Soil crushing and fertilizer mixing device

A soil crushing and mixing device technology, which is applied in the field of soil, can solve the problems of poor soil crushing effect, enlarged gaps, and not easy to blend into the soil, etc., and achieves a remarkable effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

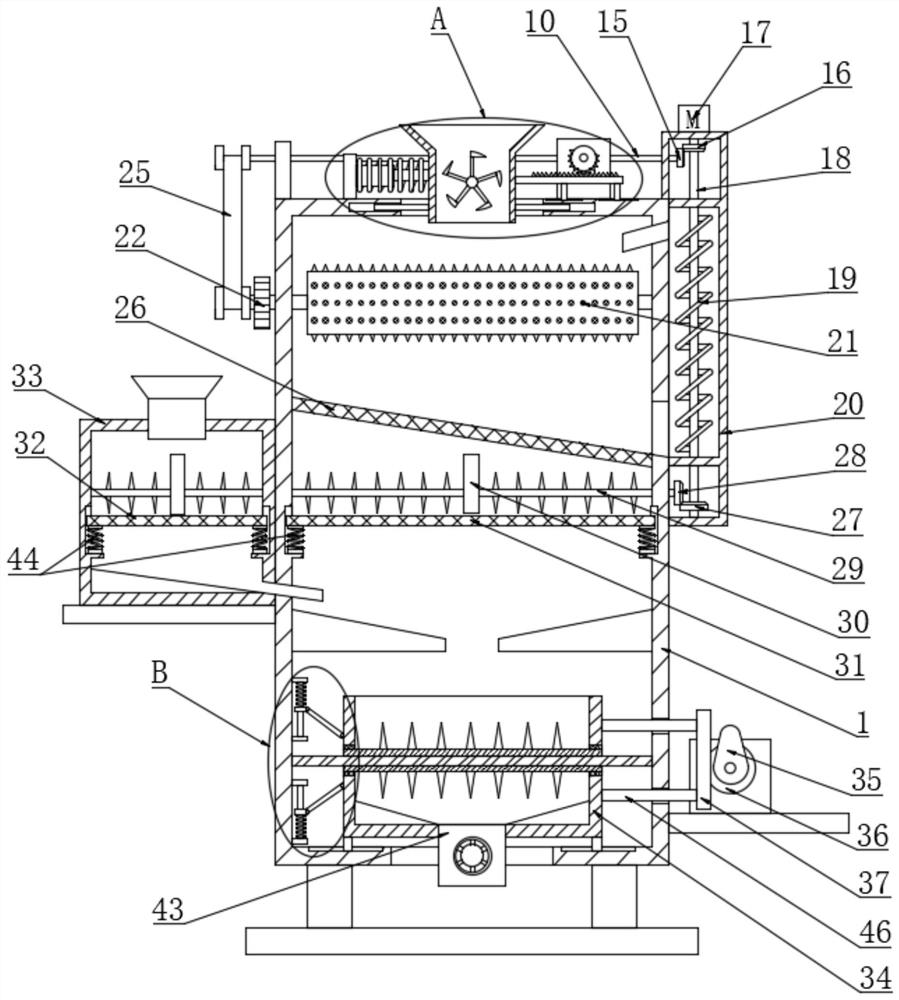

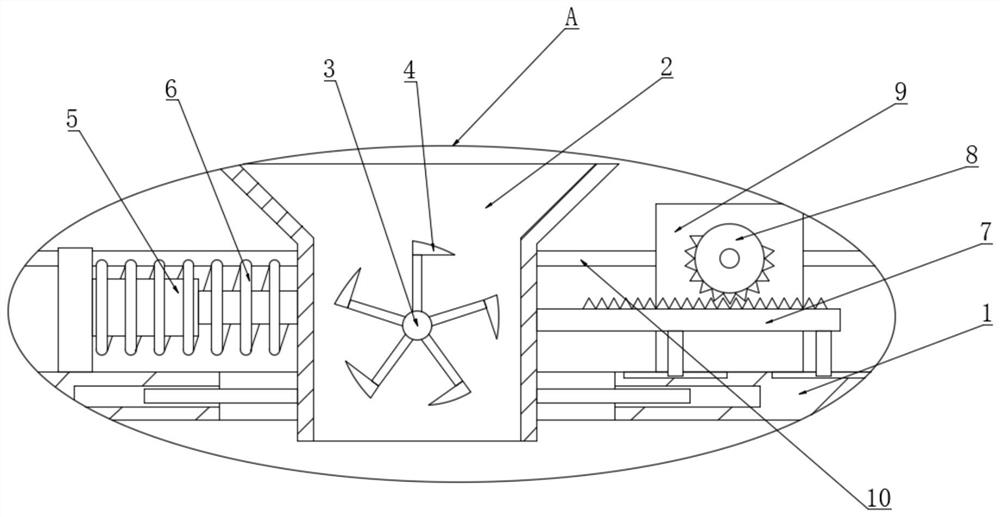

[0029] see Figure 1 to Figure 6 , a soil crushing and fertilizer mixing device, comprising a crushing box 1, the crushing box 1 is fixedly connected with a fertilizer box 33 through a pipeline, and the top of the crushing box 1 is movably connected with a feed hopper 2, and the inside of the feed hopper 2 A stirring flap 4 is provided to facilitate stirring and crushing, and a first linear reciprocating drive assembly is connected to the outside of the feed hopper 2, and the first linear reciprocating drive assembly includes a first bar tooth 7 and an incomplete gear 8 , telescoping column 5 and first spring 6, described incomplete gear 8 is connected with conveying assembly through second bevel gear 12 and second rotating shaft 10, and described conveying assembly comprises conveying bin 20, conveying shaft 18, Jiaolong blade 19 and the first motor 17, the stirring turnover plate 4 is connected with a rotating gear assembly through the first rotating shaft 3, and the rotatin...

