Patents

Literature

323results about How to "Evenly placed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

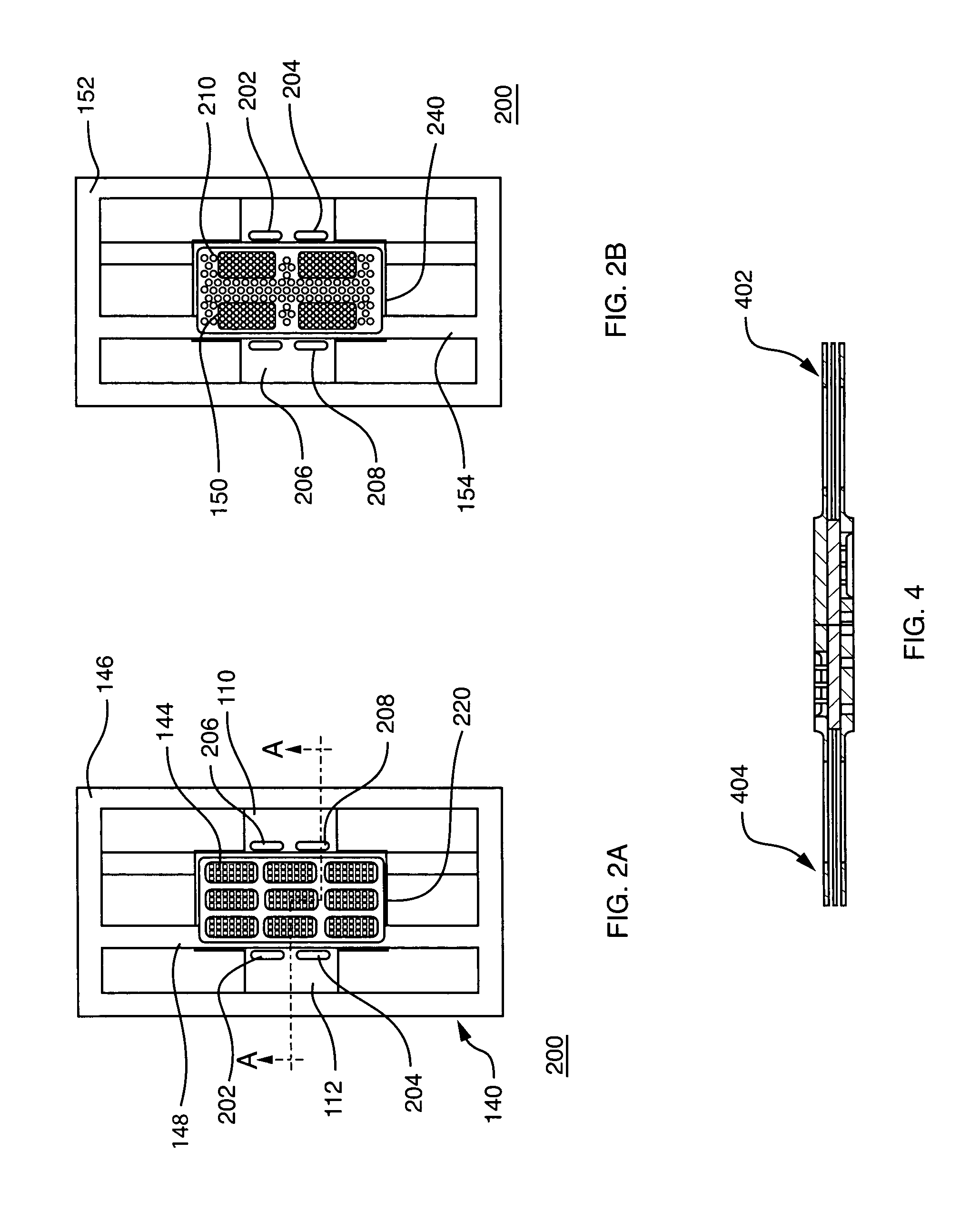

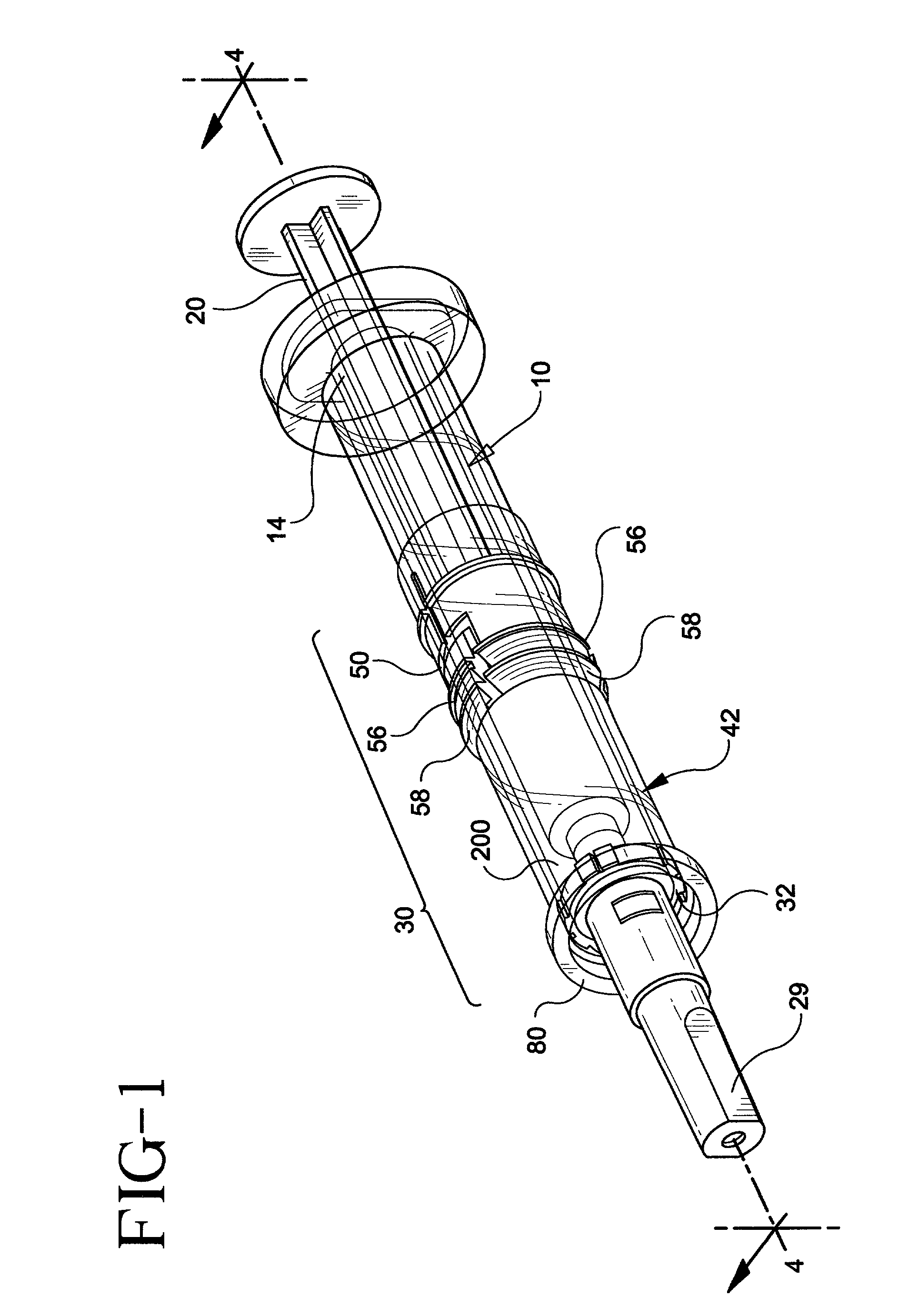

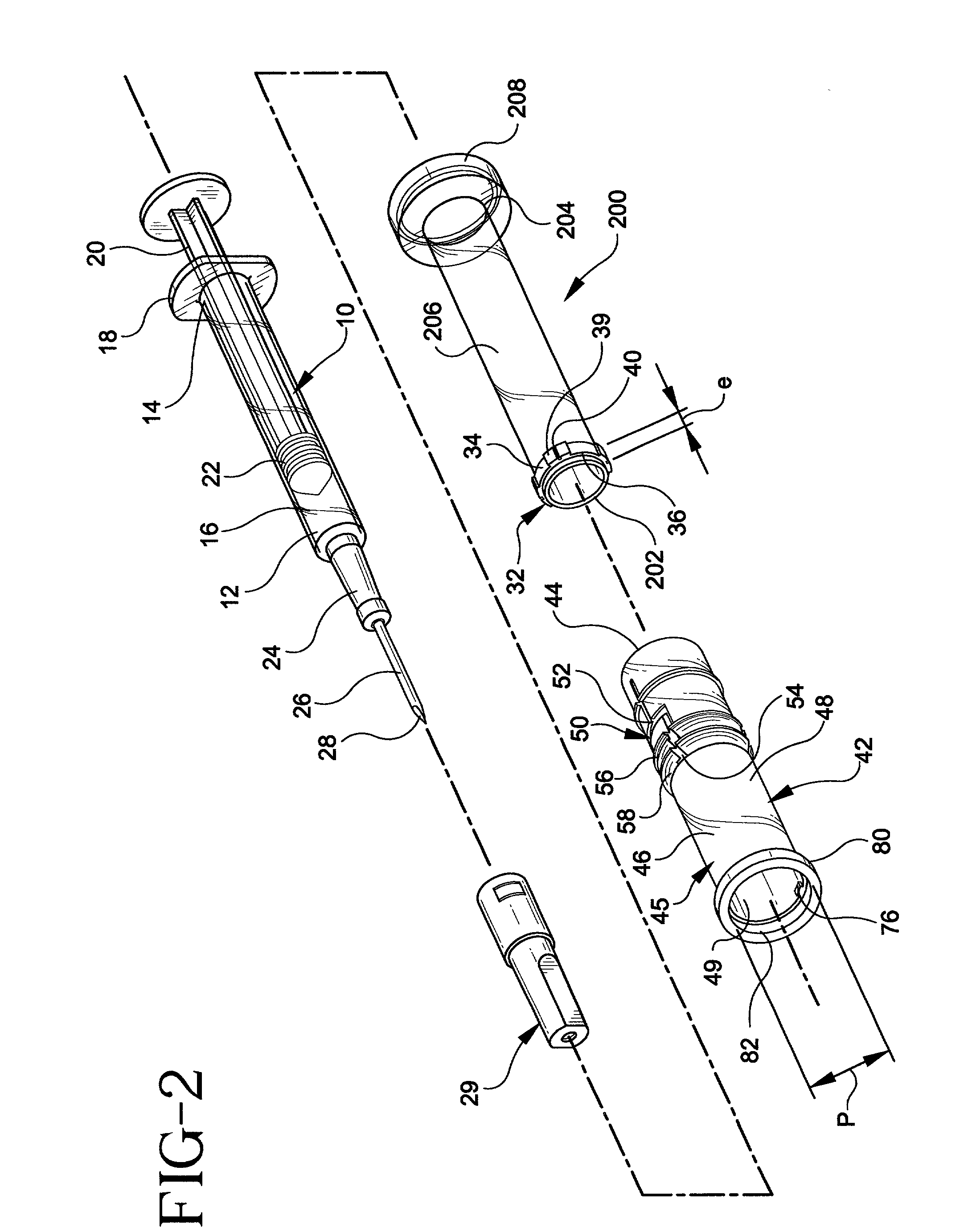

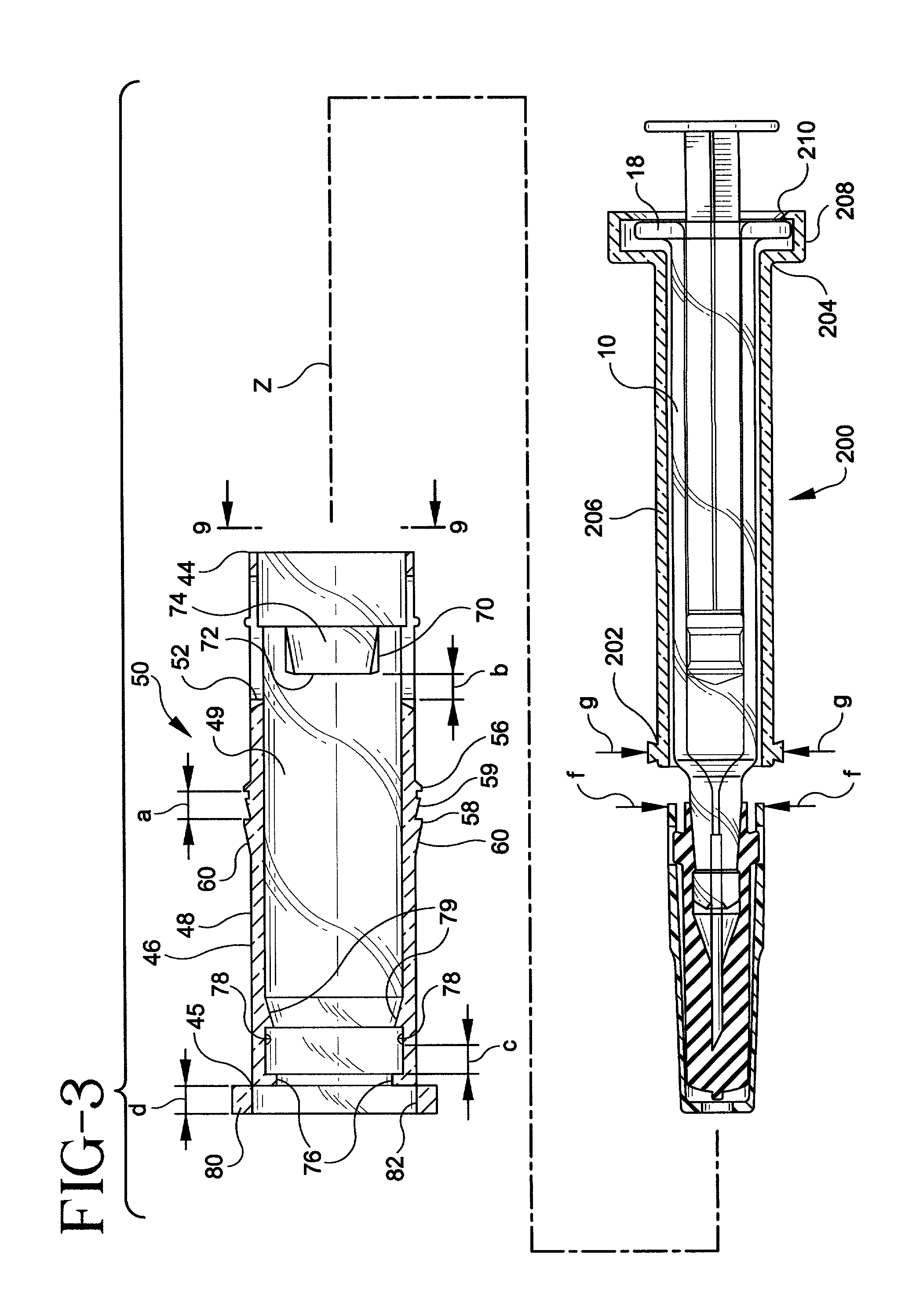

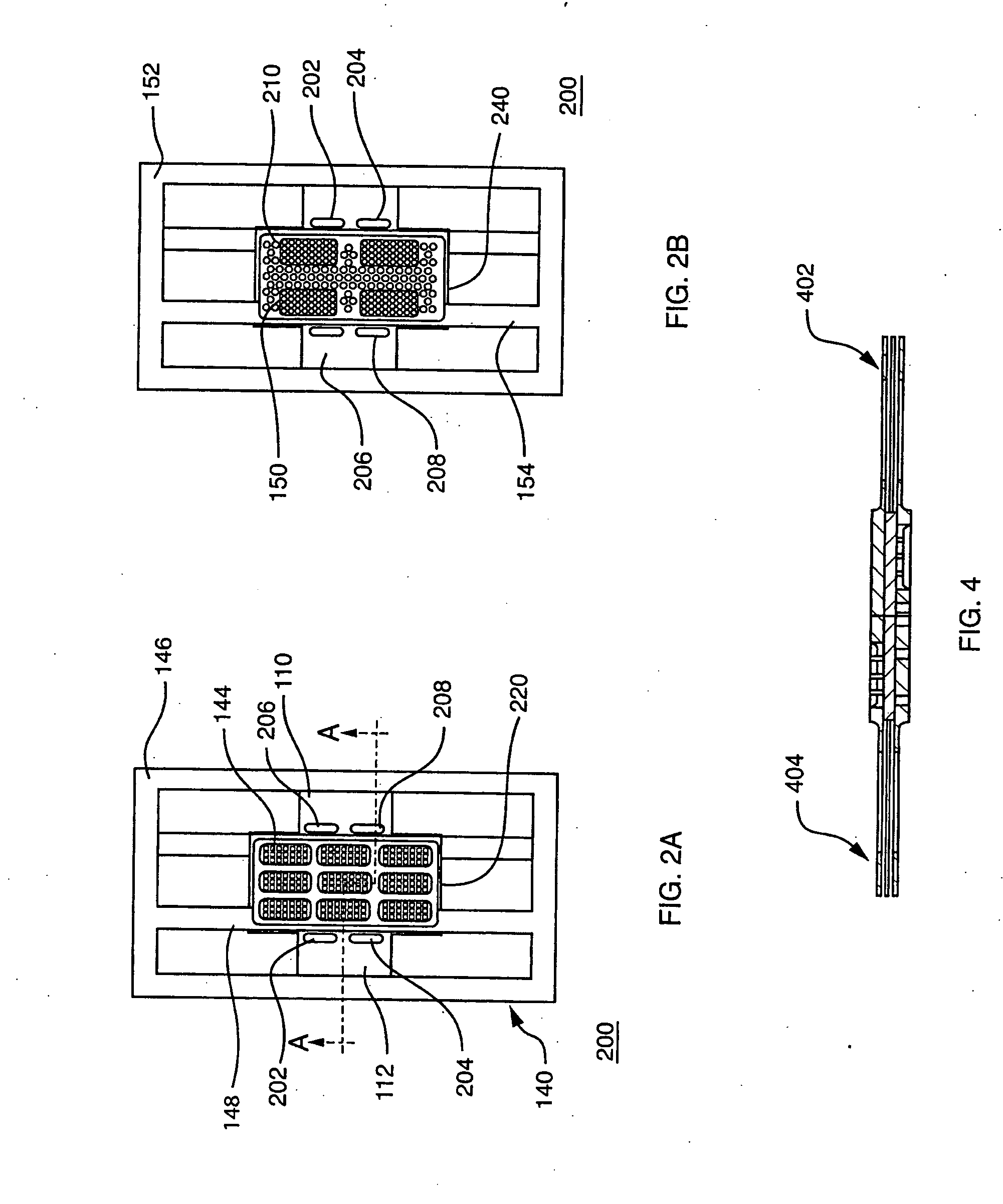

Lockable safety shield assembly for a prefillable syringe

InactiveUS6193696B1Easy to assemblePromote activationInfusion syringesMedical devicesEngineeringPrefilled Syringe

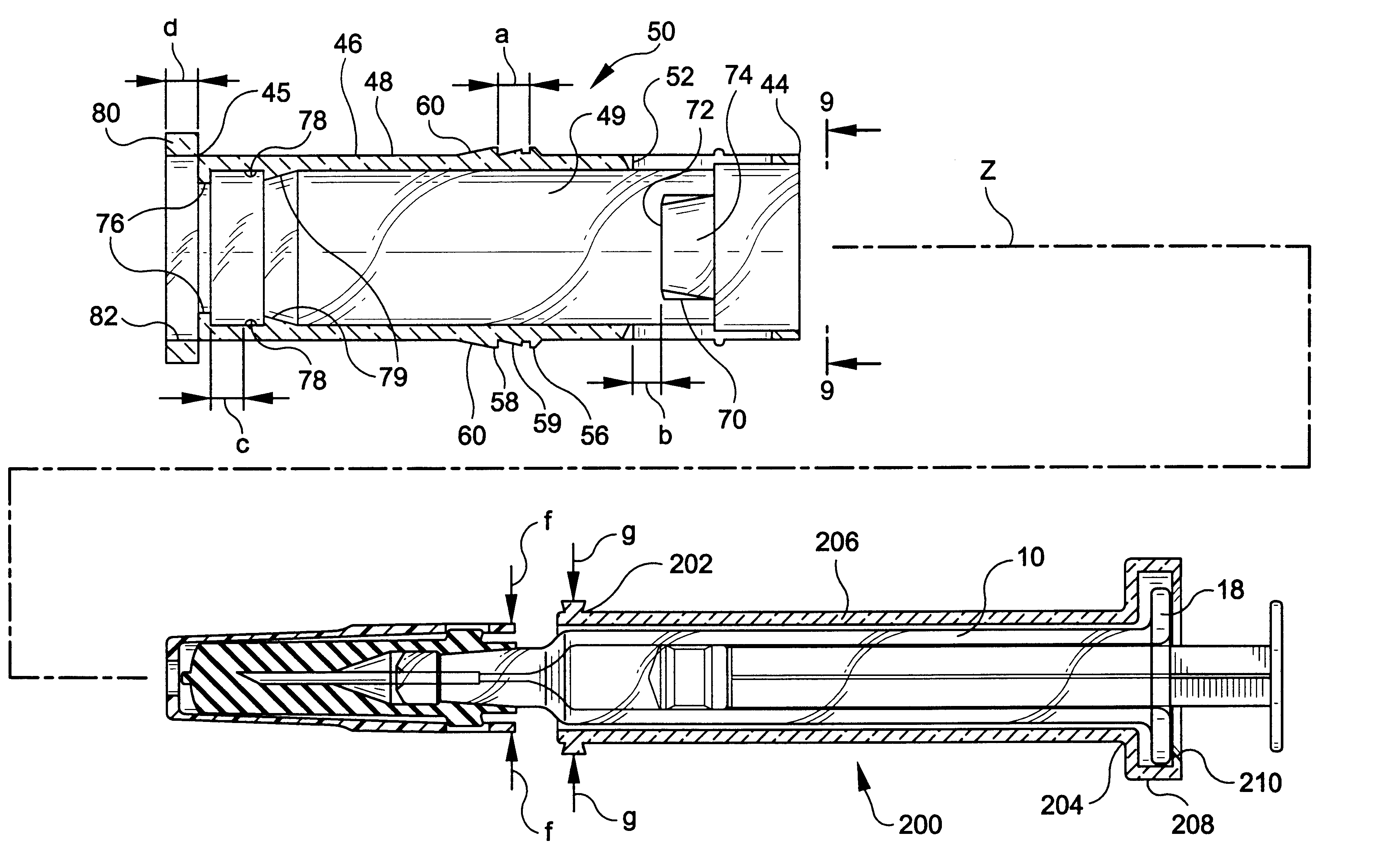

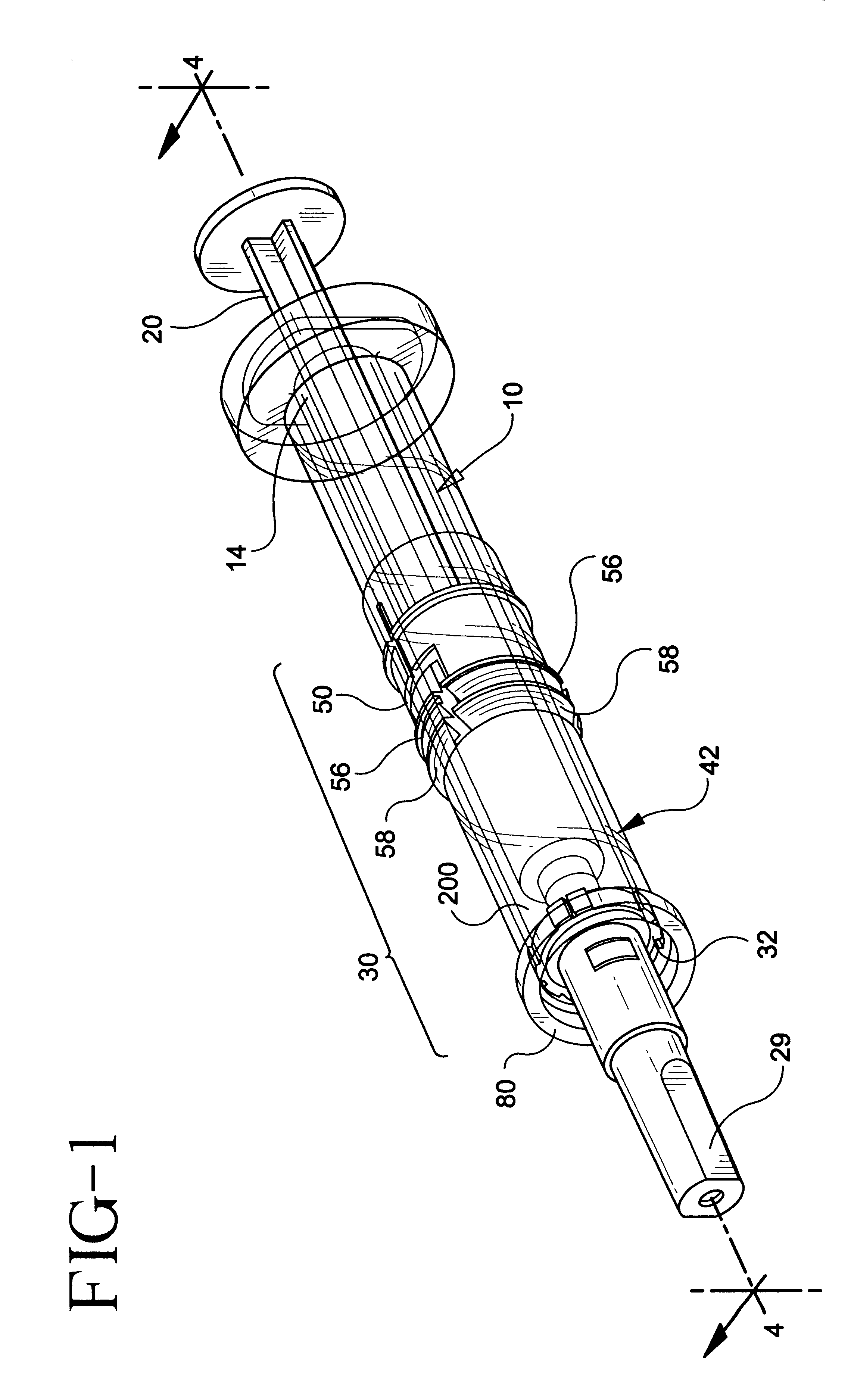

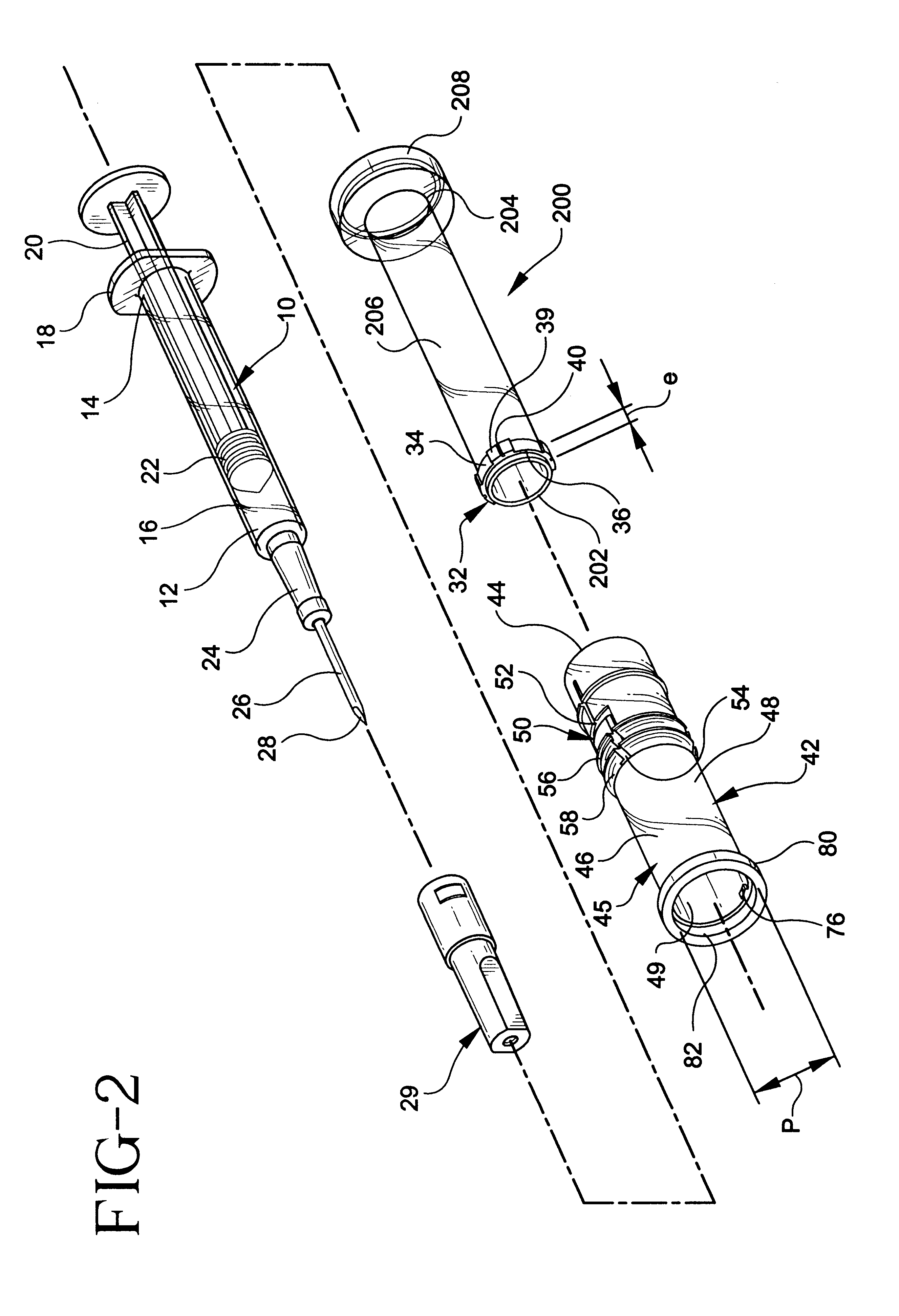

A lockable safety shield assembly for a prefillable syringe is provided. The design of the lockable safety shield assembly enhances pharmaceutical manufacturers' ease of assembling the various components as part of its filling or processing of the prefillable syringes in normal practice, while at the same time minimizes difficulties in mating parts made from different materials. A tube is placed around the outside surface of the syringe barrel and affixed thereto. A collar is provided on the tube adjacent the distal end of the syringe barrel. A safety shield is axially slidable over the tube between a retracted position, wherein the distal end of the piercing element associated with the prefillable syringe is exposed, and an extended position, wherein the safety shield is locked to the collar to protectively cover the distal end of the piercing element. The safety shield includes locking structure configured so that the shield can be easily fitted over the tube. The locking structure includes at least one deflectable arm provided on the body of the shield. The deflectable arm includes a proximal end deflectable towards the interior of the shield. A stop member is provided on the interior of a shield in spaced relation to the proximal end of the deflectable arm. A ring is axially slidable over the shield to deflect the arm towards the interior of the shield to activate the locking structure. The safety shield is slid distally by an end user such that the collar is lockingly retained between the stop member and the proximal end of the deflectable arm. The collar, the stop member, and the deflectable arm may be configured to provide tactile as well as audible indication of locking to the end user.

