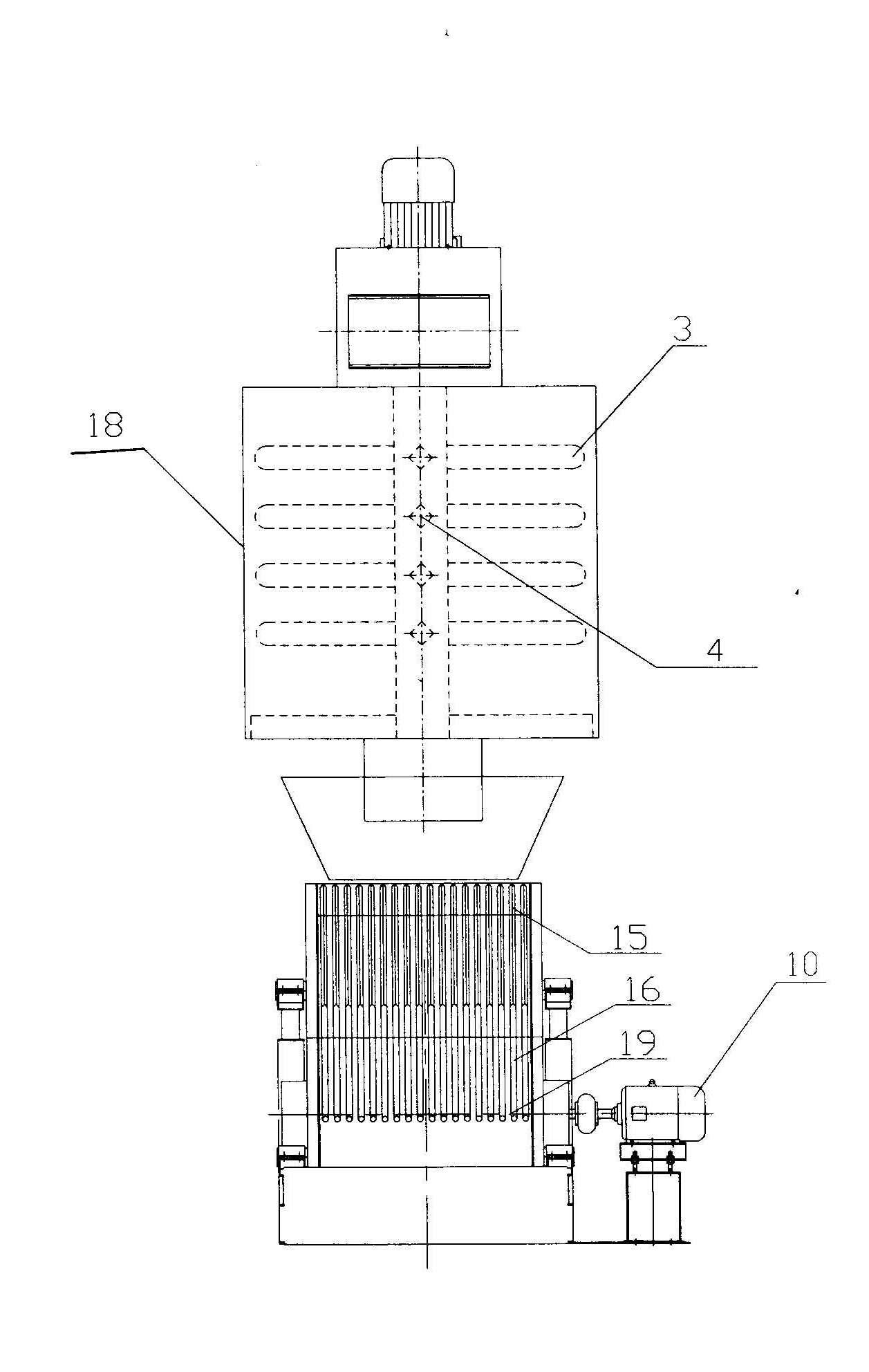

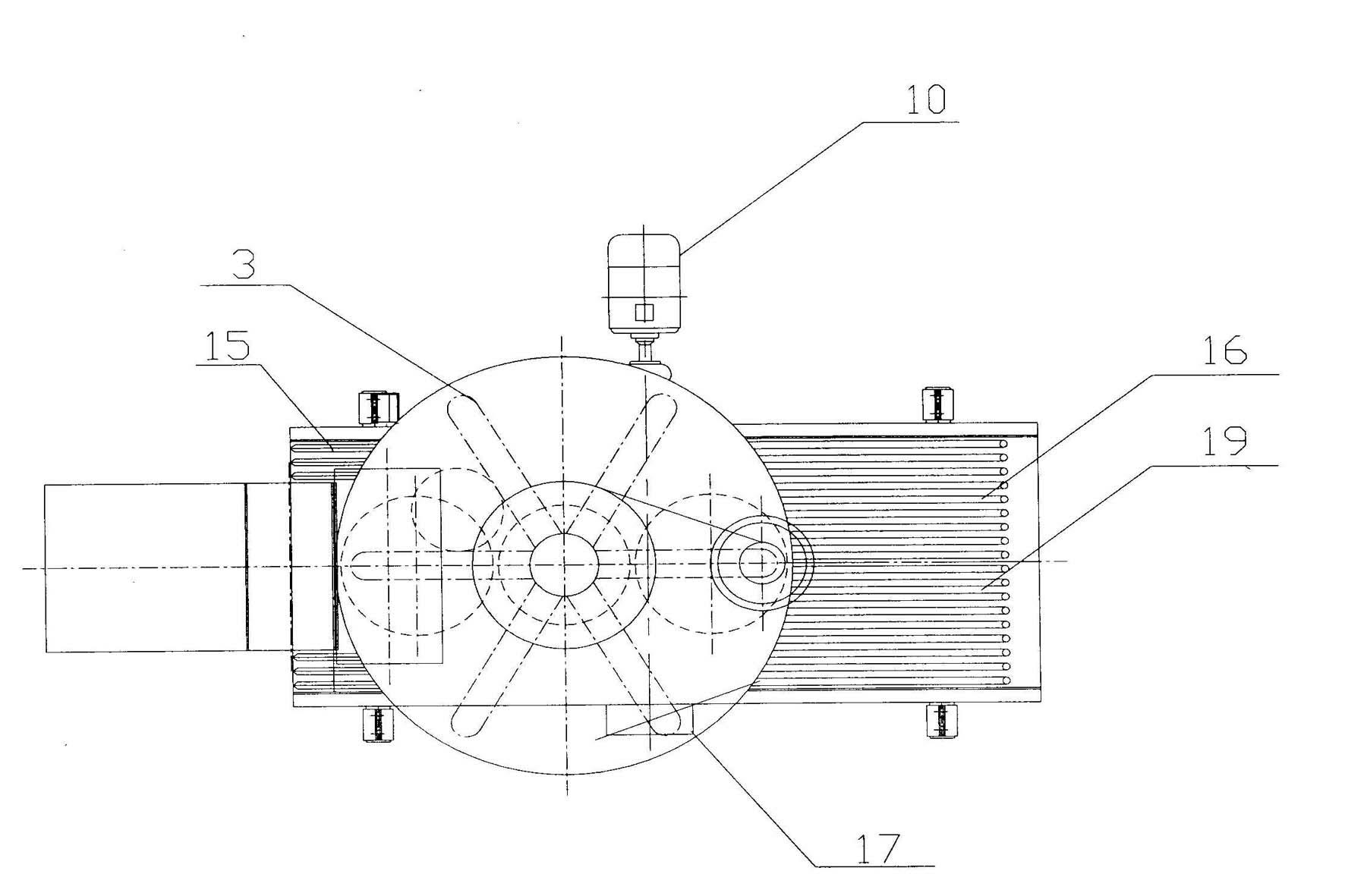

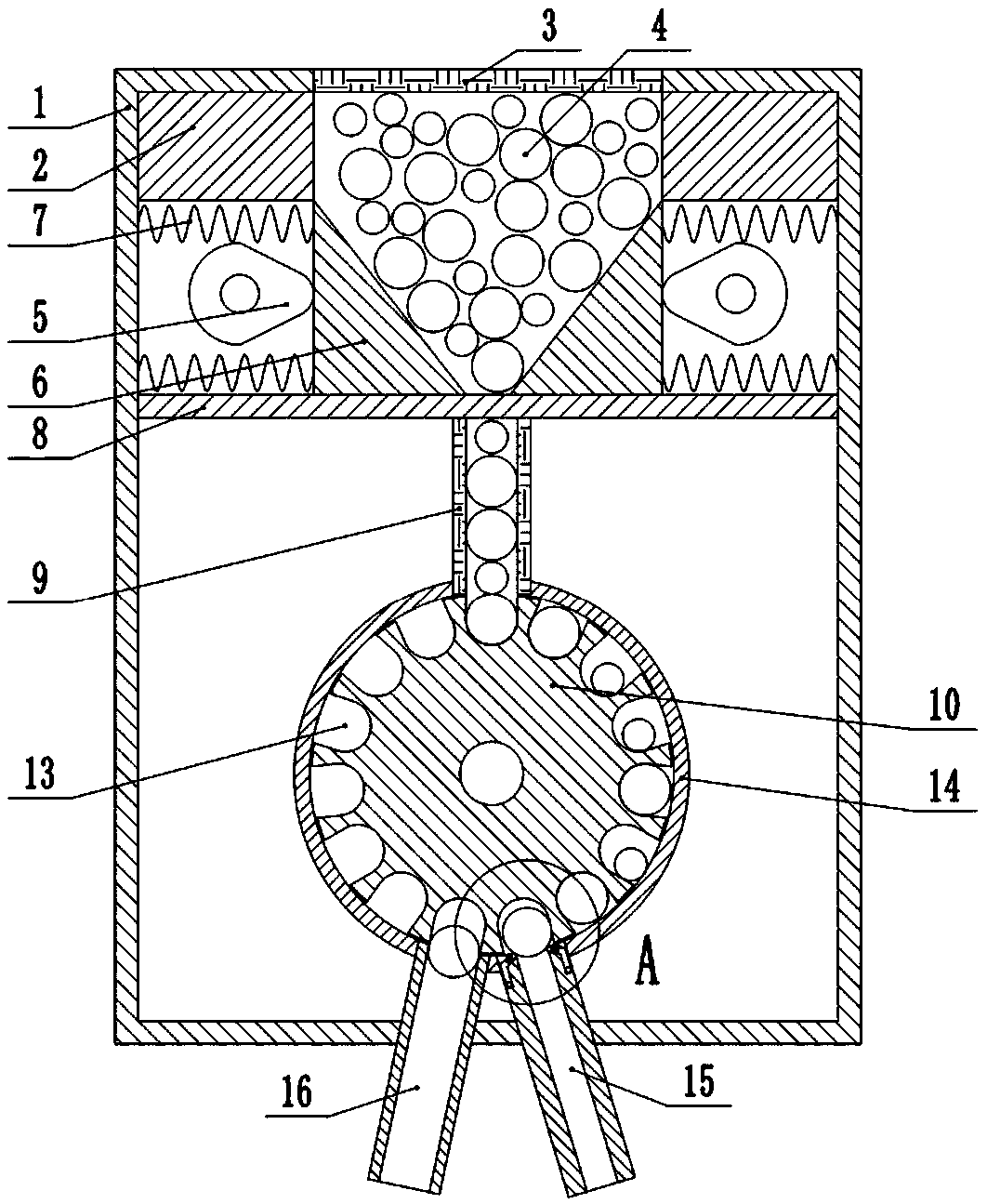

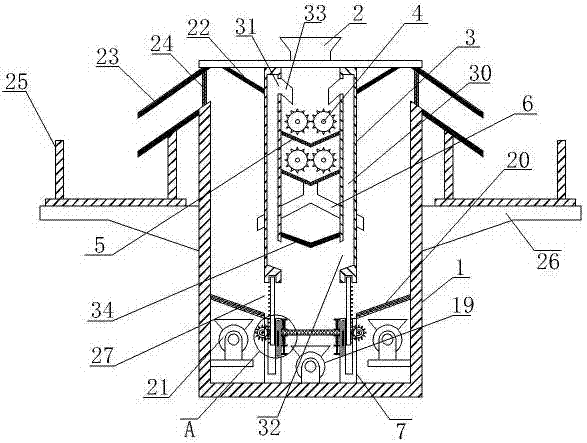

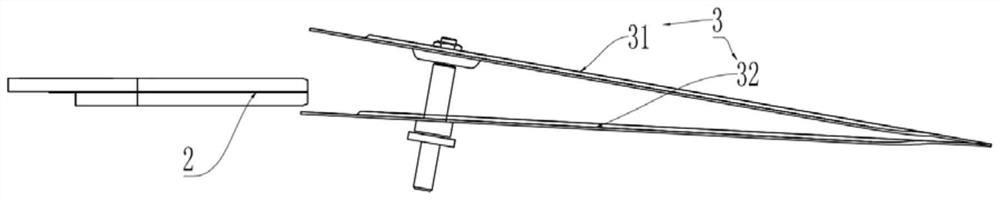

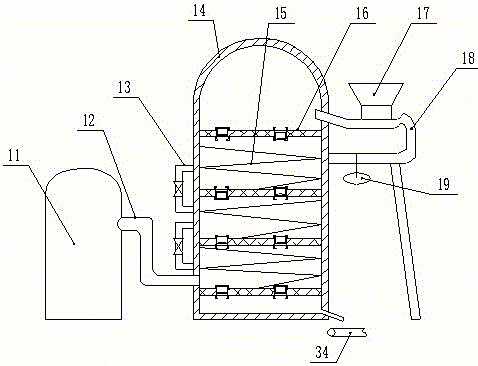

Vertical cylinder type vibration coal and gangue separator

The invention provides a vertical cylinder type vibration coal and gangue separator. The coal and gangue separator comprises a vertical cylinder body, a rotor shaft, a broken rotor, a material outlet, a feeding device and a vibration sieve; the rotor shaft is arranged in the cylinder body in a manner that the rotor shaft is coaxial with the cylinder body, and driven by a power source; the broken rotor is arranged on the rotor shaft and consists of a plurality of layers of impact bars arranged at the periphery of the rotor shaft; the material outlet is formed at the bottom of the cylinder body; the feeding device is arranged on the top of the cylinder body; the vibration sieve is arranged below the material outlet; the vibration sieve comprises a first stander, a middle stander and a second stander which are arranged on a base, and a sieve face obliquely arranged on the standers; the first stander and the second stander are hinged below the front end and the rear end of the sieve face; the middle stander is arranged below the middle part of the sieve face through a vibration shaft; the vibration shaft is combined with a vibration sieve motor through a shaft joint; the sieve face consists of a plurality of fracturing blades and a plurality of grate bars; the fracturing blades are fixed on the grate bars to form the vibration sieve face; and a gap between every two adjacent grate bars forms a sieve hole.

Owner:HENAN POLYTECHNIC UNIV

Glass product sub-packaging mechanism

ActiveCN109530239AReduce the amount of labor operationsAvoid crushingGradingPipeline transportEngineering