Embodiment 2

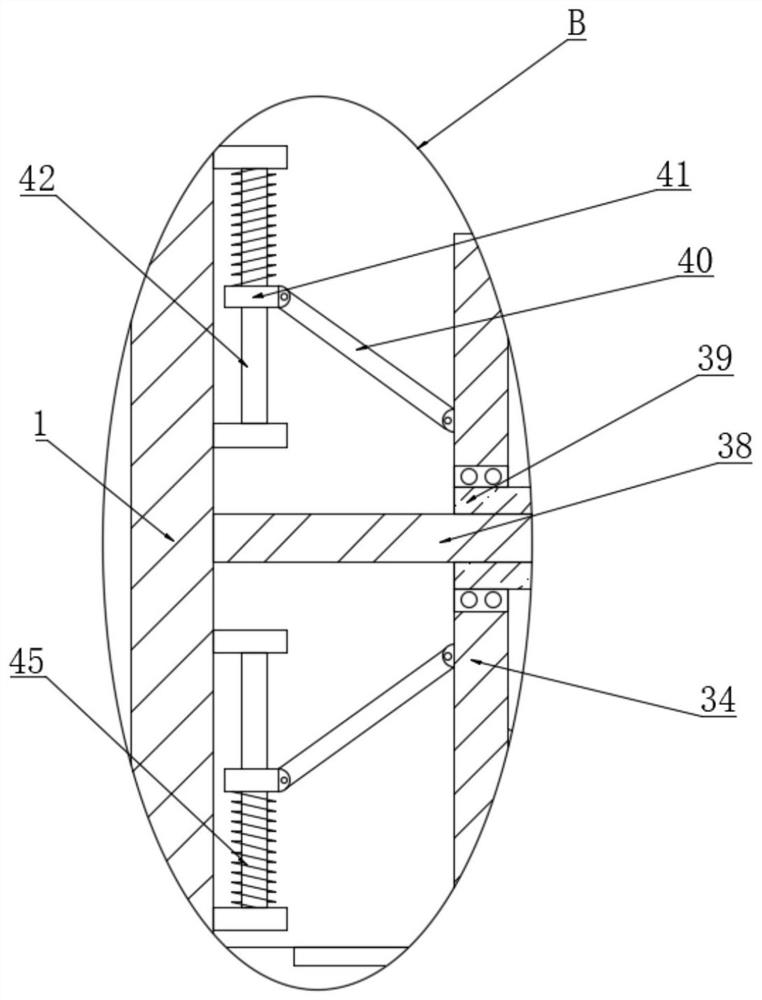

[0043] see Figure 1 to Figure 6 , a soil crushing fertilizer mixing device, comprising a crushing box 1, the crushing box 1 is fixedly communicated with a fertilizer box 33 through a pipeline, and also includes a mixing frame 34, and a stirring assembly is arranged in the mixing frame 34, and the stirring assembly includes Fixed screw rod 38 and threaded sleeve rod 39, said threaded sleeve rod 39 is fixedly connected with a number of crushing knives, said threaded sleeve rod 39 is connected to the inside of mixing frame 34 through bearing rotation, and said mixing frame 34 is slidably connected by a slider At the bottom of the crushing box 1, a second linear reciprocating drive assembly is connected to the outside of the mixing frame 34, and the second linear reciprocating drive assembly includes a connecting rod 40, a third spring 45, a second slide rod 46, a second cam 35 and the second motor 36, the bottom of the mixing frame 34 is fixedly connected with a discharge pipe 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com