Owner:BECTON DICKINSON & CO

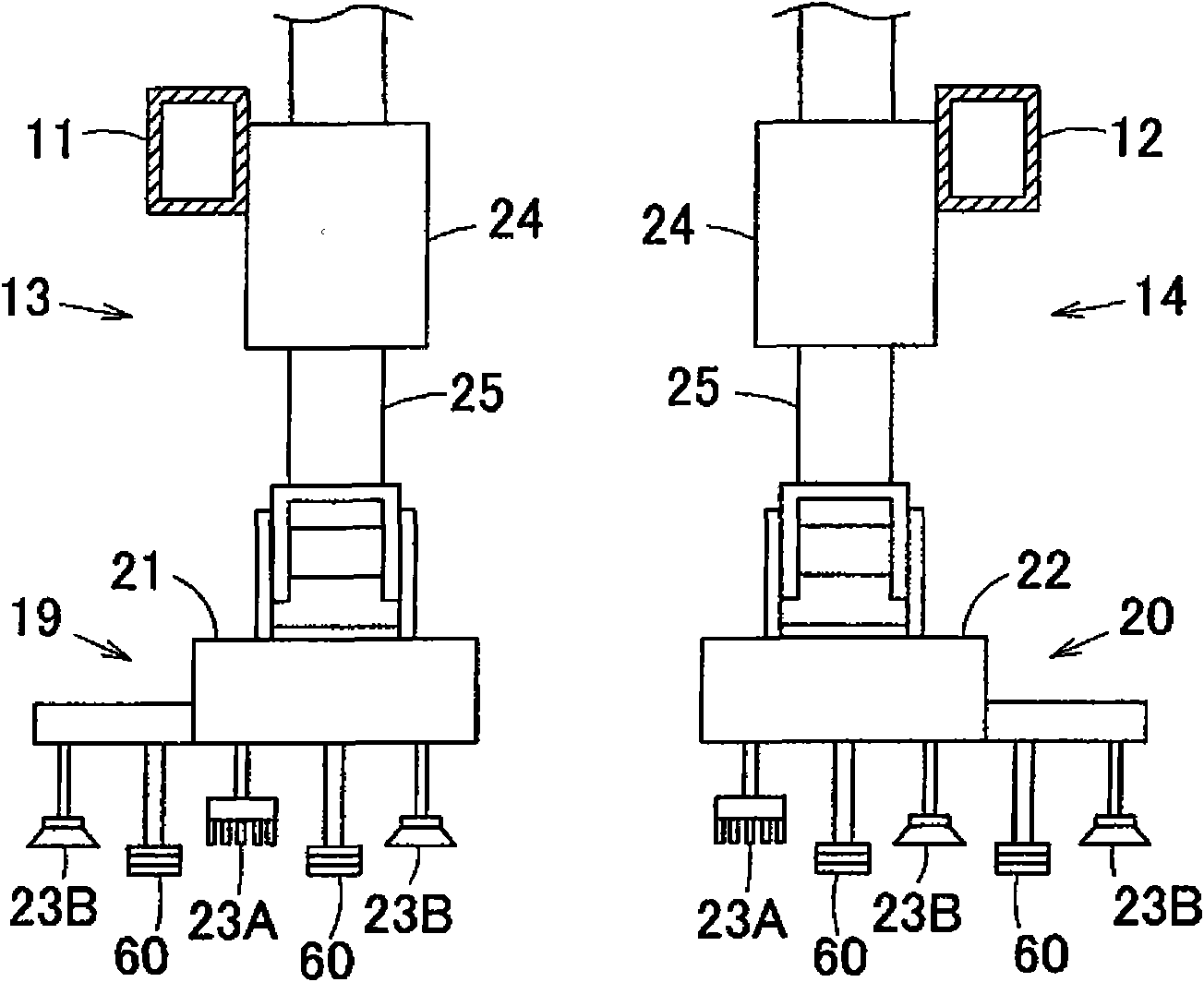

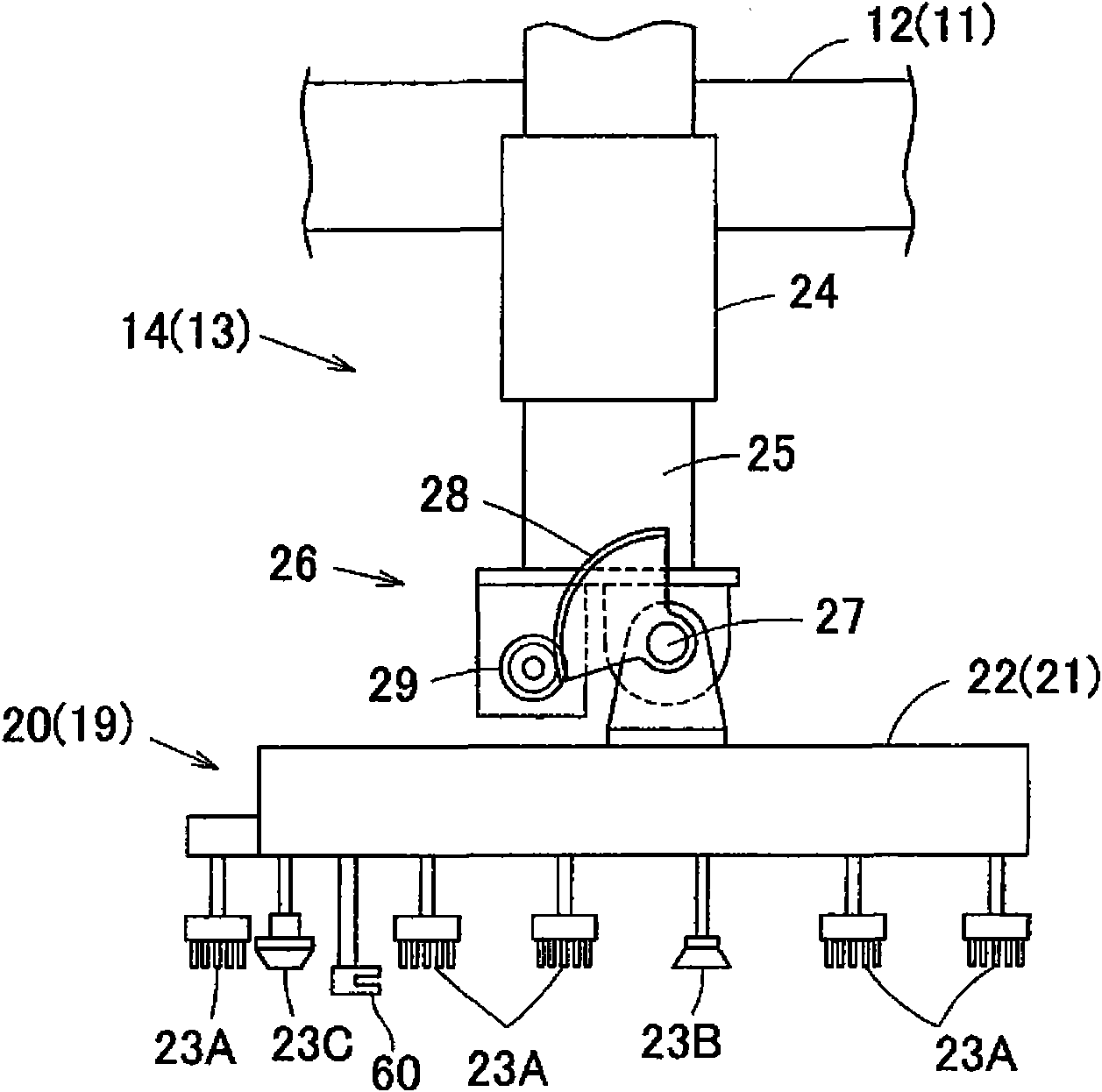

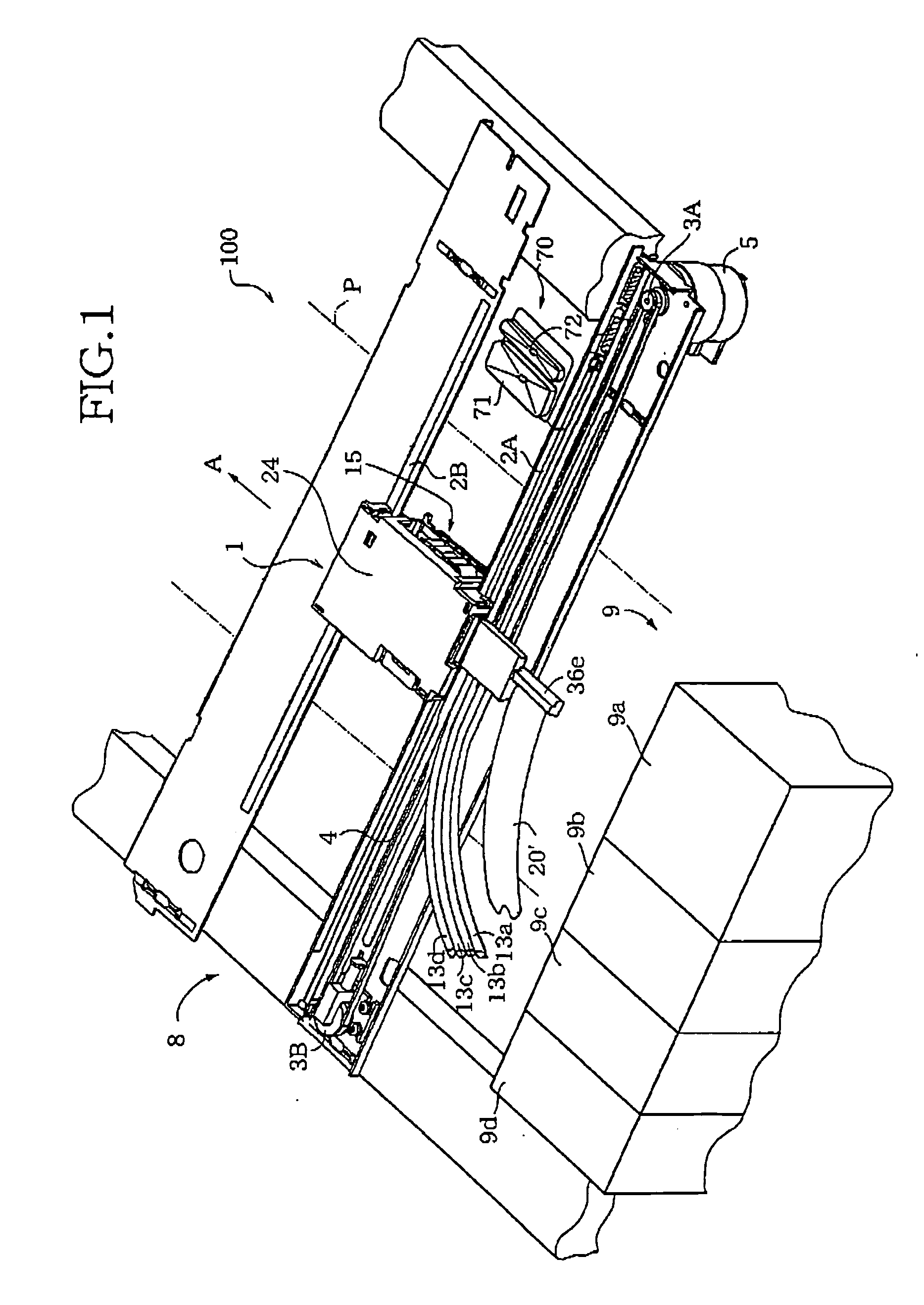

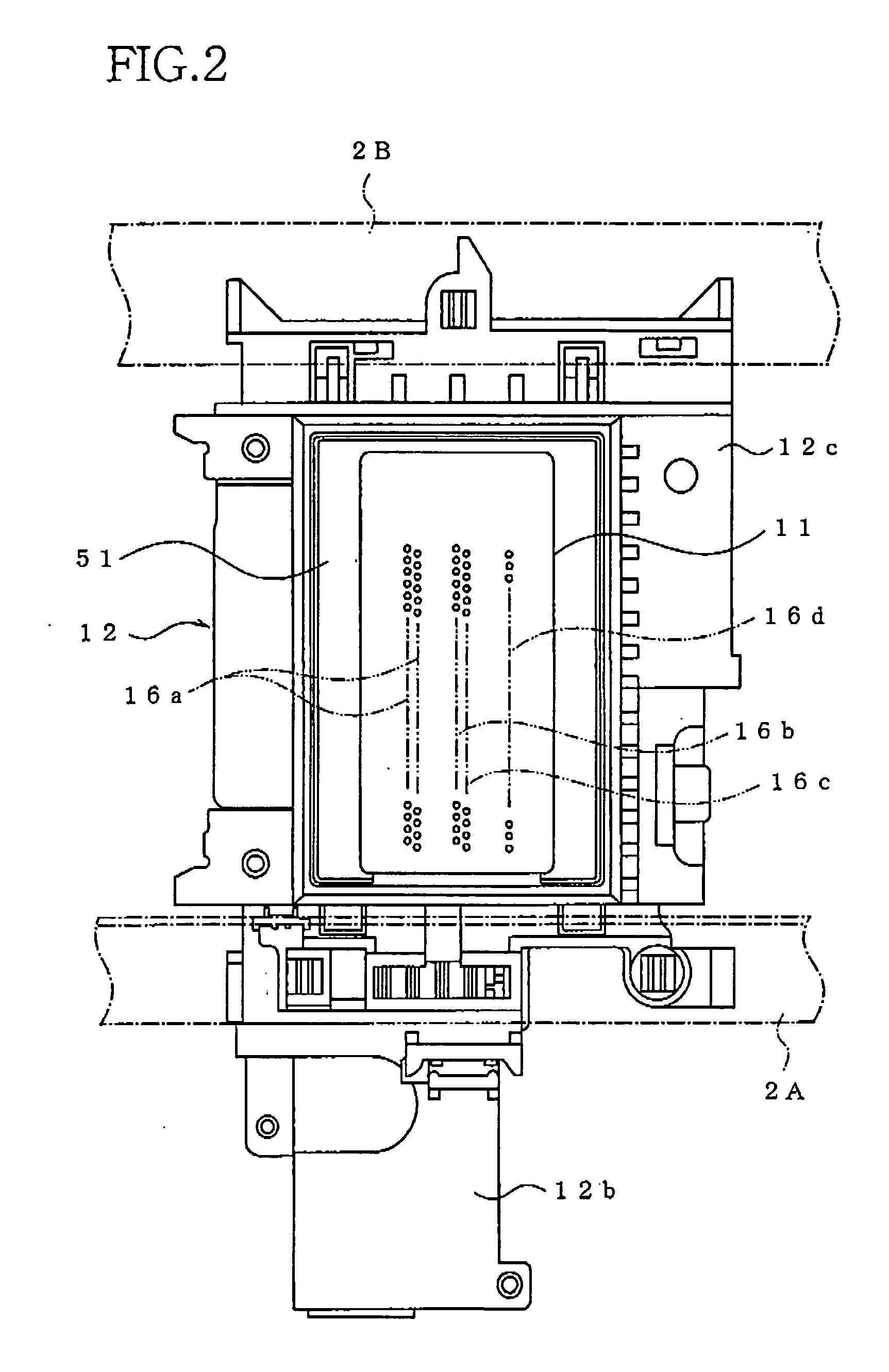

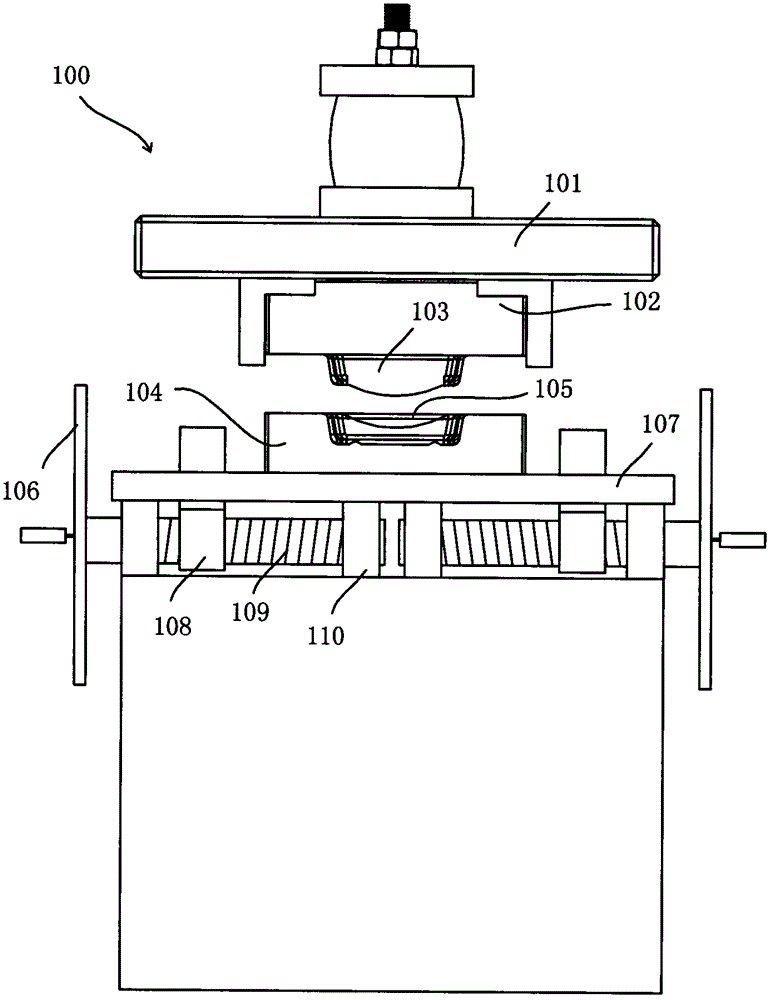

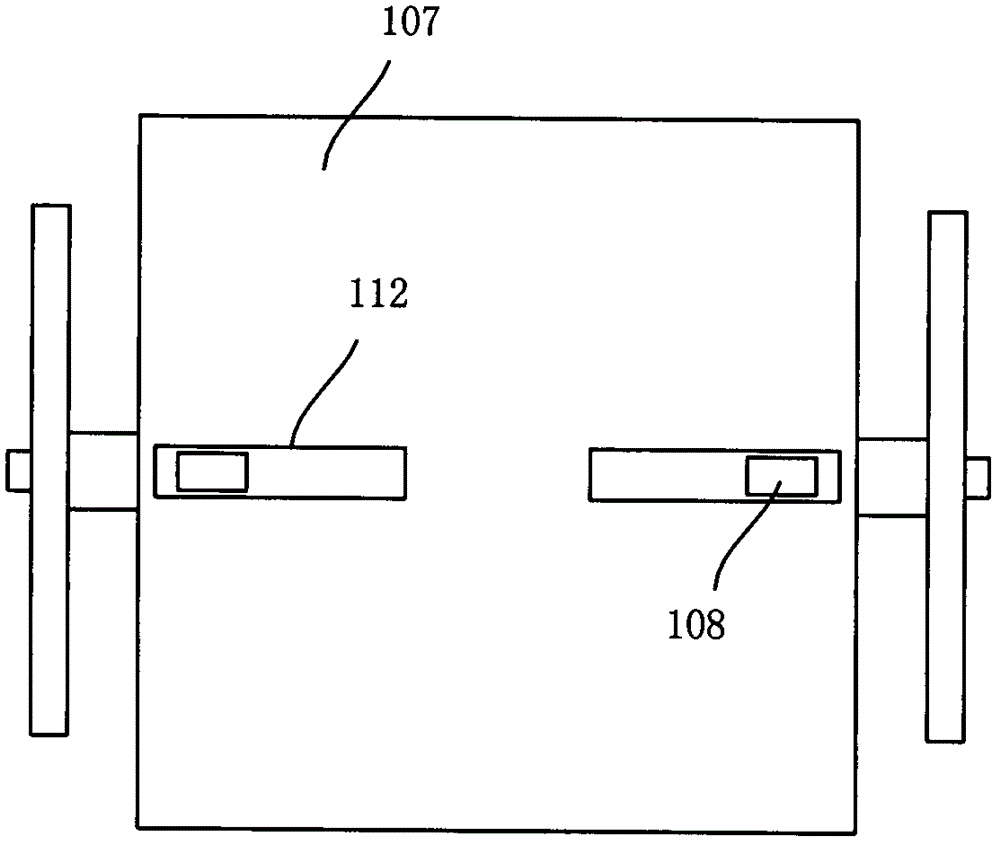

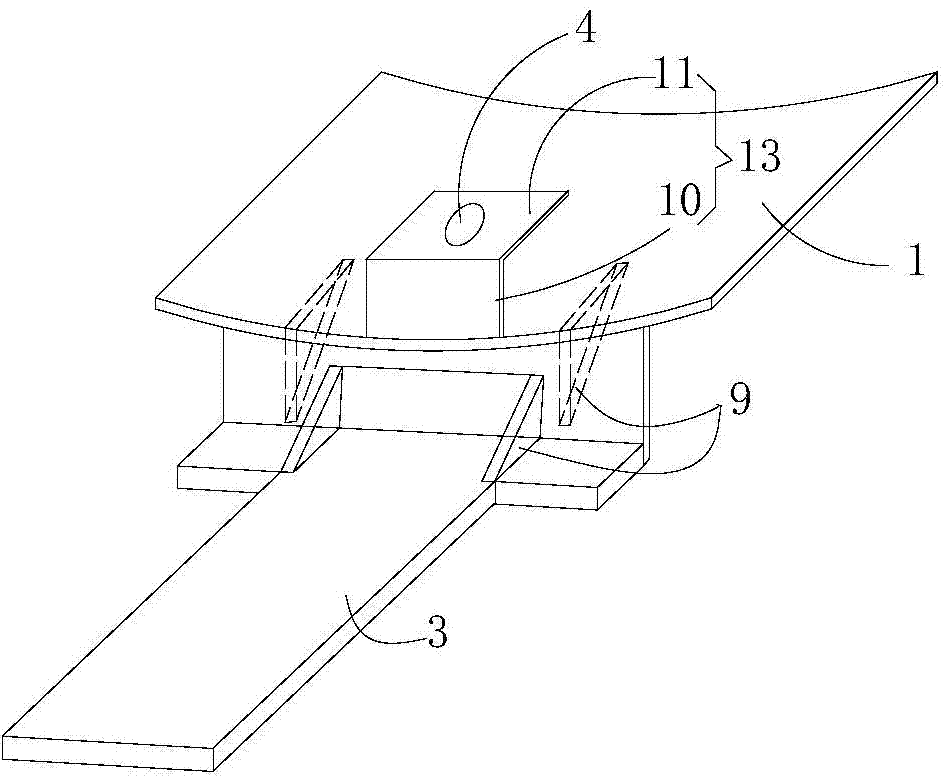

Plate material conveying device

InactiveCN101559880AIncreased conveying speedAcceleration and deceleration time is shortProgramme-controlled manipulatorMetal-working feeding devicesTurning framesEngineering

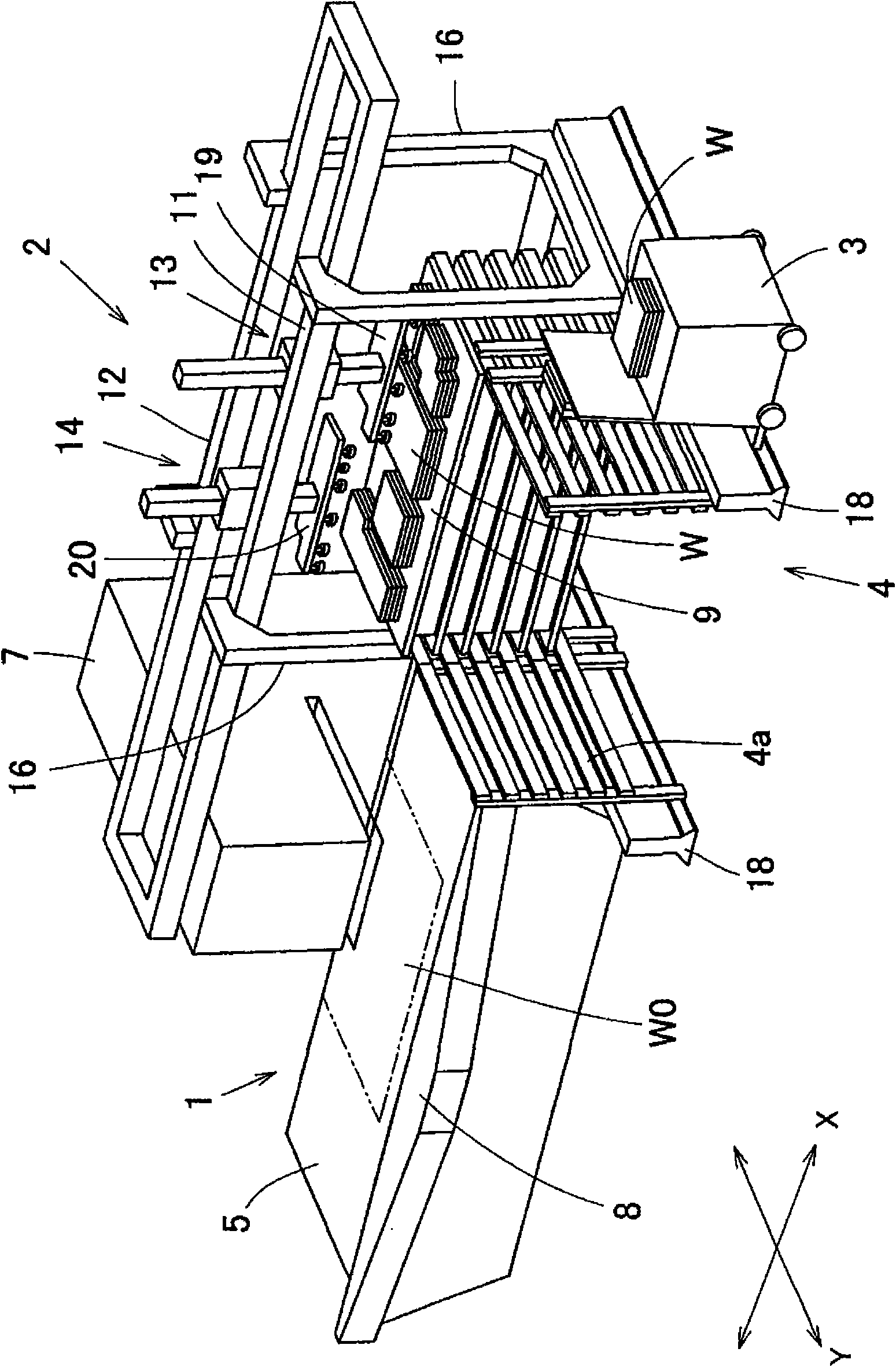

The present invention provides a plate material conveying device including a compact traveling member to enable an increase in plate material conveyance speed and a reduction in time required for acceleration and deceleration and to allow small plate materials to be more efficiently conveyed, the plate material conveying device further enabling one of a gripper and a suction type plate material holder to be selected for conveyance of a plate material. Traveling members (13, 14) are provided on respective tracks (11, 12) so as to travel freely along the respective tracks (11, 12). Each of the traveling members (13, 14) has a plate material holder support frame (21, 22) supporting suction type plate material holders (23A, 23B, 23C). The plate material holder support frame (21, 22) has a frame main body (21a, 22a), and a turning frame (21b, 22b) which is turnable in a substantially horizontal direction with respect to the frame main body (21a, 22a) and which is turnable to a position where the supported plate material planarly overlaps the adjacent track. Each of the turning frames (21b, 22b) has a gripper (60) gripping an end of the plate material. An opening of the gripper is configured to face a central side of the plate material.

Owner:MURATA MASCH LTD

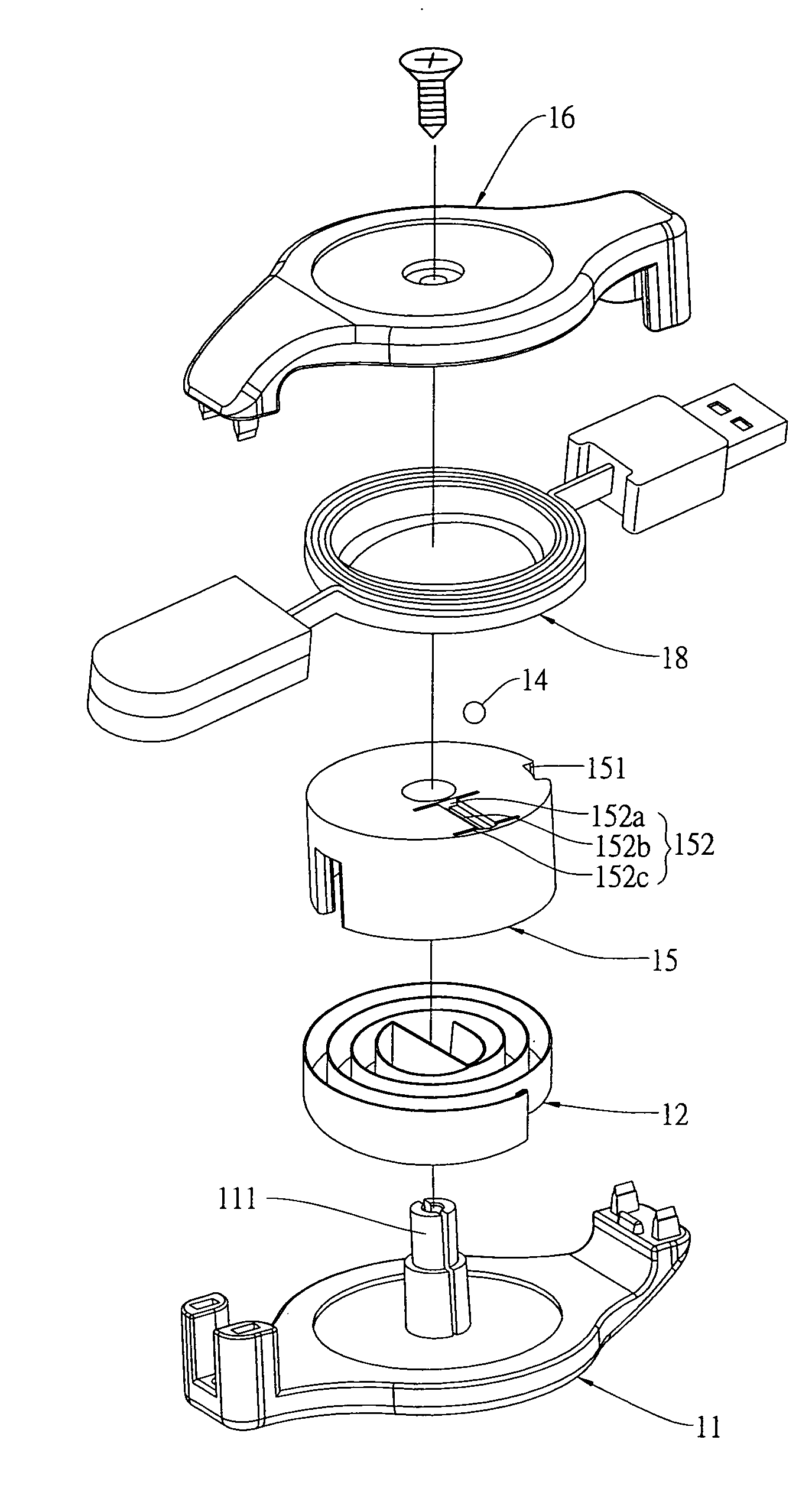

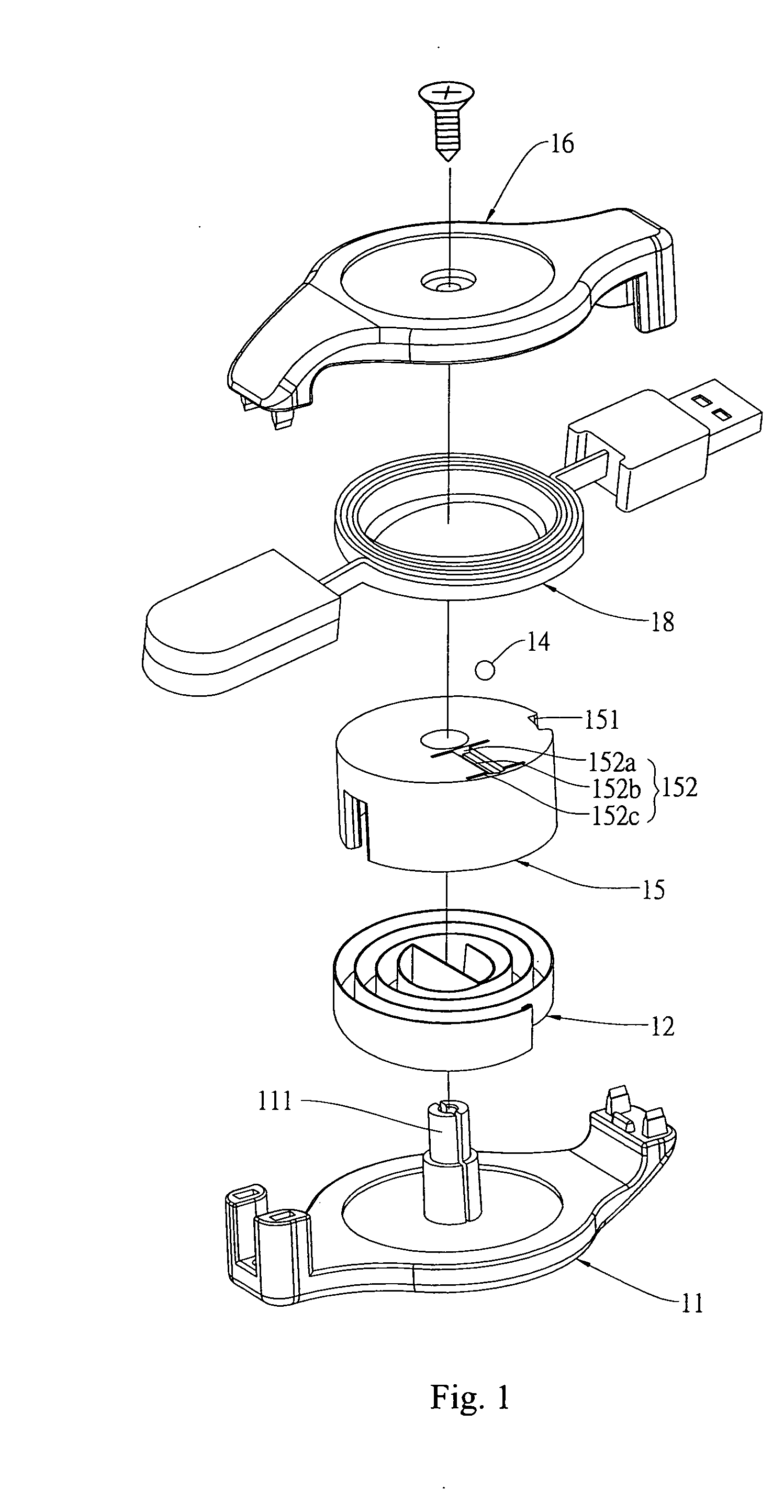

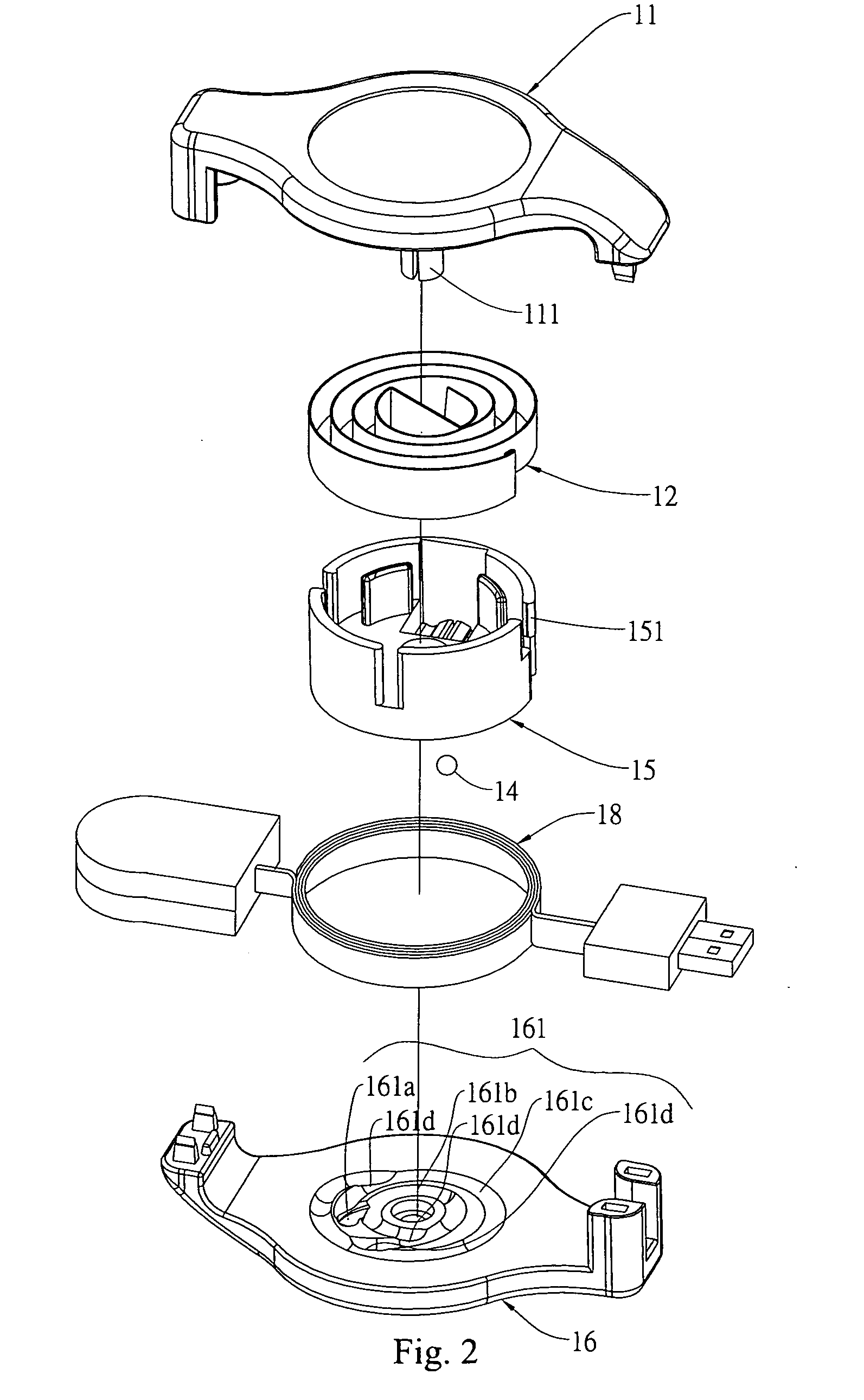

Automatically lockable cable rewinding structure

InactiveUS20070295850A1Simple structureEvenly placedArrangements using take-up reel/drumElectric cables

