Efficient stone breaking and paving device

A stone, high-efficiency technology, applied in the field of high-efficiency stone crushing and paving devices, can solve the problems of high labor consumption and high labor requirements, and achieve the effects of reduced intervention, uniform crushing, and uniform size of crushed stones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

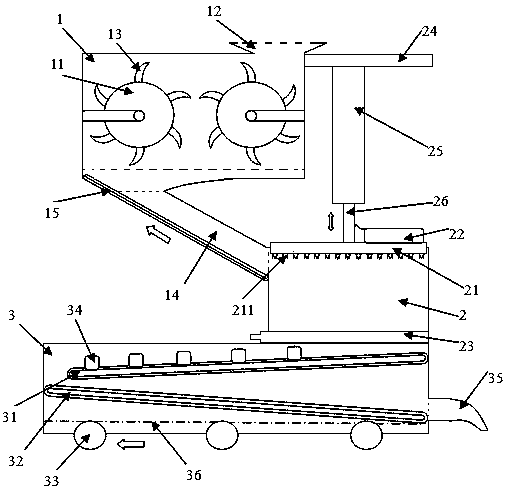

[0027] Such as figure 1 with figure 2 Shown: a high-efficiency stone crushing and paving device, including a coarse crushing chamber, a fine crushing chamber and a screening conveying chamber.

[0028] The coarse crushing chamber includes two crushing rollers stacked on top of each other, each of which is provided with half-crescent crushing blades, and the rotation direction of the crushing rollers is set to rotate toward the inner arc of the crushing blades , the upper crushing chamber shell on the right side is provided with a stone inlet, and the crushing chamber shell on the lower part of the left crushing roller is provided with an inclined coarse crushing cavity outlet slideway, and the coarse crushing chamber exit slideway The bottom is provided with a return conveyor belt, and the moving direction of the return conveyor belt is from bottom to top.

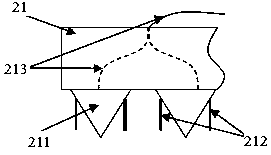

[0029] The shell of the fine cavity is set as a cylinder as a whole, the entrance of the fine cavity is set on the up...

Embodiment 2

[0044] A high-efficiency stone crushing and paving device includes a coarse crushing chamber, a fine crushing chamber and a screening conveying chamber.

[0045] The coarse crushing chamber includes two crushing rollers stacked on top of each other, each of which is provided with half-crescent crushing blades, and the rotation direction of the crushing rollers is set to rotate toward the inner arc of the crushing blades , the upper crushing chamber shell on the right side is provided with a stone inlet, and the crushing chamber shell on the lower part of the left crushing roller is provided with an inclined coarse crushing cavity outlet slideway, and the coarse crushing chamber exit slideway The bottom is provided with a return conveyor belt, and the moving direction of the return conveyor belt is from bottom to top.

[0046] The rotation direction of the crushing roller is set as follows: the crushing roller on the right side rotates counterclockwise, and the crushing roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com