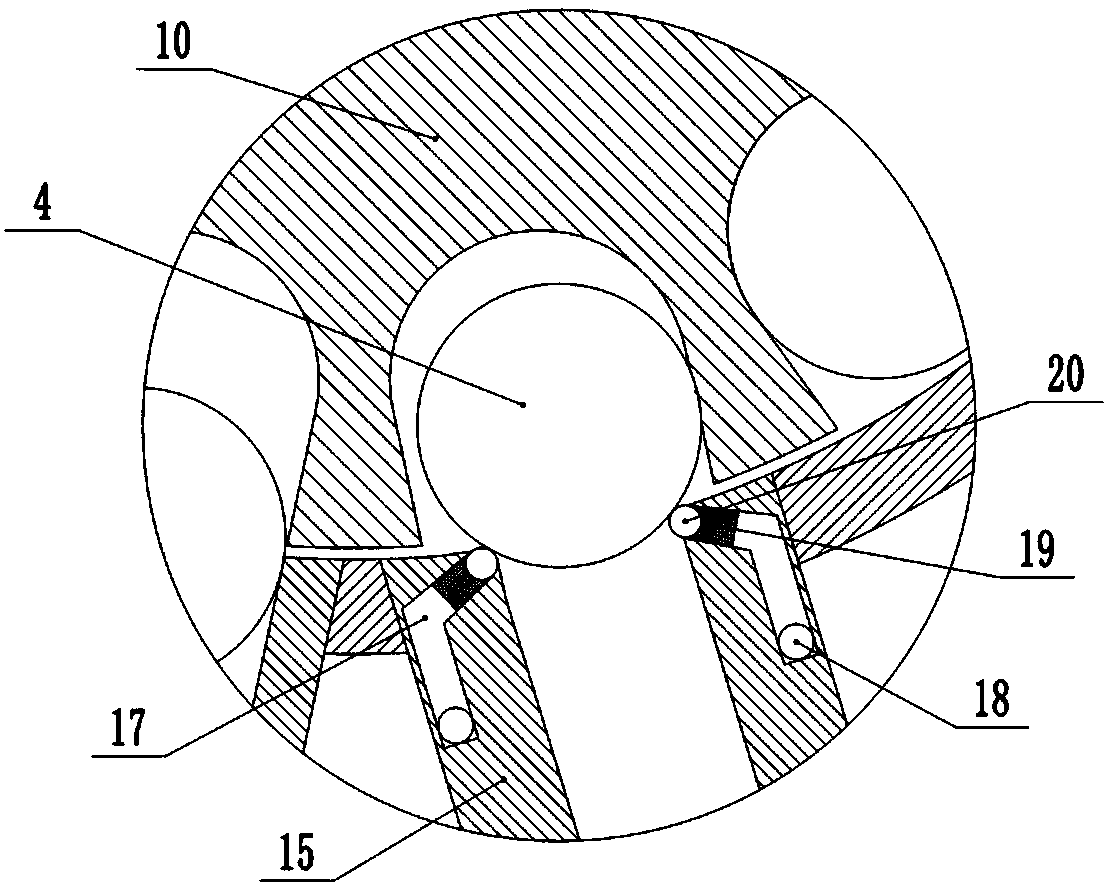

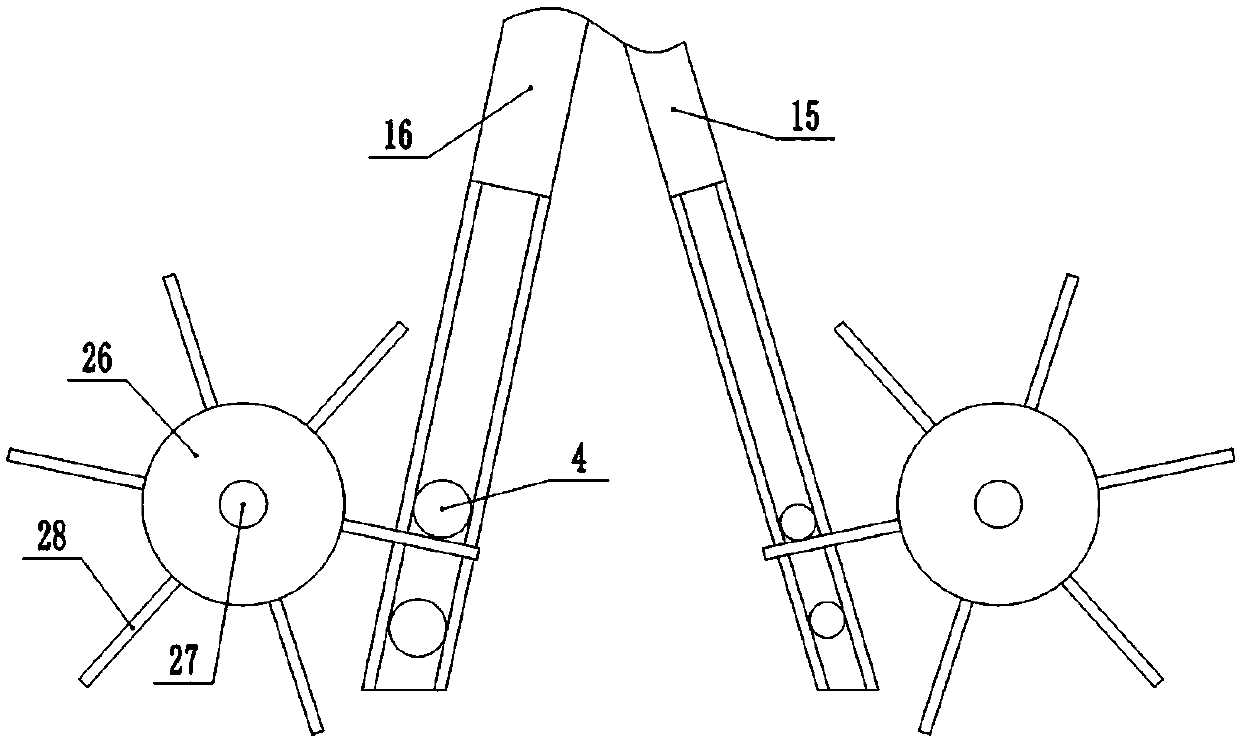

The invention relates to the technical field of sub-packaging devices, in particular to a glass product sub-packaging mechanism. The device comprises a screening cylinder, wherein a feeding port is formed in the screening cylinder, a rotating disc is rotationally connected in the screening cylinder, and grooves are distributed in the rotating disc, the screening cylinder is fixedly connected witha fence which is located on the circumferential direction of the rotating disc, the top of the fence communicates with the feeding port, and the bottom of the fence communicates with a first screeningbranch pipeline and a second screening branch pipeline; an anti-blocking mechanism is arranged at a pipeline port of the first screening branch pipeline, the anti-blocking mechanism comprises channels arranged on the two sides of a pipeline port of the first screening branch pipeline, the channels on the two side communicate with each other, blocking blocks are both connected in the channels on the two sides in a sliding mode, two blocking blocks are used for sealing the channels on the two side, and rotating parts are rotationally connected with one ends, facing the rotating disc, of the twoblocking blocks. The invention is intended to provide the glass product sub-packaging mechanism so as to solve the problem that glass products with two kinds of size and shapes are screened and the glass products are prevented from being broken.

Owner:CHONGQING XINGBAOXING GLASS PROD CO LTD

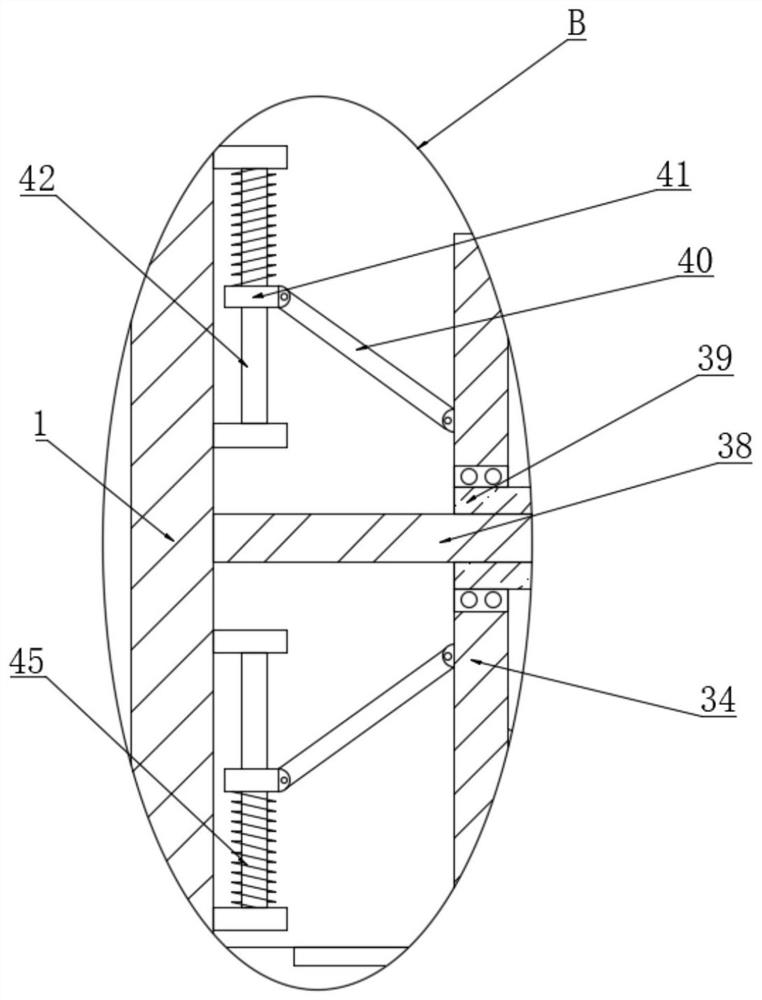

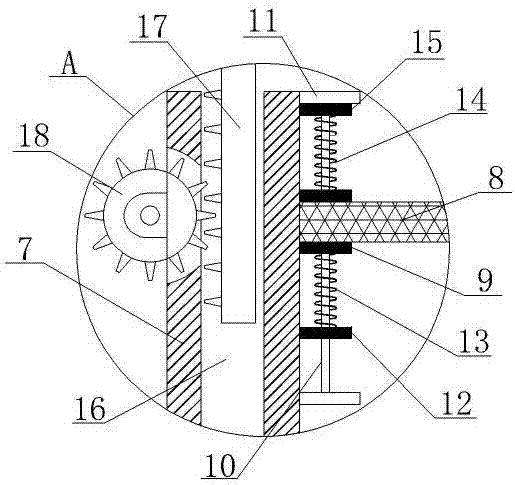

Electric quantity load detection device after waste storage battery recovery

InactiveCN111323707AAchieve sievingContact stabilityElectrical testingSortingElectrode ContactMechanical engineering

The invention discloses an electric quantity load detection device after waste storage battery recovery. A base is included. A positioning plate is arranged on an upper side of the base; a transposition device is arranged on a left side of the positioning plate; and the transposition device comprises a translation frame which is in sliding connection with an end surface of the upper side of the base. In the invention, through lifting and plugging, a detection electrode is in contact with or disconnected from the electrode of the storage battery; through a bidirectional clamping mode, during electric quantity detection, contact is ensured to be stable and a determination result is not affected; and in addition, the determination result further controls an inclination angle of a bearing plate where the storage batteries are placed so that the storage batteries with the residual electric quantity and the storage batteries without the residual electric quantity are screened, manual intervention can be abandoned in a whole process, and the device is more convenient, efficient and suitable for batch processing requirements.

Owner:建德希傅电子科技有限公司

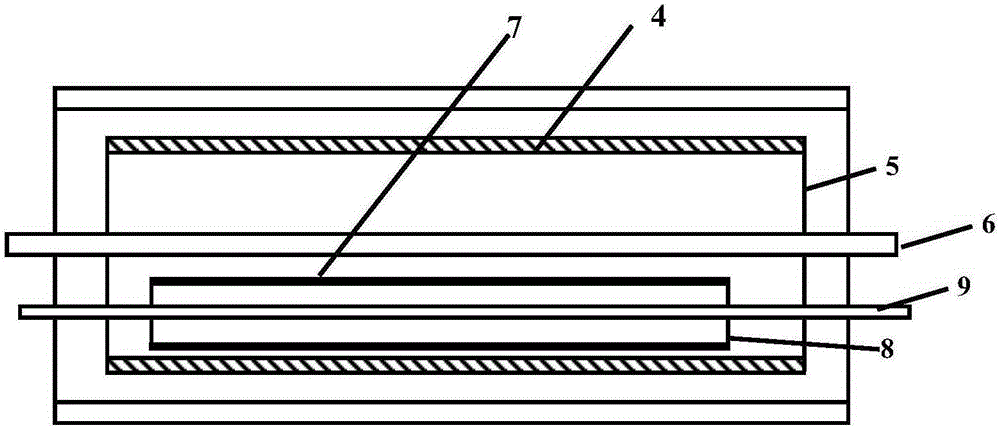

Caking index tester and application method thereof

InactiveCN104089845ASimple and efficient operationReduce labor intensityWeighing by removing componentAgricultural engineeringAutomation

The invention discloses a caking index tester. The caking index tester comprises a motor, a rotary drum and an aggregate bin, wherein the rotary drum is connected with the motor, a plurality of screening pores are uniformly distributed in the surface of the rotary drum, the aggregate bin is arranged below the rotary drum, a weighing device is arranged below the aggregate bin, and a signal output end of the weighing device is connected with a signal input end of a recording and calculating device. By adopting the caking index tester and the application method thereof, no other manual operation is needed in the entire test process, so that more simplicity and convenience in operation can be achieved, the labor intensity can be alleviated, and the automation can be realized.

Owner:拜城县众泰煤焦化有限公司

Novel wheat screening device for flour processing

InactiveCN111744575ASmall footprintCompact structureSievingGas current separationAgricultural engineeringStructural engineering

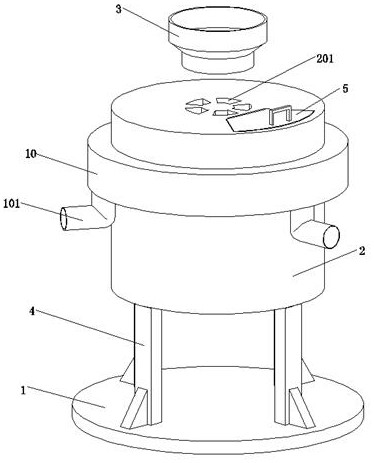

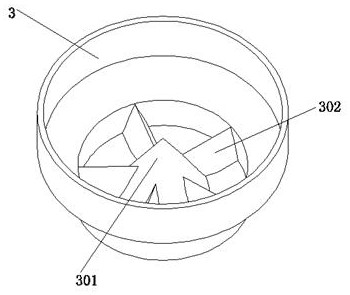

The invention relates to the technical field of wheat screening machines, and particularly discloses a novel wheat screening device for flour processing. The novel wheat screening device comprises a bottom plate, a screening barrel and a feeding hopper, wherein the lower surface of the screening barrel is connected with a plurality of supporting legs; the supporting legs are fixedly connected to the upper surface of the bottom plate; a plurality of feeding openings are formed in the circle center of the upper surface of the screening barrel in an annular array mode; the feeding hopper is arranged at the circle center of the upper surface of the screening barrel; a cleaning opening is formed in the top wall, located beside the feeding hopper, of the screening barrel; a cover plate is rotationally arranged on the cleaning opening; a bearing is arranged at the circle center of the top wall of the screening barrel; a rotating shaft is welded to the bearing; and the lower end of the rotating shaft is connected with a centrifugal screening disc. The novel wheat screening device can screen large gravels, small gravels and wizened and empty wheat in wheat at the same time, and is compact in structure and small in occupied area.

Owner:ANHUI TIANQI FLOUR TECH CO LTD

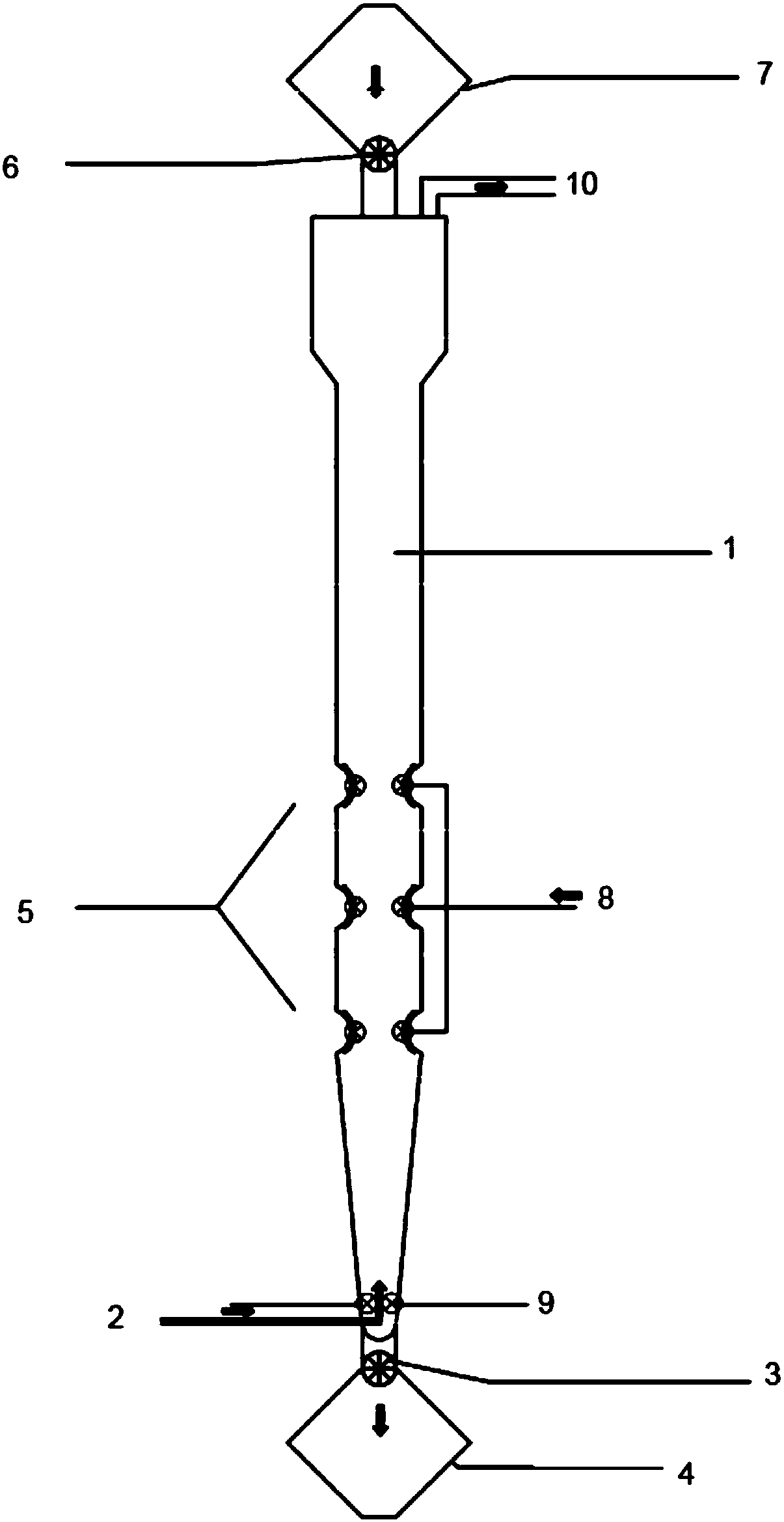

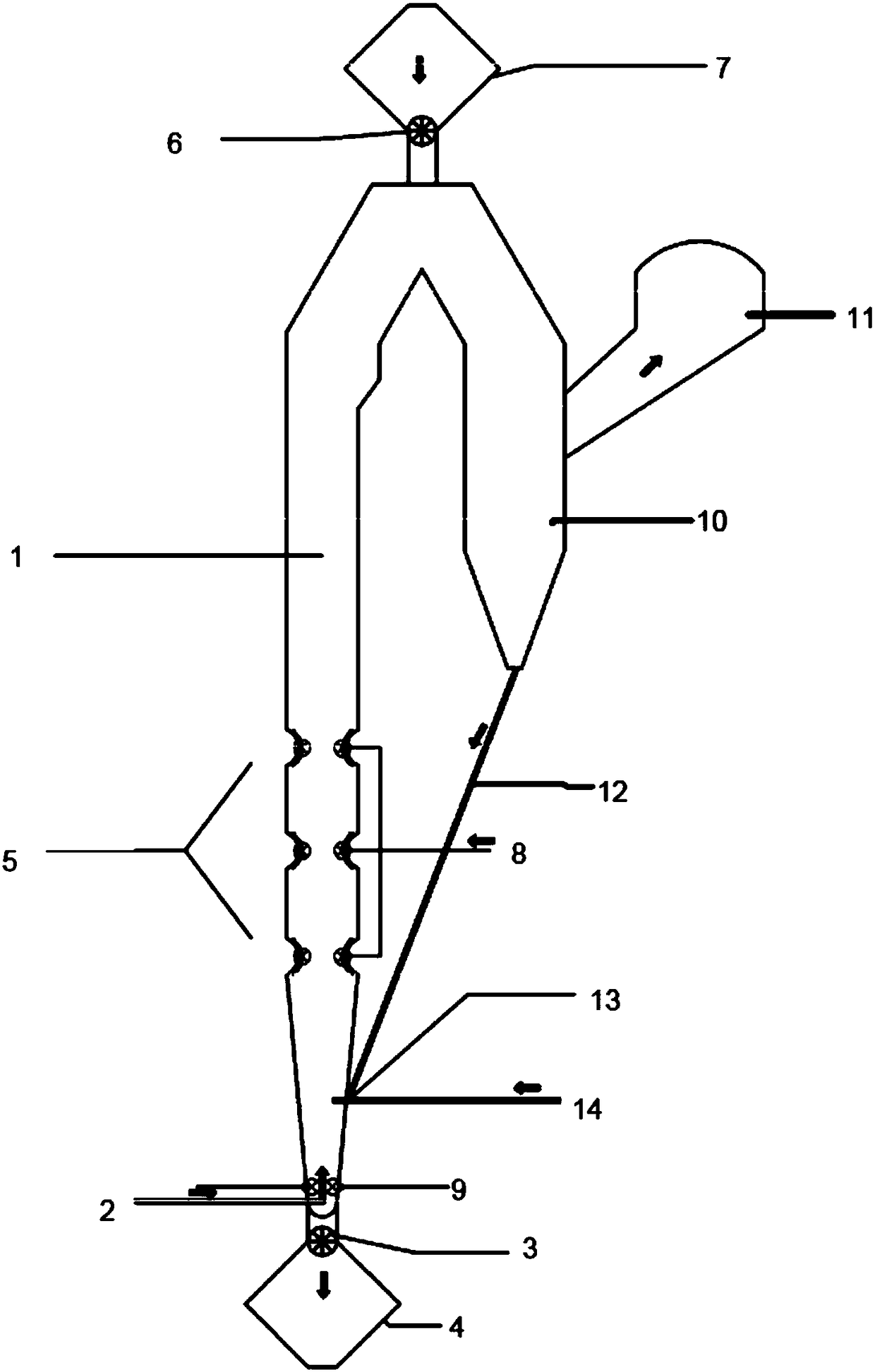

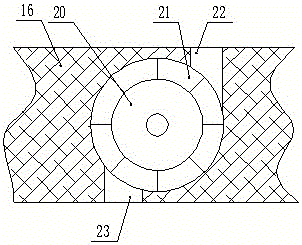

Single-stage continuous carbon nano tube preparation device and method

ActiveCN108726507AAids in fluidizationAchieve sievingCarbon preparation/purificationMulti-walled nanotubesSingle stageFluidized bed