Owner:HONG WEN CHENG +1

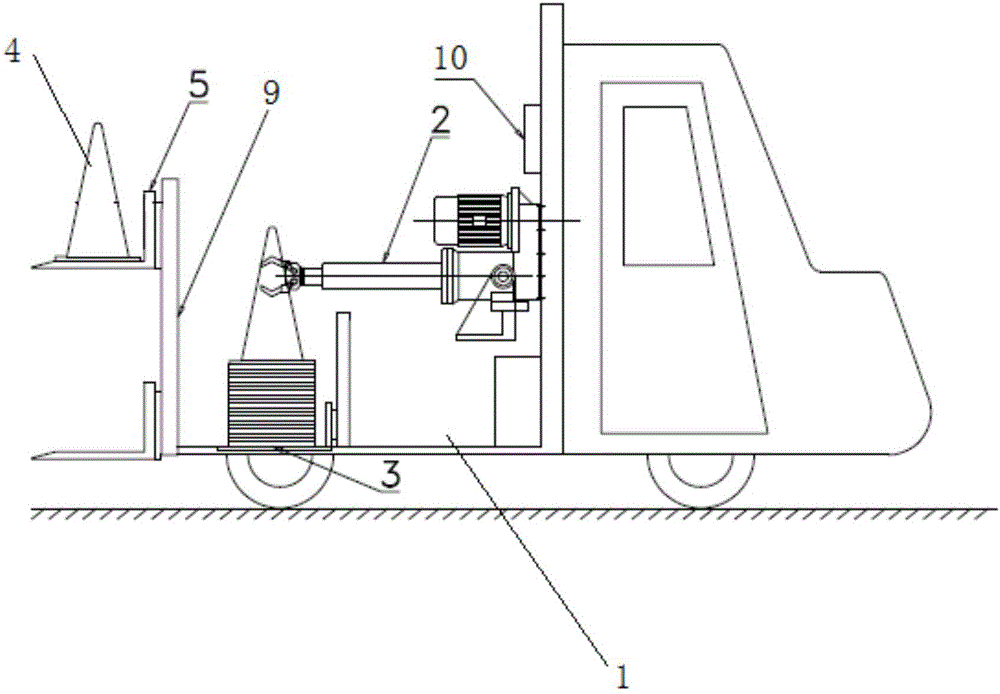

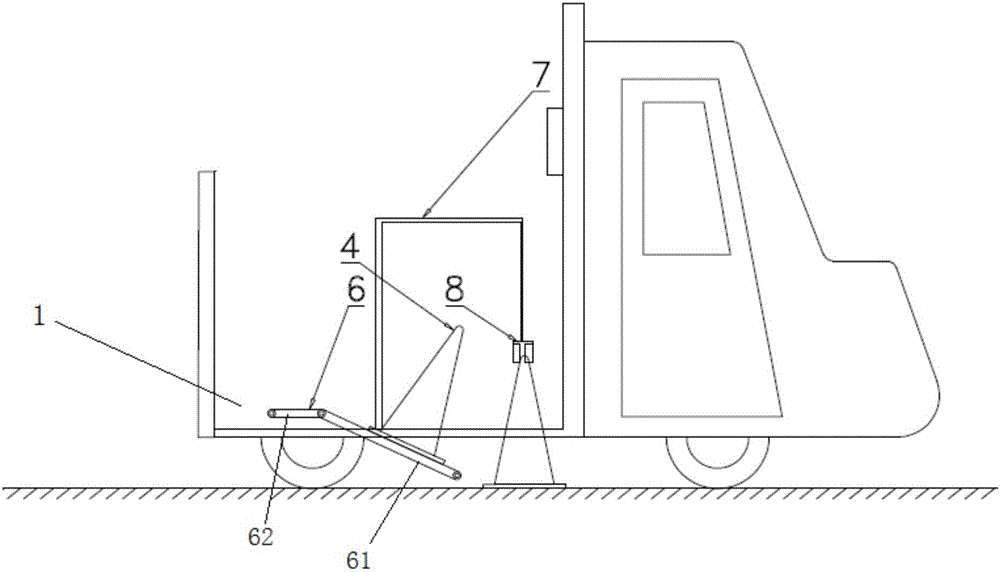

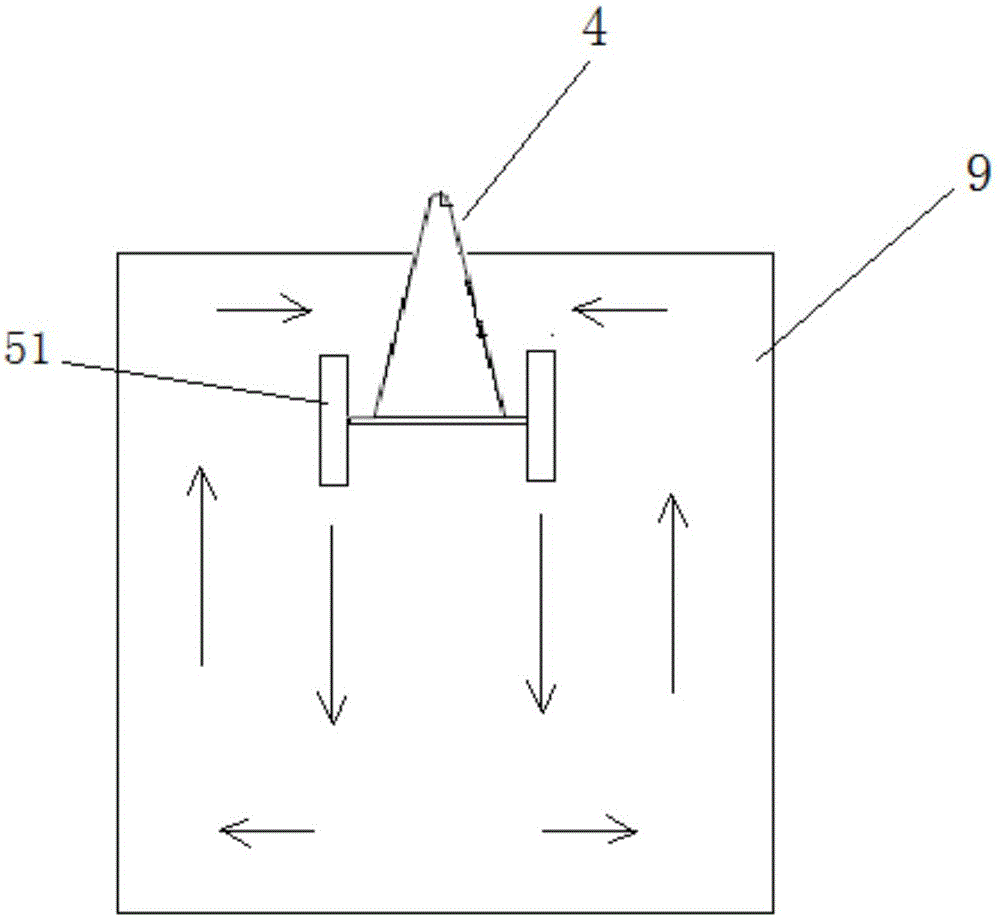

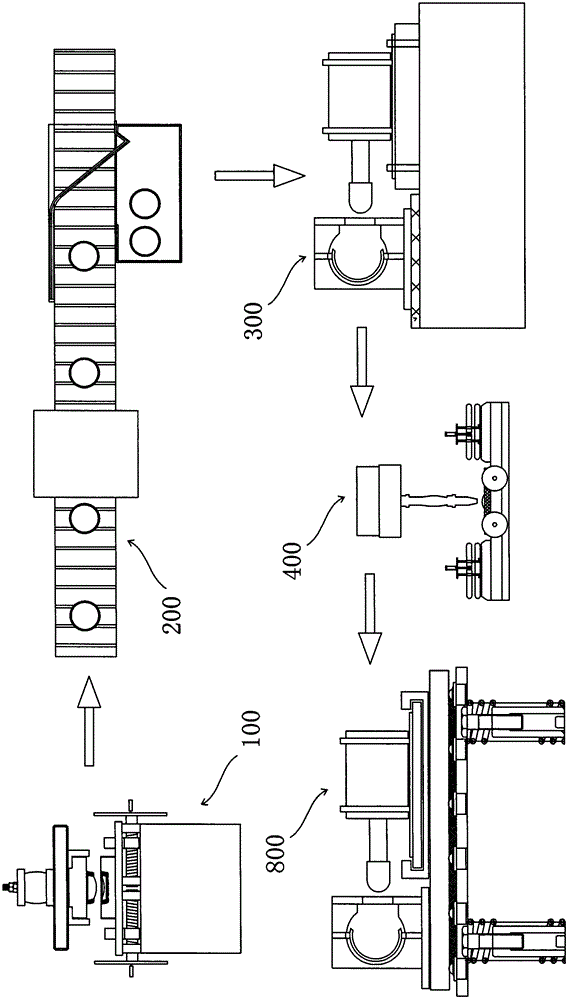

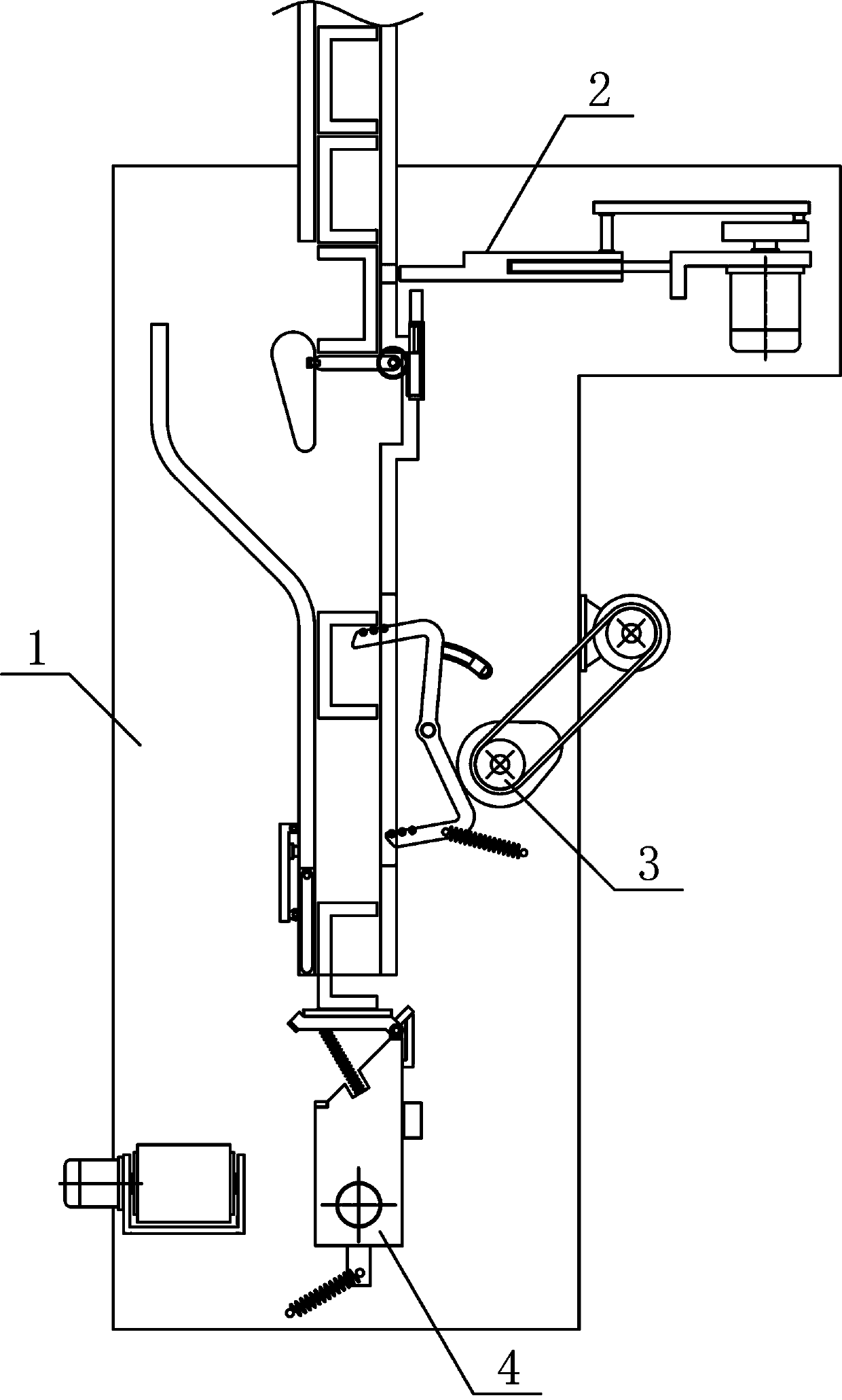

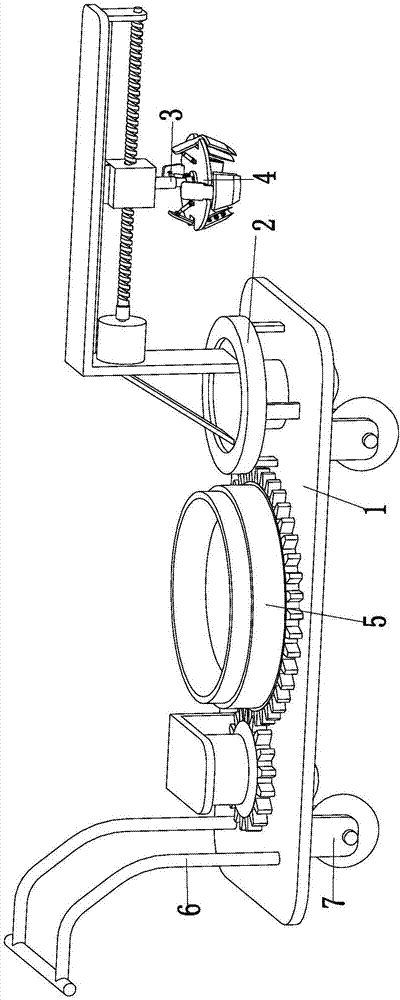

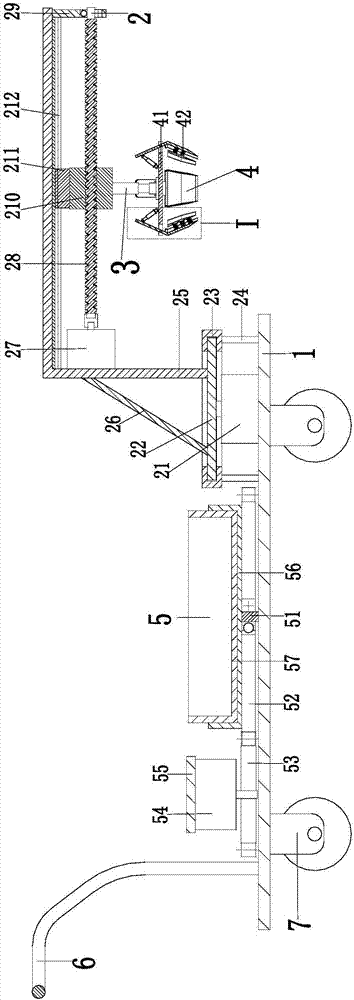

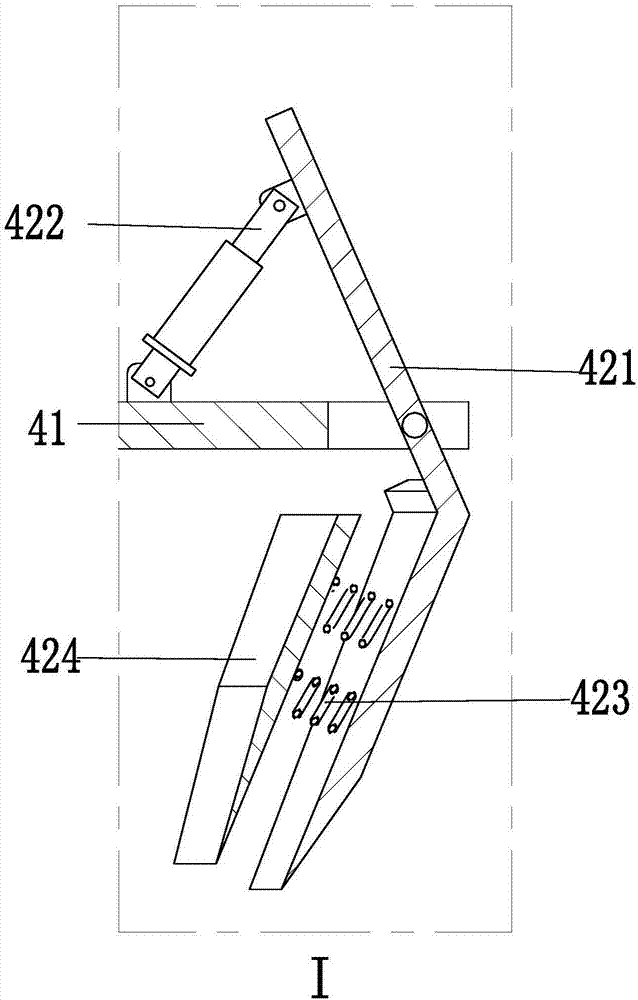

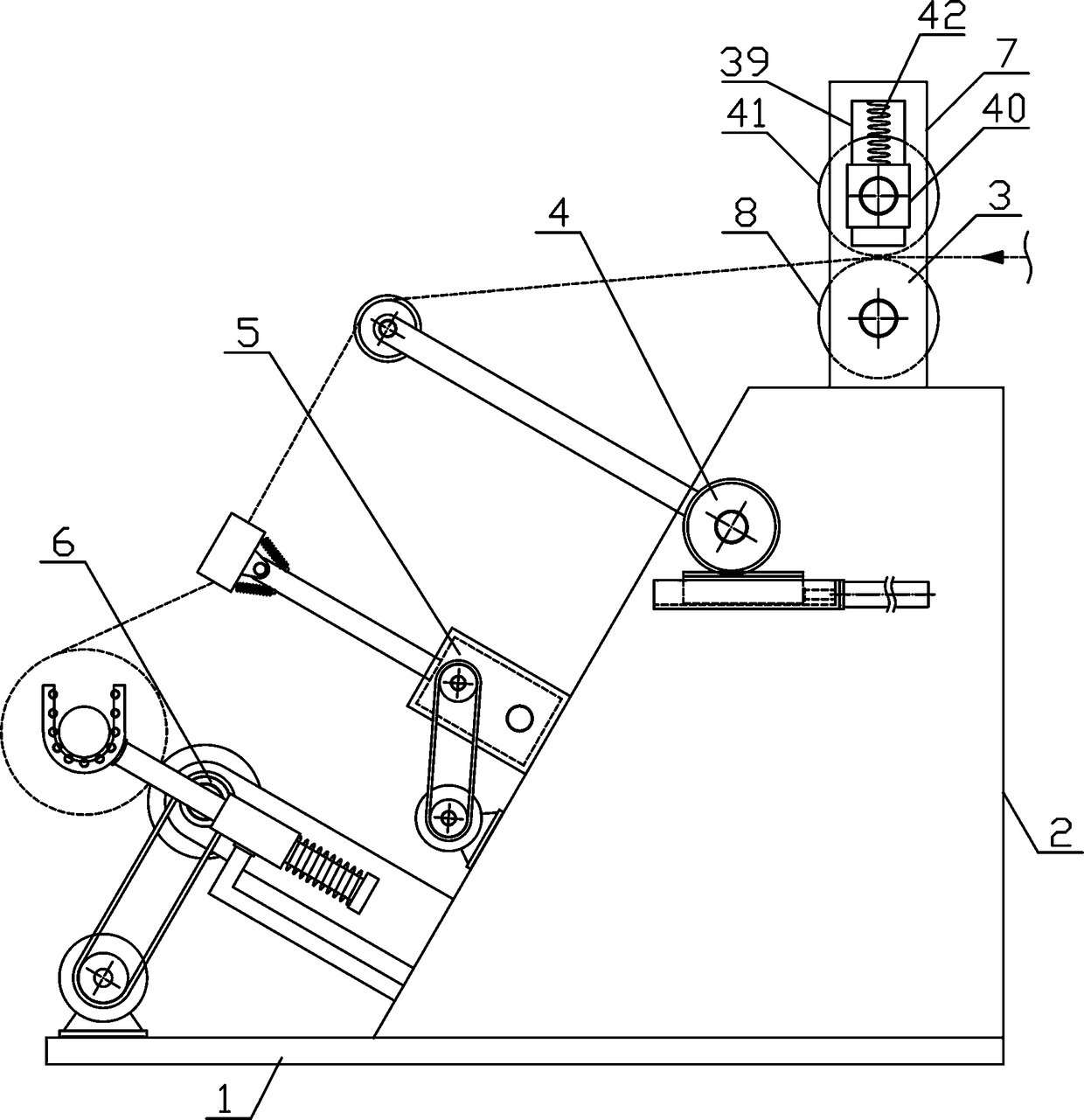

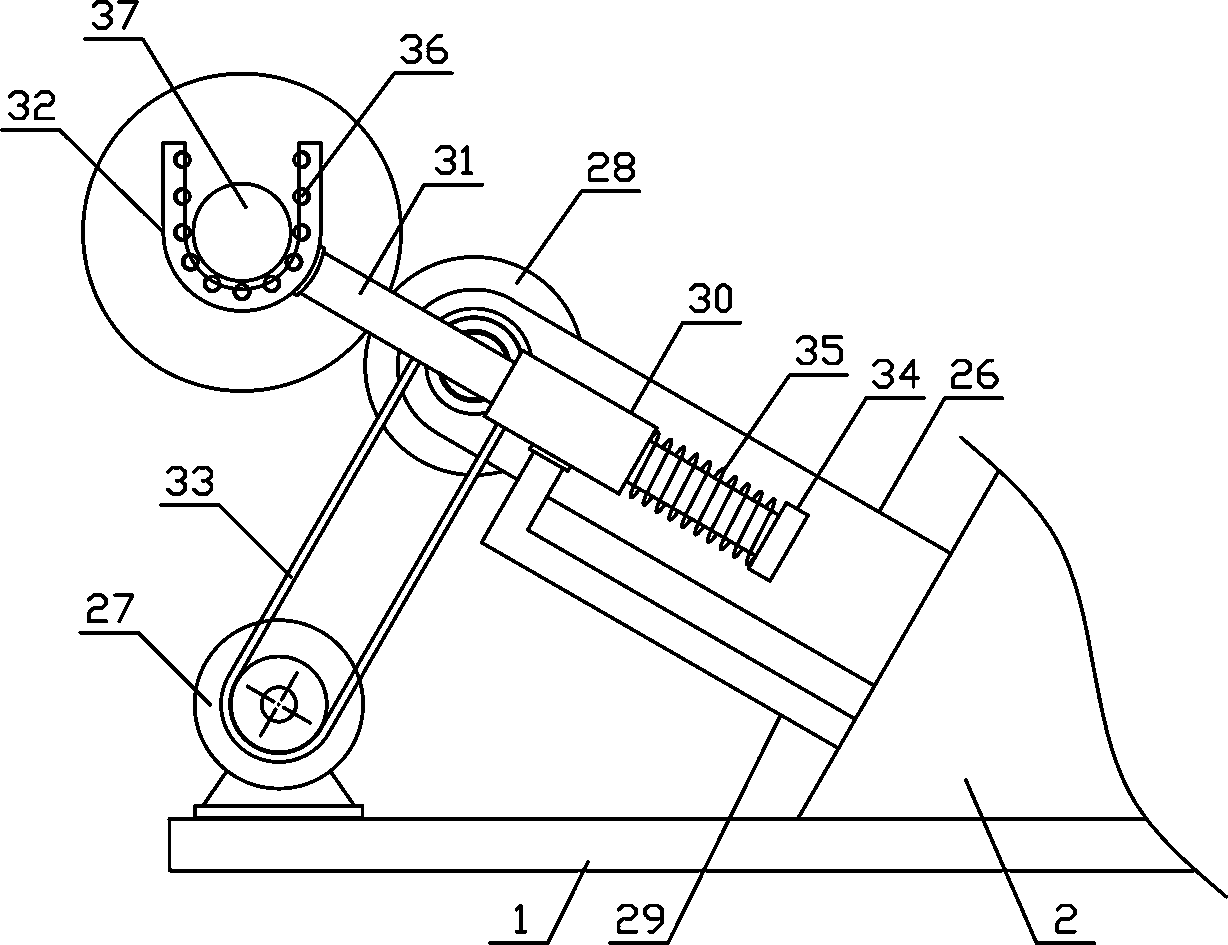

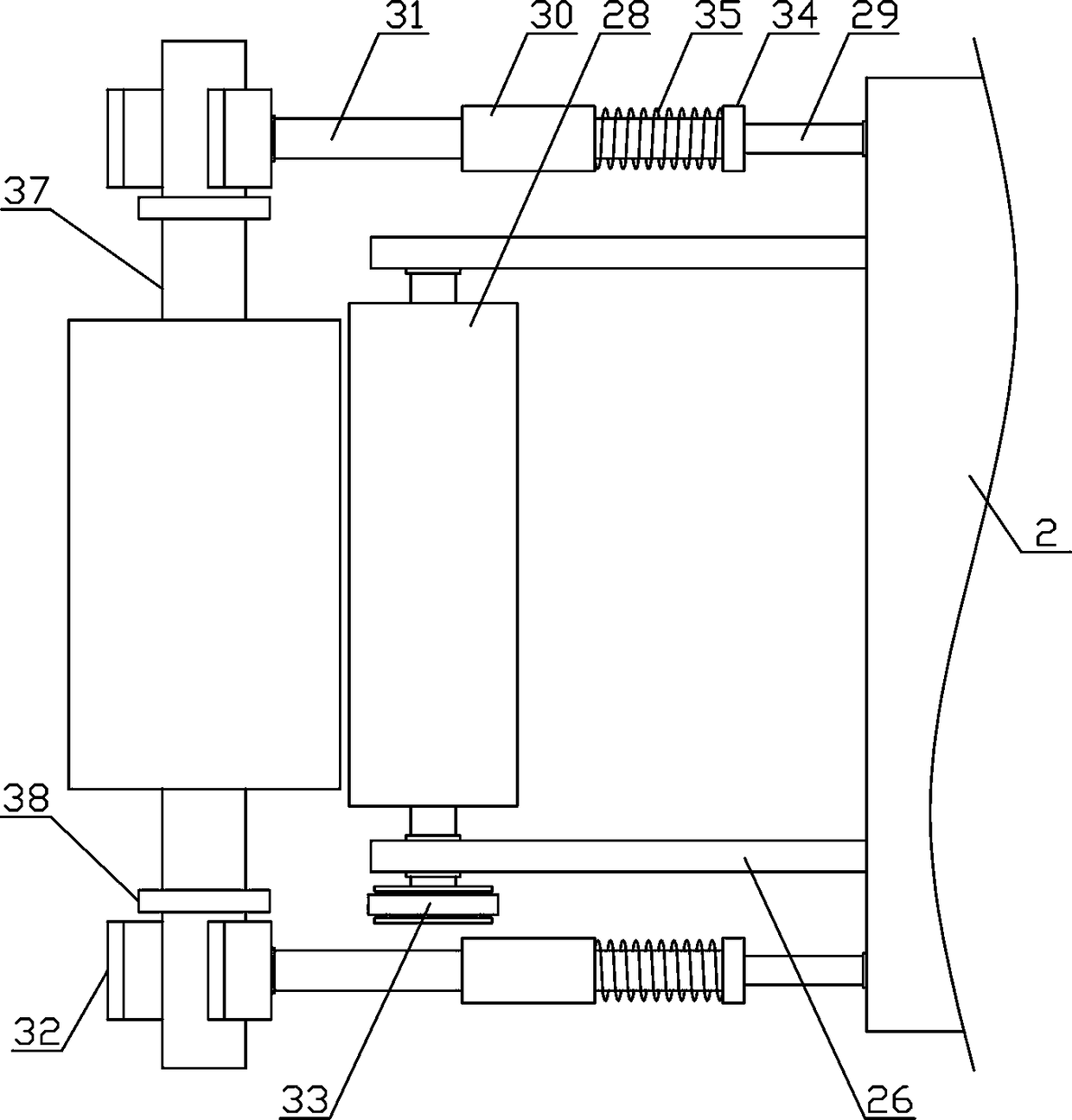

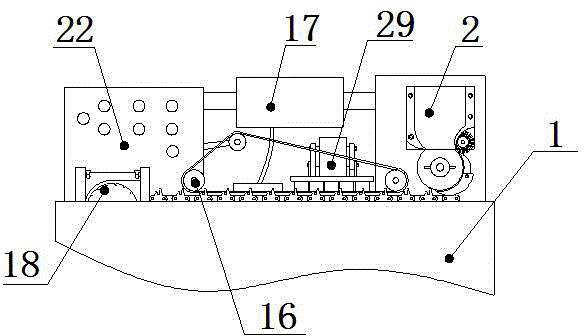

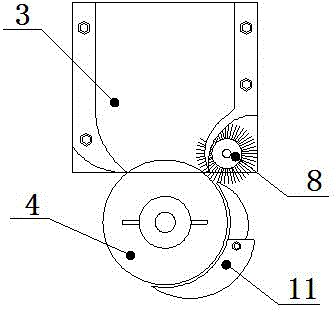

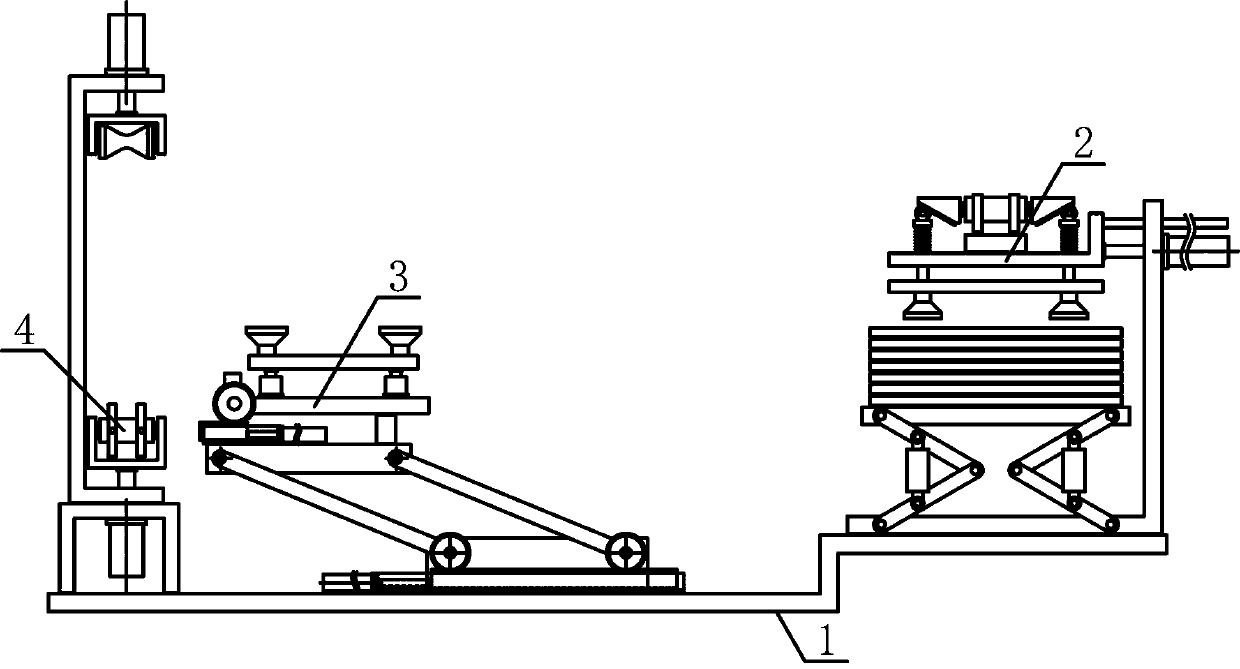

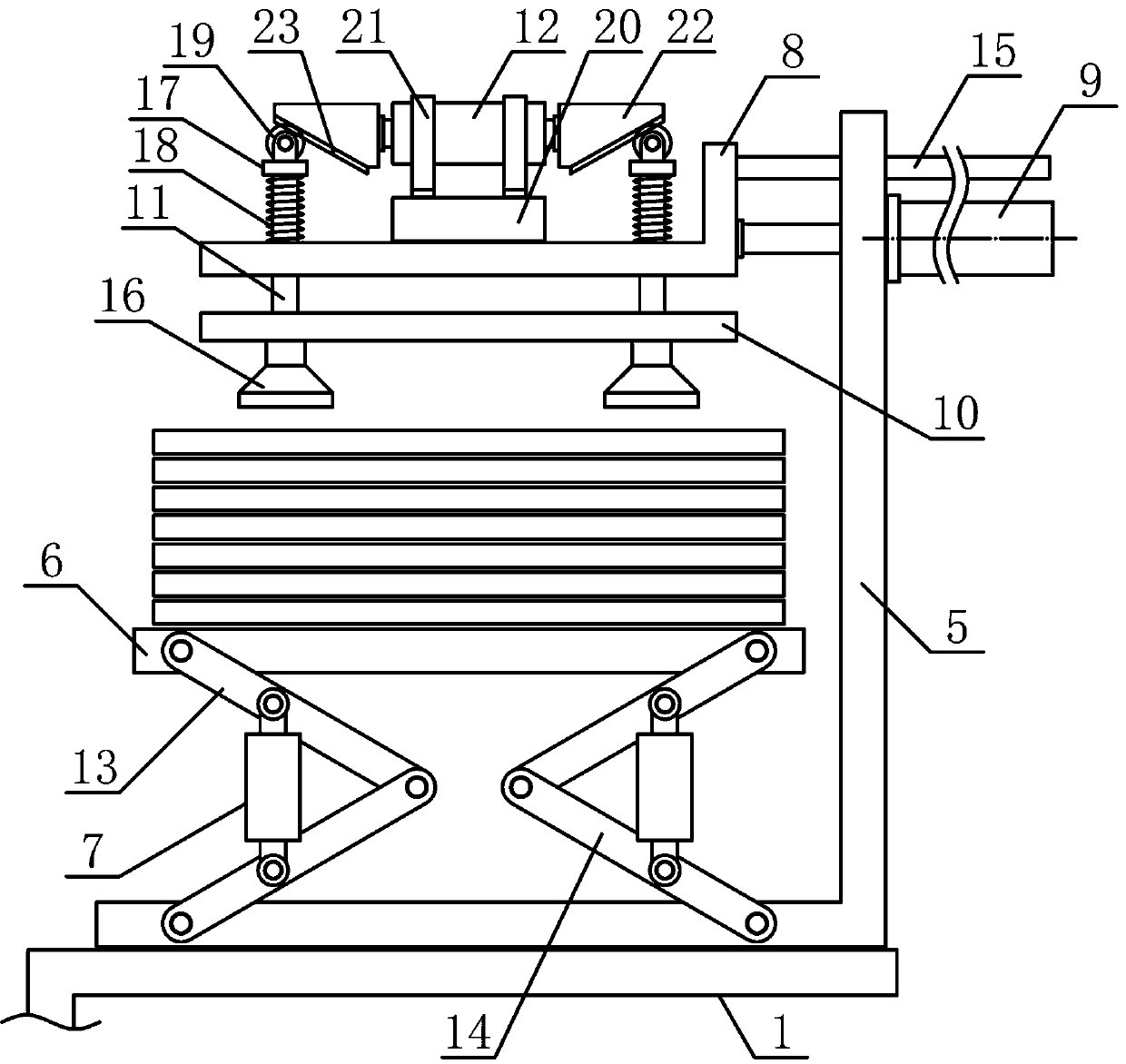

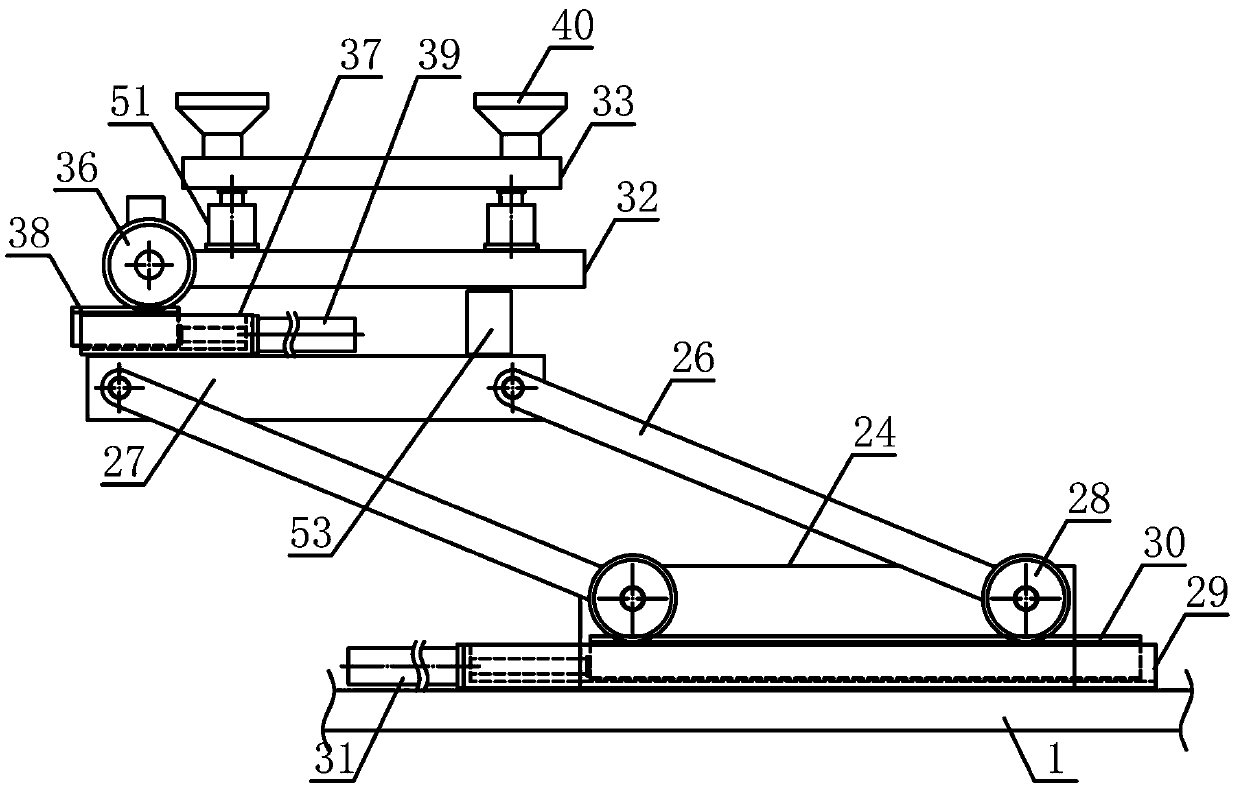

Automatic recycling and placing vehicle for traffic road cones

ActiveCN105735166AHigh degree of automationFully automatedTraffic signalsRoad signsRoad surfaceConveyor belt

The invention relates to an automatic recycling and placing vehicle for traffic road cones. The automatic recycling and placing vehicle comprises a vehicle body, a placing device, a recycling device and an intelligent control cabinet, wherein the placing device, the recycling device and the intelligent control cabinet are arranged on the vehicle body. Both the placing device and the recycling device are connected with the intelligent control cabinet. The placing device comprises a mechanical hand, an automatic lifting assembly and a forklift assembly, wherein the automatic lifting assembly is arranged on a bottom board of the vehicle body; the multiple traffic road cones are placed on the automatic lifting assembly; the mechanical hand is arranged on the inner side wall of the vehicle body and used for moving the traffic road cones on the automatic lifting assembly to the forklift assembly; and the forklift assembly is arranged on the outer side of a baffle on the rear side of the vehicle body and used for placing the traffic road cones on a road surface. The recycling device is arranged on the outer side of the vehicle body and comprises a conveyor belt assembly for conveying the traffic road cones into the vehicle body and a recycling rod used for moving the traffic road cones on the road surface to the conveyor belt assembly. Compared with the prior art, the automatic recycling and placing vehicle has the beneficial effects of being simple in structure, high in automation degree, capable of placing and recycling the traffic road cones accurately and the like.

Owner:TONGJI UNIV

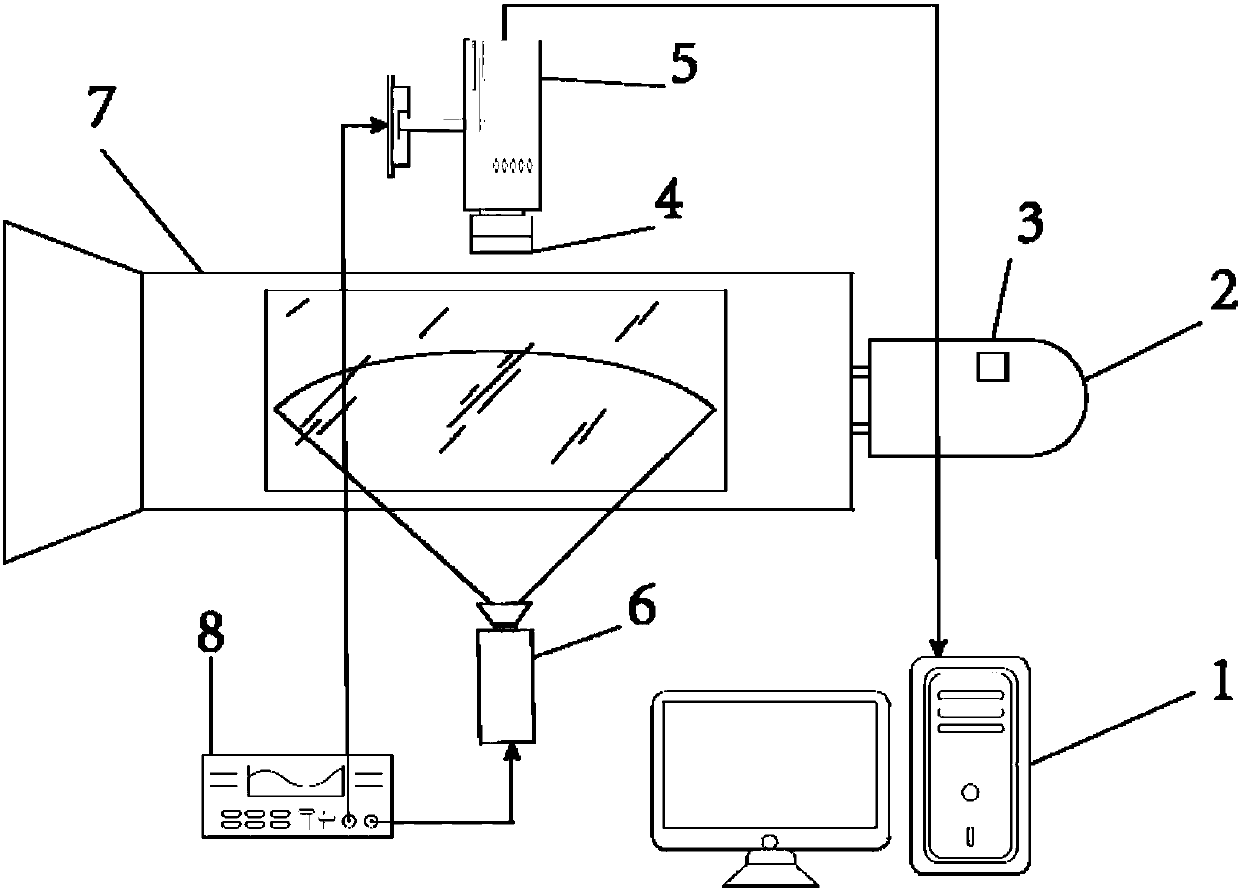

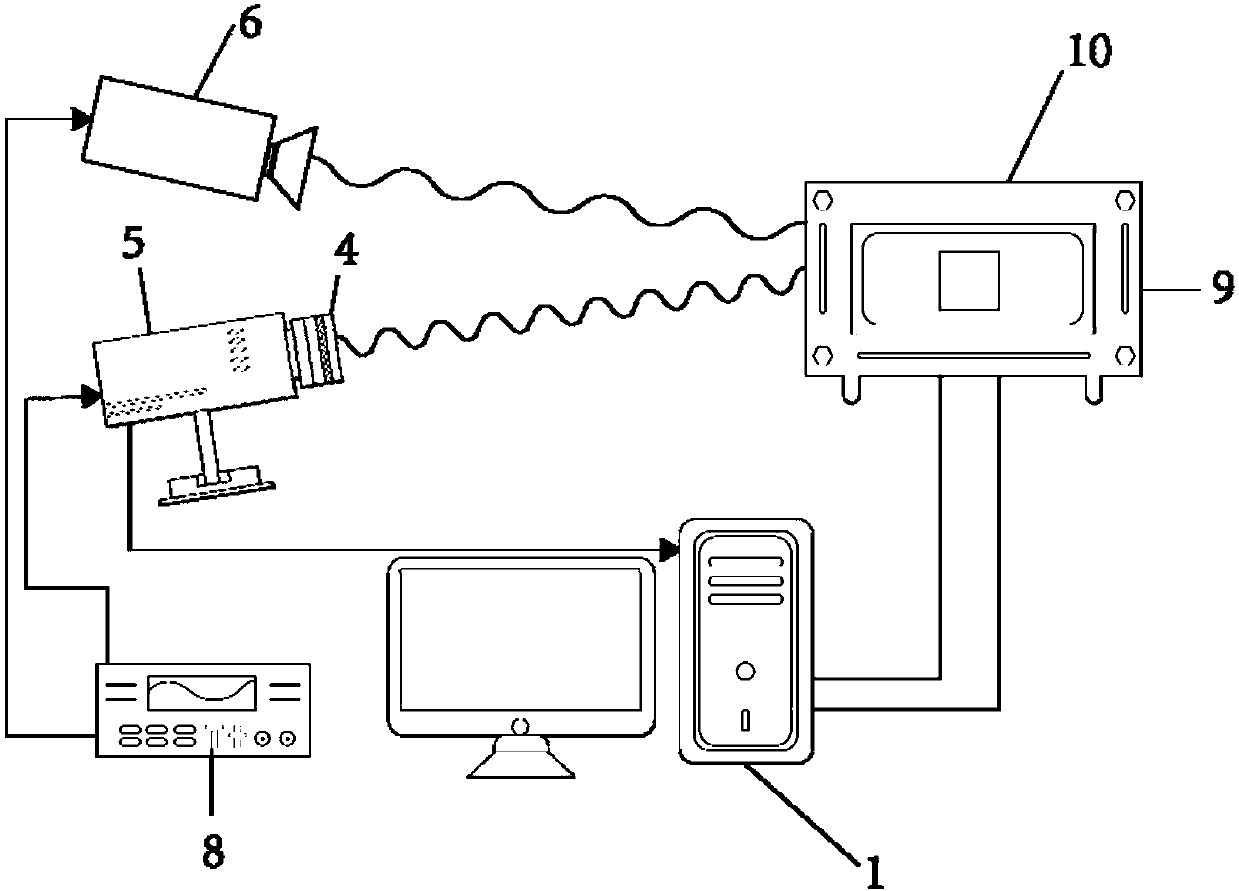

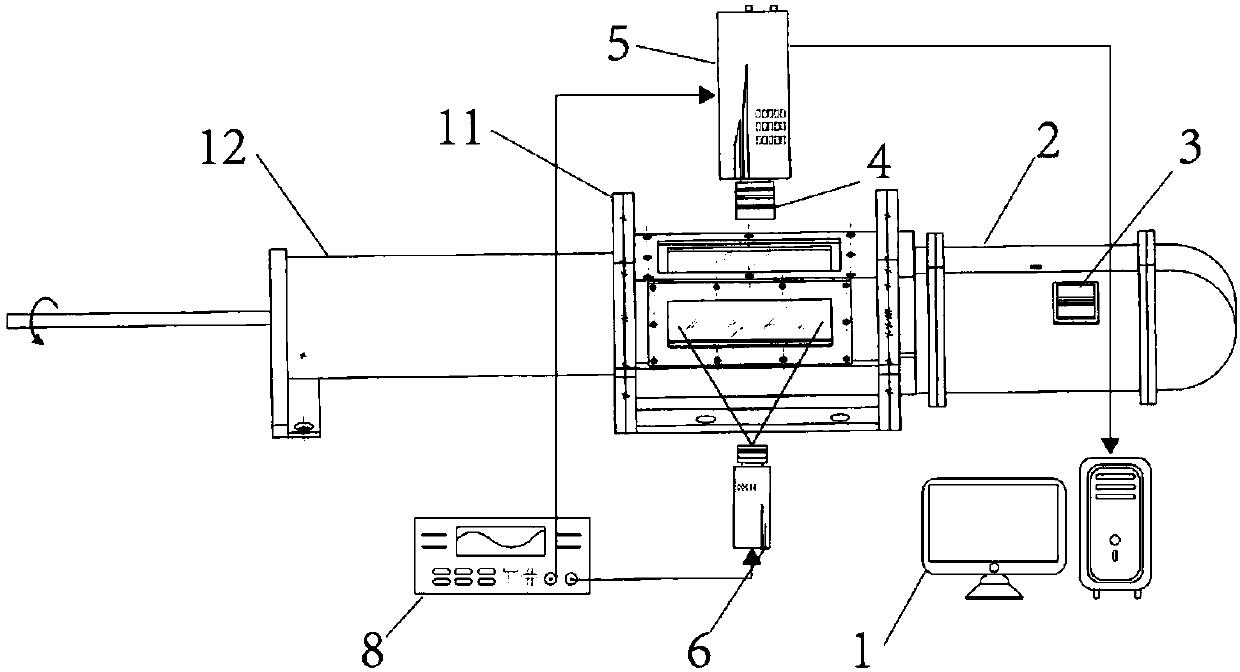

