Novel wheat screening device for flour processing

A screening device and technology for wheat, applied in the directions of sieving, application, and separation of solids from solids by air flow, etc., can solve the problems of large area of screening equipment, large area of screening system, complicated screening steps, etc. To achieve the effect of compact structure, excellent screening effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

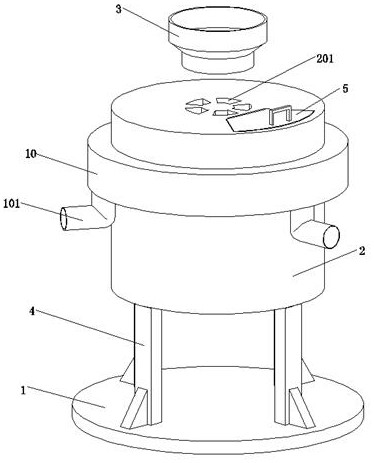

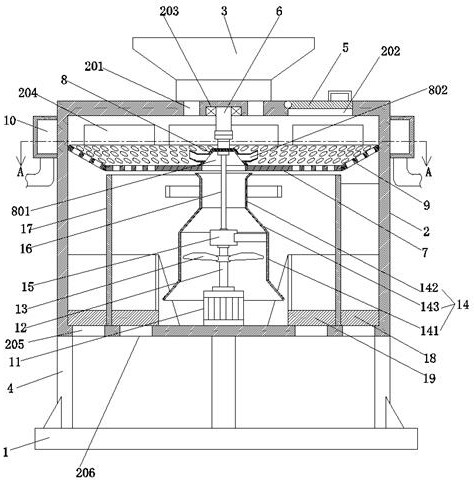

[0035] Example 1 introduces a new type of wheat screening device for flour processing, which rotates the centrifugal sieve disc to make the wheat to be screened roll around, and then realizes multi-stage screening through wind force and sieve holes with different diameters. its specific instructions.

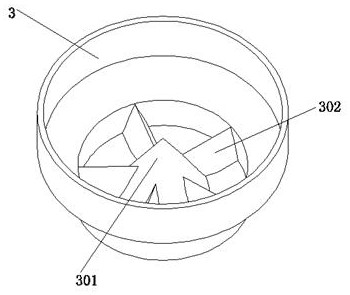

[0036] Reference attached figure 1 and reference attached figure 2 , its main structure includes a bottom plate 1, a screening cylinder 2 and a feed hopper 3, four legs 4 are connected to the lower surface of the screening cylinder 2, and the legs 4 are fixedly connected to the upper surface of the bottom plate 1, and the center of the upper surface of the screening cylinder 2 There are five feeding ports 201 in an annular array at the center, and the feeding hopper 3 thereof is arranged at the center of the circle on the upper surface of the screening drum 2 . In order to make the wheat to be screened in the feed hopper 3 evenly fall into each feed port 201, a conical block ...

Embodiment 2

[0042] Embodiment 2 is a further improvement on the basis of Embodiment 1, which mainly improves the air supply pipe 14 and specifically improves the discharge modes of the small gravel discharge port 206 and the wheat discharge port 205 . It is described in detail below:

[0043] Embodiment 2 is similar to Embodiment 1 and will not be described again. The difference is that this embodiment designs the air supply pipe 14 in sections. Refer to the appended image 3 , the air supply pipe 14 in this embodiment includes a lower air inlet pipe section 141 and an upper reinforced pipe section 142, wherein the lower air inlet pipe section 141 and the upper reinforced pipe section 142 are connected by a round platform pipe section 143, and the lower air inlet pipe section 141 The diameter is greater than the diameter of the upper reinforced pipe section 142, and the design will ensure that the fan blade 13 and the reduction box 15 are designed inside the lower air inlet pipe section 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com