The invention provides a single-stage continuous carbon nano tube preparation device and the device is based on a fluidized bed reactor. The fluidized bed reactor comprises an annular variable-diameter area, a raw material gas inlet, a catalyst feeding opening, a protection gas inlet and a pulse gas controller, wherein the position of the annular variable-diameter area is arranged from the 1 / 4 position of the bottom of the fluidized bed reactor to the top of the fluidized bed reactor, the pulse gas controller is arranged at the arc top of the annular variable-diameter area, the catalyst feeding opening is arranged at the top of the fluidized bed reactor, and the raw material gas inlet and the protection gas inlet are arranged at the bottom of the fluidized bed reactor. The device is further provided with a product outlet and a tail gas outlet. The device has the advantages of simple structure, low cost, easiness in operation, high raw material utilization rate, ability of effectively controlling the problem of carbon deposit on an inner wall of a main reactor, ability of preparing high-purity carbon nano tubes and suitability for industrialized large-scale production.

Owner:SHANDONG DAZHAN NANO MATERIALS

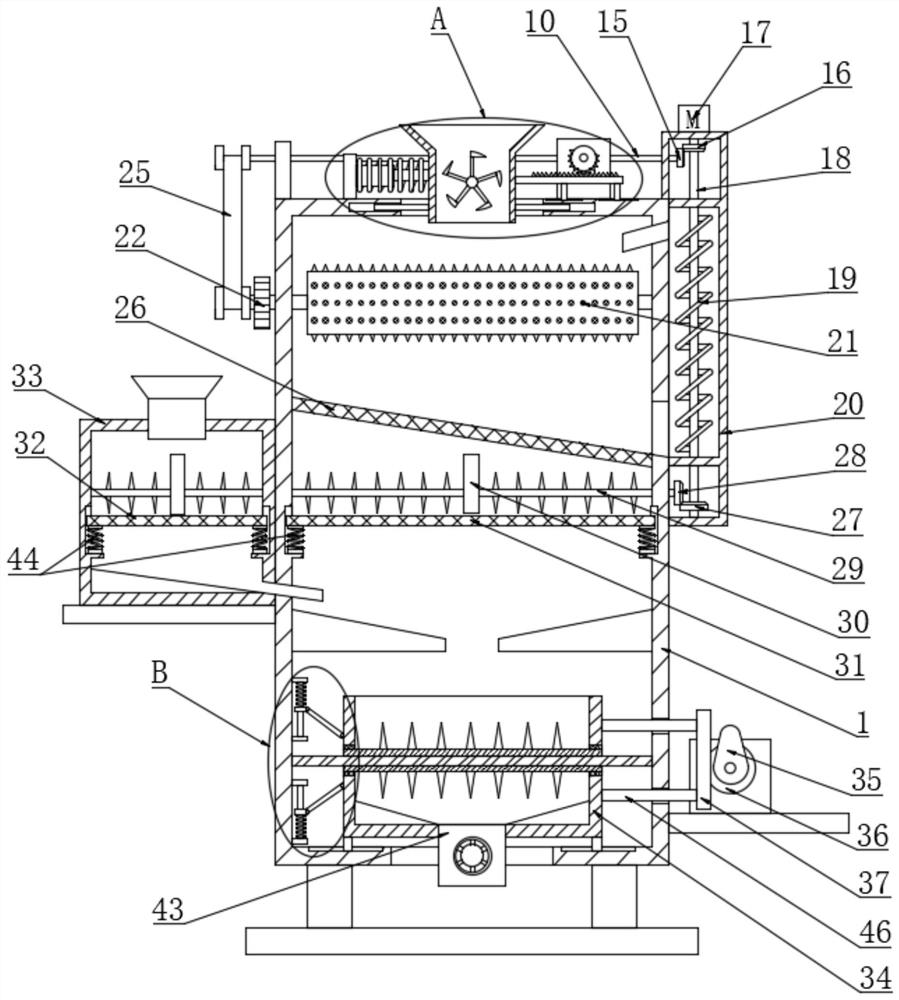

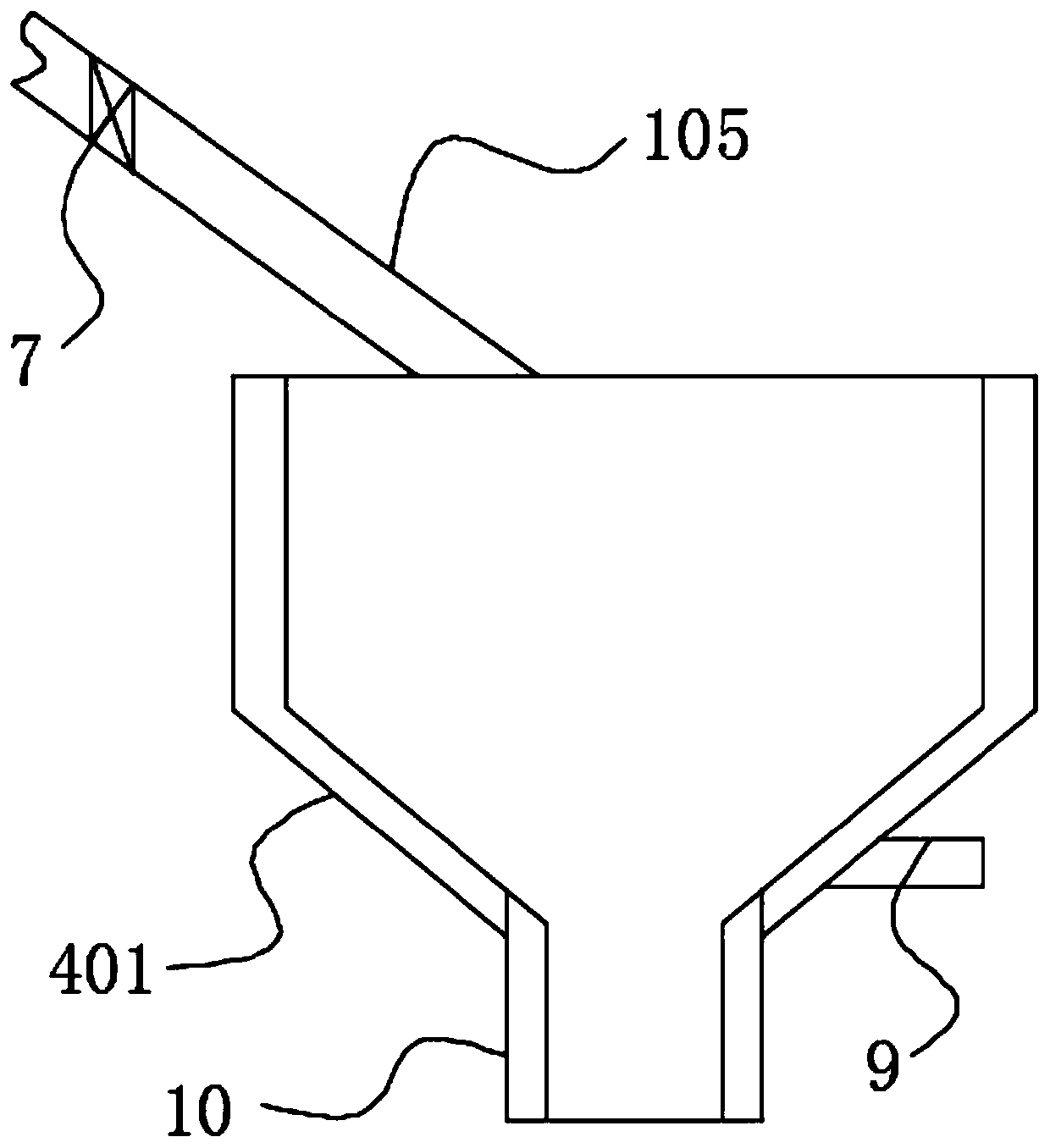

Energy-saving environment-friendly construction waste reusing device and recycling method

InactiveCN111570480AAchieve sievingFully integratedConstruction waste recoveryTransportation and packagingElectric machineryGrinding

The invention discloses an energy-saving environment-friendly construction waste reusing device and a recycling method. A breaking mechanism, a grinding mechanism and a blending device are arranged ina machine hood from top to bottom; the breaking mechanism comprises a breaking outer plate and a breaking wheel, and the breaking wheel is provided with breaking protrusions in the circumferential direction; a grinding pipe inclines towards the lower left portion, a grinding motor drives a grinding motor shaft to rotate in the grinding pipe, and the grinding motor shaft is provided with second grinding protrusions; the blending device comprises a blending bucket, a blending motor and a stirring shaft, the upper end of the stirring shaft stretches into the blending bucket, the lower end of thestirring shaft is connected with a blending driven wheel, the blending motor drives a blending driving wheel to rotate, the blending driving wheel is connected with the blending driven wheel througha blending driven belt, and the stirring shaft is provided with stirring paddles; and a transmission device is arranged at the bottom of a shell, and a transmission stepping motor drives a transmission belt to move through a transmission driving wheel. According to the energy-saving environment-friendly construction waste reusing device, waste can be made into bricks for building and bricks for road paving after being smashed, recycling is achieved, and pollution to the environment is reduced. The energy-saving environment-friendly construction waste reusing device is suitable for being widelyapplied to construction waste disposal.