Space fluid velocity and pressure synchronous measurement system based on pressure-sensitive particle light intensity measurement

ActiveCN107655517AEvenly placedReal flow field informationMeasurement devicesDigital imageCcd camera

The invention relates to a space fluid velocity and pressure synchronous measurement system based on pressure-sensitive particle light intensity measurement. The system comprises a signal emitter, a pulse laser generator connected with the signal emitter, a high-speed CCD camera arranged opposite to the pulse laser generator and connected with the signal emitter, and a computer for receiving and processing digital image signals of the high-speed CCD camera. A flow field to be measured is arranged between the pulse laser generator and the high-speed CCD camera; the flow field to be measured isconnected with a particle generator for uniformly injecting pressure-sensitive particles to the flow field to be measured; and the front end of the high-speed CCD camera is equipped with an optical filter. Compared with the prior art, the system has the capability of capable of measuring pressure and velocity distribution in a space simultaneously; in the test process, the pressure-sensitive particles are light in weight and small in size, and can be injected to the flow field without influencing flow of the flow field, so that velocity distribution and pressure distribution in the flow fieldcan be measured directly; and the measurement method is direct and convenient, and is wide in application range.

Owner:SHANGHAI JIAO TONG UNIV

Ink-jet printer

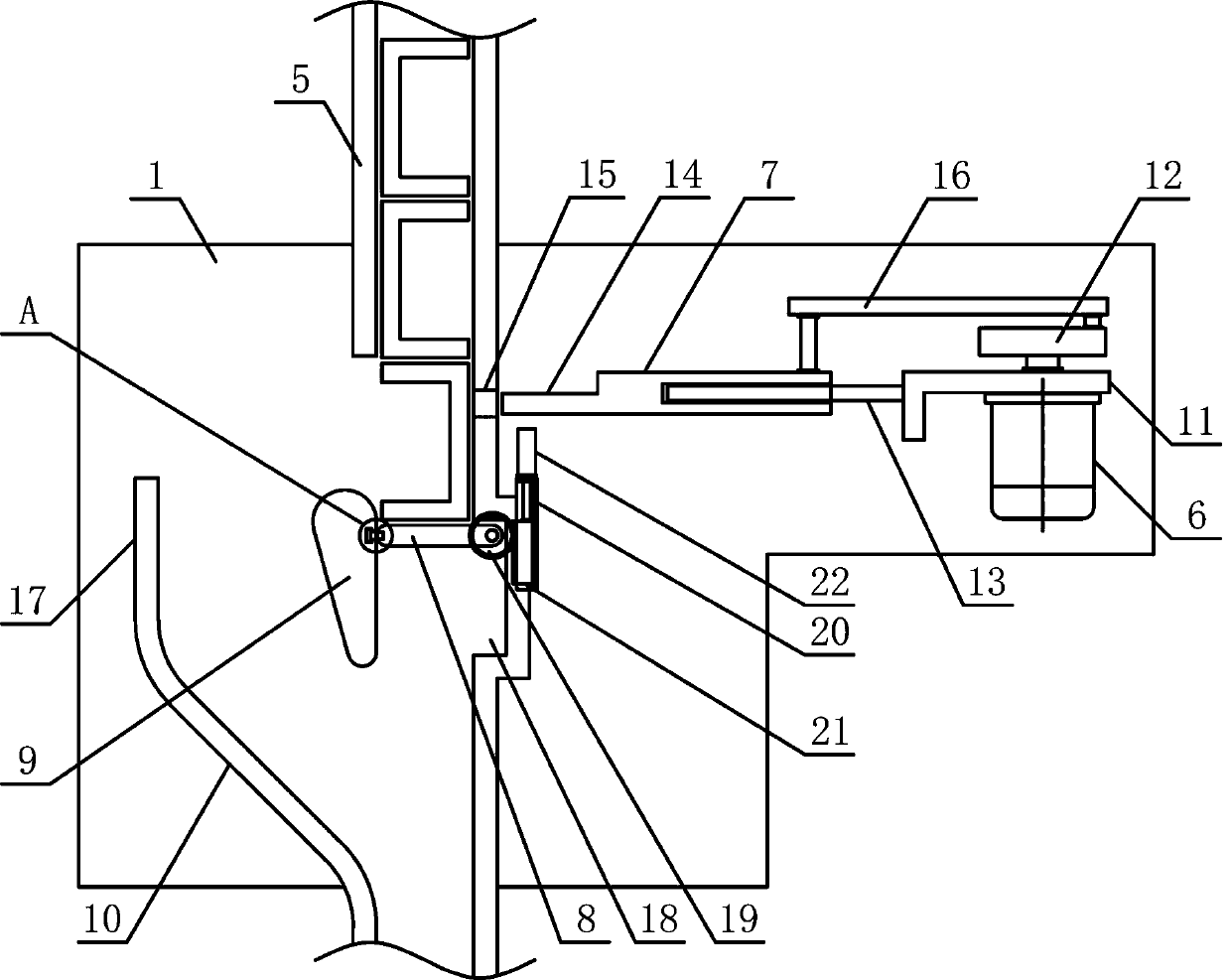

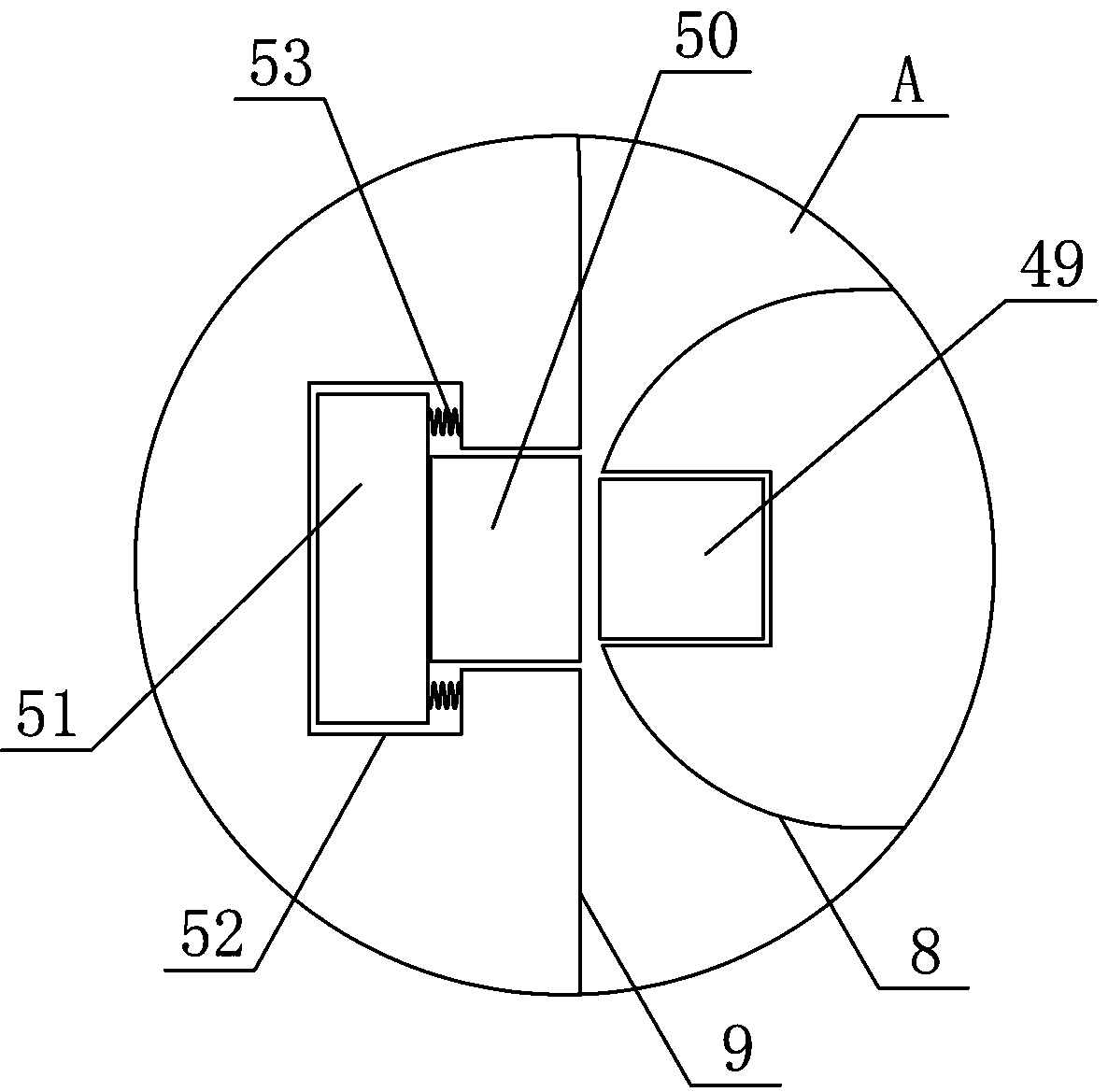

An ink-jet printer including: a buffer tank; an air-discharging valve device; and a valve opening-and-closing device. The ink-jet printer father includes an operating member which is arranged to be interposed between the air-discharging valve device and the valve opening-and-closing device. The valve opening-and-closing device operates the air-discharging valve device via the operating member, such that the air-discharging valve device is placed in a valve-open state and a valve-close state. The ink-jet printer is arranged to execute a first discharge operation in which the air separated from the ink in the buffer tank is discharged while placing the air-discharging valve device in the valve open state, and a second discharge operation in which an inside of the air-discharging valve device is exhausted to remove the ink remaining in the air-discharging valve device while placing the air-discharging valve device in the valve-close state.

