Screening method and screening device for screening nano materials

A technology of nanomaterials and screening equipment, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc., can solve problems such as nanomaterial screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

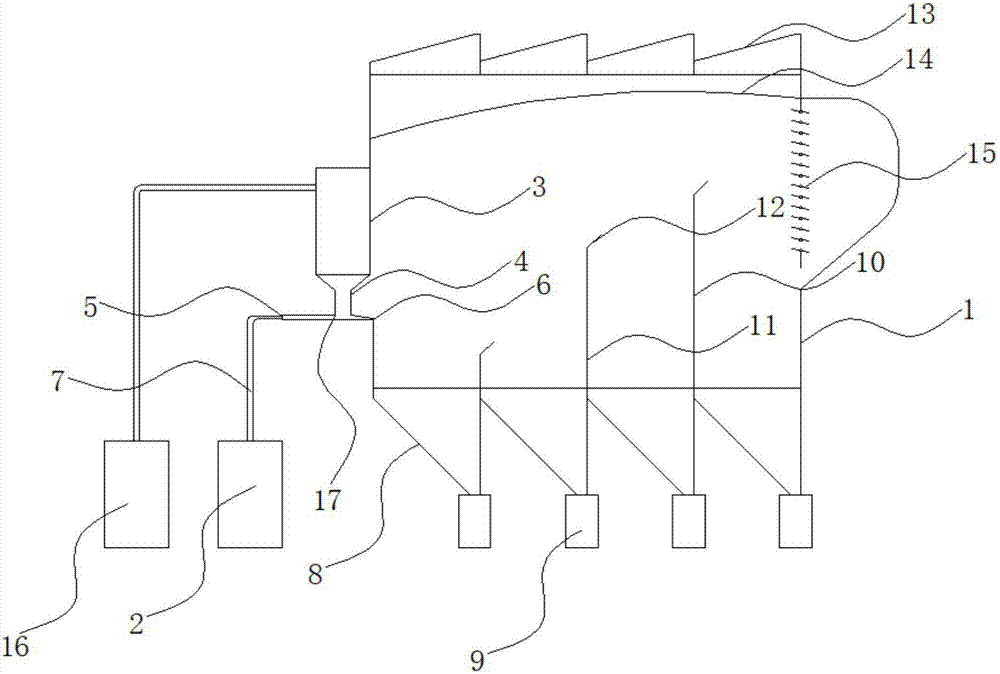

[0024] The invention provides a screening method for nanometer materials, comprising the following steps: using ion wind to blow the nanometer materials, dispersing the nanometer materials and separating the nanomaterials in different particle size ranges. The nanomaterial is any one of carbon nanospheres, carbon nanotubes, nano oxide particles, nano metal particles and graphene. The wind volume of the ion wind is 35-600CFM. The sieving method also includes setting at least one nanometer material collecting device along the wind blowing direction, and the nanometer material collecting device is used to collect the nanometer material within a certain particle size range. The ionic wind can promote the electrical neutralization of nanomaterials and prevent the agglomeration of nanomaterials. Under the blowing of ionic wind, nanomaterials with different particle sizes travel different distances and then settle down. The particles with larger particle sizes settle at a shorter dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com