Owner:徐立军

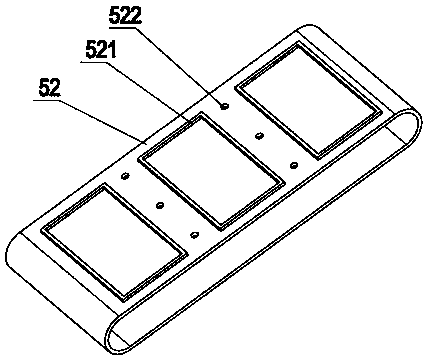

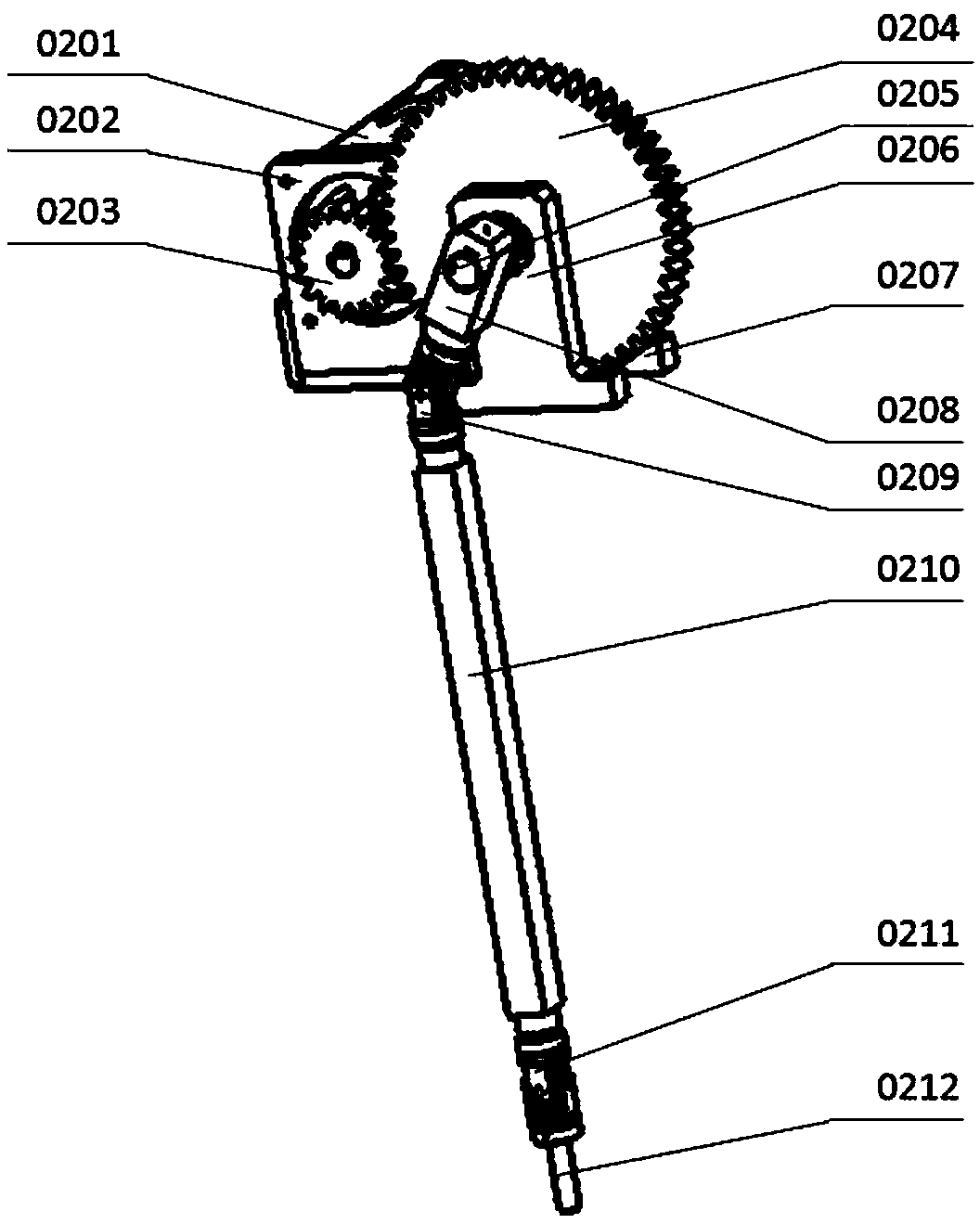

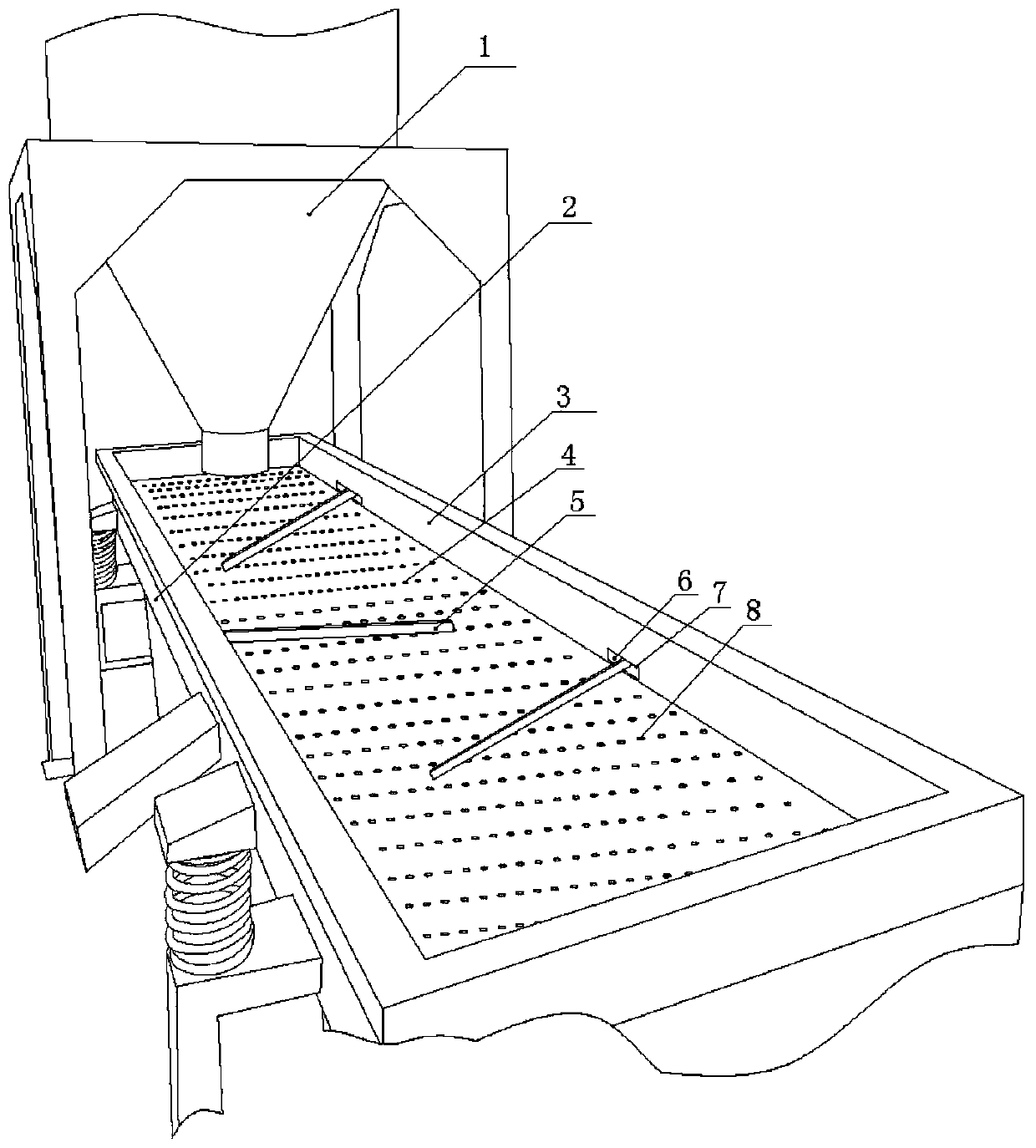

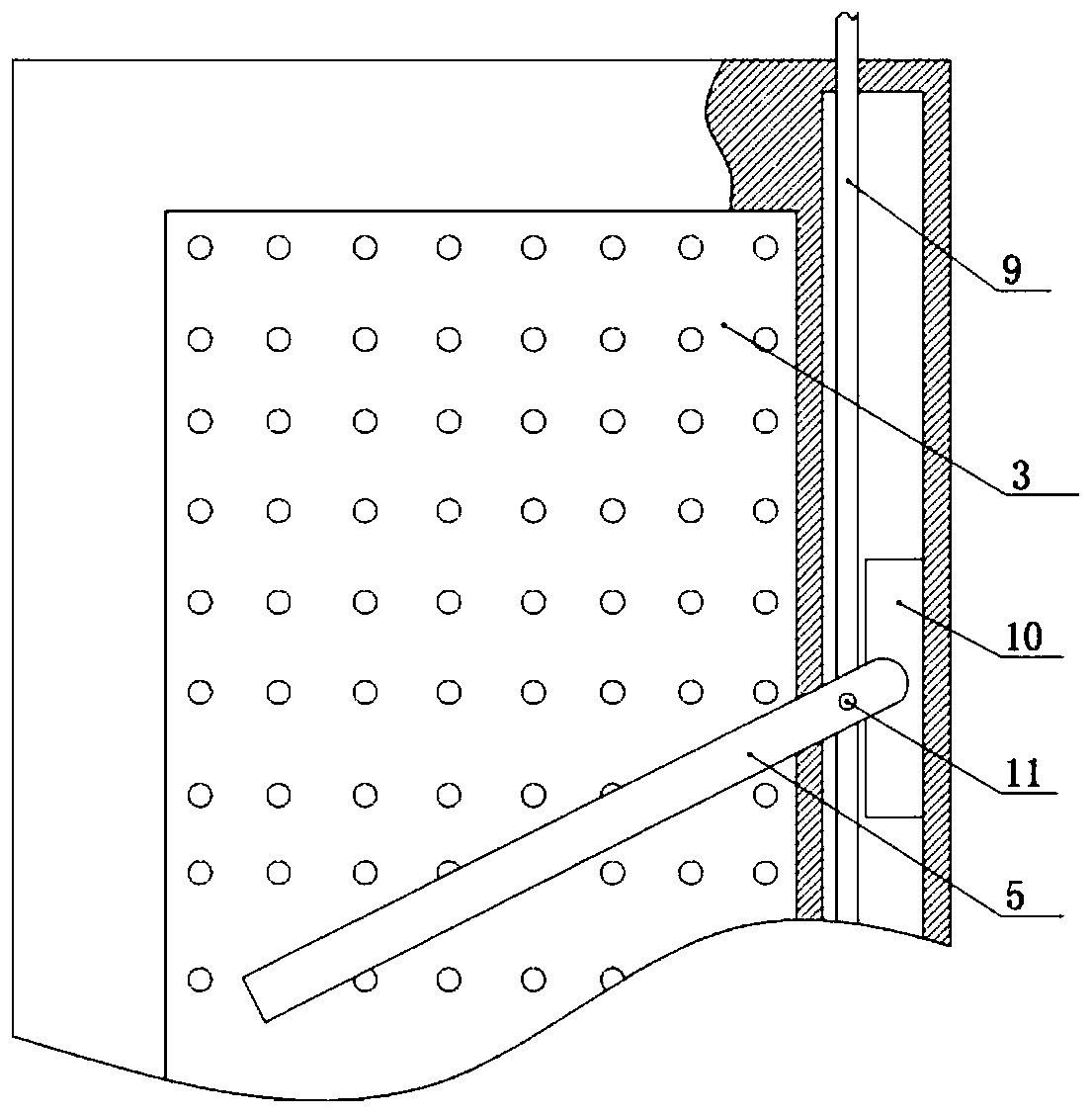

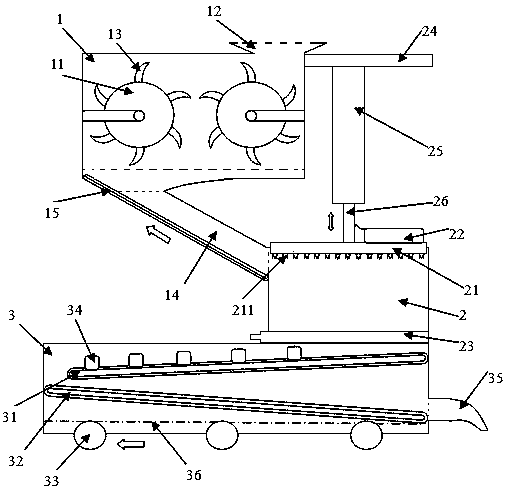

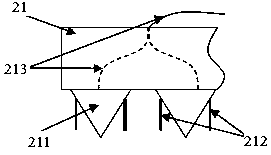

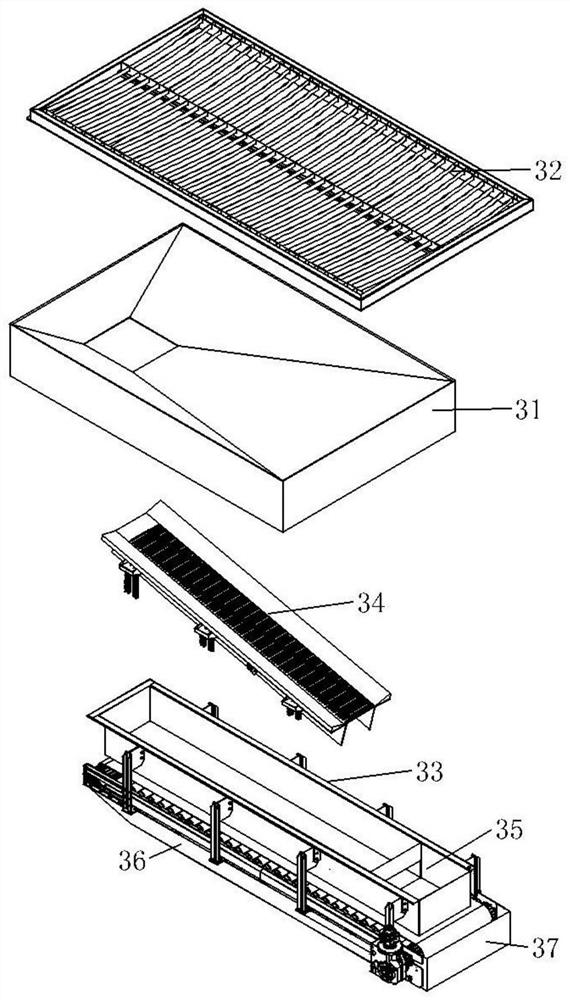

Maggot material separation multi-dimensional vibrating screen with material feeding and discharging device

The invention discloses a maggot material separation multi-dimensional vibrating screen with a material feeding and discharging device, and particularly relates to the field of vibrating screens. Thescreen comprises a material storage bin assembly, a first branch chain, a second branch chain, a third branch chain, a vibrating screen platen, a screen frame assembly, a first baffle, a second baffle, a third baffle, a belt conveying assembly, a rack and a material collection frame; a material falls into a screen frame of the vibrating screen; the three branch chains are connected with a power assembly through three rotating pairs, two-time rotation and one-time movement of the screen frame are simultaneously achieved through the rotating pairs, universal joints and screw rods respectively, the controllable mechanical separation of fly maggots and maggot manure is achieved at last, and the screening efficiency of separating a mixture of the fly maggots and a culture medium is improved; after screening is finished, the maggot manure fallen on a belt conveyor is collected into the material collection frame through the belt conveying assembly, the fly maggots remaining in the screen frame can be drawn out of a screen framework along with the screen frame, and the process of collecting the fly maggots is completed. The whole vibrating screen is small in spatial size, high in rigidityand stable and reliable in screening performance, and has practical significance for factory application.

Owner:JIANGSU UNIV

Efficient powder sieving equipment

ActiveCN102814276AEliminate the "arch bridge effect"Simple structureSievingScreeningReciprocating motionAir knife

The invention discloses efficient powder sieving equipment which comprises a support, a discharge bin, a sieving box and a sieving box swing system. The sieving box comprises a box body and a sieve, the box body is arranged on the support and capable of reciprocating along a rail mounted on the support, a compressed gas blowback system is arranged below the box body and comprises two polish rods, a gas knife, a servo motor, a first synchronous pulley, a second synchronous pulley and a synchronous belt, the two polish rods are parallelly mounted on the support, the servo motor and the second synchronous pulley are mounted on the support, the first synchronous pulley is mounted on an output shaft of the servo motor, the first synchronous pulley and the second synchronous pulley are connected by the aid of the synchronous belt, the gas knife is positioned below the sieve, mounted between the two polish rods through linear bearings and capable of reciprocating along the polish rods and blowing the sieve, and one end of the gas knife is fixedly connected with the synchronous belt. The efficient powder sieving equipment is simple in structure, reasonable in design, convenient to operate, no easy to block meshes of the sieve, accurate in sieving and high in efficiency.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Recycled concrete screening device

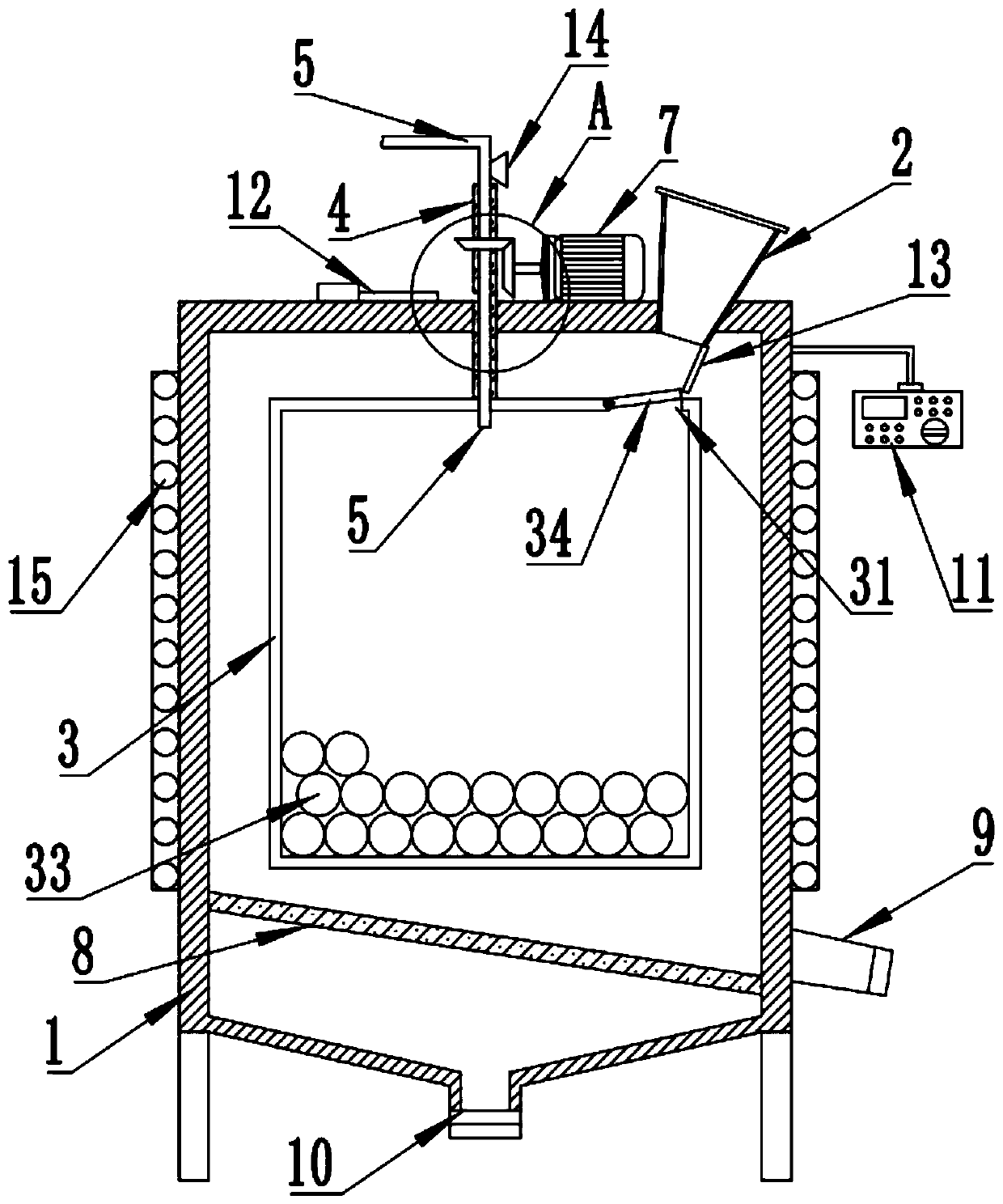

InactiveCN111111853AAchieve sievingImproved porosity is largerEdge grinding machinesPolishing machinesElectric machineryStructural engineering

The invention discloses a recycled concrete screening device which comprises a barrel. An internal barrel is arranged in the barrel. Recycled concrete aggregate passes through a feeding hopper and a feeding opening in sequence to be fed into the internal barrel, a motor can be controlled by a controller to rotate so as to drive the internal barrel to rotate in the axial direction, so that steel balls in the internal barrel are driven to collide with the aggregate, and therefore the operation of rubbing down corners on the surfaces of the aggregate and removing hardened cement mortar on the surfaces of the aggregate is helped. A water injection pipe is arranged and used for injecting water into the internal barrel, and therefore the effect of washing the aggregate so as to remove the hardened cement mortar on the surfaces is achieved. Through the rotary centrifugal effect and holes in the side wall of the internal barrel, the aggregate of recycled concrete is screened out and slides outof a discharging opening through a partition plate, meanwhile, screened-out cement mortar or impurities can be filtered through filter holes in the partition plate, and therefore the functions of screening the recycled concrete aggregate and meanwhile further washing and separating the hardened cement mortar on the outer surfaces of the recycled concrete aggregate are achieved.

Owner:安徽省海仁材料科技有限公司

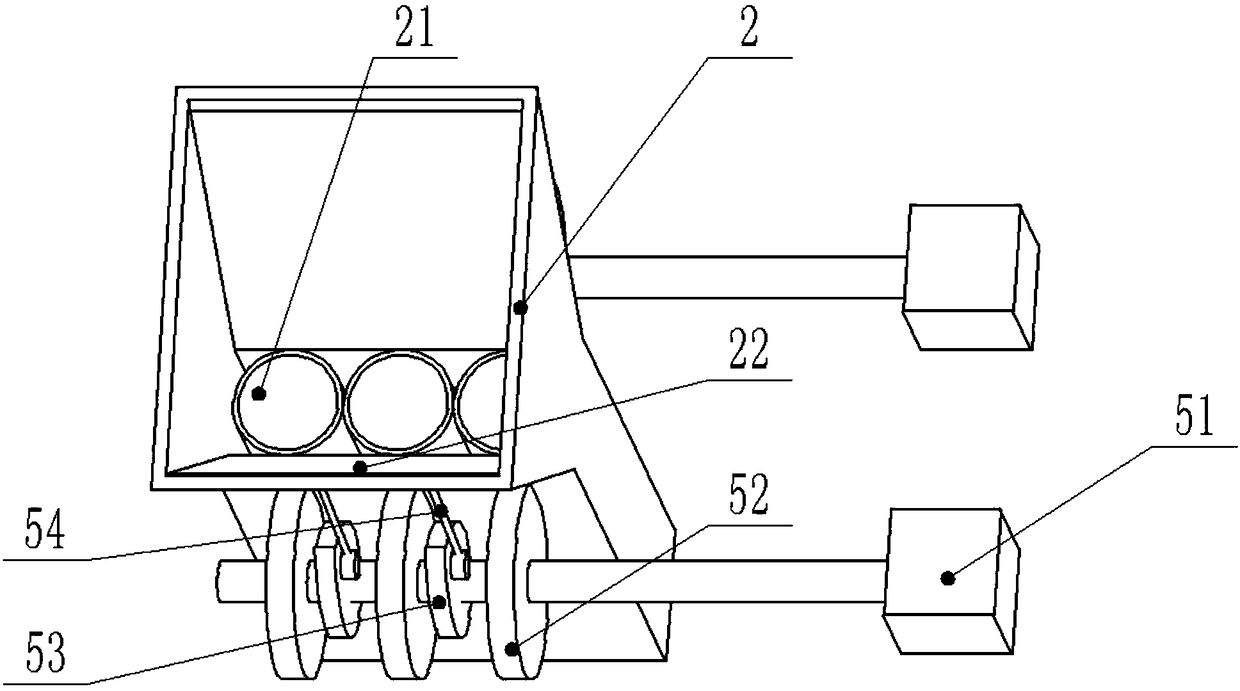

Chinese traditional medicine smashing device

InactiveCN107570264AAchieve primary crushingAchieve sievingGrain treatmentsGranularityChinese traditional

The invention relates to the technical field of medical instruments, in particular to a Chinese traditional medicine smashing device. The Chinese traditional medicine smashing device comprises a device outer shell and supporting plates installed on the two sides of the device outer shell, and a feeding hopper is installed at the top end of the device outer shell. Two separation plates are installed inside the device outer shell and divide the inner space of the device outer shell into a middle smashing area and discharging areas on the two sides, an upper set of smashing rollers and a lower set of smashing rollers are arranged in the smashing area, and primary smashing of Chinese traditional medicines is realized. Second fans are installed in the discharging areas to blow primarily smashedmedicine residues towards a collecting pipe. Large-granularity and small-granularity medicine residues can be sieved through the action of a third separation net, so that the small-granularity medicine residues are collected, and the large-granularity medicine residues fall into a first separation net in the smashing area. The large-granularity medicine residues are then fed into an area above the smashing rollers through a first fan, a secondary smashing effect is realized, and high smashing efficiency and a high-uniformity smashing effect can be further realized.