Owner:BROTHER KOGYO KK

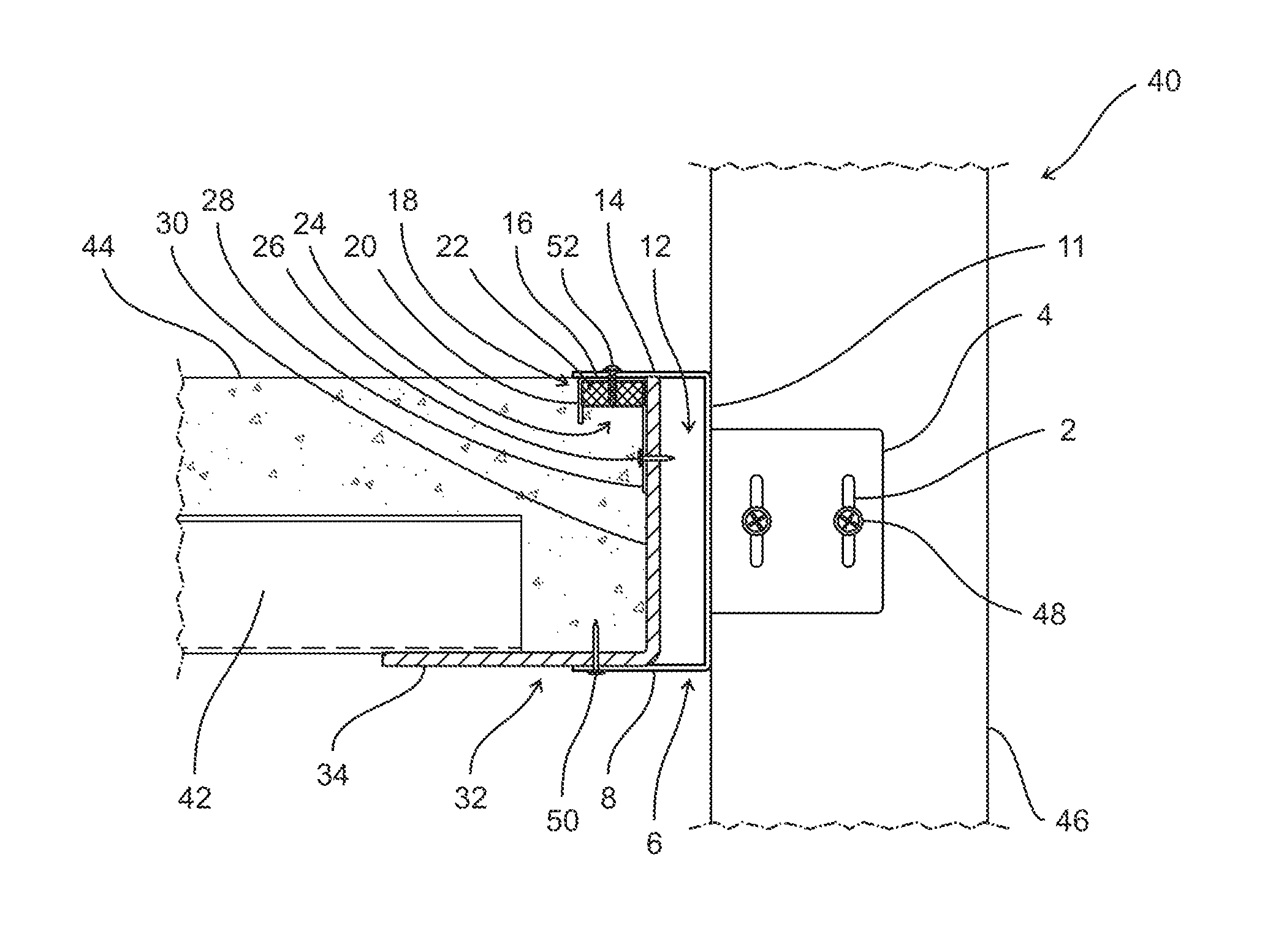

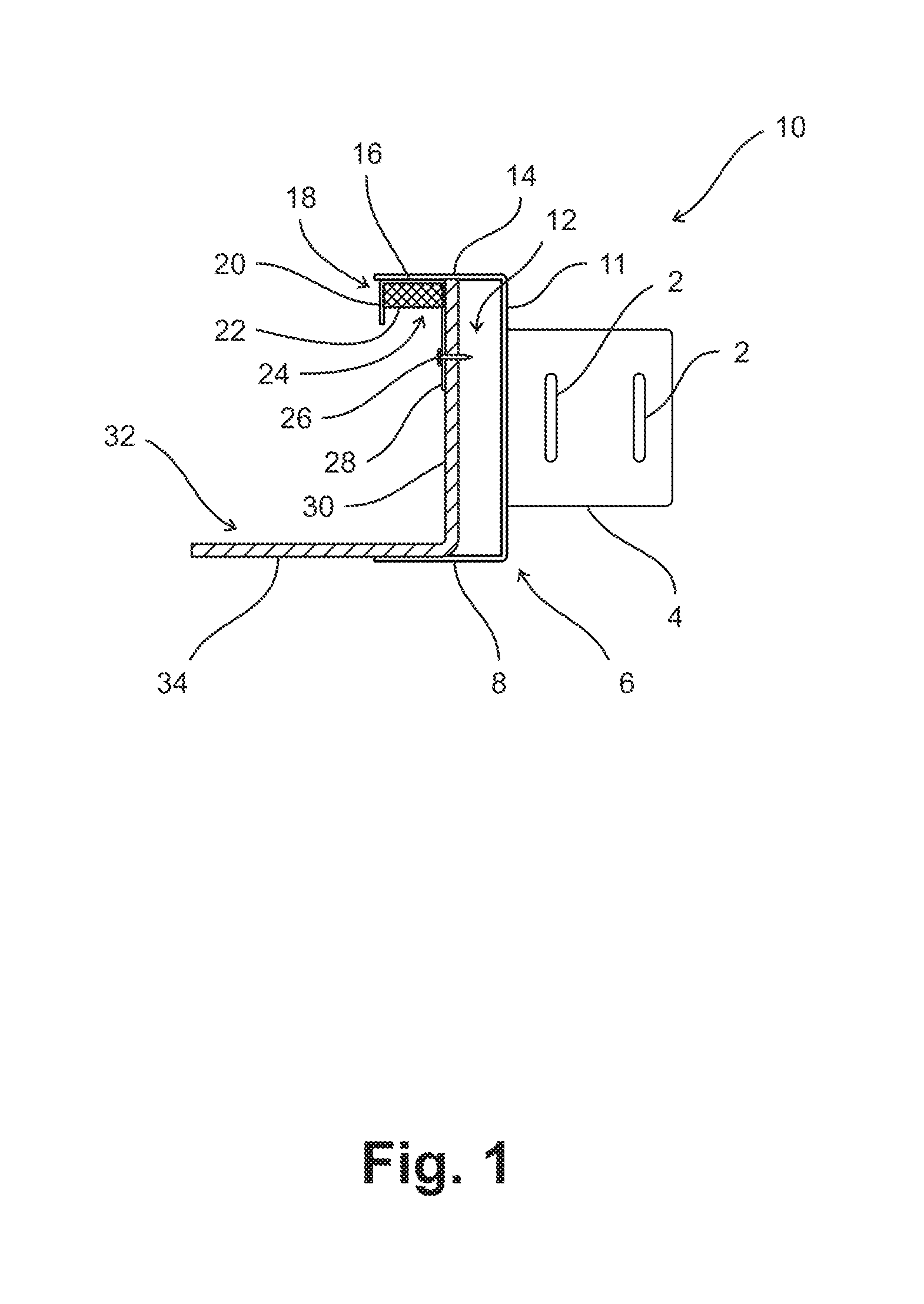

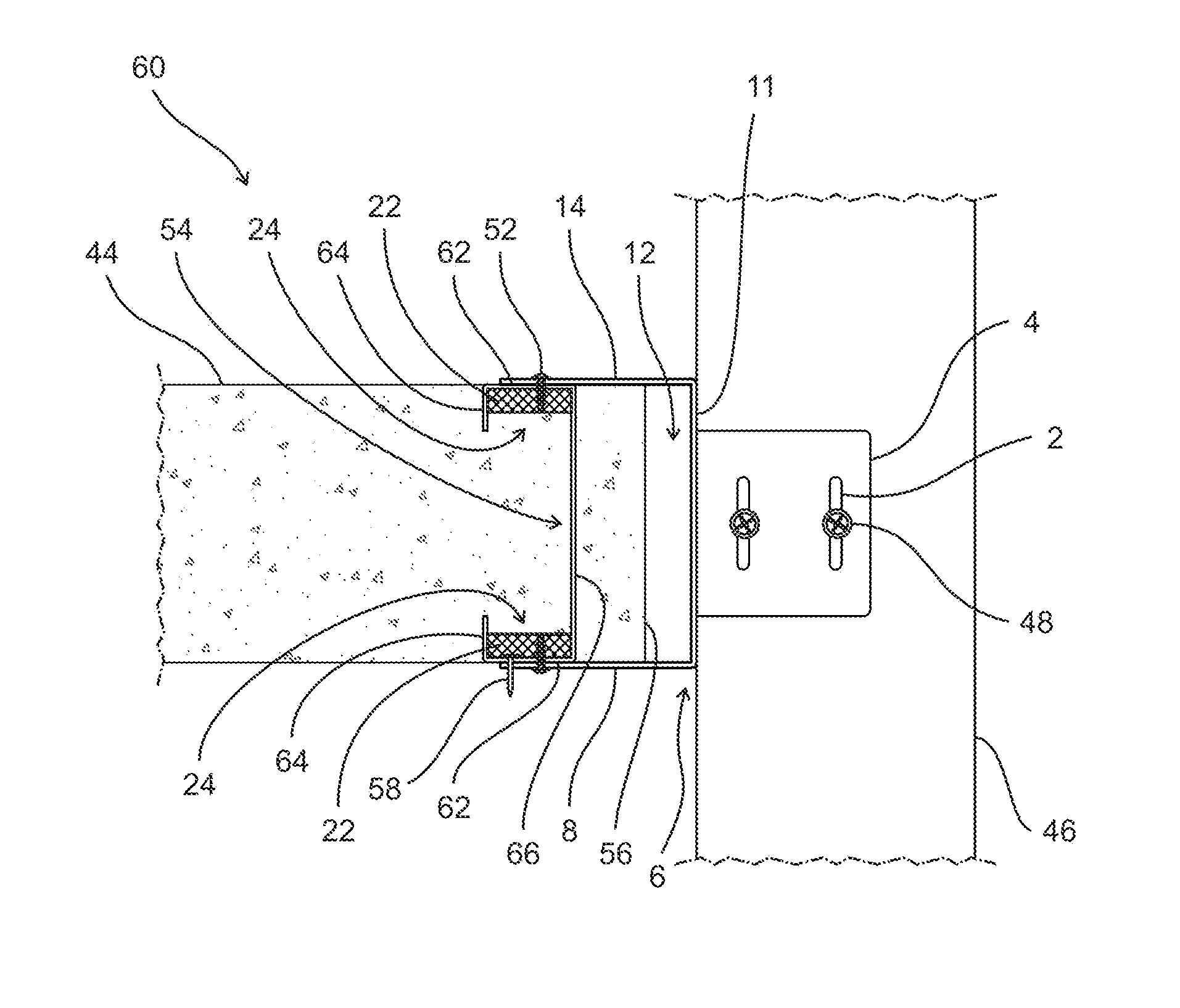

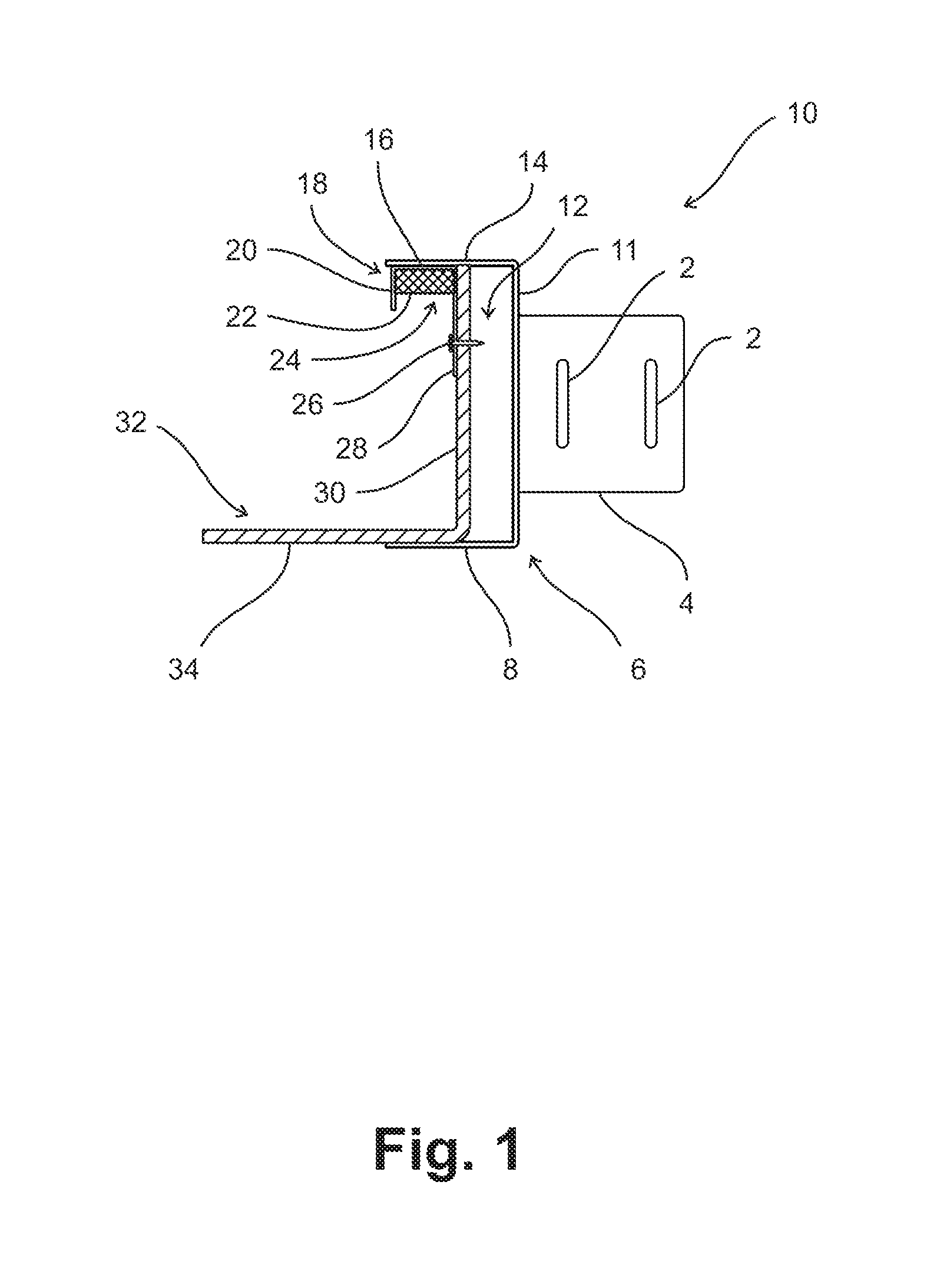

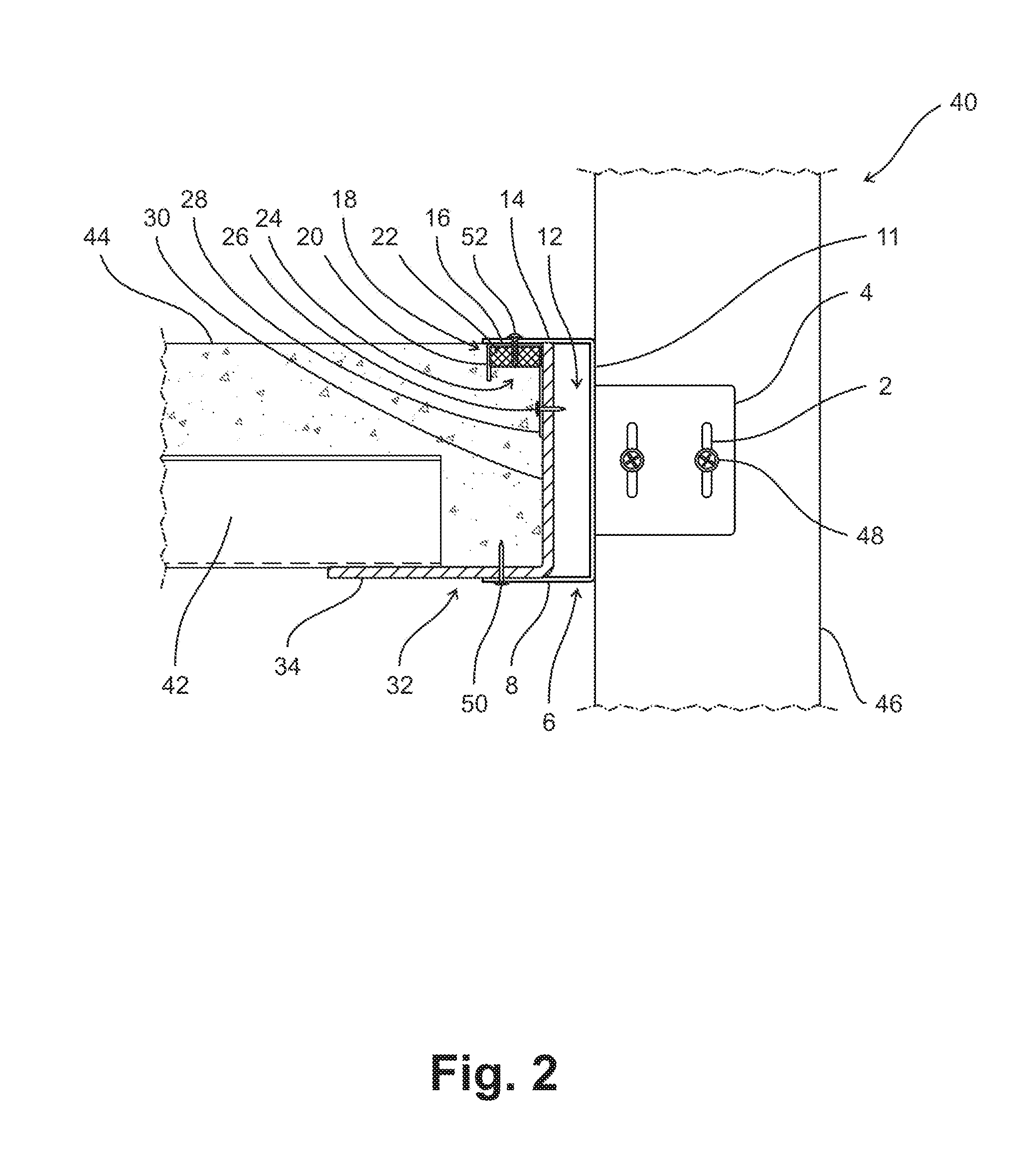

Building construction system

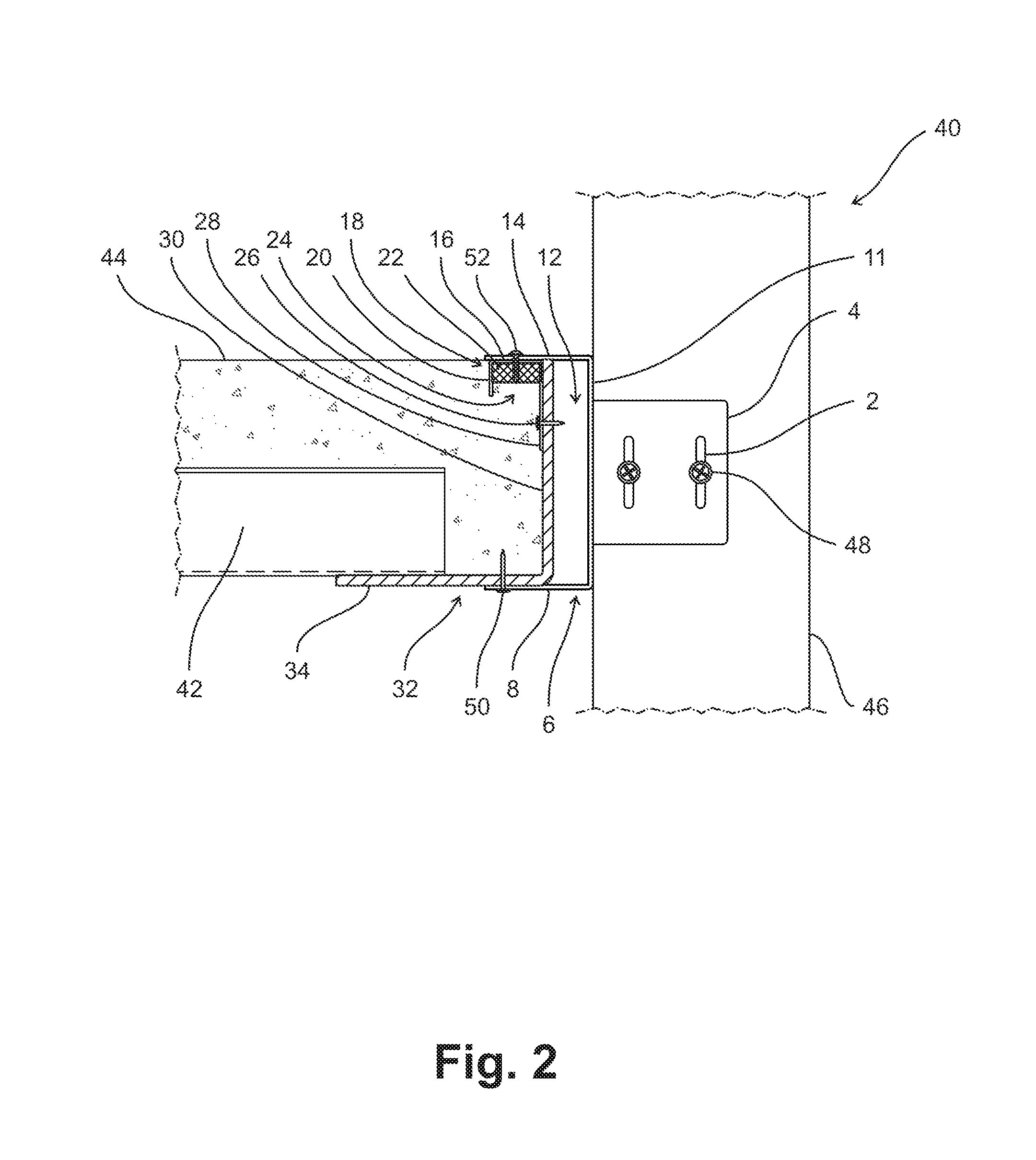

InactiveUS9032681B1Reduce generationFlat surfaceCovering/liningsInclined ship-liftingFront edgeBuilding construction

A building construction system is provided having an elongated track (bypass clip track) that overlays a front edge of a concrete slab. The elongated track provides an even flat surface along an uneven concrete slab because the elongated track can be placed at adjustable distances from slab edges that may be uneven. The track is secured to a bracketing structure that has foam inserts that become embedded within the top and / or bottom surface of the concrete slab after the concrete hardens. By attaching the track to these foam inserts instead of the concrete directly, breakage or spalling of the slab edge is reduced. Studs are then attached to a stud attachment plate extending from the track, such that thereafter, a wall or façade may be attached to the track that overlays the uneven slab edge.

Owner:BRADY TODD A

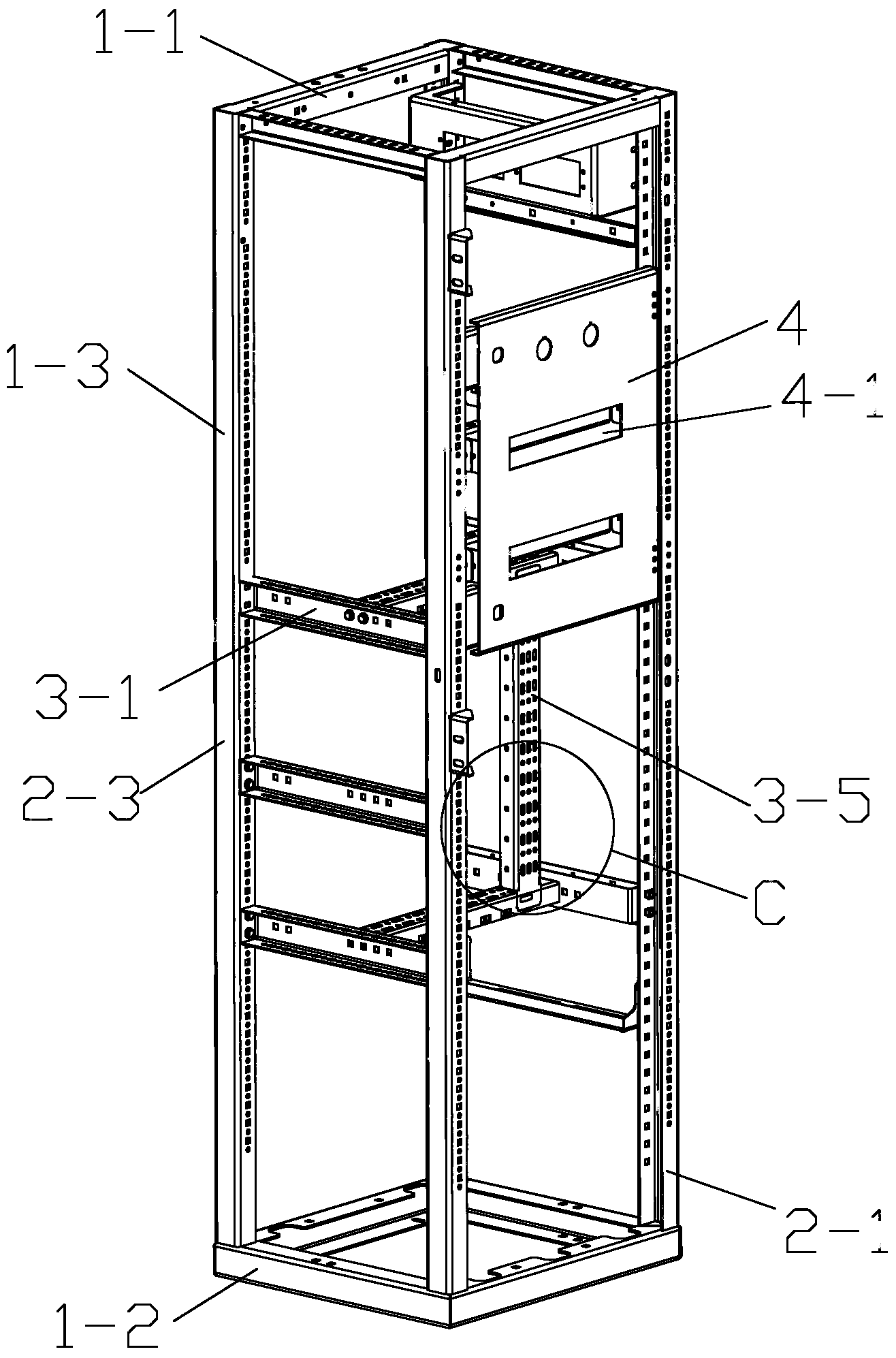

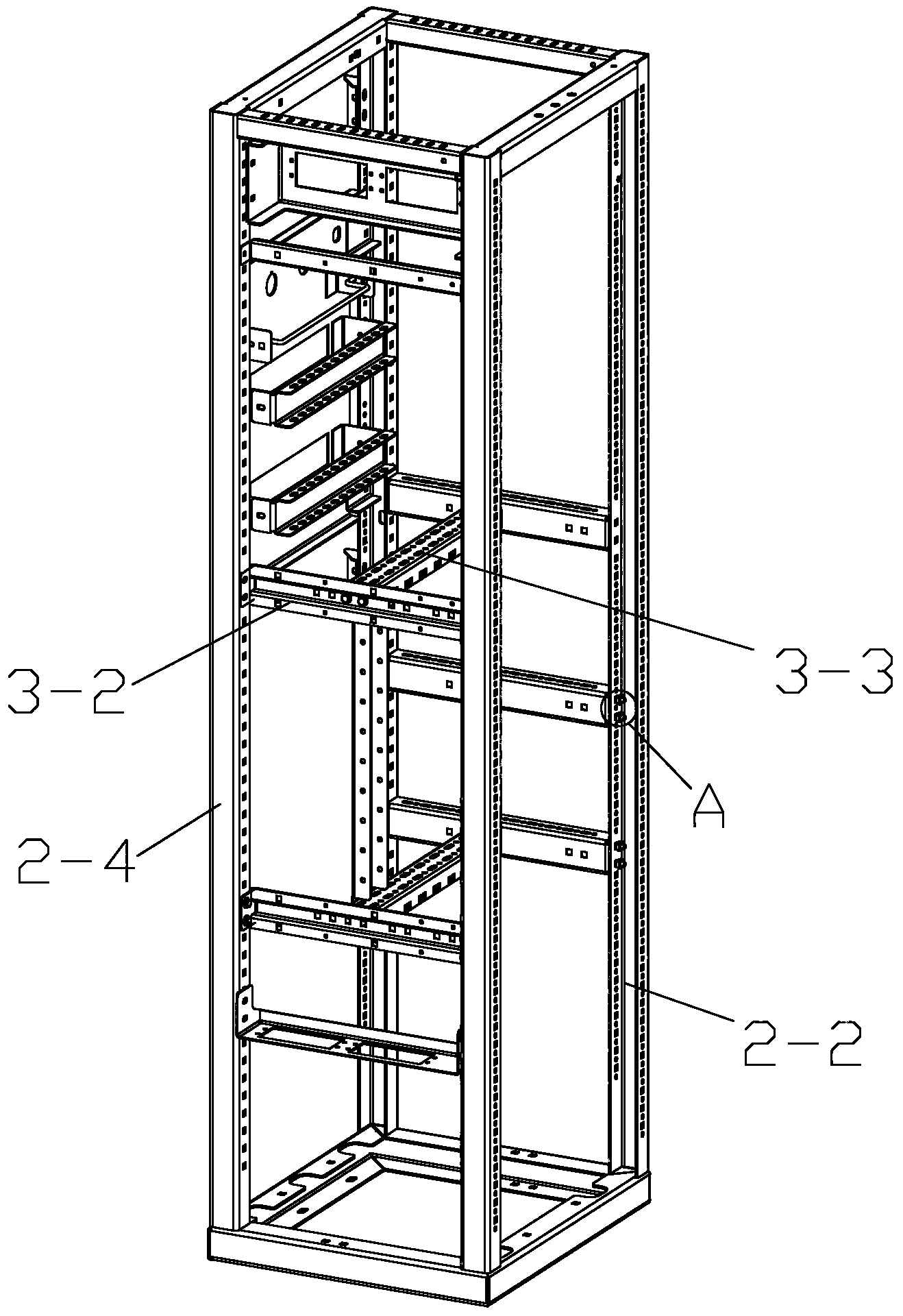

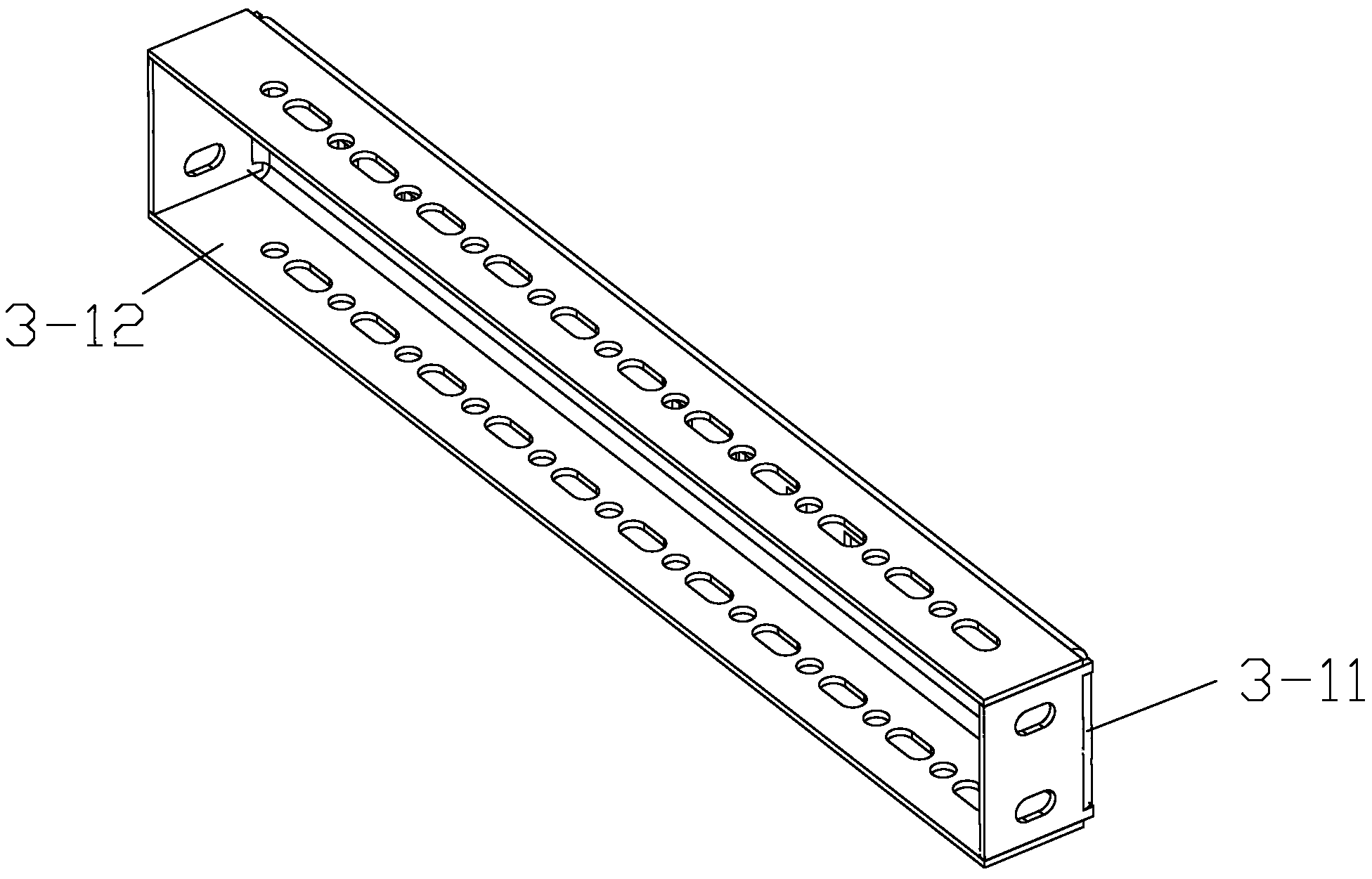

Electrical cabinet frame for railway vehicle passenger room

ActiveCN103280696AHighly integratedEasy to installSubstation/switching arrangement casingsComputer moduleEngineering