Owner:朱雪梅

Sieving and crushing device

The invention discloses a sieving and crushing device. The device comprises a base and a sieve box, wherein two layers of sieve plates are arranged in the sieve box, the size of sieve pores of the upper layer sieve plate is larger than that of sieve pores of the lower layer sieve plate, the upper layer sieve plate and the lower layer sieve plate are obliquely arranged in the same direction in thesieve box, an included angle between the upper layer sieve plate and the horizontal direction is larger than that between the lower layer sieve plate and the horizontal direction, and the two layers of sieve plates horizontally vibrate in the opposite directions in the sieving process. According to the device, the two sieve plates which have included angles correspondingly and move relative to each other are arranged in the sieving box, so that the dual functions of sieving and crushing are realized, the utilization rate of powder coatings is improved, continuous sieving is realized, the device is simple, and the operation cost is low.

Owner:孙斐

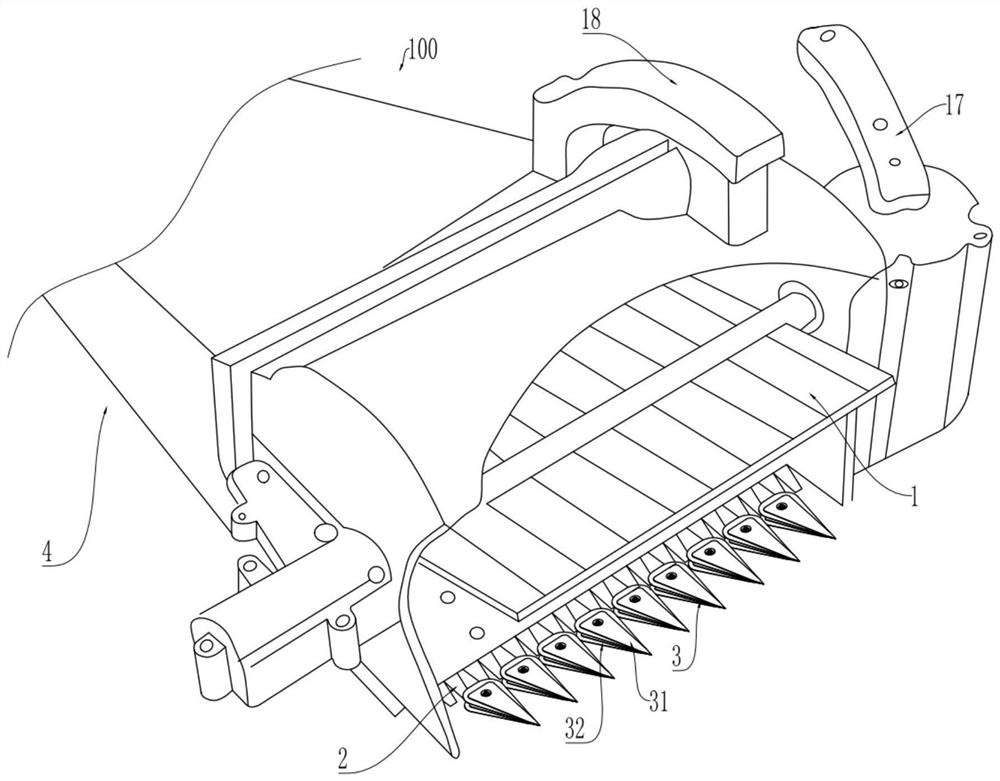

Energy-saving tea picking device

InactiveCN111602514AReduce the burden on handsSolve the labor-intensivePicking devicesAgricultural engineeringMechanical engineering

The invention relates to the technical field of tea picking and particularly discloses an energy-saving tea picking device. The device comprises a tea picking machine body and a collector, wherein thecollector comprises a collecting basket capable of being carried on the body of a tea picker, the collecting basket is communicated with the tea picking machine body, and the tea picking machine bodyis provided with a leaf sweeping plate capable of rotating and a tea picking cutter capable of shearing tea leaves; the tea leaves picked by the tea picking cutter can be swept into the collecting basket by the leaf sweeping plate, a material receiving rake is rotationally connected into the collecting basket, a plurality of rake teeth are arranged on the material receiving rake, a collecting table is arranged in the collecting basket, and the collected tea can be poured into the collecting table after the material receiving rake rotates. According to the scheme, by arranging the collecting basket, picked tea leaves are carried on the back, the handling weight is reduced, tea leaf separation is achieved, and the problems that in the prior art, a tea picker operated by a single person is heavy in hand burden and large in labor intensity of long-term tea picking are solved.

Owner:WENZHOU UNIVERSITY

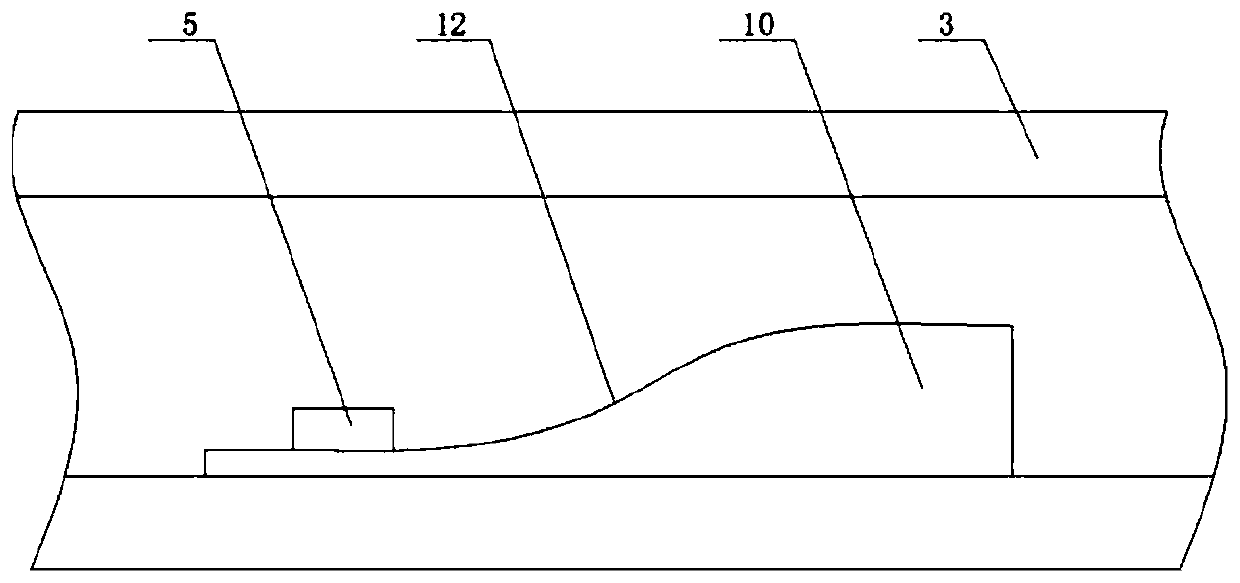

Plastic particle vibrating sieve

The invention relates to the technical field of plastic processing and particularly relates to a plastic particle vibrating sieve. The plastic particle vibrating sieve comprises a vibrating sieve mainbody, wherein the vibrating sieve main body is connected with a vibrating mechanism used for driving the vibrating sieve main body to vibrate, the vibrating sieve main body comprises a sieve box witha top opening, the top of the sieve box is provided with a hopper, the bottom of the hopper is provided with a plurality of sieve holes, both the hopper and the sieve box are obliquely arranged, andthe low end of the sieve box is provided with a discharging opening; and baffles used for guiding plastic particles to move in a wavy path are arranged on the side wall of the hopper from the high endto the low end in a staggered manner. The problem of poor plastic particle sieving effect in the prior art is solved.

Owner:CHONGQING JINGBANG HIGH MOLECULAR MATERIAL CO LTD

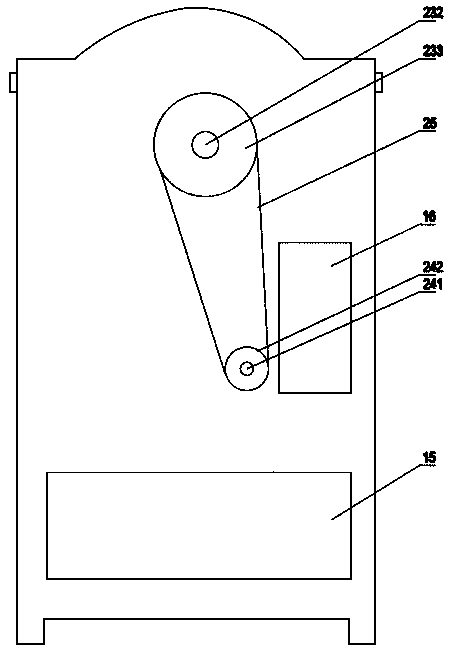

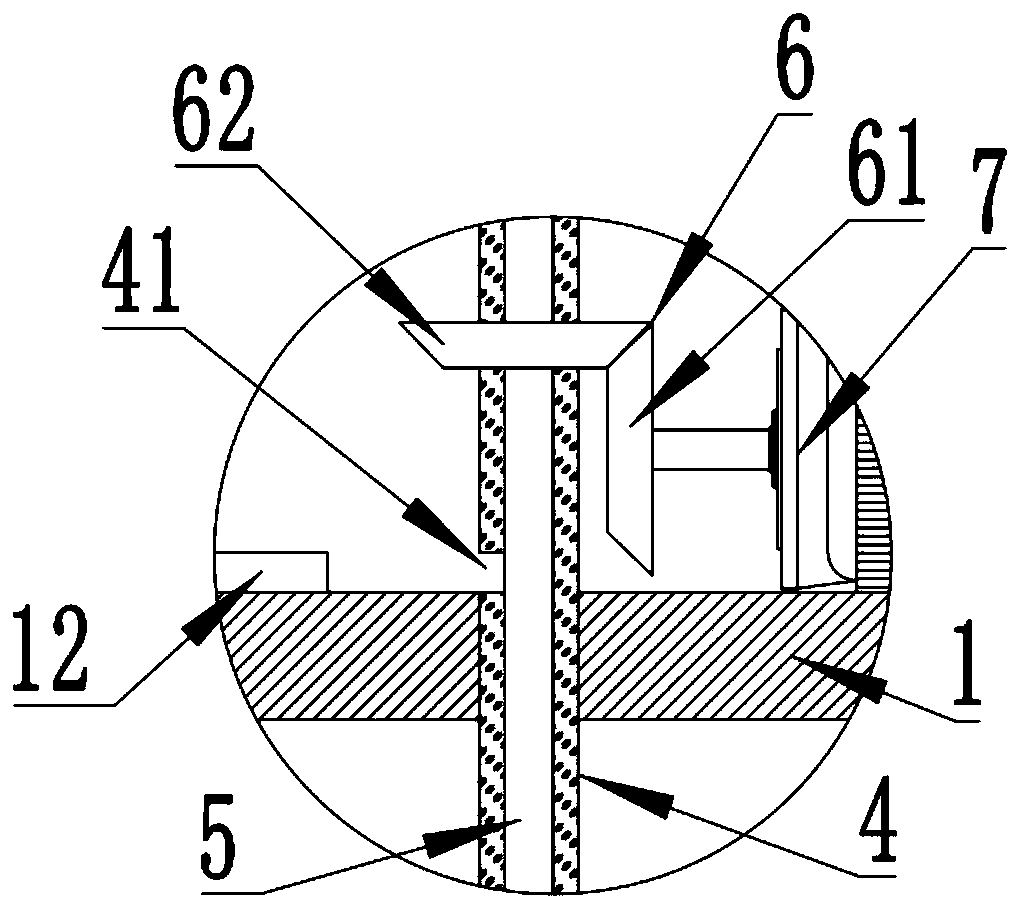

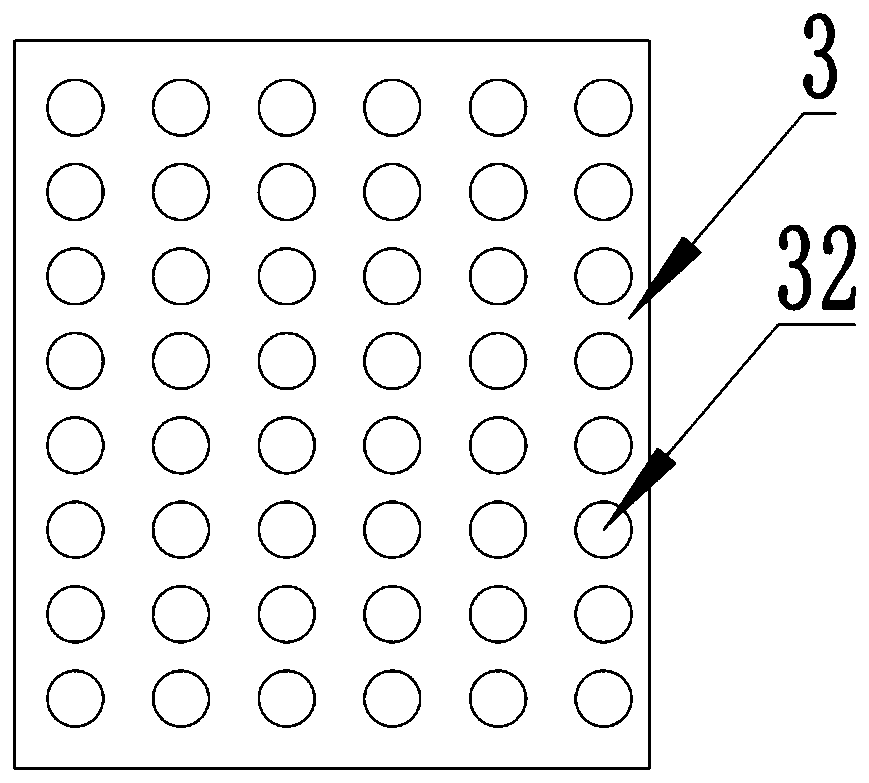

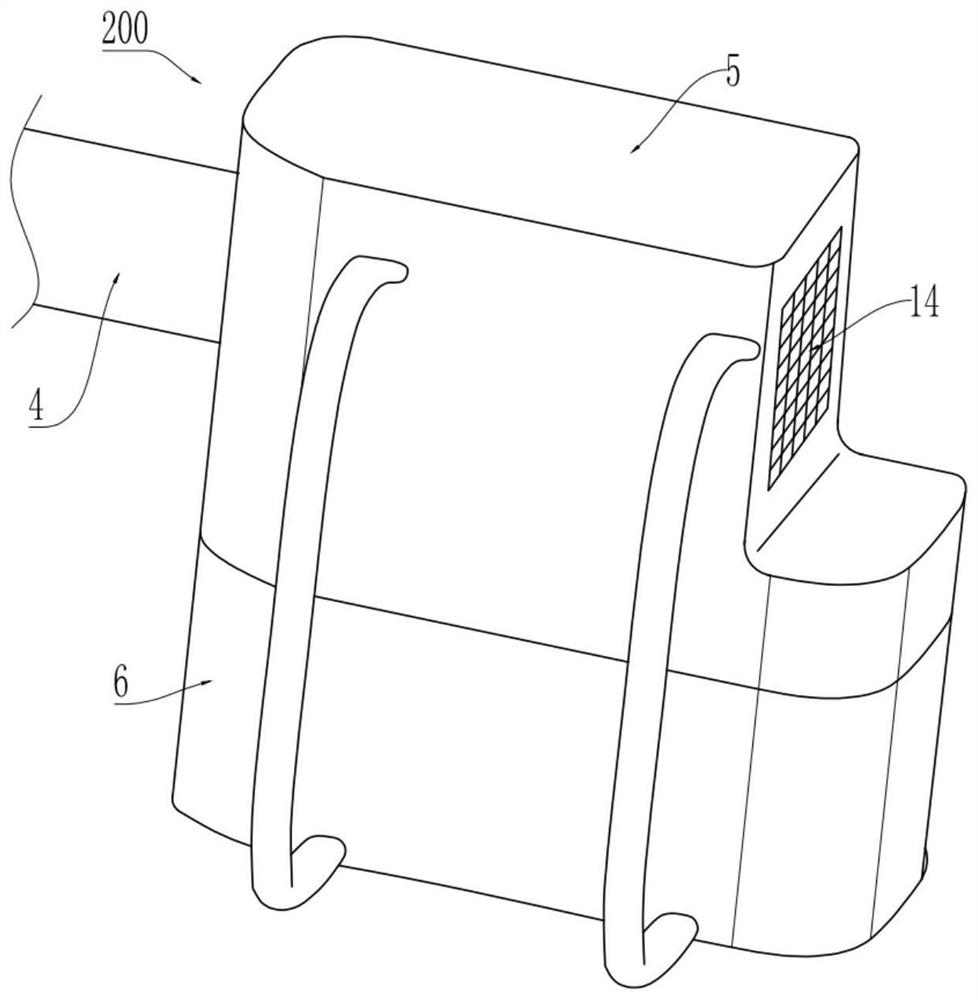

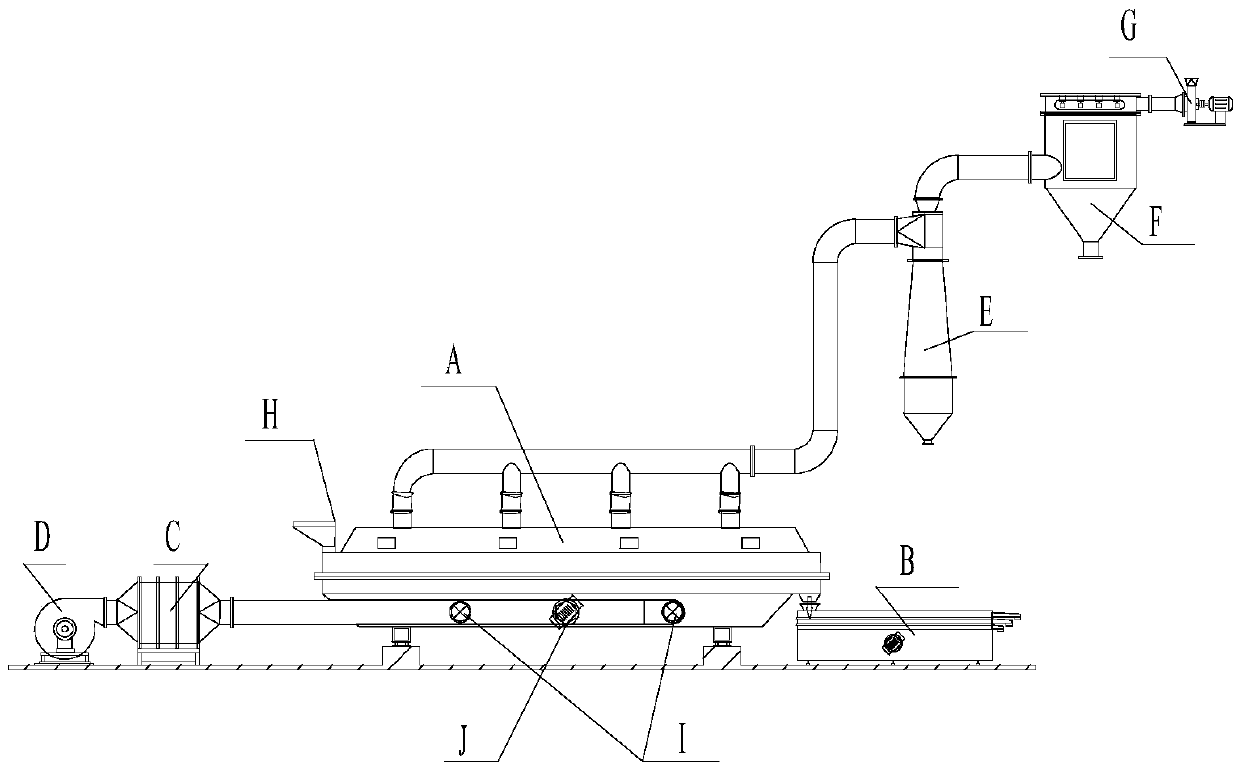

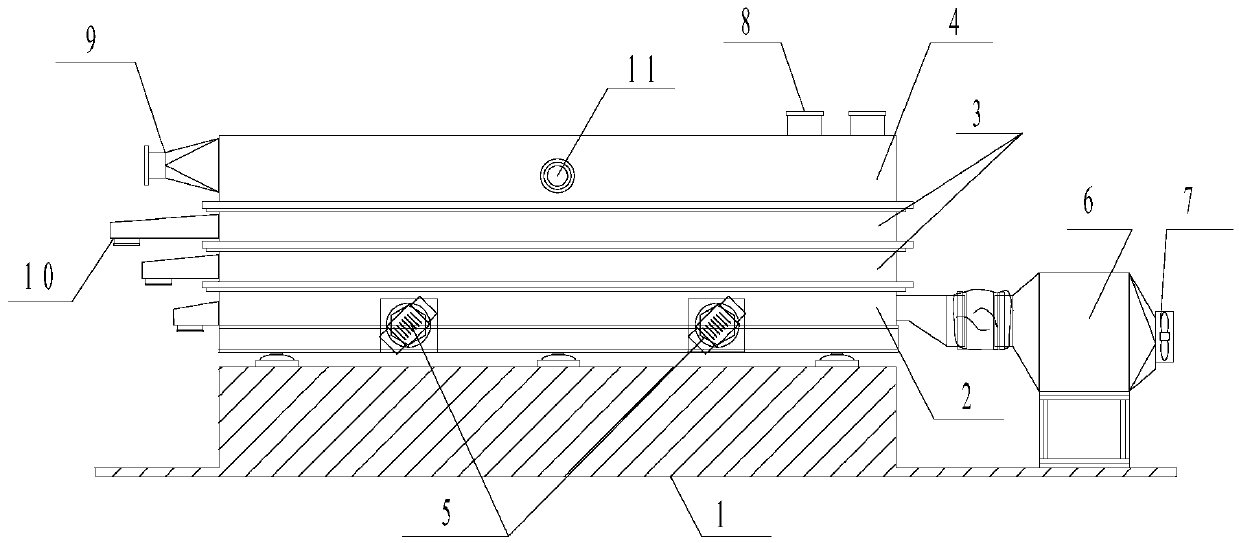

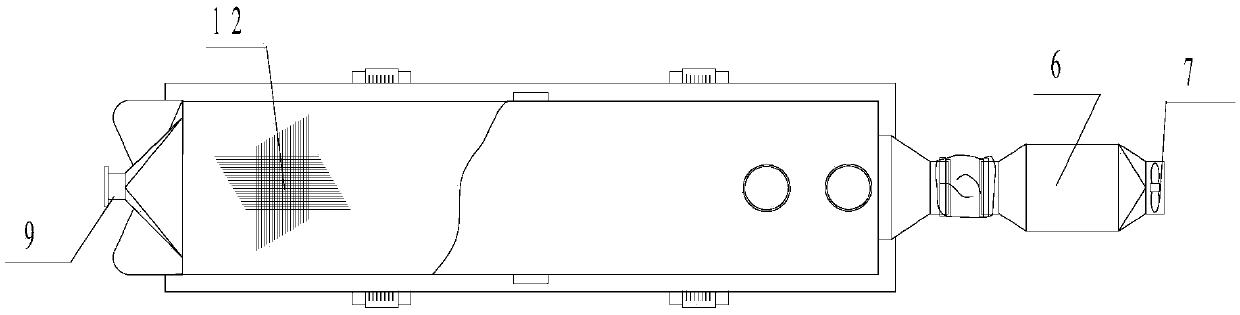

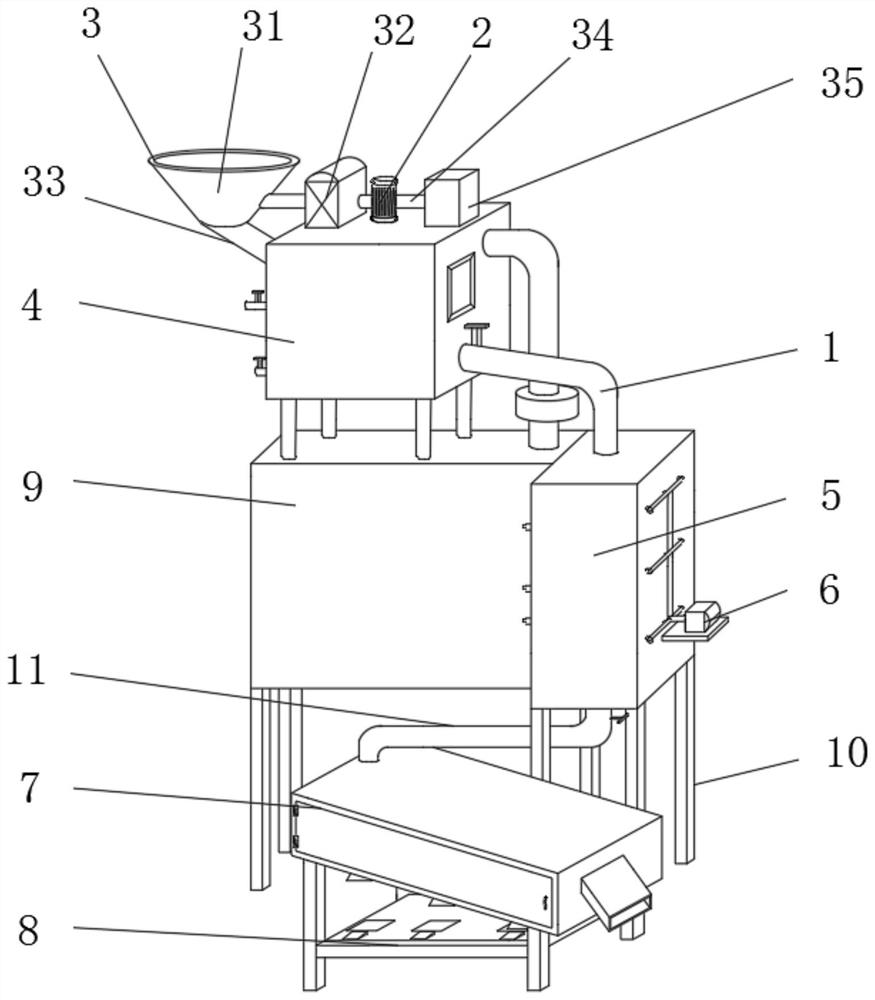

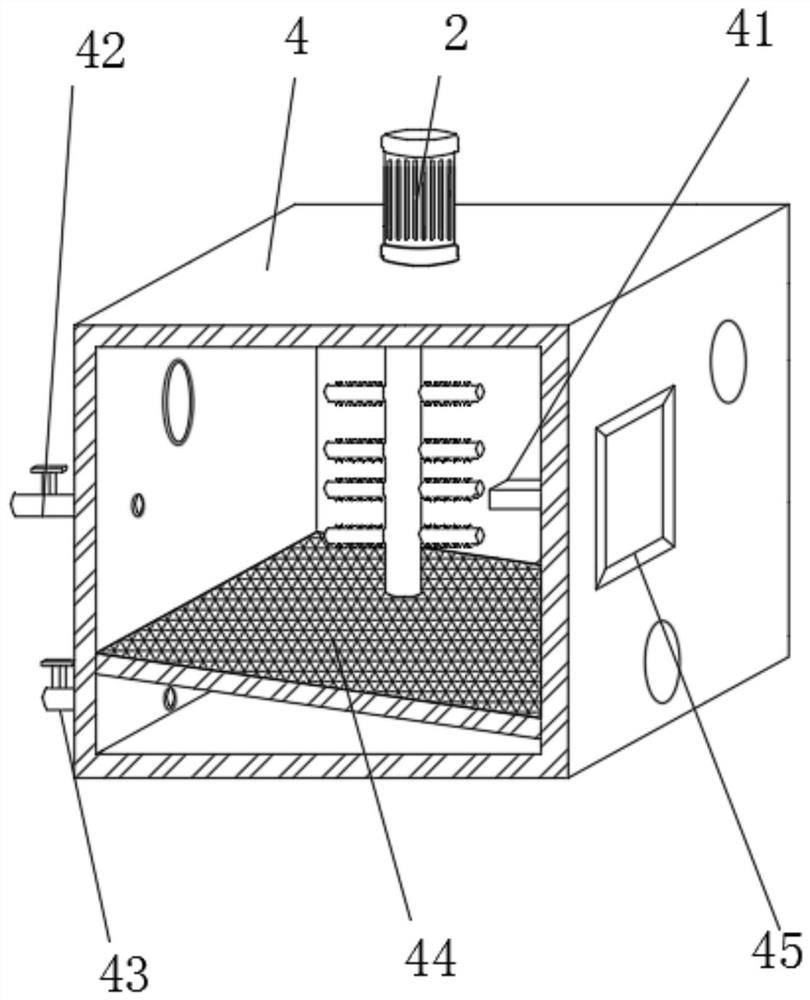

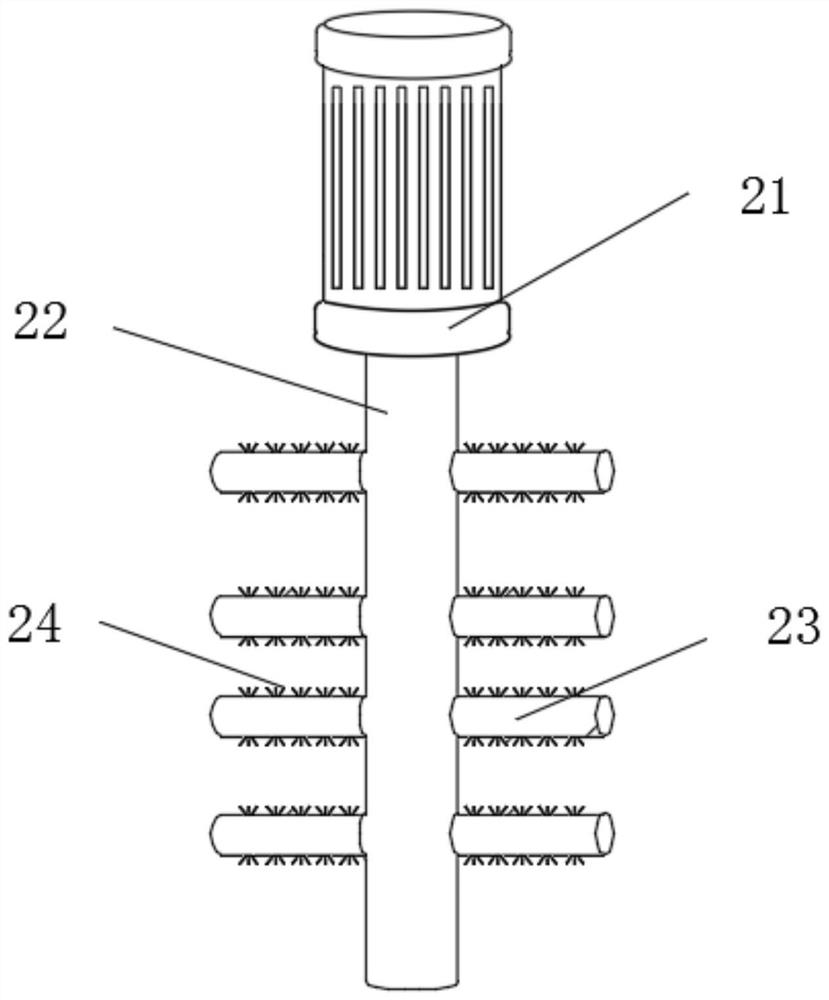

Drying and sieving all-in-one machine

The invention discloses a drying and sieving all-in-one machine. The all-in-machine comprises a rack (1), wherein the rack (1) is provided with a lower box body (2), at least one middle box body (3) and an upper box body (4) which are fixedly connected from bottom to top in sequence, wherein the lower ends of the middle box bodies are all provided with sieves (12), and the two adjacent middle box bodies are distributed according to sieve holes of the upper box body larger than those of the lower box body; the lower box body (2) is provided with at least one air inlet which is connected with a hot air transmitting device, and the lower box body (2) is connected with a vibrator (5); the upper box body (4) is provided with at least one material inlet (8), and is also provided with an air outlet (9); the middle box bodies are provided with material outlets which are provided with material feeding channels (10). According to the drying and sieving all-in-one machine provided by the invention, particle materials can be sieved in the drying process, the energy consumption is reduced, and the pollution is alleviated.