Owner:CRRC NANJING PUZHEN CO LTD

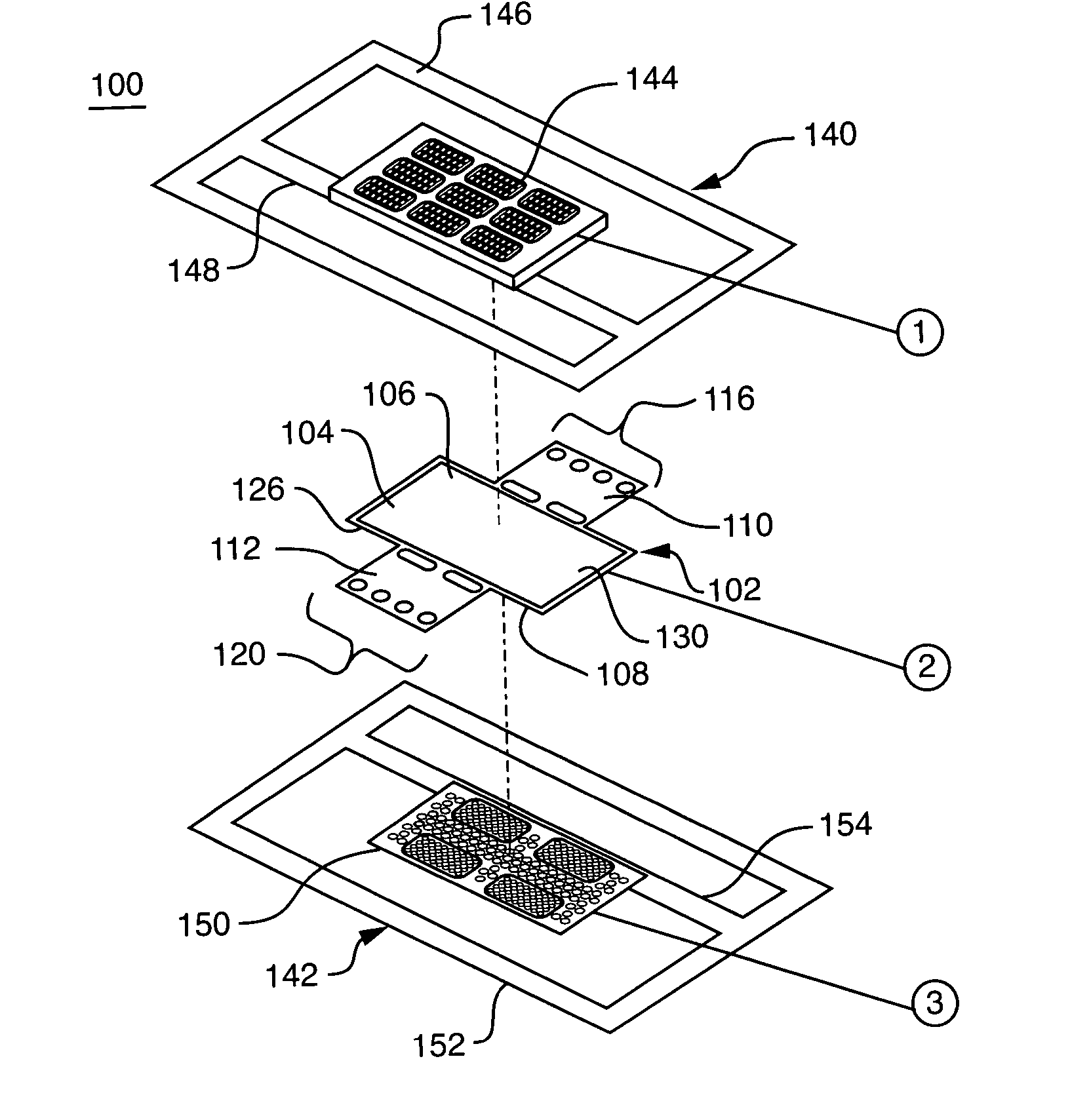

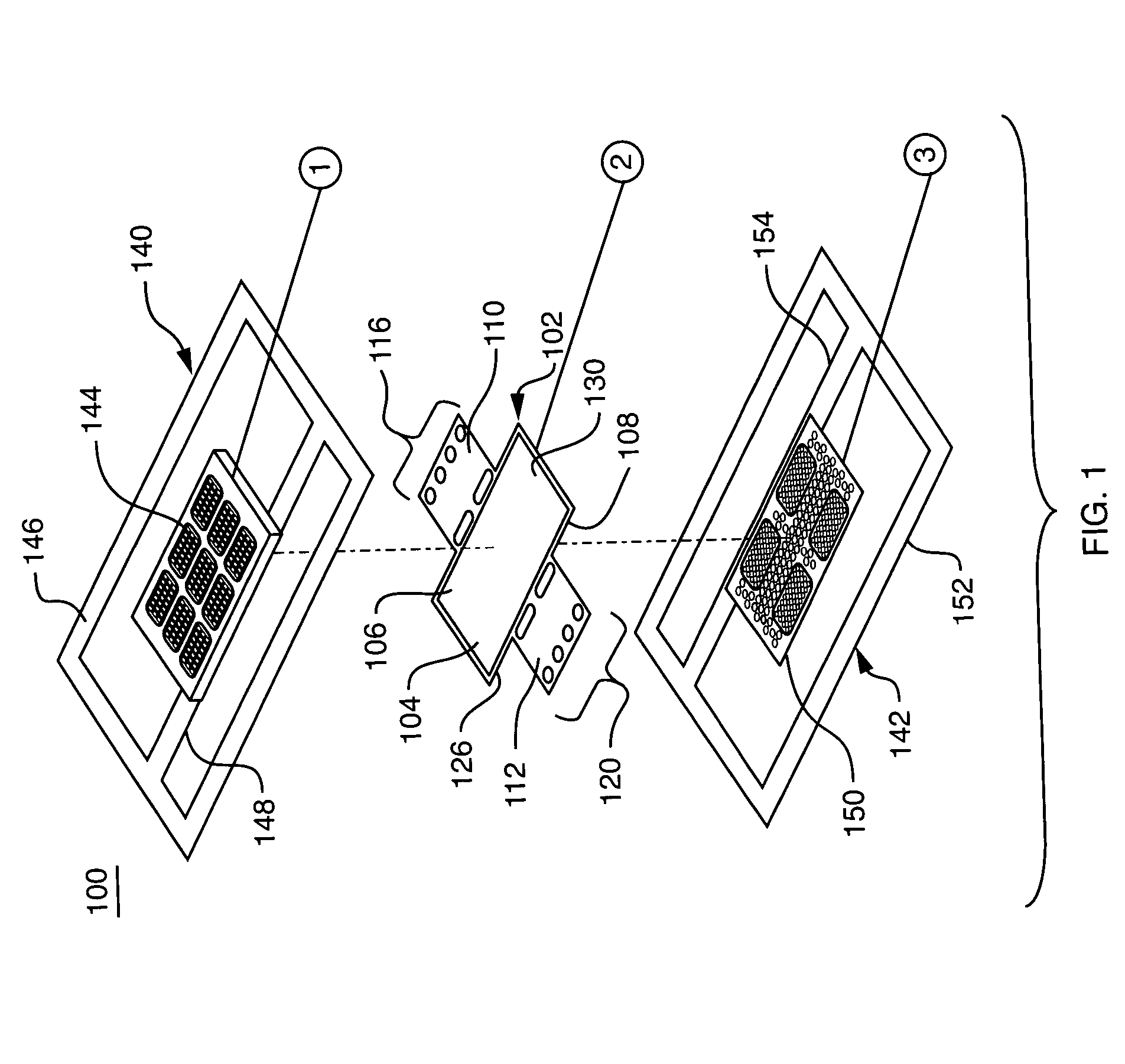

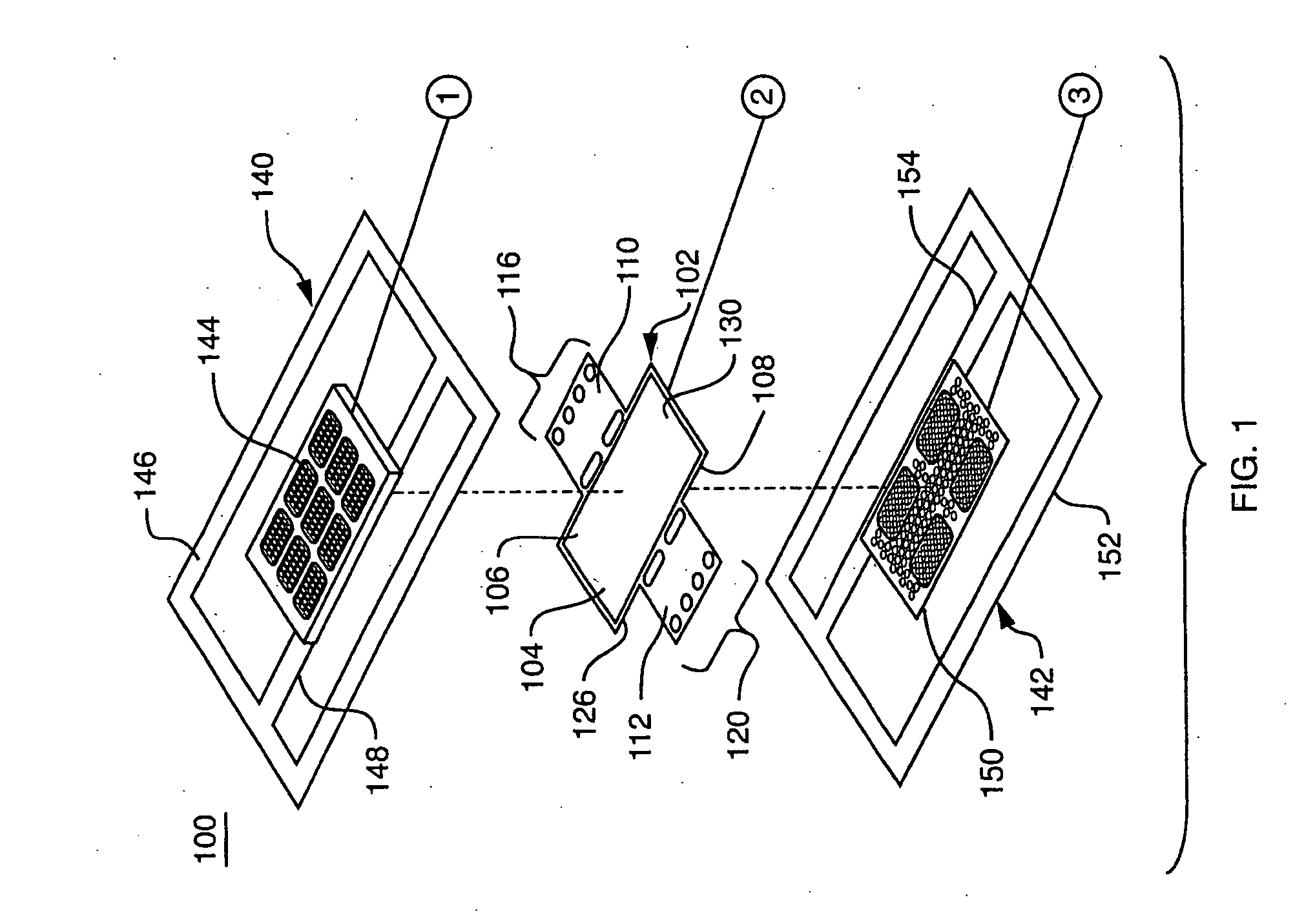

Method of manufacturing a fuel cell array and a related array

InactiveUS20050048349A1Facilitate molding processEliminate needFuel cells groupingFinal product manufactureFastenerCurrent collector

A process for fabrication and molding of a fuel cell, or an array of fuel cells is provided. The inventive process, in accordance with one aspect of the invention, includes diffusion layers being hot-press bonded onto current collectors. A catalyzed membrane is sandwiched between two current collectors integrated into the lead frames designed for use in a molding process. A raised surface on each current collector provides a means for shut off of the mold plates. A suitable moldable material is introduced into a mold cavity to form a frame around the current collectors, which provides a tight and secure seal, eliminating the need for gasketing, and which further also provides compression thus further eliminating screws, nuts and other fasteners.

Owner:MTI MICROFUEL CELLS

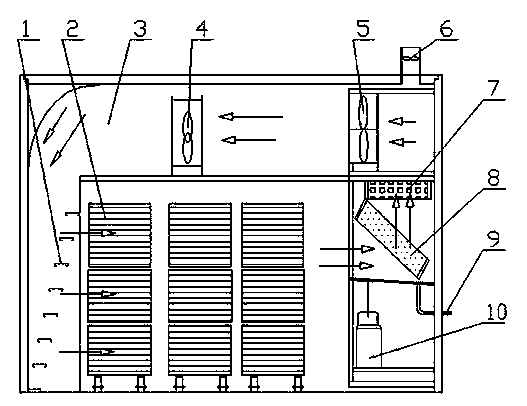

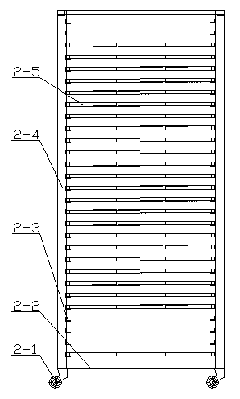

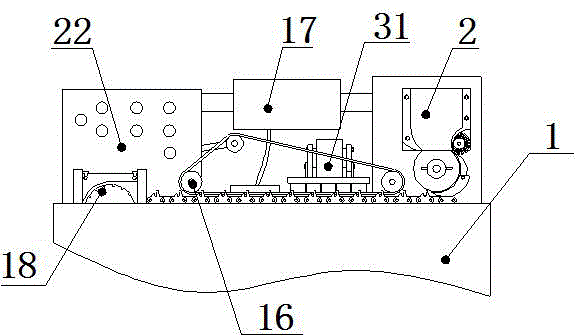

Automotive brake pad production line

ActiveCN104476200AHigh precisionImprove processing efficiencyOther manufacturing equipments/toolsProduction lineHeat transfer efficiency

The invention relates to an automotive brake pad production line which comprises a tabletting device, a thermal treatment device, a grinding device, a drilling device, a code spraying device and a conveying device connected among the former. Through the tabletting device, a concave die can be closely clamped, so that position of the concave die can be adjusted accurately; through the thermal treatment device, an automotive brake pad storage shelf after being subjected to thermal treatment can be automatically conveyed to a goods storage area, and heat transfer efficiency of a drum brake pad is improved; through the grinding device, an automotive brake pad is closely clamped, and position of an automotive brake pad clamp can be adjusted accurately, so that grinding accuracy is improved remarkably; through the drilling device, the automotive brake pad is closely clamped, the position of the automotive brake pad can be adjusted accurately, and a clamping clamp can be accurately positioned, so that drilling accuracy is improved remarkably; through the code spraying device, the brake pad is clamped closely, code spraying accuracy is improved, and one-step code spraying forming of multiple batches of brake pads is realized.

Owner:HUANGSHAN FEIYING AUTO PARTS

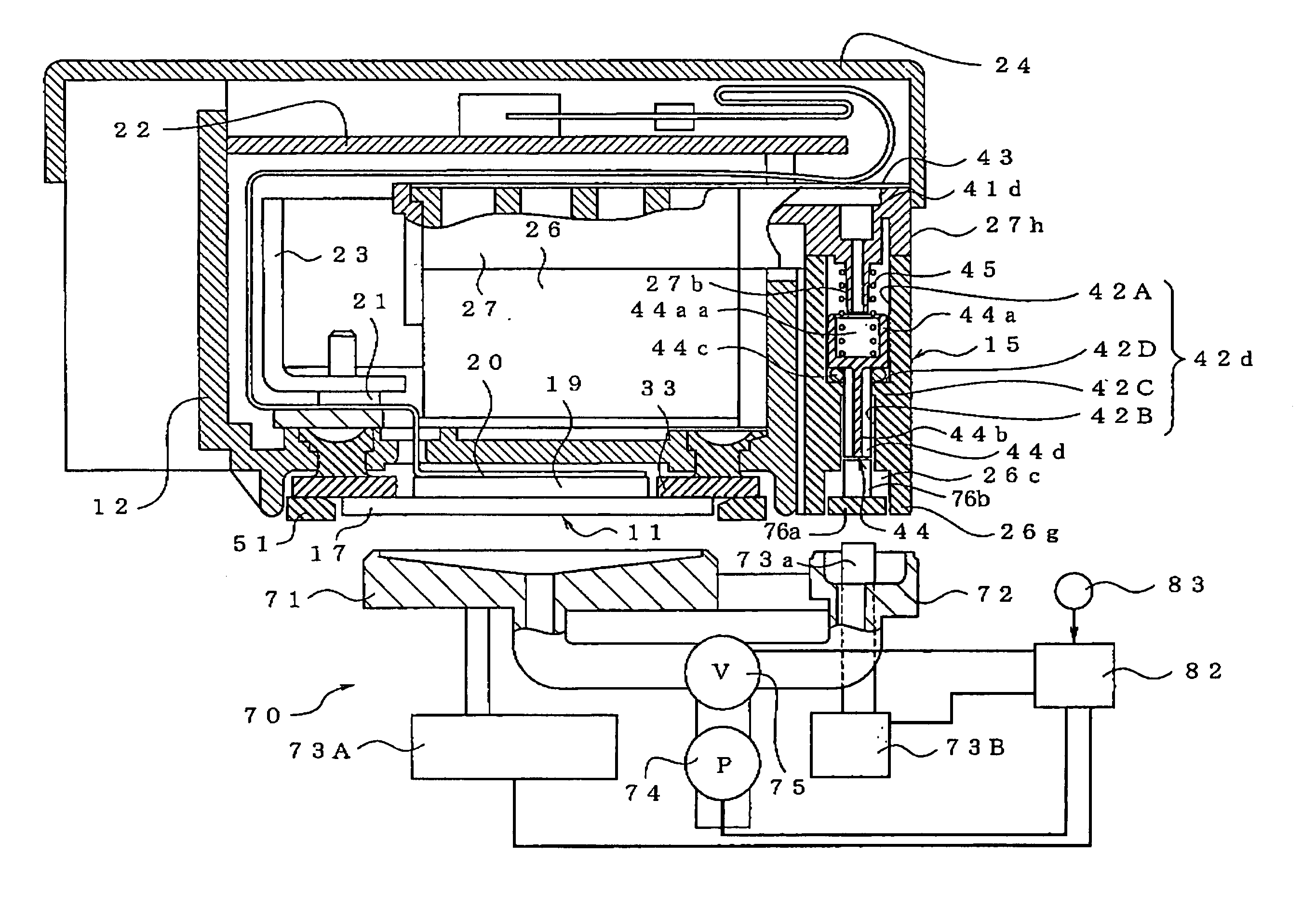

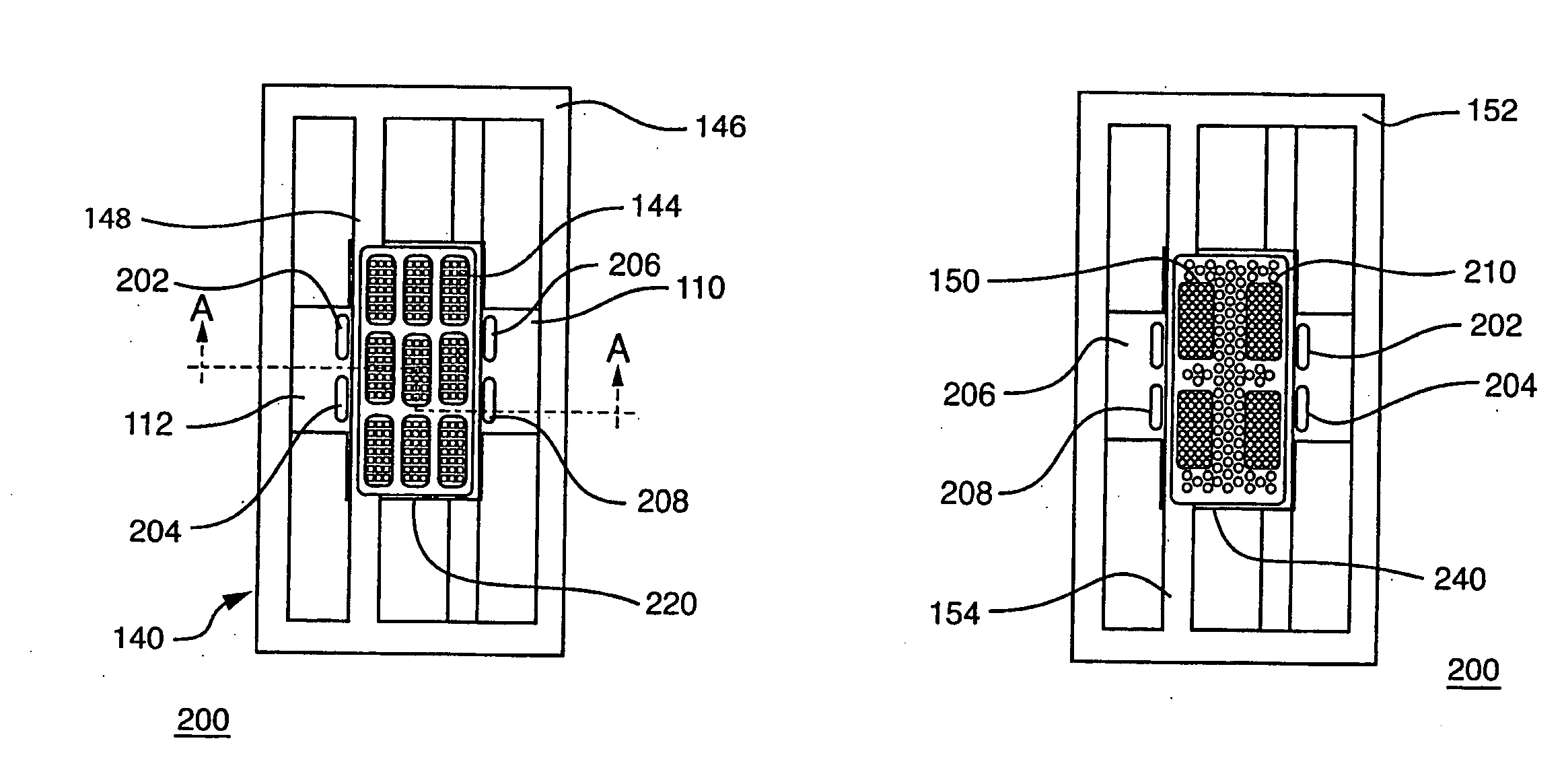

Lockable safety shield assembly for a prefillable syringe

InactiveUS20010004685A1Easy to assemblePromote activationInfusion syringesMedical devicesEngineeringPrefilled Syringe

A lockable safety shield assembly for a prefillable syringe is provided. The design of the lockable safety shield assembly enhances pharmaceutical manufacturers' ease of assembling the various components as part of its filling or processing of the prefillable syringes in normal practice, while at the same time minimizes difficulties in mating parts made from different materials. A tube is placed around the outside surface of the syringe barrel and affixed thereto. A collar is provided on the tube adjacent the distal end of the syringe barrel. A safety shield is axially slidable over the tube between a retracted position, wherein the distal end of the piercing element associated with the prefillable syringe is exposed, and an extended position, wherein the safety shield is locked to the collar to protectively cover the distal end of the piercing element. The safety shield includes locking structure configured so that the shield can be easily fitted over the tube. The locking structure includes at least one deflectable arm provided on the body of the shield. The deflectable arm includes a proximal end deflectable towards the interior of the shield. A stop member is provided on the interior of a shield in spaced relation to the proximal end of the deflectable arm. A ring is axially slidable over the shield to deflect the arm towards the interior of the shield to activate the locking structure. The safety shield is slid distally by an end user such that the collar is lockingly retained between the stop member and the proximal end of the deflectable arm. The collar, the stop member, and the deflectable arm may be configured to provide tactile as well as audible indication of locking to the end user.

Owner:BECTON DICKINSON FRANCE

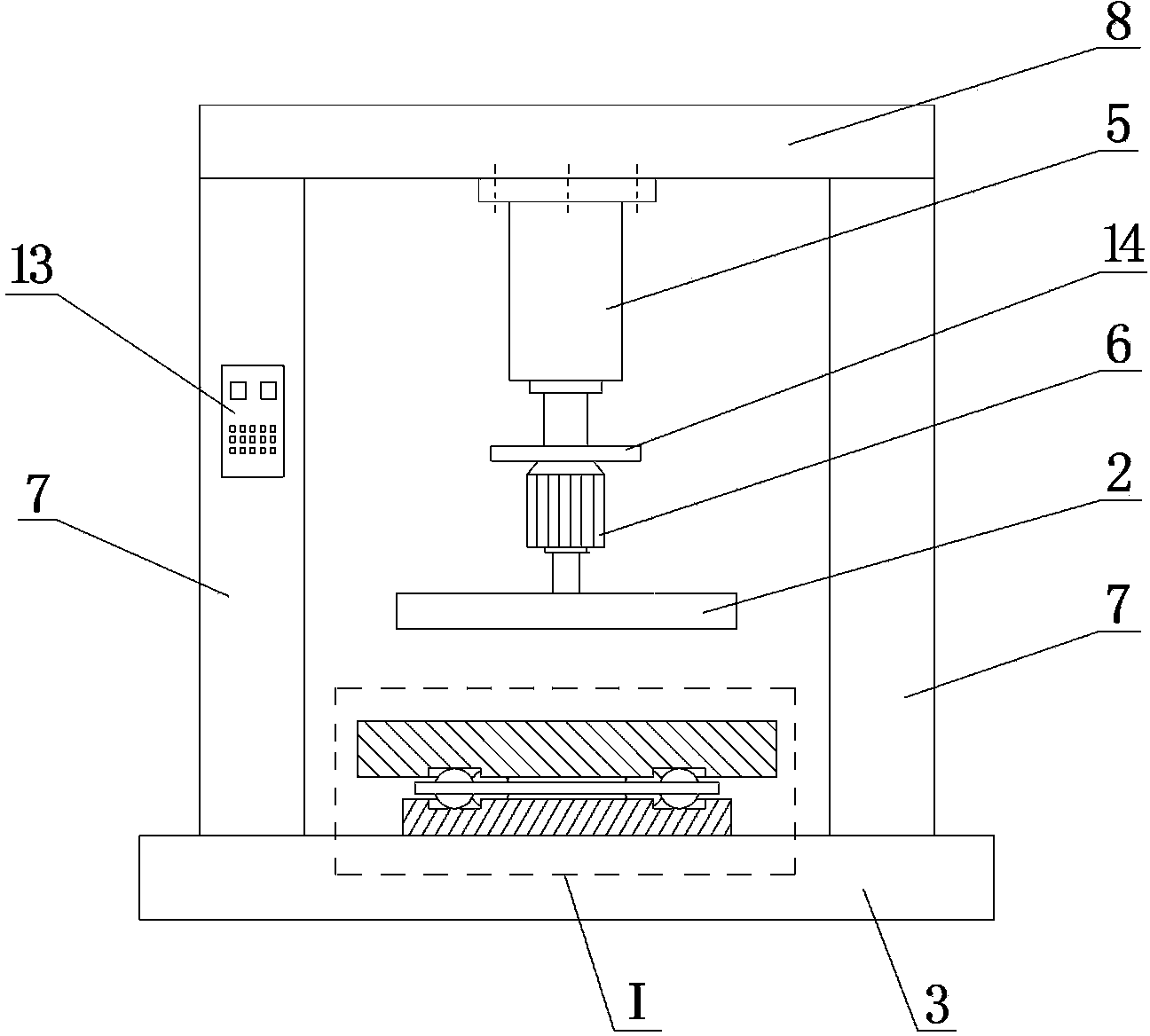

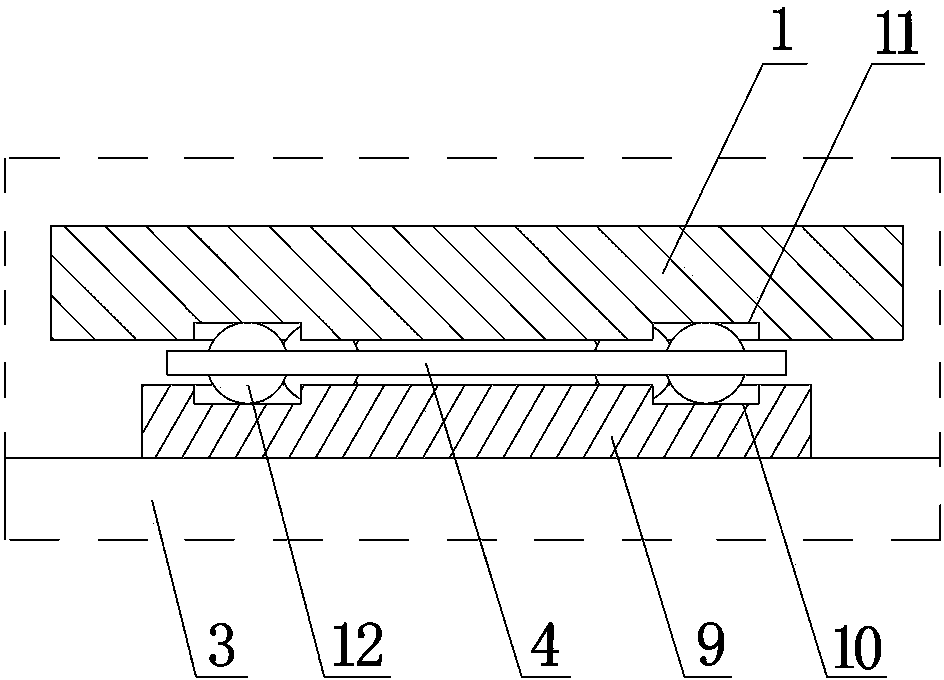

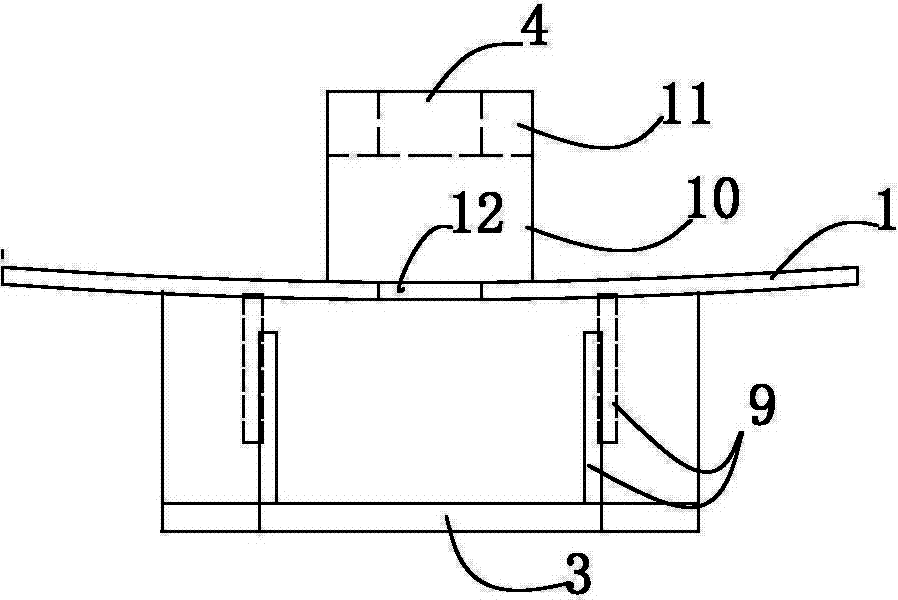

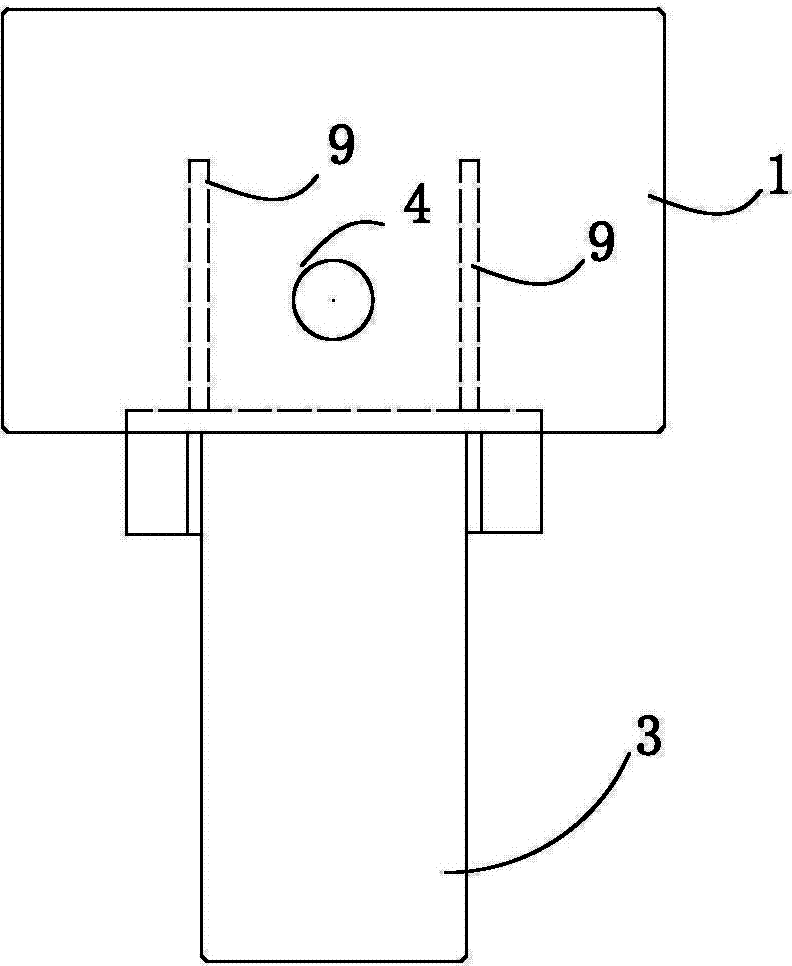

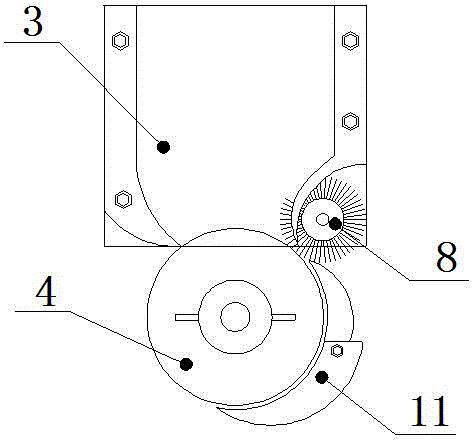

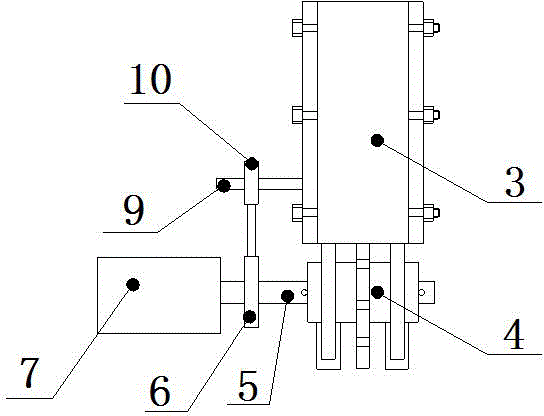

Grinding machine

ActiveCN104385117AImprove bearing strengthImprove carrying capacityLapping machinesEngineeringAutomation

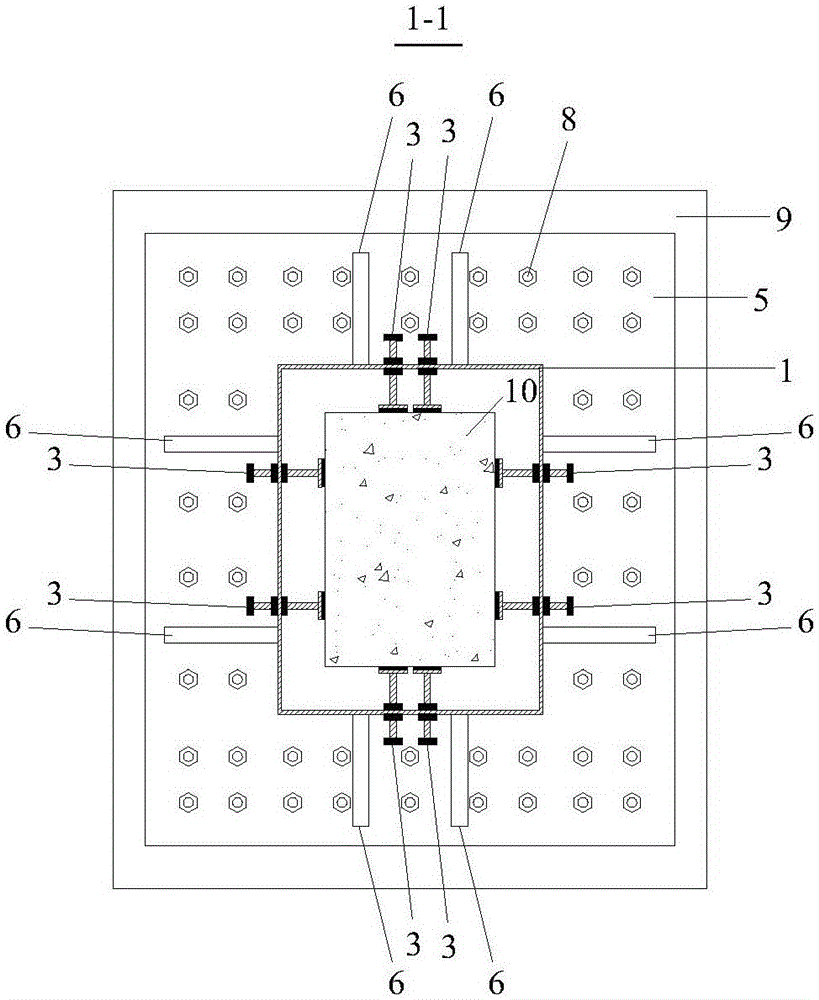

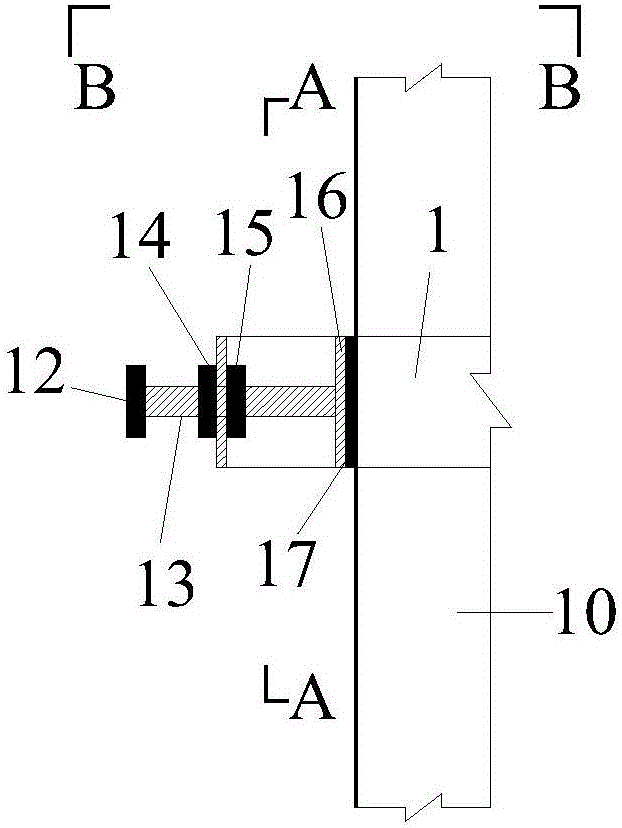

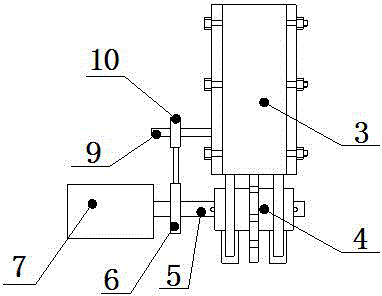

The invention discloses a grinding machine. The grinding machine comprises a stand (3), a rolling bearing (4), an oil cylinder (5) and a servo motor (6), wherein a cross beam (8) perpendicular to stand columns (7) are arranged between the two stand columns (7); a piston rod of the oil cylinder (5) is provided with the servo motor (6) perpendicular to the cross beam (8); an output shaft of the servo motor (6) is provided with a grinding disc (2) parallel to the stand (3); the stand (3) is also provided with a bearing table (9); the top surface of the bearing table (9) is provided with an annular groove I (10); a working table (1) is arranged parallel to the grinding disc (2), and the bottom surface of the working table (1) is provided with an annular groove II (11); balls (12) of the rolling bearing (4) are arranged between the annular groove I (10) and the annular groove II (11). The grinding machine has the beneficial effects of compact structure, high grinding precision, large bearing capacity, long service life and high degree of automation.