Owner:苏州工业园区顺事达氢能机电有限公司 +1

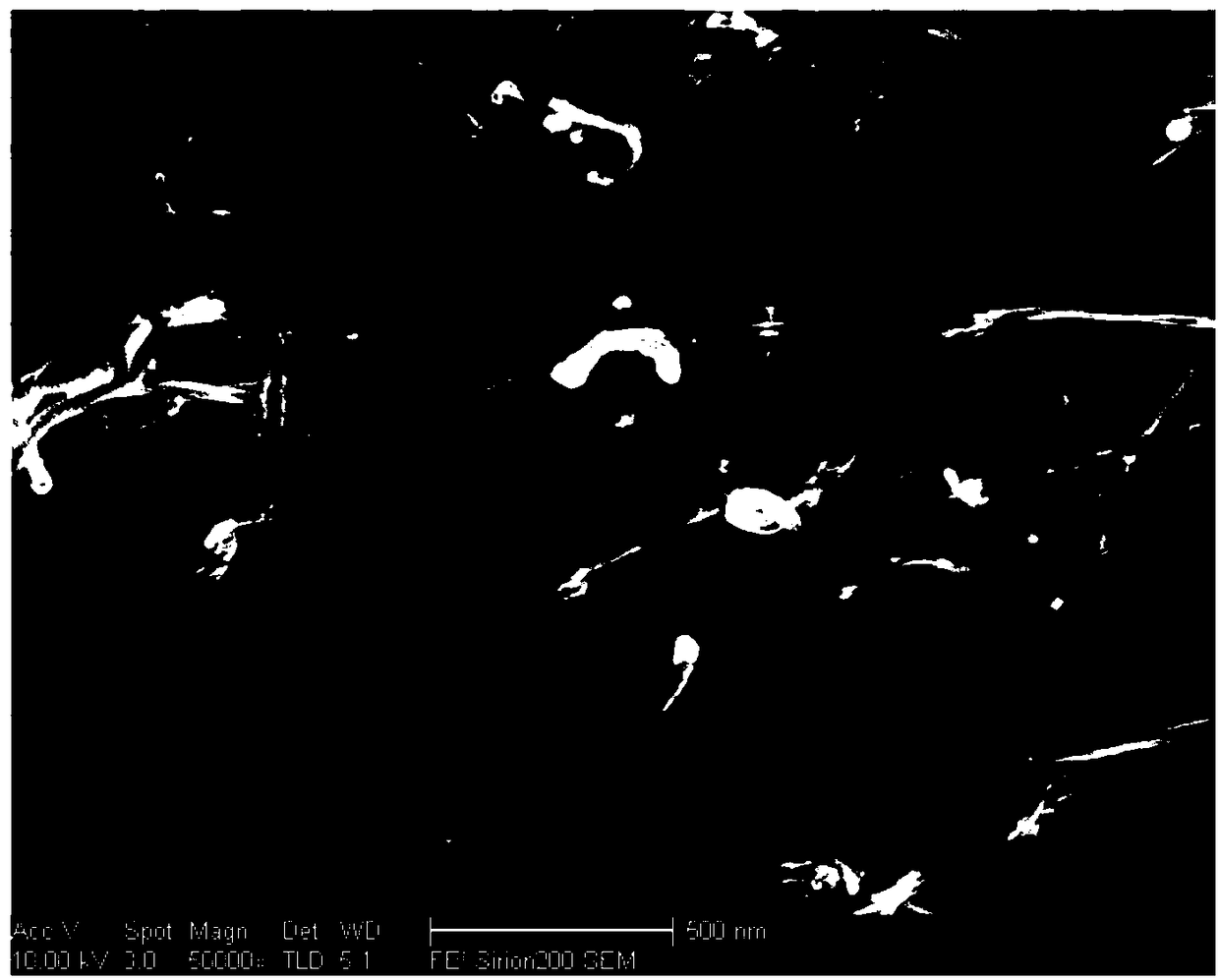

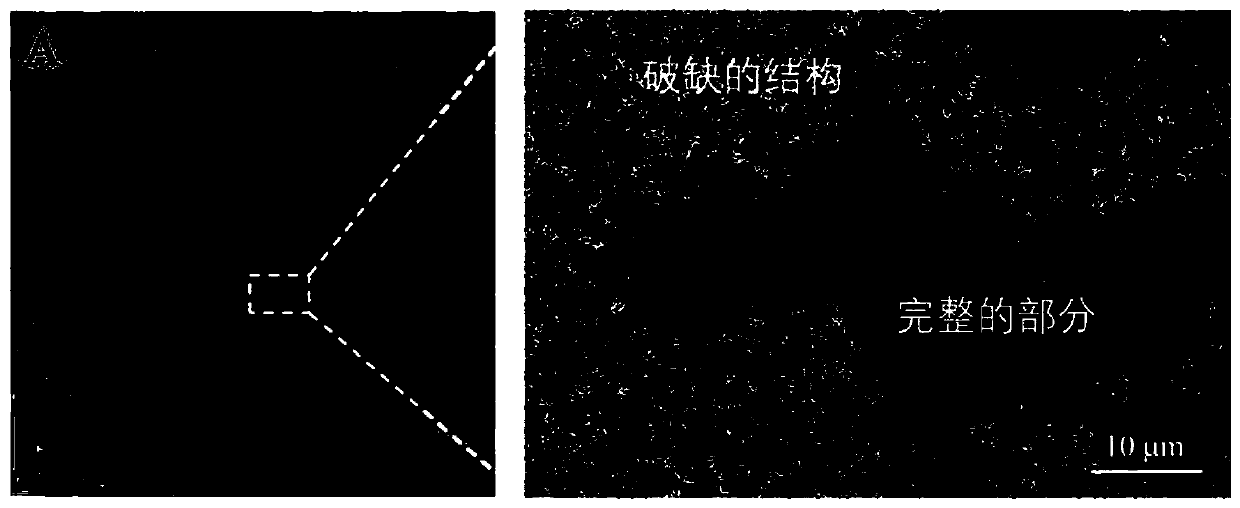

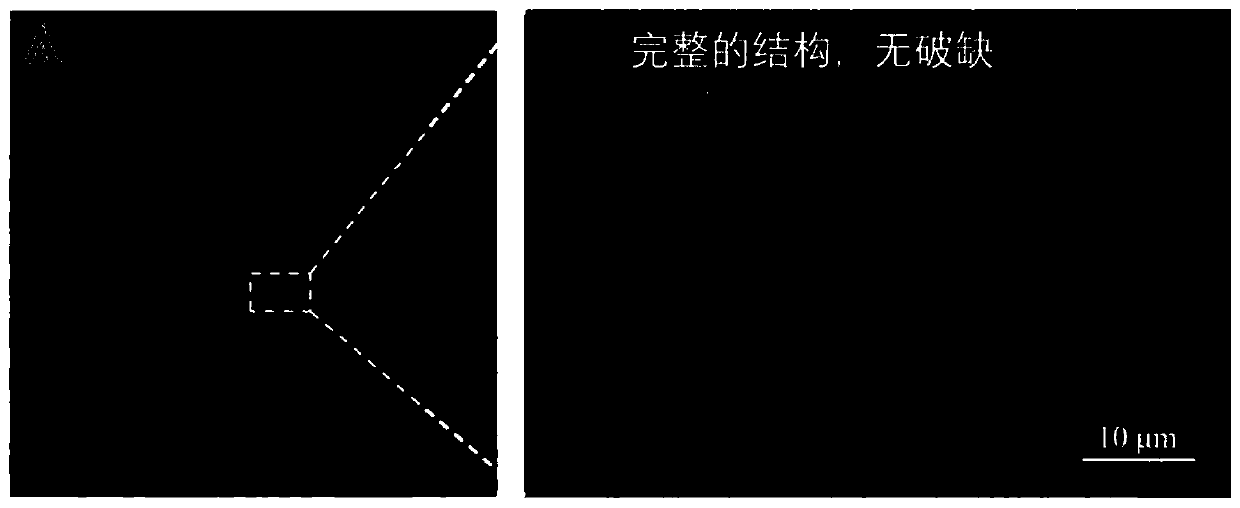

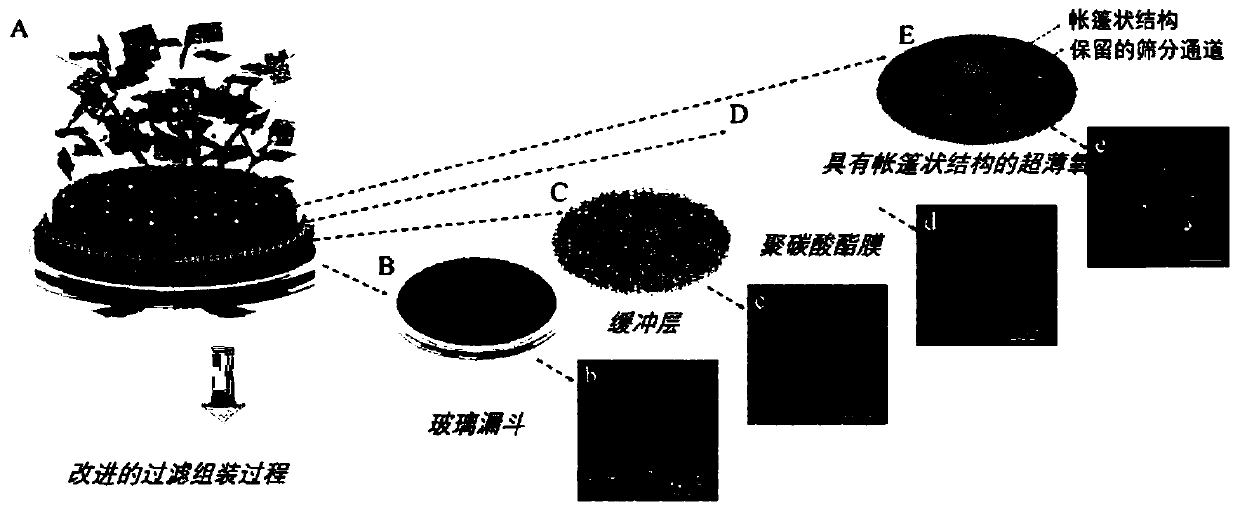

Graphene oxide membrane with tent-like structures, and preparation method and application thereof

ActiveCN110860215AIncrease water fluxAchieve water fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisGraphite oxideNanoparticle

The invention discloses a graphene oxide membrane with tent-like nanostructures as well as a preparation method and application thereof. According to the invention, an improved filter assembly methodis established so as to realize reliable preparation of an ultra-thin graphene oxide membrane on a flexible substrate. By intercalating nanoparticles into an ultra-thin structure, construction of tent-like nanostructures in the ultra-thin structure is realized The special tent-like nanostructures are capable of realizing maximum water flux under the premise of retaining retention performance. By adjusting intercalation ratio of the nanoparticles, regulation on sieving channels of the graphene oxide membrane can be realized on the molecular scale; and moreover, selective separation on small molecules of similar sizes is also enabled. The tent-like nanostructures of the graphene oxide membrane in aqueous solutions of different pH values are stable; and moreover, surface roughness, wettability and surface electrical property of the graphene oxide membrane are adjustable. The graphene oxide membrane with the tent-like nanostructures has excellent separation performance, as well as adjustable structures and properties; and thus, the graphene oxide membrane with the tent-like nanostructures has very broad application prospects in the fields of environmental pollution control and membraneseparation technology.

Owner:ZHEJIANG UNIV

Metal powder screening device of 3D printer

The invention discloses a metal powder screening device of a 3D printer, which comprises a containing assembly, a screening assembly, a pressure stabilizing assembly and a material receiving assembly.The containing assembly comprises a supporting frame, a screening tank, two sets of feeding pipes, a discharging pipe and a plurality of slag discharging pipes. The screening assembly comprises a supporting block, a screening motor, a plurality of conical screening nets, a motor protective cover and a plurality of material stirring rods. The pressure stabilizing assembly comprises a draught fan,a filter net, an air suction pipe, an exhaust pipe and an exhaust branch pipe. The material receiving assembly comprises a plurality of slag storage boxes and material storage boxes. Screening space is provided through the containing assembly; multi-stage screening of the metal powder is achieved through the screening assembly; metal powder can be screened into metal powder with different particlesizes and classified, subsequent recycling is facilitated, the interior of the screening tank is sucked through the pressure stabilizing assembly, the screening tank is kept in a micro-negative-pressure environment, the metal powder can fall into the discharging pipe conveniently, the metal powder is prevented from drifting out of the screening tank, and the screening environment is maintained.

Owner:安徽隆源成型科技有限公司

Efficient stone breaking and paving device

The invention relates to an efficient stone breaking and paving device. A coarse breaking cavity, a fine breaking cavity and a sieving and conveying cavity are arranged, so that stones can be broken into sizes according with paving conditions in real time in a paving process. Specific parts of the coarse breaking cavity and the fine breaking cavity are reasonably set so that the stones are uniformly broken; specific parts of the sieving and conveying cavity are set so that the sizes and specific distribution of the broken stones for paving a road are uniform and stable and the quality and thestability of road construction are improved.