Owner:四川泰美克科技有限公司

Sorting and conveying mechanism for groove workpieces

ActiveCN110451228AReasonable structural designHigh degree of automationConveyor partsEngineeringMechanical equipment

The invention discloses a sorting and conveying mechanism for groove workpieces, and belongs to the field of workpiece conveying and machining mechanical equipment. A material transferring pipe is vertically and fixedly arranged in the middle of the upper side of a material transferring support, a horizontal moving push plate is horizontally and fixedly provided with a material pushing pressing rod along the side of the material transferring material pipe, a material guide inclined plate is obliquely and downwards fixedly arranged on one side below the material transferring material pipe, anda material bearing baffle is arranged on one side of a turnover baffle; a material guiding pipe is vertically and fixedly arranged on the material transferring support at the lower side of the material transferring pipe, a material guiding rotating plate is arranged on the material transferring support on one side of the material guiding pipe, the end part the lower side of a transferring guide plate is rotationally connected to the material transferring support, a material bearing rotating plate is arranged on the upper side of the transferring guide plate, and a material transferring belt ishorizontally arranged on the upper side of a conveying base. The sorting and conveying mechanism has the advantages that the structural design is reasonable, the groove workpieces can be convenientlyand efficiently subjected to directional arrangement in the discharging process, automatic overturning and conveying of the groove workpieces can be realized, the workpiece feeding and conveying automation degree is improved, and the requirements of production and use are met.

Owner:泰州市宠友宠物服务有限公司

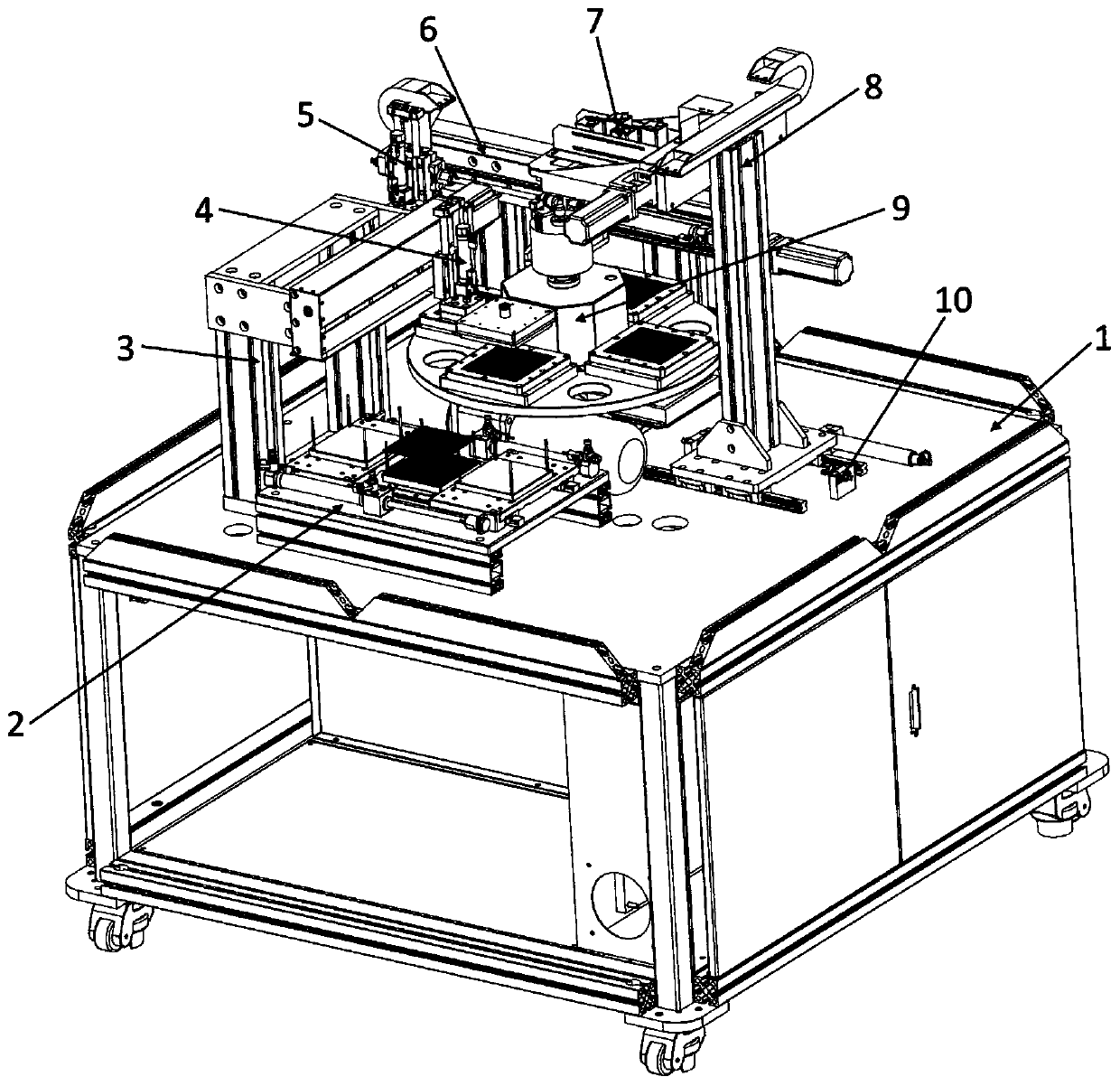

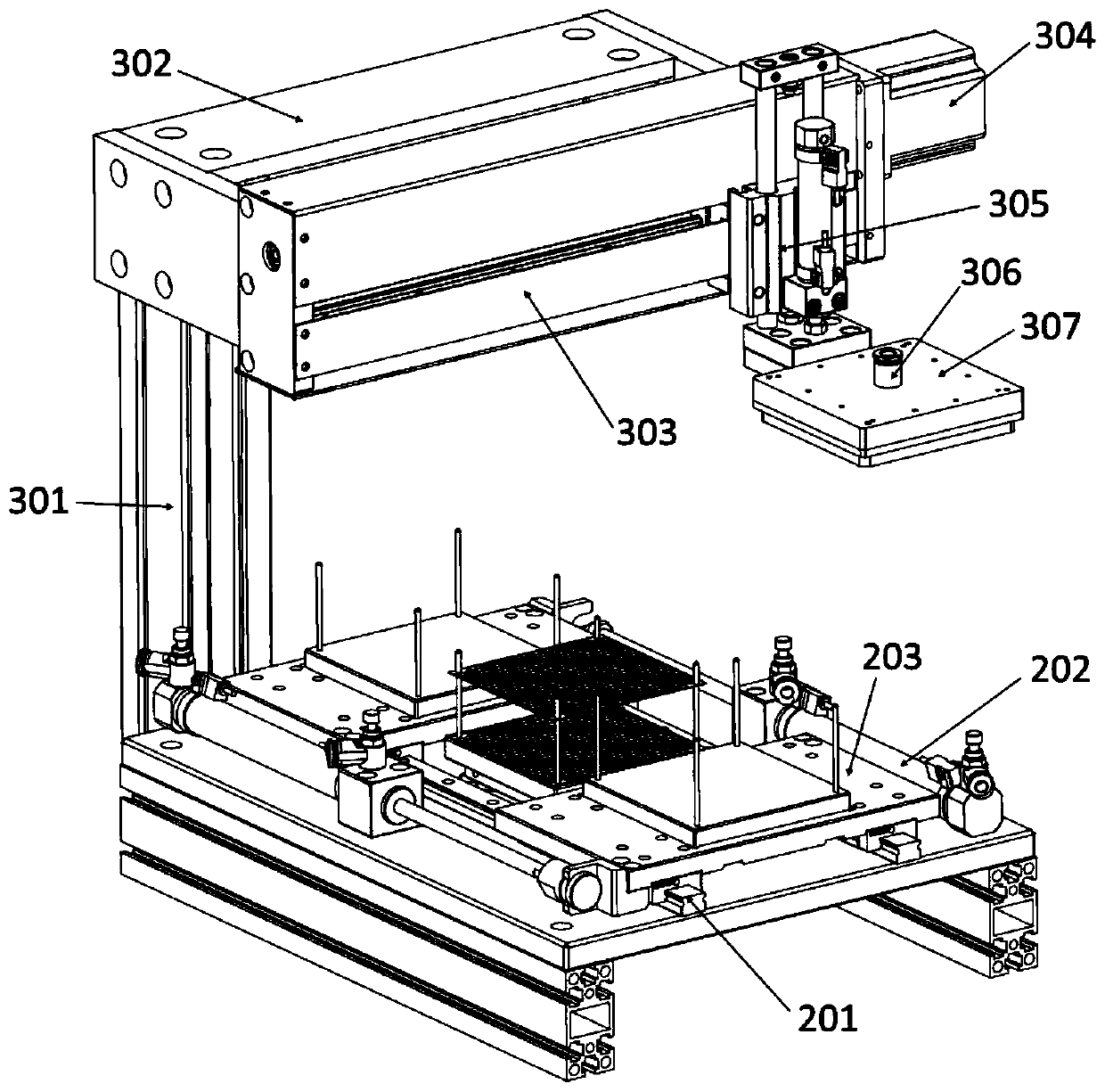

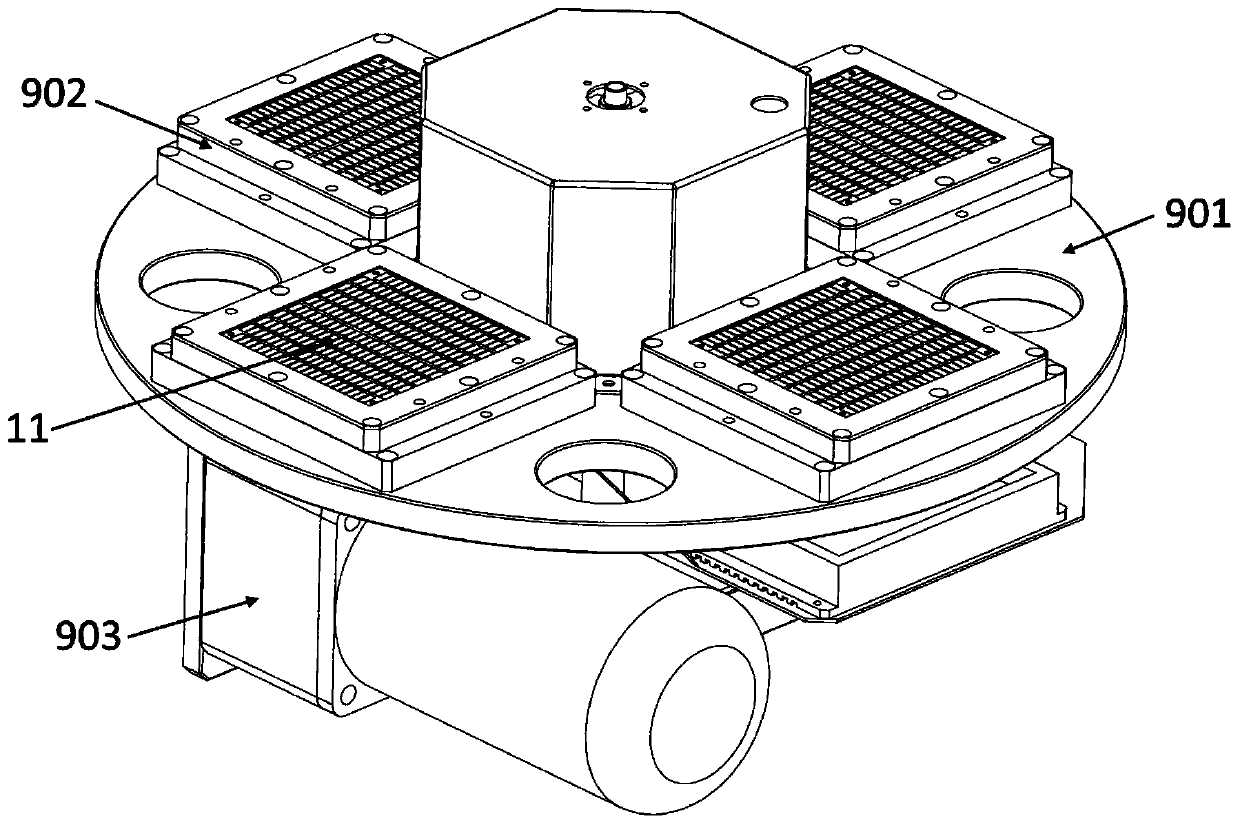

Visual detection robot for flexible circuit board and transmission method of visual detection robot

InactiveCN110104388AEvenly placedPlace stableMaterial analysis by optical meansConveyor partsFlexible circuitsComputer module

The invention relates to a visual detection robot for a flexible circuit board and a transmission method of the visual detection robot. The visual detection robot comprises four parts of a feeding mechanism, a rotation mechanism, a visual assembly and a discharging mechanism. The feeding mechanism grabs the to-be-detected flexible circuit board, infrared rays emitted by an infrared transmitter arereceived by an infrared receiver, whether a pneumatic suction cup is aligned with a detection station or not is judged, and it is ensured that a to-be-detected workpiece is placed on the detection station smoothly and steadily. An image collecting module collects images and transmits the images back to a computer, and finally, sorting and discharging are completed by the discharging mechanism. Arotation disc can make dividing movement of 90 degrees once, the rotation disc is self-locked during every rotation of 90 degrees and stays by a predetermined time interval, and at the moment, the visual assembly captures images and transmits the images back to the computer for processing. The rotation mechanism can integrate four stations on one disc, the space is saved, the transmission precision is also improved, the visual detection robot is suitable for conveying of the flexible circuit board, transmission is smooth, vibration is avoided, and positioning is accurate.

Owner:NANJING HANMINGZHI INTELLIGENT TECHNOLOGY CO LTD

Efficient automatic fruit sorting robot

ActiveCN106976102AGrasp firmlyReduce labor intensityGripping headsConveyor partsHydraulic cylinderEngineering

The invention relates to an efficient automatic fruit sorting robot comprising a base plate. An adjusting mechanism is mounted at the front end of the base plate. A lifting hydraulic cylinder is mounted at the lower end of the adjusting mechanism. The bottom end of the lifting hydraulic cylinder is mounted on a hard-shell fruit grabbing mechanism through a flange. A collecting mechanism is mounted in the middle of the base plate, and a pushing handle is mounted at the rear end of the base plate. Four universal wheels are mounted symmetrically at the lower end of the base plate. The adjusting mechanism can drive the hard-shell fruit grabbing mechanism to conduct position adjusting. The adjusting mechanism, the hard-shell fruit grabbing mechanism and the collecting mechanism are mutually matched to complete the process of fruit sorting. The problems that in the existing fruit sorting process, soft-shell fruit and hard-shell fruit need to be carried through labor, the surface of the soft-shell fruit is prone to damaging, fruit selling is affected, and carrying of the hard-shell fruit through the labor is large in labor intensity and low in working efficiency can be solved, and the function of efficient fruit sorting can be achieved.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

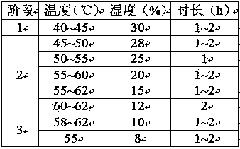

Drying method of organic edible flower

ActiveCN103988890AEasy to operateEasy to controlFruits/vegetable preservation by dehydrationBiotechnologyHigh humidity

A drying method of an organic edible flower comprises the following steps: 1) grading and selecting picked organic chrysanthemum, then artificially placing a dish; 2) drying with a heat pump, to be more specific, the moisture content of a product is 9.5%-11.5% by selection of heat pump type drying for 9-13h, the heat pump type drying is divided into three stages comprising low temperature high humidity slow drying for 1-2h in the first stage being, gradual warming dehumidifying drying for 5-8 h in the second stage and high temperature low humidity drying for 3-4h in the third stage; 3) again grading and selecting the dried organic chrysanthemum according to quality, and filling nitrogen to pack each piece of organic chrysanthemum. The drying method is environmentally friendly and efficient, zero-pollution to a dry matter and the environment, and simple in operation and control process, can work continuously, is high in industrial production efficiency, avoids petal scattering and falling phenomena of organic edible flowers, improves the appearance aroma and taste of the prepared flower, and ensures the nutritional effects of a product, and the product is high in quality and long in storage time.

Owner:江西隆平有机农业有限公司

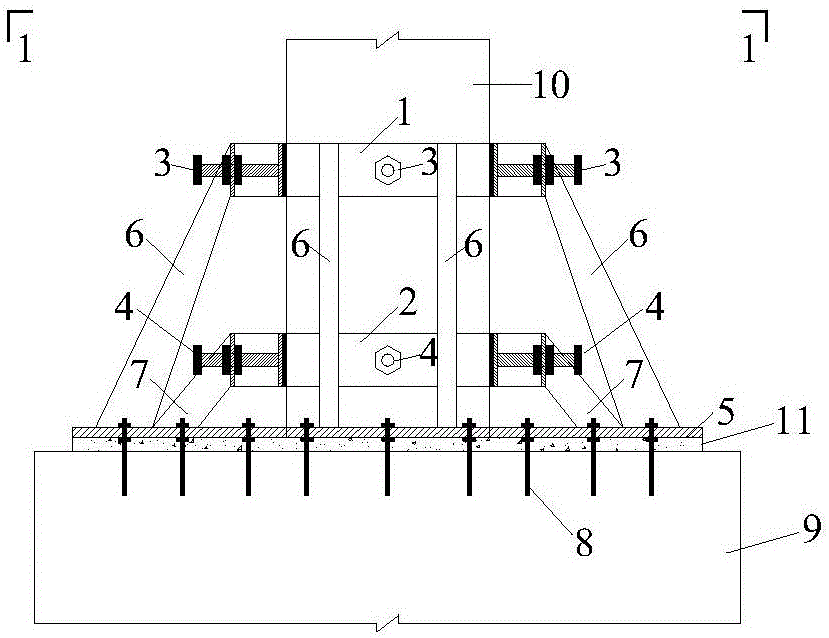

Positioning device for installation of precast pier stud

ActiveCN106758787AEasy to makeQuick installationBridge structural detailsBridge erection/assemblyHollow coreBuilding construction

The invention discloses a positioning device for installation of a precast pier stud, and the positioning device is applicable to precast pier studs in all structural forms and comprises an annual steel bottom plate arranged outside a precast pier stud, an upper annular sleeve arranged over the annual steel bottom plate as supported by an upper inclined leg, a lower annular sleeve arranged over the annual steel bottom plate as supported by a lower inclined leg, an upper positioner arranged on the upper annular sleeve, and a lower positioner arranged on the lower annular sleeve. The positioning device in the invention is simple to fabricate, quick and convenient to install, and reusable; the perpendicularity of the precast pier stud may be adjusted rapidly for the purpose f accurate positioning; the positioning device is extensive in application range, and suitable for accurate positioning of not only precast solid and hollow pier studs, but also precast pier studs in different section forms. With the positioning device for installation of a precast pier stud, convenient construction and simple and easy operation are achieved with effectively improved construction efficiency of accurate positioning in installation of the precast pier stud and accelerated construction progress.

Owner:SOUTHEAST UNIV

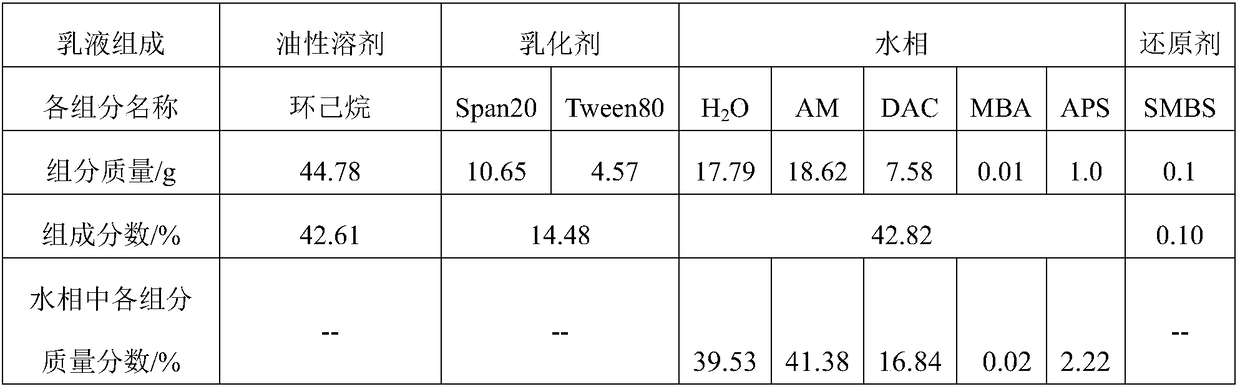

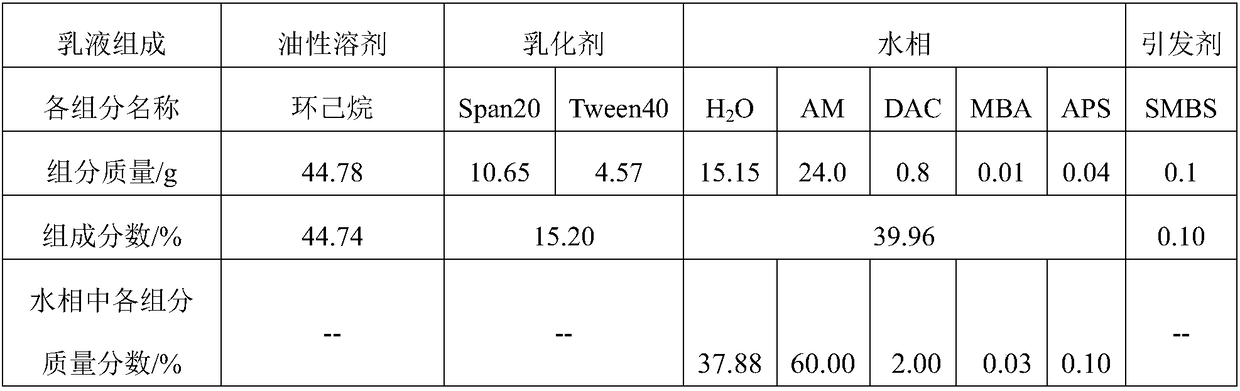

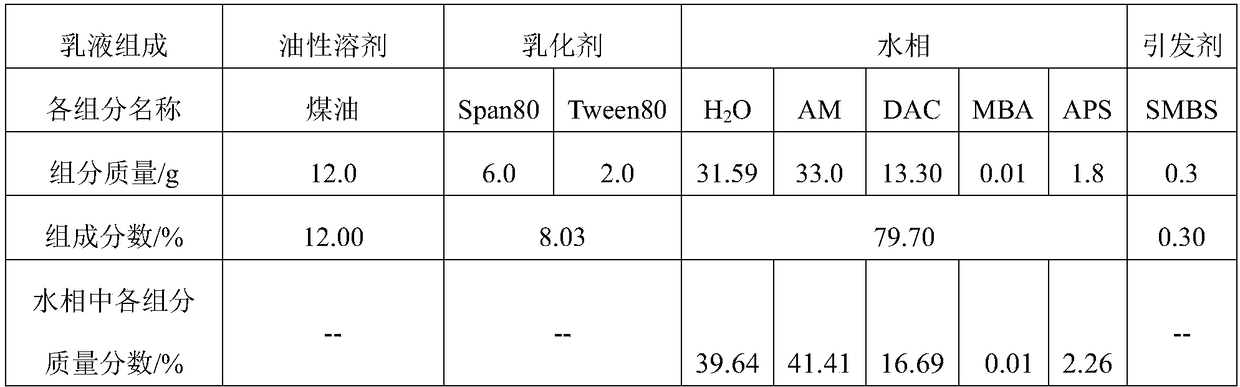

Method for preparing fracturing fluid thickener with self-destruction effect

The invention discloses a fracturing fluid thickener with a self-destruction effect. The fracturing fluid thickener comprises, by weight, 5-80% of monomer aqueous phase, 12-70% of oil-based solvents and 8-25% of emulsifiers. The usage of reducing agent solution in oxidation-reduction initiators accounts for 0.1-0.5% of the mass of emulsion. A method for preparing the fracturing fluid thickener mainly includes dissolving the emulsifiers in the oil-based solvents; adding the monomer aqueous phase with excessive oxidizing destruction agents into the oil-based solvents; carrying out stirring and deoxidizing, adding the reducing agent solution at the temperatures of 10-40 DEG C and initiating reaction for 0.5-4 hours to obtain inverse emulsion with the oxidizing destruction agents partially coated by micro-spheres; directly diluting the emulsion by the aid of water to prepare the fracturing fluid thickener with the self-destruction effect, or separating out the micro-spheres by sedimentation and then preparing the fracturing fluid thickener with the self-destruction effect. The fracturing fluid thickener and the method have the advantages that the fracturing fluid thickener and destruction agents can be produced by the aid of the method in an integrated manner, the destruction agents can be uniformly placed and can be released in a delayed manner, and accordingly the problems of difficulty in controlling the destruction time of directly mixed destruction agents for use in conventional processes or high cost and uneven destruction of capsule destruction agents can be solved.

Owner:YANSHAN UNIV

Building construction system

InactiveUS9140000B1Reduce generationFlat surfaceCovering/liningsWallsFront edgeBuilding construction

A building construction system is provided having an elongated track (bypass clip track) that overlays a front edge of a concrete slab. The elongated track provides an even flat surface along an uneven concrete slab because the elongated track can be placed at adjustable distances from slab edges that may be uneven. The track is secured to a bracketing structure that has foam inserts that become embedded within the top and / or bottom surface of the concrete slab after the concrete hardens. By attaching the track to these foam inserts instead of the concrete directly, breakage or spalling of the slab edge is reduced. Studs are then attached to a stud attachment plate extending from the track, such that thereafter, a wall or façade may be attached to the track that overlays the uneven slab edge.

Owner:BRADY TODD A

Method of manufacturing a fuel cell array and a related array

InactiveUS20070087253A1Easy to shapeEliminate needFuel cells groupingFinal product manufactureFuel cellsEngineering

Owner:FANNON MEGAN +2

Woolen strip continuous winding mechanism

InactiveCN108792787AWind evenlyThe winding mechanism conveys the wool sliver at a uniform speed and stablyFilament handlingEngineeringScrew thread

The invention discloses a woolen strip continuous winding mechanism, and belongs to the field of textile processing machinery equipment. According to the technical scheme, a strip guide mechanism, a tensioning mechanism, a strip swing mechanism and a winding mechanism of the woolen strip continuous winding mechanism are sequentially and fixedly arranged on a material conveying support from top tobottom in the conveying direction of woolen strips, a strip bearing rotating roller is horizontally and rotationally connected to a strip guide support, one side of a swing support is horizontally androtationally connected with a tensioning rotating roller, a translation connecting plate is arranged on a translation guide rod in a sliding mode in the horizontal direction, a reciprocating screw rod is in threaded connection with the translation connecting plate horizontally, the winding rotating roller is horizontally and rotationally connected to the upper side of the rotating roller support,a bearing roller guide rod is obliquely and slidably arranged on a lifting sleeve, a winding compression spring sleeves the part, between a spring baffle and the lifting sleeve, of the bearing rollerguide rod, and a bearing roller limiting clamp is fixedly arranged at the upper end of the bearing roller guide rod. According to the woolen strip continuous winding mechanism, the structural designis reasonable, woolen strips can be efficiently, conveniently, fast, continuously and stably conveyed and wound, so that the automation degree of winding processing of the wool strips is improved, andthe requirements of production and use are met.