Owner:HUBEI CHANGJIANG ROAD & BRIDGE HLDG

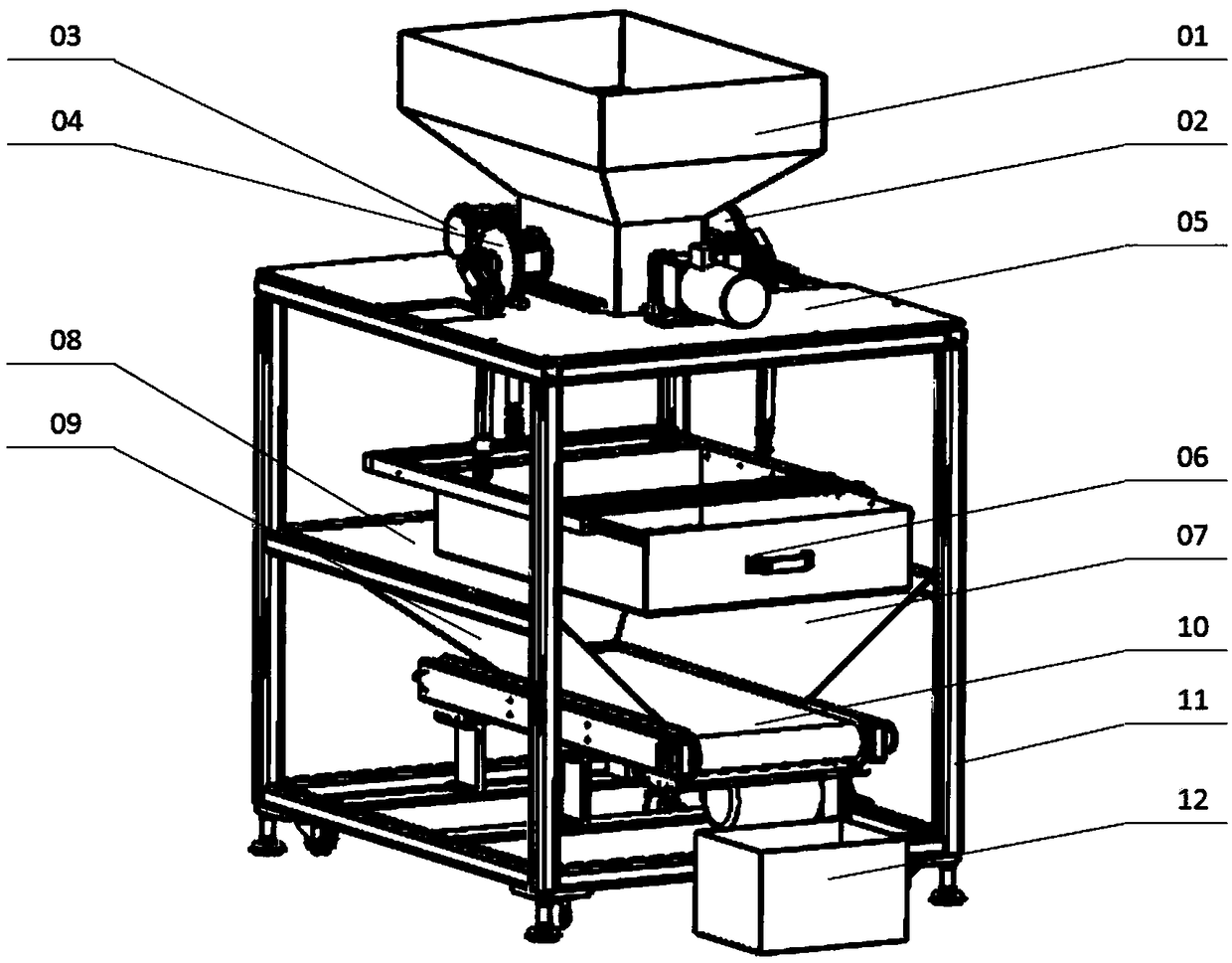

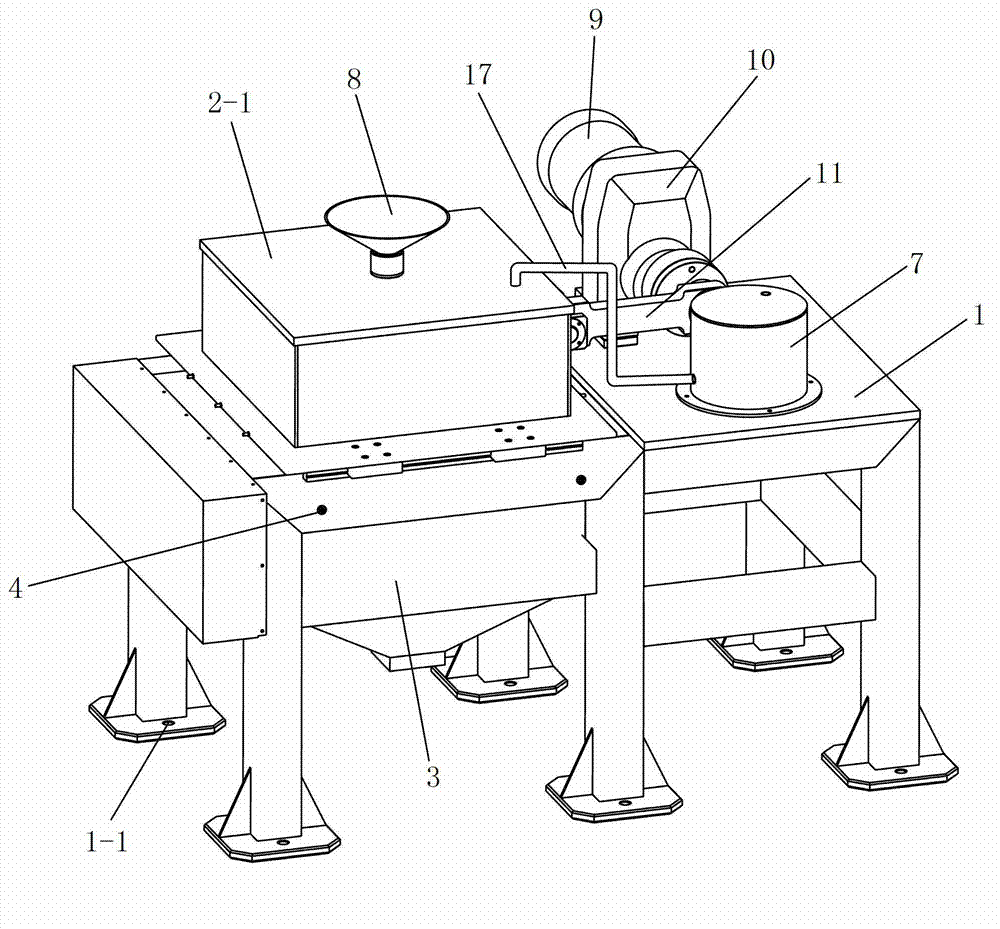

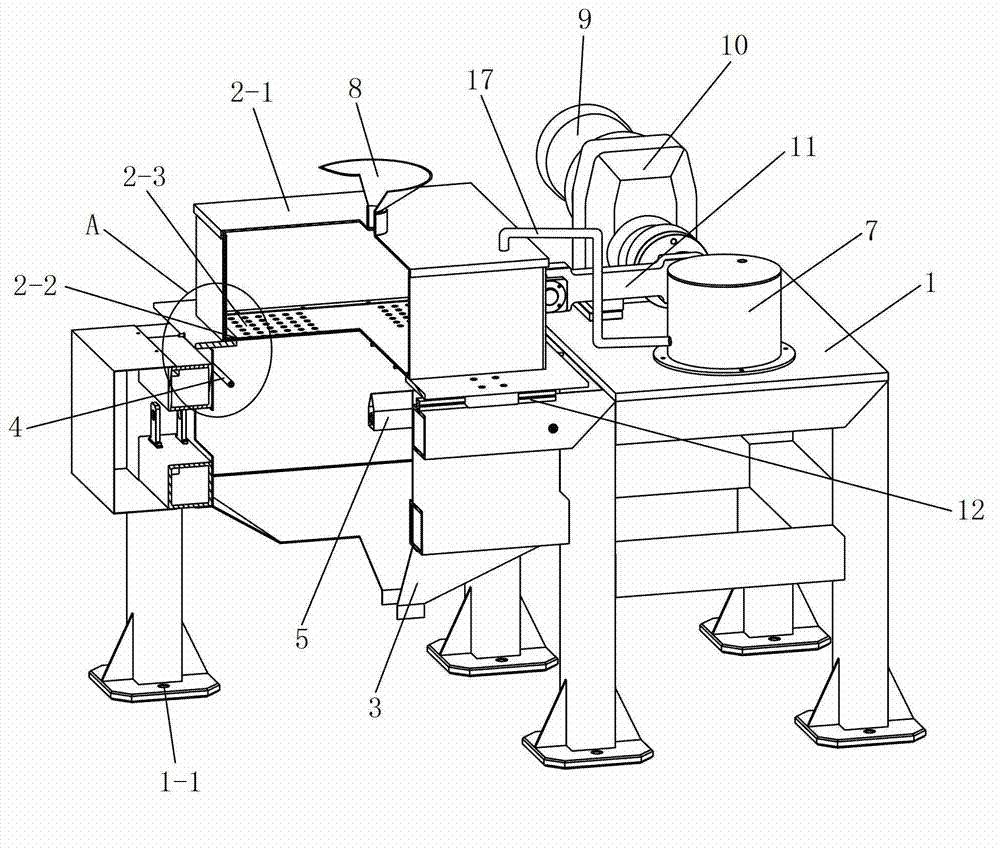

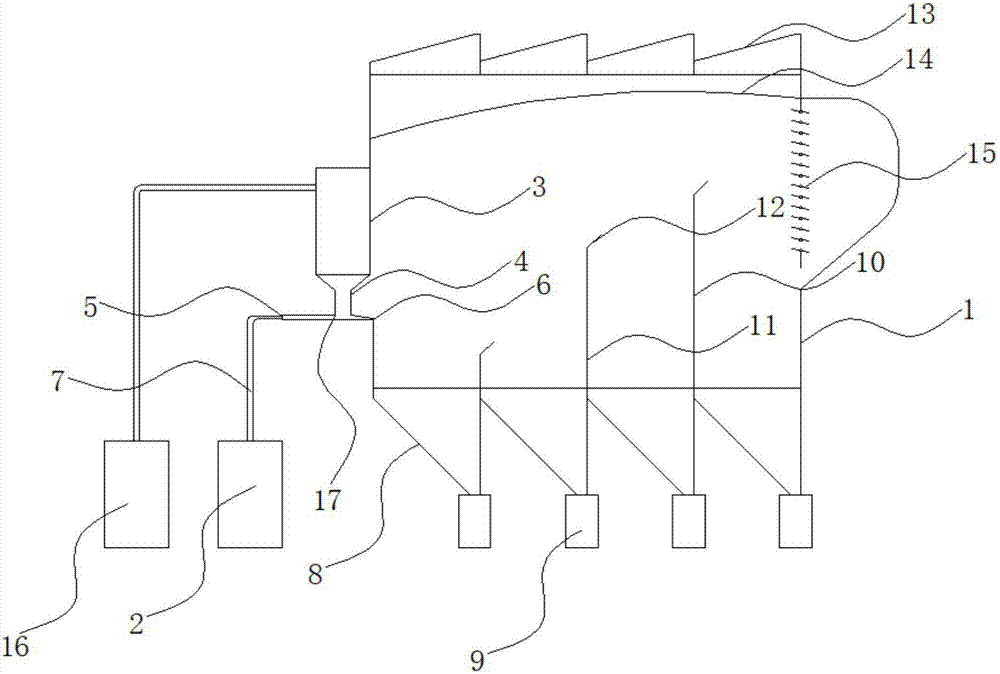

Automatic compound fertilizer granulation assembly system

ActiveCN103694064AAchieve granulationAchieve dryingGranulation in rotating drumsFertiliser formsEconomic benefitsAgricultural engineering

The invention discloses an automatic compound fertilizer granulation assembly system which comprises a granulator and a drier connected with the granulator. The system is characterized in that the granulator comprises a rotating drum, wherein the top of the rotating drum is provided with a feed port, the middle of the rotating drum is provided with a worm transmission part, the position with the same center of circle as the worm transmission part in the rotating drum is provided with a rotary sprayer, and the rotating drum and the rotary sprayer are driven to rotate by the same power source. The system has the advantages of ingenious and reasonable design and high systematicness; by arranging the multistage equipment, the system can effectively implement the functions of granulating, drying screening and assembling the compound fertilizer, has high degree of automation and superior performance; and compared with the existing split equipment, the efficiency is enhanced by more than 40%, and the economic benefit is enhanced by more than 30%.

Owner:河北百斗嘉肥料有限公司

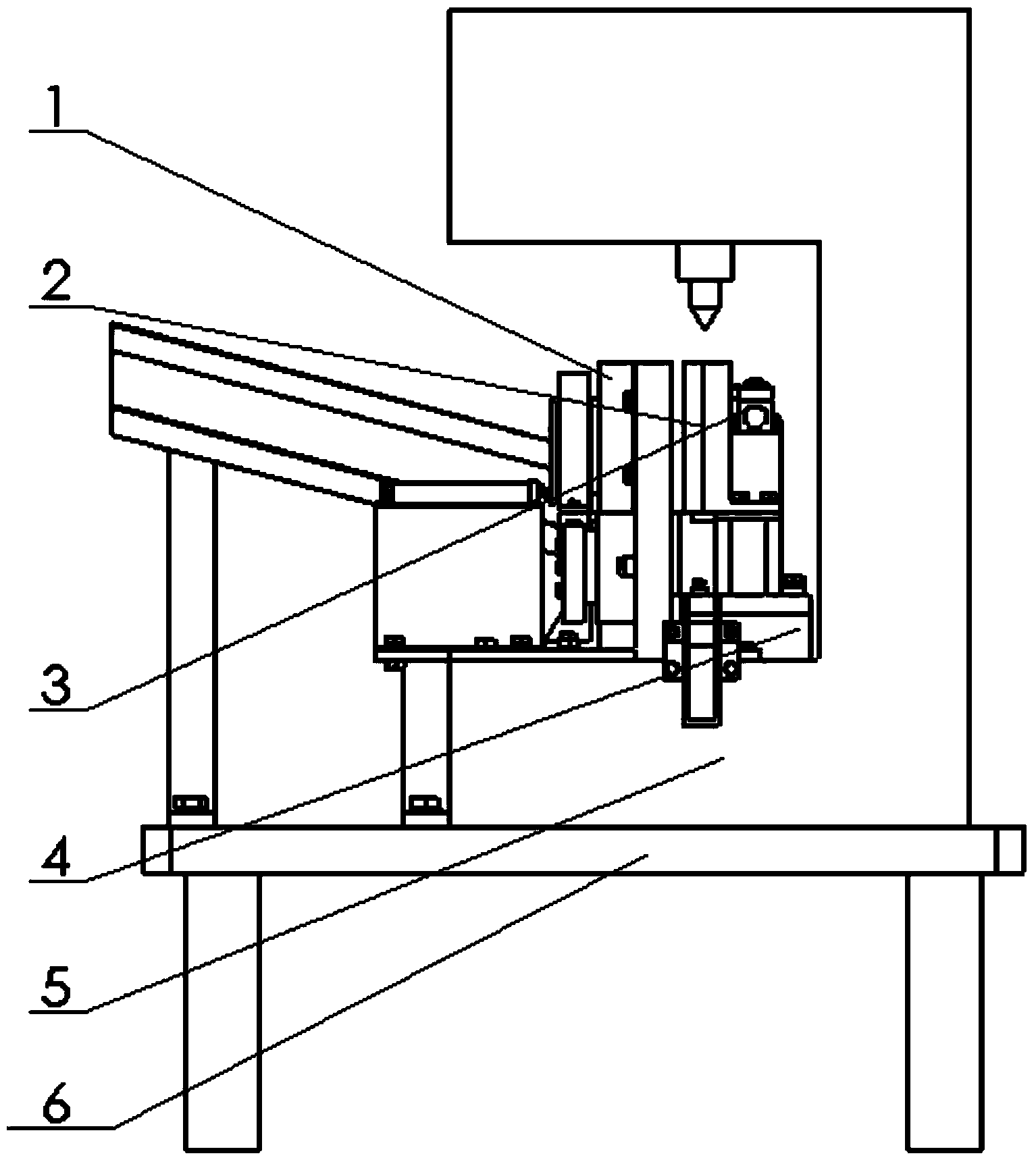

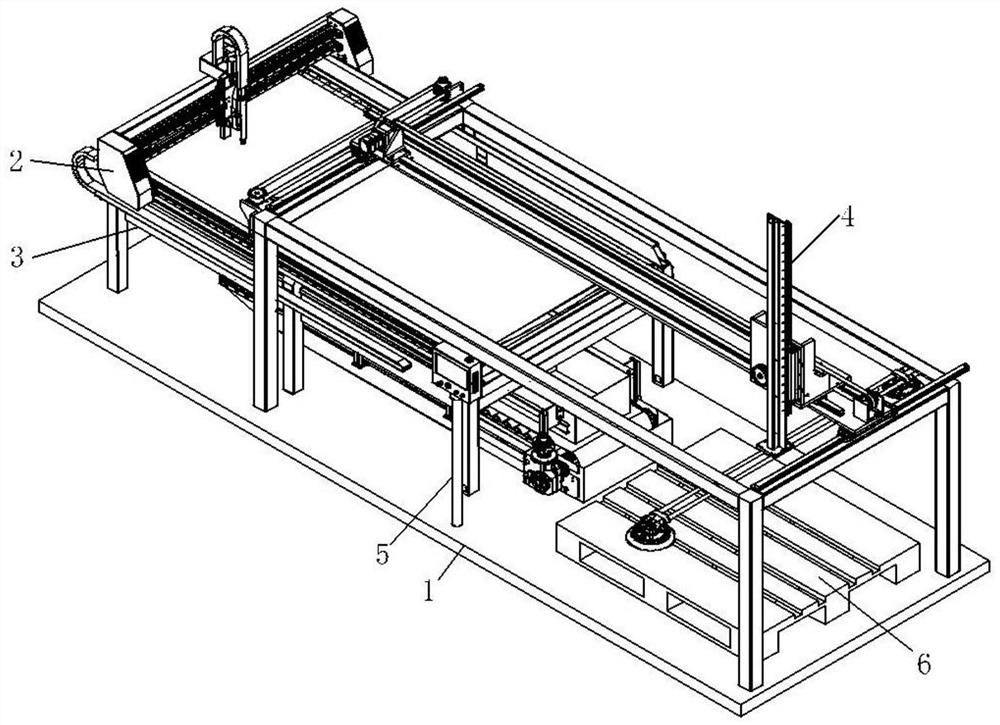

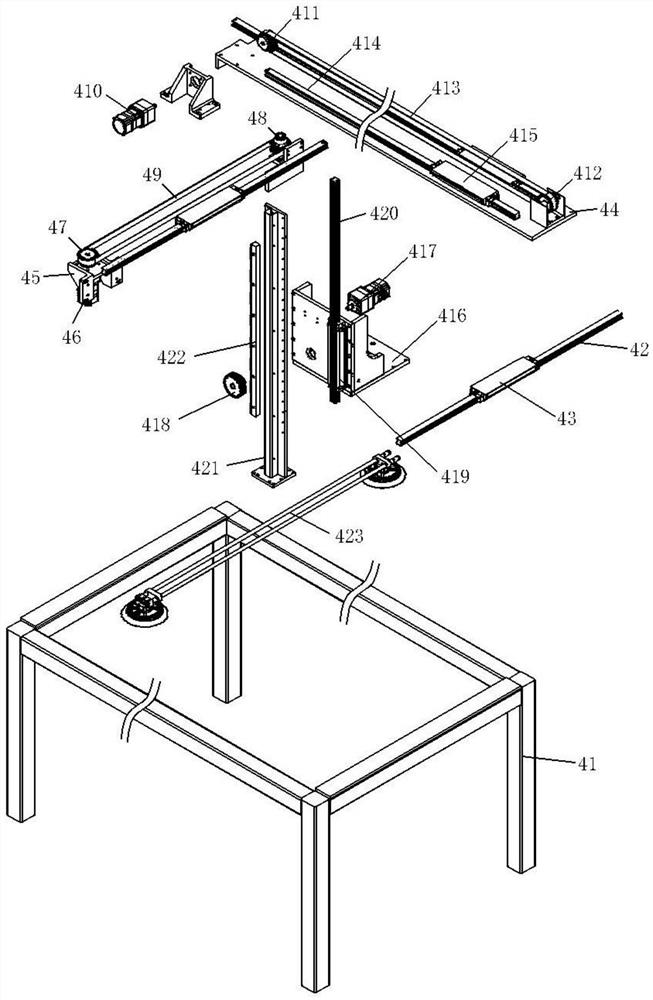

Numerical control laser cutting and automatic discharging device

InactiveCN112247369ARealize processingRealize automatic unloadingLaser beam welding apparatusNumerical controlStructural engineering

The invention discloses a numerical control laser cutting and automatic discharging device. The device comprises a base, a numerical control laser cutting device, a material discharge mechanism, a plate waste discharging mechanism, a control box and a loading and unloading area. The numerical control laser cutting device is arranged on the left side of the top end of the base through a support inthe left-right direction. The material discharge mechanism is arranged at the lower end of the numerical control laser cutting device in the left-right direction. The plate waste discharging mechanismis arranged on the right side of the top end of the base in the left-right direction and located on the outer side of the numerical control laser cutting device. The control box is installed on the front side of the top end of the base through a support. According to the numerical control laser cutting and automatic discharging device, automatic unloading of whole waste plates after laser cuttingcan be achieved, manual operation of workers is not needed, operation is easier and faster, automatic screening of cut machined finished products and cutting chippings is achieved, manual sorting ofthe workers is not needed, manual operation items of the workers are reduced, and time and labor are saved.

Owner:杨宝辉

Steel shot production line

The invention relates to the technical field of steel shot production, in particular to a steel shot production line. The steel shot production line comprises a centrifugal machine, a steel shot collecting device, a tempering furnace and a screening device, wherein the steel shot collecting device comprises a quenching bath; a frustum protruding upwards is arranged in the middle of the quenching bath; the centrifugal machine is mounted at the top of the frustum; steel shots thrown out by the centrifugal machine enter the quenching bath and are collected and then poured into a feed hopper of the tempering furnace through a skip, so that tempering treatment of the steel shots is started; and after finish of tempering, the steel shots are fed into a second feed hopper through a conveyor belt to be screened, so that the finally obtained steel shots are all screened, and accordingly, the steel shot production efficiency is improved.

Owner:南通壹选智能科技有限公司

Agricultural mechanical equipment for screening excellent seeds in agricultural planting

InactiveCN112221694AImprove screening qualityBeautiful appearanceSievingGas current separationAgricultural engineeringAgricultural science

The invention discloses agricultural mechanical equipment for screening excellent seeds in agricultural planting. The agricultural mechanical equipment comprises a water supply part, wherein the rightend of the water supply part is fixedly connected with a drying box, the right end of the drying box is fixedly provided with a drying device, the middle of the upper end of the drying box is fixedlyconnected with a first conveying pipe, and the left end of the first conveying pipe is fixedly connected with a screening box; and a feeding device is fixedly installed at the upper end of the screening box, a cleaning device penetrates through the middle of the upper end of the screening box, a second conveying pipe is fixedly connected to the middle of the lower end of the drying box, a sievingbox is fixedly connected to the lower end of the second conveying pipe, and collecting devices are fixedly installed at the four corners of the lower end of the sieving box jointly. According to theagricultural mechanical equipment for screening the excellent seeds in agricultural planting, wizened seeds or hollow seeds damaged by worms can be removed, the screening quality of the seeds is improved, agricultural planting is facilitated, the screened seeds are easy to store, in addition, multiple seeds can be screened, and bagging of the seeds is facilitated.

Owner:澄迈农博农业发展有限公司

Screening method and screening device for screening nano materials

The invention discloses a screening method and screening device for screening nano materials. According to the screening method, ionic wind is adopted to blow the nano materials, to disperse the nano materials and separate the nano materials in different particle size ranges. The screening device comprises a nano material storage device, a screening chamber, an ion fan and a nano material collecting device. The nano material storage device comprises a discharging port, and the discharging port is provided with an air inlet end and an air outlet end. The ion fan comprises an air outlet structure. The air outlet structure is connected with the air inlet end, and the air outlet end is disposed in the screening chamber. The ion fan blows ionic wind towards the discharging port through the air outlet structure. The nano materials are blown into the screening chamber from the air outlet end under the effect of the ionic wind, and the ionic wind can effectively disperse the nano materials to prevent the nano materials from aggregating. Under the blowing by the ionic wind, the nano materials with the different particle sizes move at different distances and then subside, so that grain screening is implemented.

Owner:SHENZHEN HADESHENG PRECISION TECH

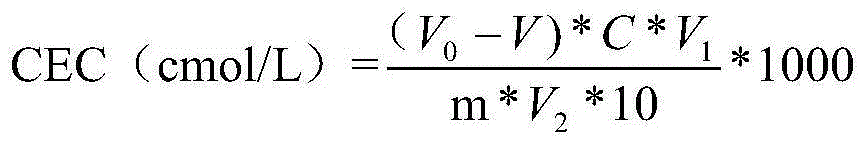

Fast detection method for cation exchange capacity

ActiveCN105223309ARealize batch verificationQuick removalChemical analysis using titrationPreparing sample for investigationCation-exchange capacityChemistry

The invention discloses a fast detection method for cation exchange capacity. A soil sample is selected, turned over, dried, conveyed into a grinding and screening machine to be crushed and screened, then dried in air naturally and pressed into a block to form a sample block, the sample block is filtered after being soaked in an ammonium chloride solution and centrifuged, and filter liquor is calibrated. By means of drying treatment, water in the soil sample is removed fast, crushing and screening can be achieved fast, crushing and screening integration of the grinding and screening machine is achieved, efficiency is improved, by means of block pressing treatment, batch detection of the sample can be achieved, and tedious manual weighing is avoided.

Owner:中国国检测试控股集团青岛京诚有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com