Owner:盛奇石

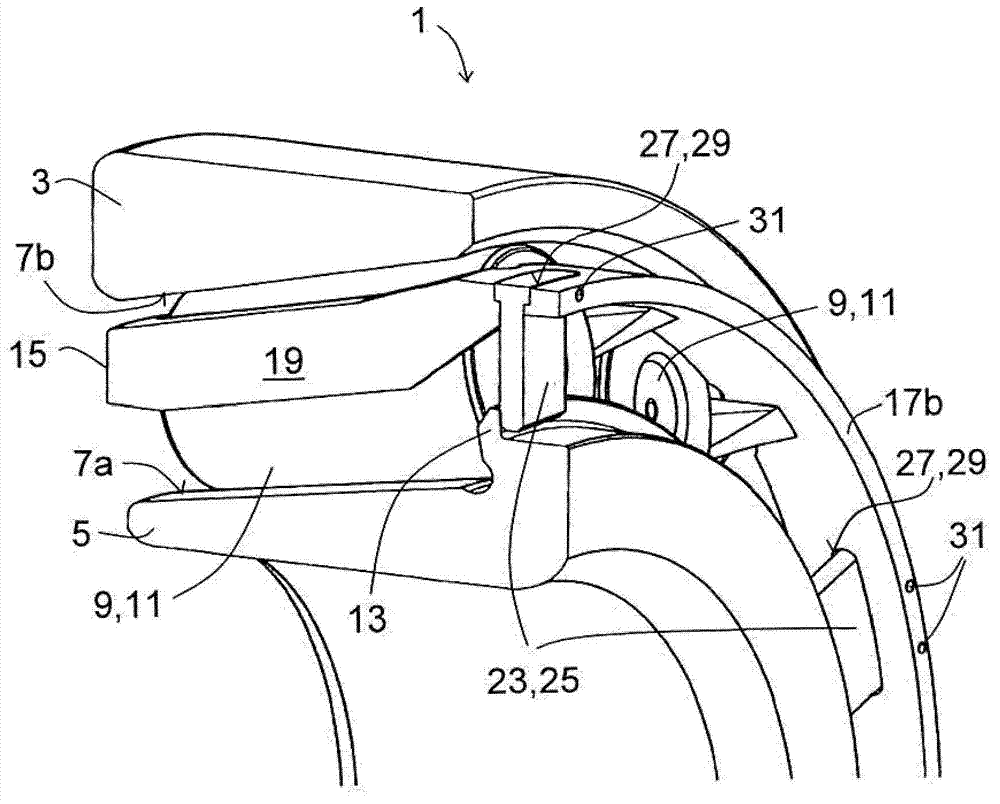

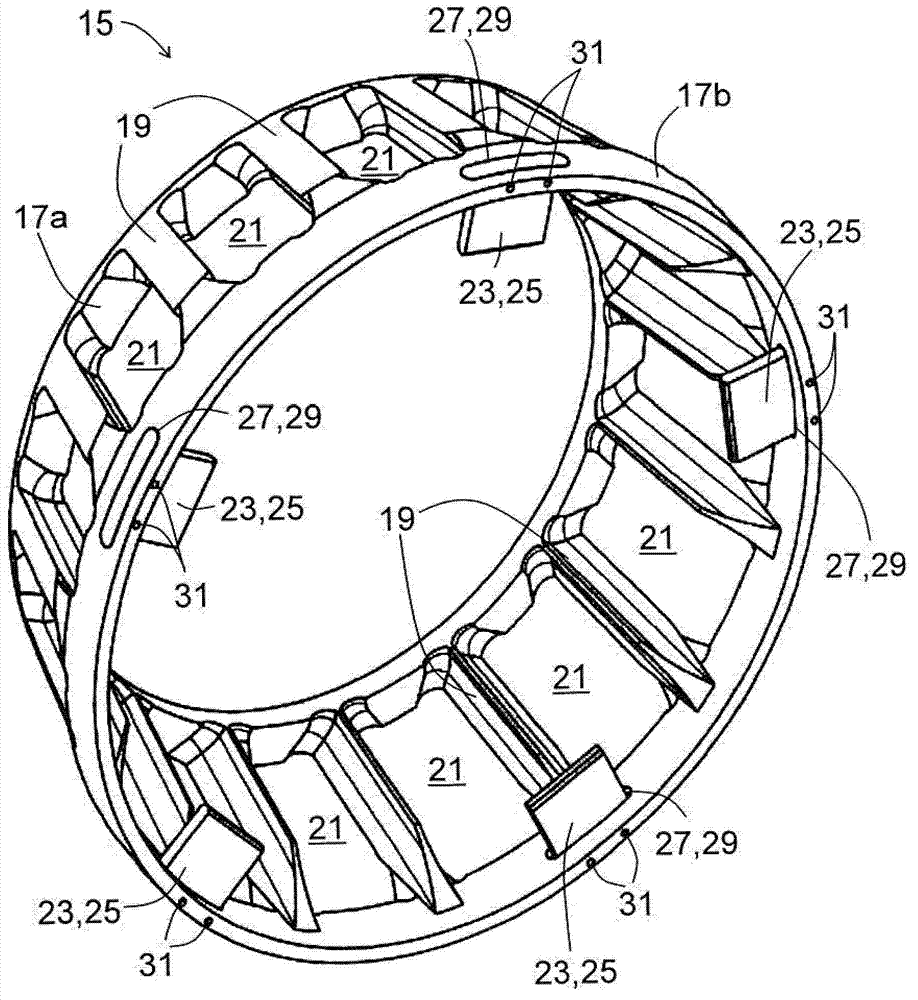

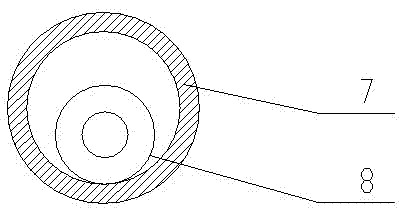

Anti-friction bearing

InactiveCN103328839AEasy to installSafe installationRolling contact bearingsBearing assemblyEngineeringMechanical engineering

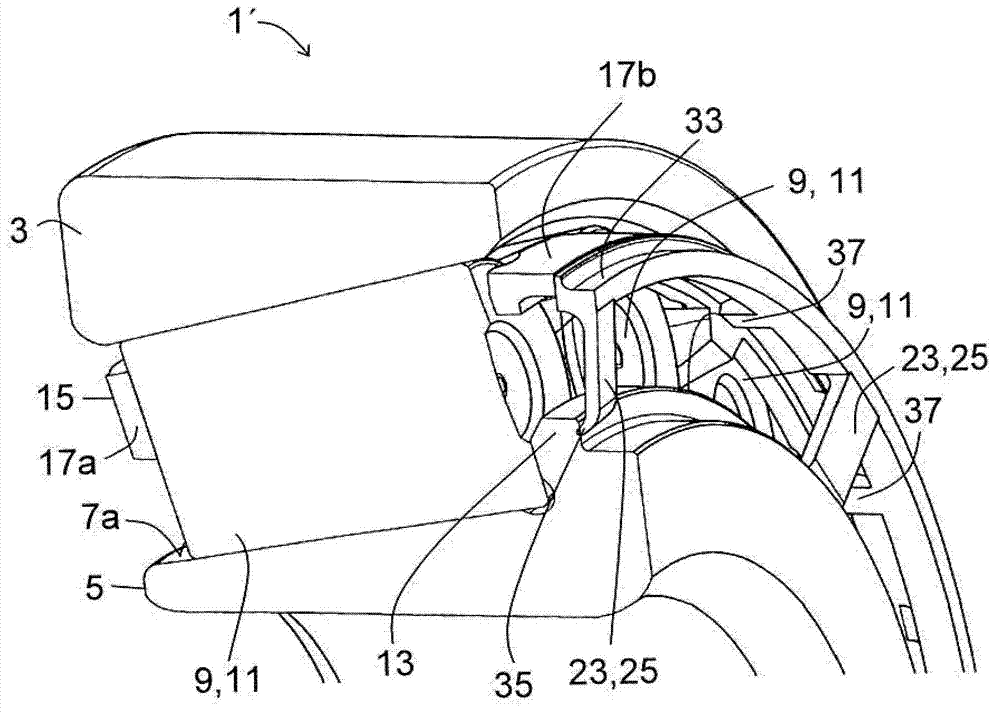

The invention relates to an anti-friction bearing (1) having a bearing outer ring (3), a bearing inner ring (5) and a plurality of rolling bodies (9) which are arranged between the bearing outer ring (3) and the bearing inner ring (5), are held at predefined spacings from one another by a bearing cage (15) and roll on raceways (7a, 7b) of the bearing rings (3, 5), of which at least one raceway is delimited by a rim (13), wherein the bearing cage (15) has two cage side rings (17a, 17b) and a plurality of cage webs (19) which connect the cage side rings (17a, 17b), and in which at least one guiding and holding element (23) extends from the bearing cage (15) towards the rim (13) and engages axially behind the rim (13). According to the invention, at least one opening (27) is formed in one of the cage side rings (17b), in which opening (27) the at least one guiding and holding element (23) is fastened. As an alternative to this, in an anti-friction bearing (1') according to the invention, an additional ring (33) is fastened to one of the cage side rings (17b), with which additional ring (33) the guiding and holding element (23) is formed in one piece. The proposed construction avoids the risk that the guiding and holding element (23) is damaged during the assembly of the anti-friction bearing (1).

Owner:SCHAEFFLER TECH AG & CO KG

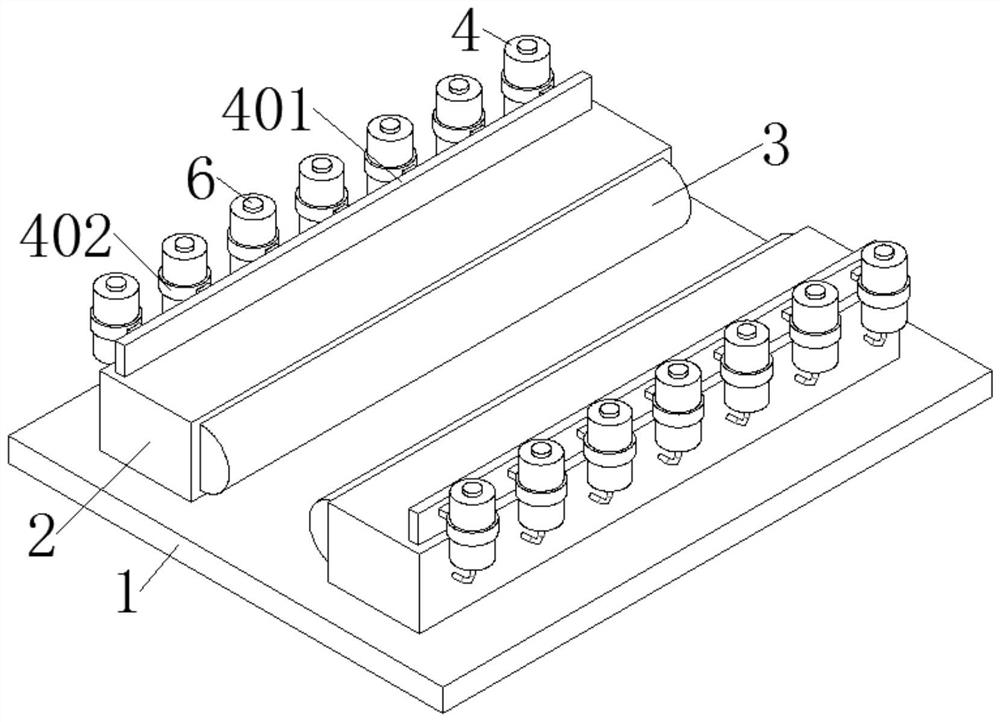

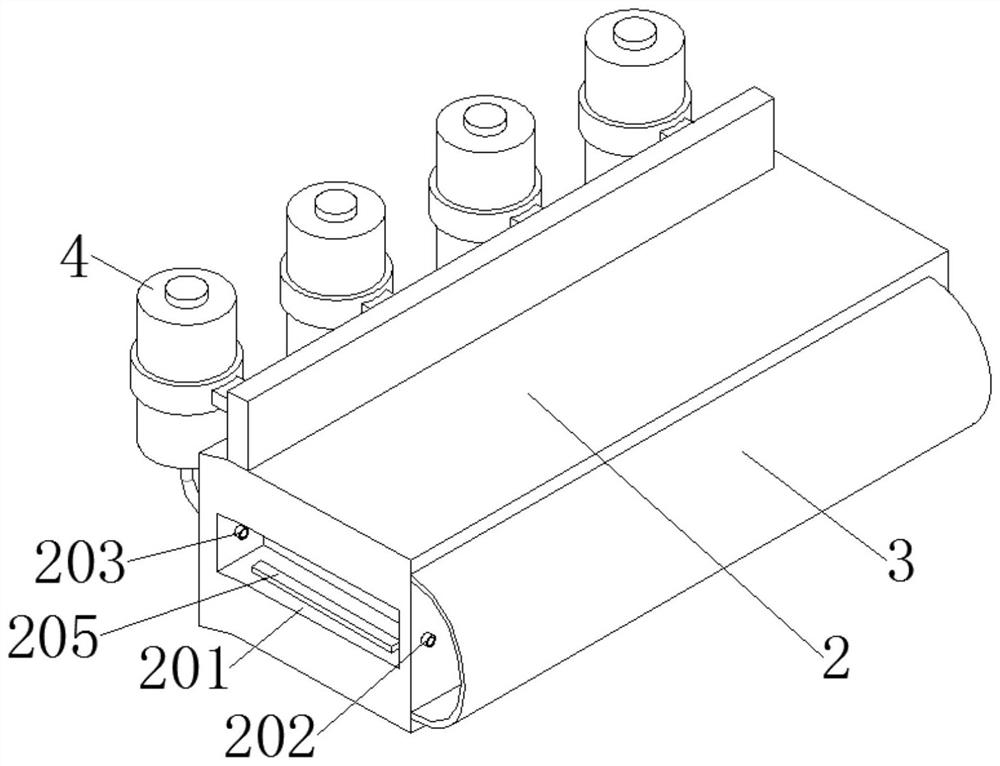

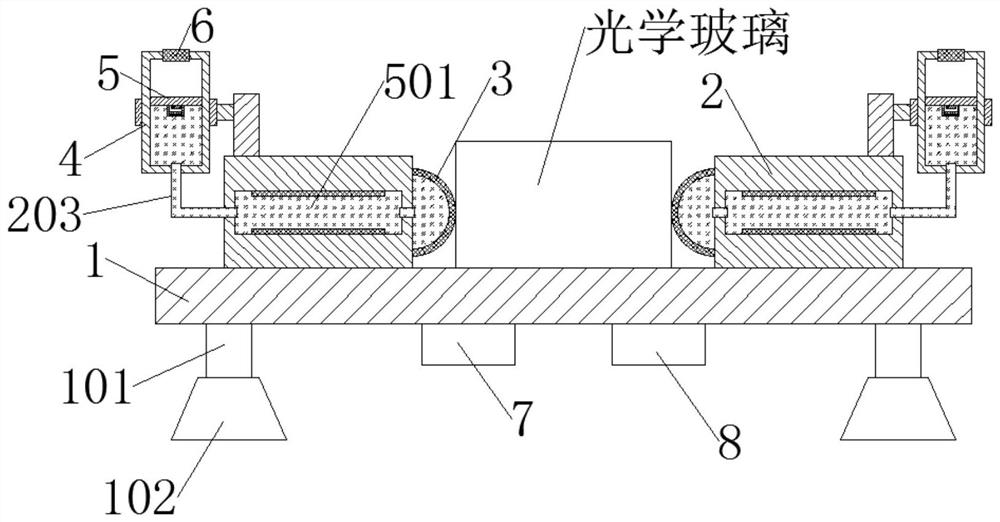

Constant-pressure clamping device for processing of strip-shaped optical glass

The invention discloses a constant-pressure clamping device for processing of strip-shaped optical glass. The constant-pressure clamping device comprises a base, mounting seats, a clamping air bag, a liquid storage cylinder, a piston and an electromagnet. In the using process, to-be-processed optical glass is placed between the mounting seats, in the initial state, due to the fluidity of fluid and the elasticity of the clamping air bag, the optical glass can be smoothly placed, and thus the optical glass in different sizes can be conveniently placed between the mounting seats; then the electromagnet is electrified, the electromagnet generates magnetism when electrified, the polarities of the sides, close to each other, of the piston and the electromagnet are the same, the magnetic repulsion force between the electromagnet and the piston drives the piston to descend, thus the fluid is squeezed into the clamping air bag, the clamping air bag is expanded, and thus the optical glass is fixed and clamped; and the optical glass is clamped through the flexible clamping air bag, thus the enough clamping force can be kept, and the circumstance that the optical glass is damaged in the clamping process can also be avoided.

Owner:吴懋萱

Drilling device and positioning assembly

ActiveCN104722799AReduce labor intensityImprove construction efficiencyDrilling/boring measurement devicesWork benchesDrill holeDrill bit

The invention discloses a drilling device and a positioning assembly. The drilling device comprises the positioning assembly. The positioning assembly comprises an attachment plate, a clamping piece, a positioner, a drilling assembly and a magnetic drill, wherein the attachment plate is attached to a shell plate and provided with a first through hole, and the first through hole is correspondingly attached to a hole to be drilled; the clamping piece is fixed to the attachment plate and provided with a second through hole; the positioner is arranged in the second through hole; the drilling assembly comprises a supporting plate, the supporting plate is fixed to the attachment plate, and the supporting plate and the clamping piece are located on the two sides of the attachment plate; the magnetic drill is fixed to the supporting plate, and a drill bit of the magnetic drill penetrates through the positioner to drill the hole to be drilled. The drilling device solves the technical problems that in the prior art, the drilling accuracy is low and a drilling device is complex, and has the advantages of being high in drilling accuracy, easy and convenient to operate and convenient to carry.

Owner:武汉武船特种船艇有限责任公司

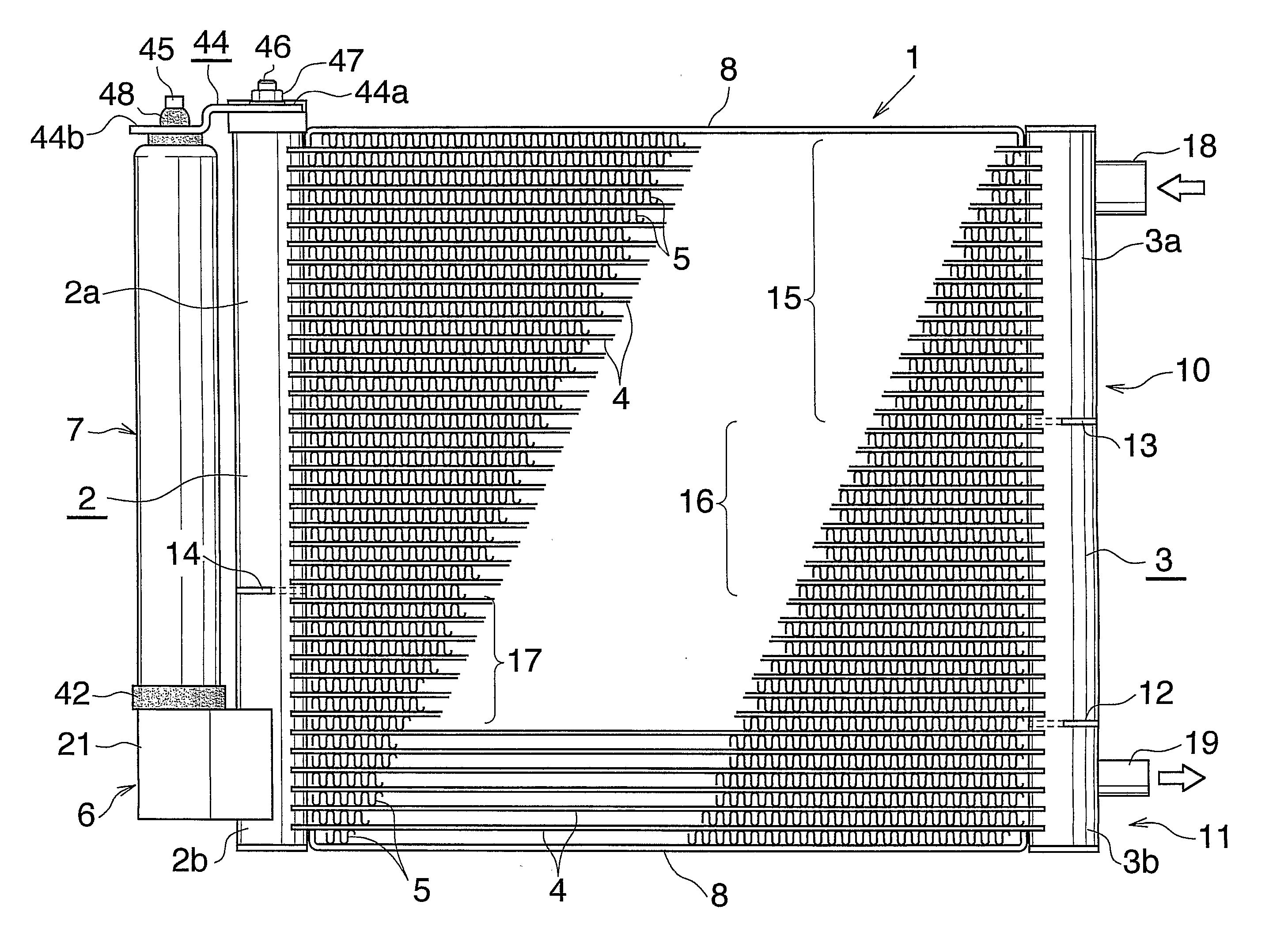

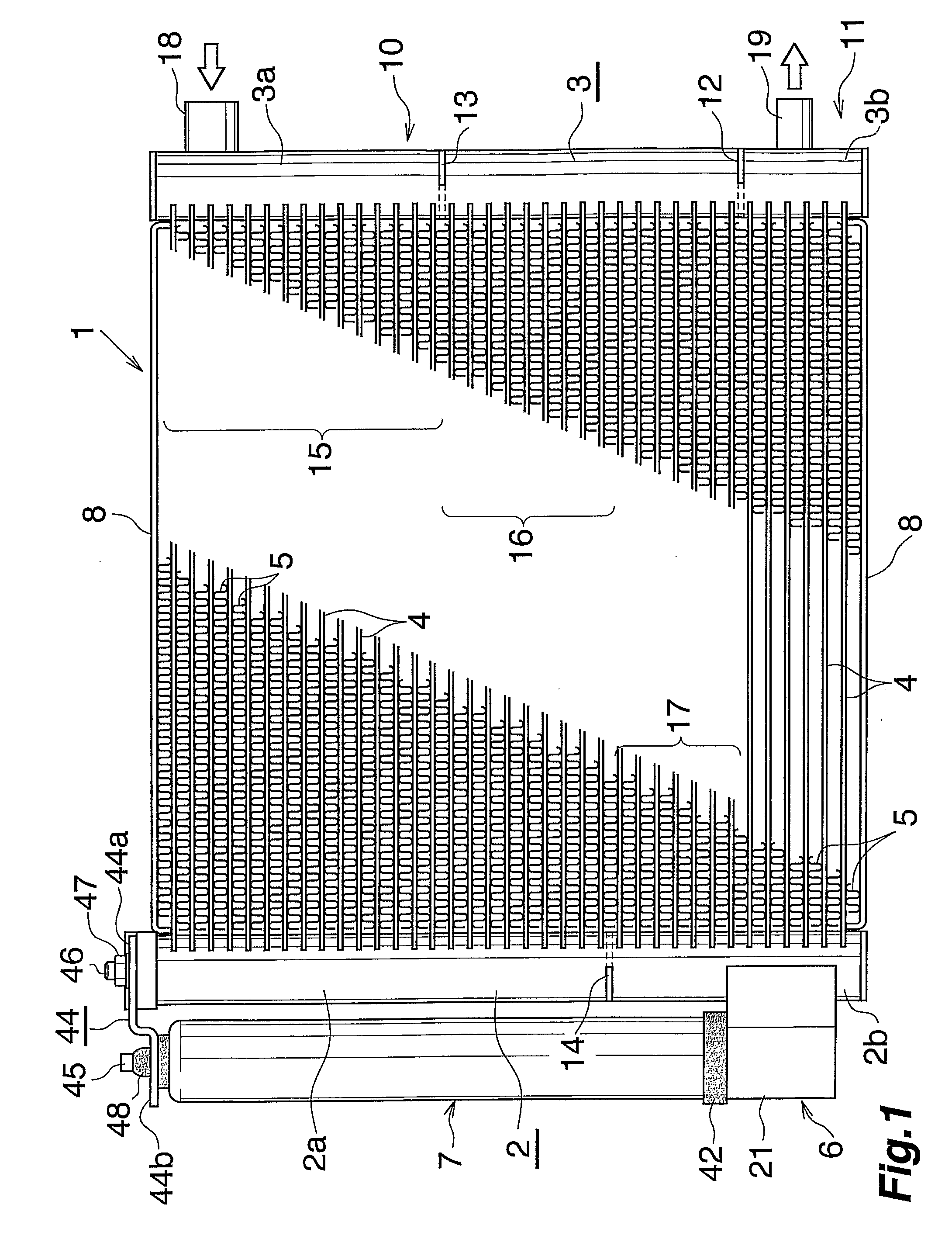

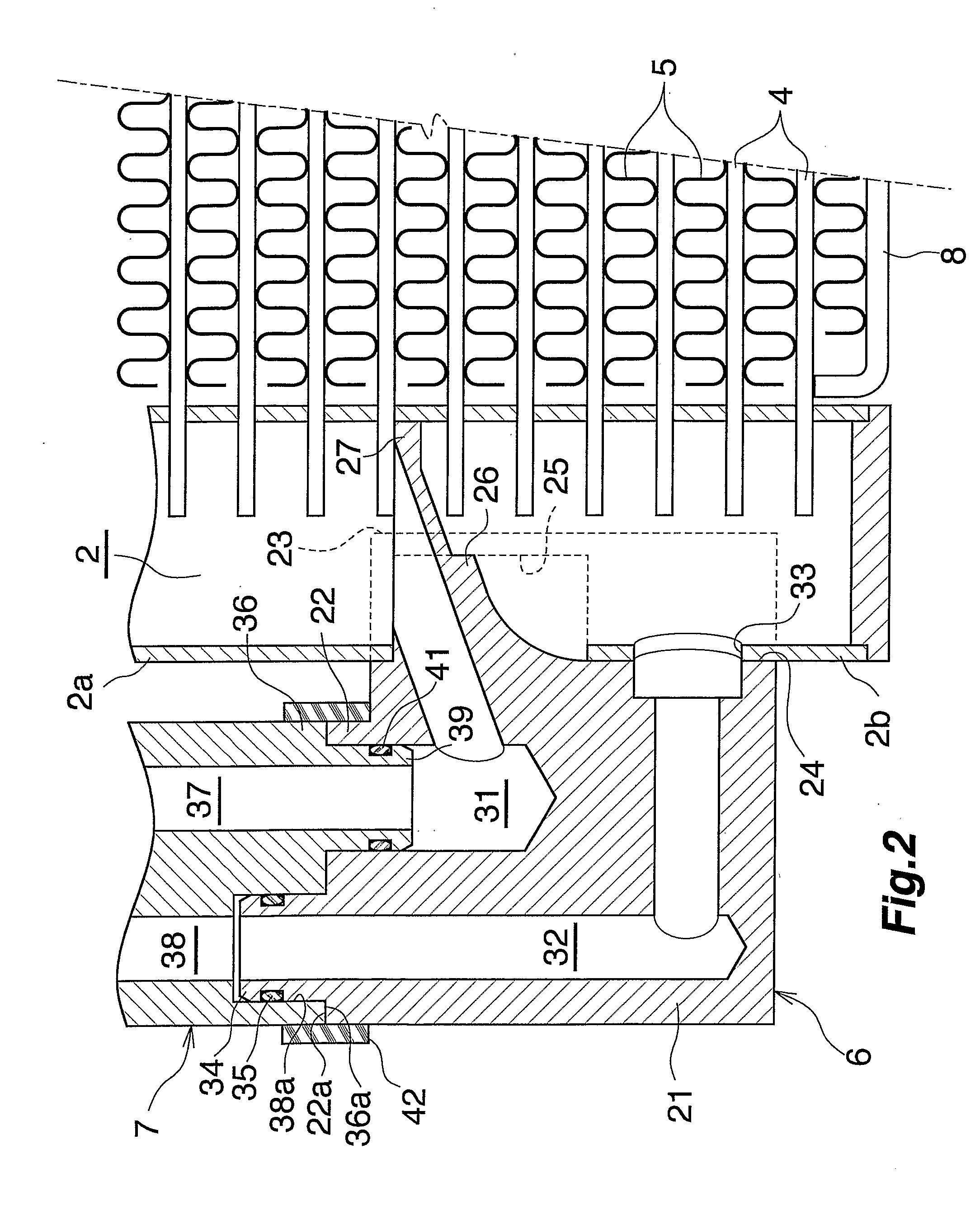

Heat exchanger and refrigerant passage portion connecting structure for refrigeration cycle

ActiveUS20070163760A1Avoid corrosionEasy transferEngine sealsEvaporators/condensersRefrigerationRefrigerant

Fixed to the peripheral wall of a header 2 of a unit-type heat exchanger 1 is a receiver connecting block 6 having channels 31, 32 for causing the interior of the header 2 to communicate with the interior of a liquid receiver 7 therethrough. The block 6 and the liquid receiver 7 have respective fixing portions 32, 36 and respective contact faces 22a, 36a each provided on the fixing portion. The outer peripheral surfaces of the fixing portions 22, 36 have respective contours of the same shape and the same size. The liquid receiver 7 is fixed to the block 6 with the contact faces 22a, 36a of the fixing portions 22, 36 in intimate contact with each other. A tubular seal member 42 having rubber elasticity is liquid-tightly fitted around the fixing portions 22, 36. The seal member 42 has an inner shape smaller than the contours of the outer peripheral surfaces of the fixing portions 22, 36 and is fitted as elastically deformed around the fixing portions 22, 36. Rainwater or the like can be prevented from ingressing into an interstice between the contact faces of the block and the liquid receiver.

Owner:MAHLE INT GMBH

Medical cotton swab machine

InactiveCN104826227AStable structureSimple structureMedical applicatorsSwabsEngineeringMechanical engineering

The invention relates to a medical cotton swab machine. The medical cotton swab machine comprises a machine base. A discharge device is arranged on the machine base and connected with a pressing device A. The pressing device A is connected with a conveying chain which is sequentially connected with a glue beating device, a shaping device, a glue spray device and a conveying device. The shaping device is connected with a smashing device. The medical cotton swab machine has the advantages of being simple in structure, low in running cost, practical, convenient and rapid to use and comprehensive in function.

Owner:崔怀鹤

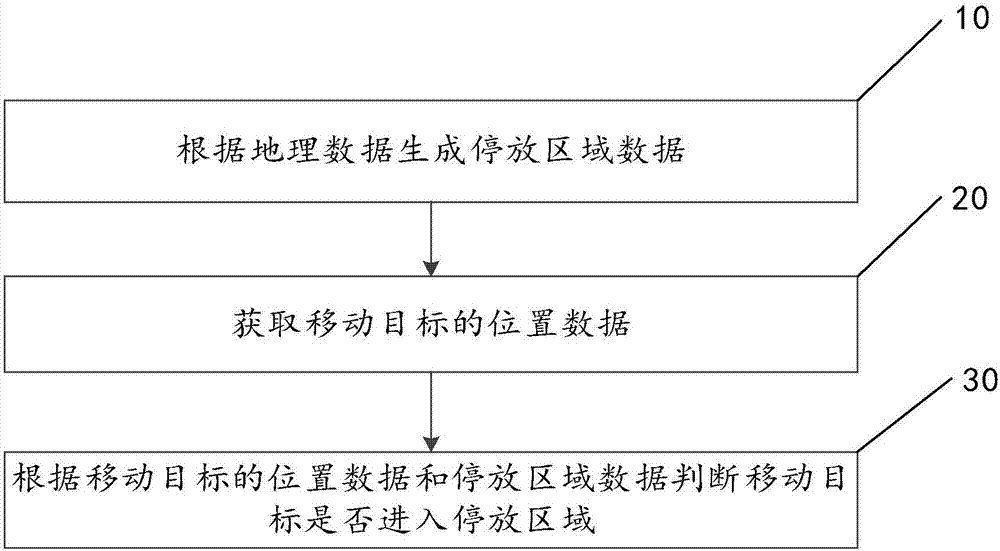

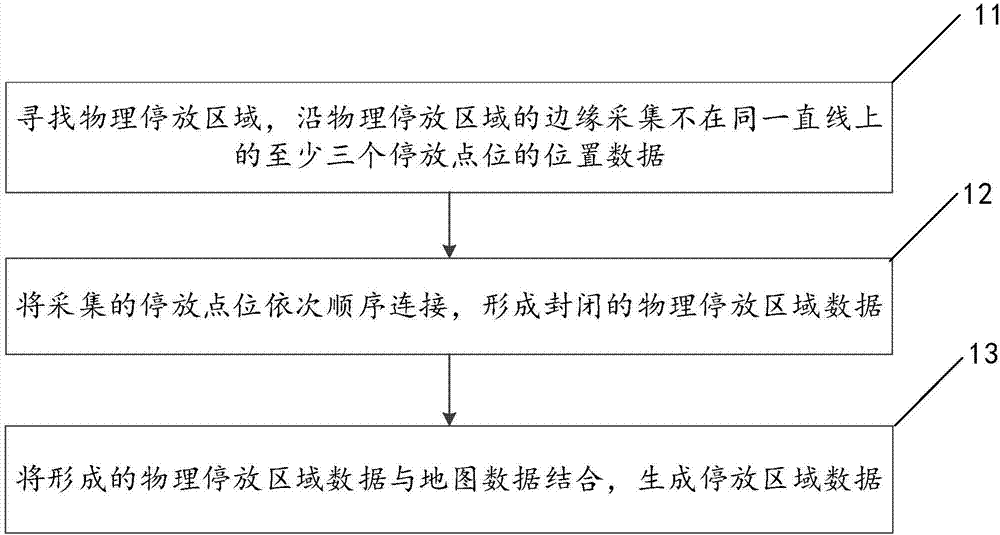

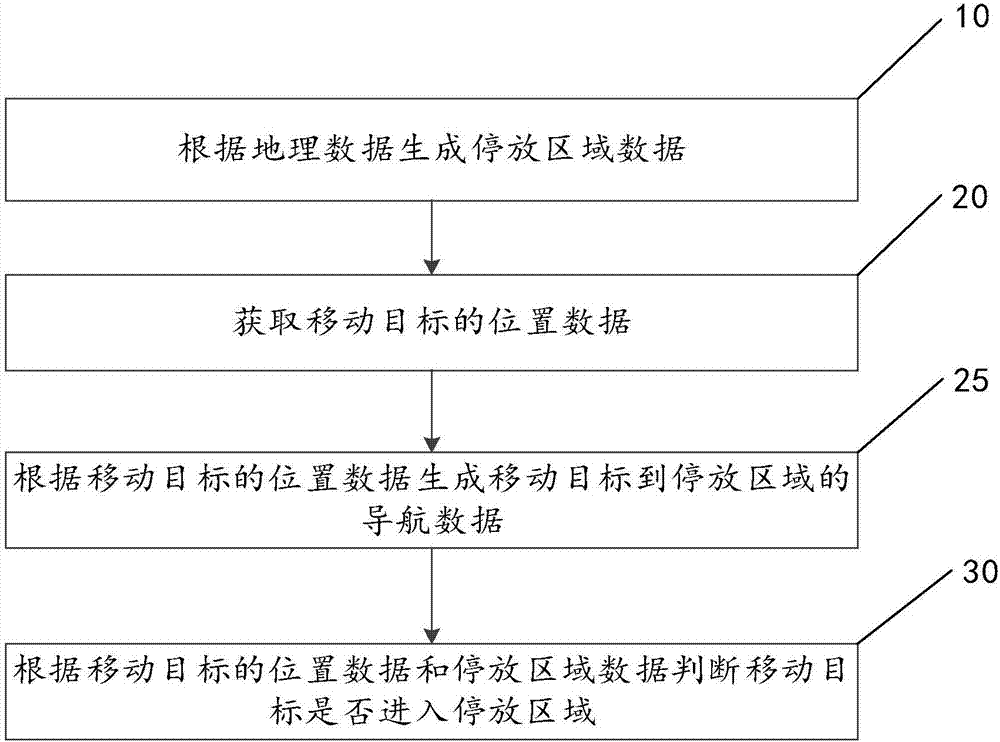

Method and system for setting and applying parking area

InactiveCN107197437AImplement identity virtualizationEvenly placedRoad vehicles traffic controlSubstation equipmentVirtualizationParking space

An embodiment of the invention provides a method and a system for setting and applying a parking area. The method comprises the steps of: generating parking area data based on geographic data; acquiring position data of a moving object; and judging whether the moving target enters the parked area according to the position data of the moving object and the parking area data. According to the method and the system for setting and applying the parking area, the parking area data is generated based on the geographic data, the position data of the moving object is acquired, and whether the moving target enters the parked area according to the position data of the moving object and the parking area data is detected and judged, thereby realizing the identifier virtualization of the parking area, and enabling the moving target to be placed to the identifier-virtualized parking area successfully.

Owner:上海共佰克智能科技有限公司

Panel transferring and overturning mechanism

InactiveCN109625955ASmooth transmissionImprove efficiencyConveyorsConveyor partsMechanical equipmentEngineering

The invention discloses a panel transferring and overturning mechanism, and belongs to the field of plate conveying and machining auxiliary mechanical equipment. A lifting bearing plate is horizontally arranged on one side of a material bearing support, an adsorption connecting plate is horizontally arranged on the lower side of a horizontal movement connecting plate, a plurality of plate moving suckers are uniformly arranged on the lower side of the adsorption connecting plate, and a transferring bearing plate is horizontally arranged on the upper side of a fixing base, a overturning connecting plate is arranged on the upper side of the transferring bearing plate, and a material bearing connecting plate is arranged on one side of the overturning connecting plate; and a plurality of overturning suckers are arranged on the upper side of the material bearing connecting plate, a material guide support is vertically and fixedly arranged on the upper side of a material guide base, the upperside of the bearing plate support at the output end of a material bearing air cylinder is sequentially and rotationally connected with a plurality of bearing plate rotating rollers, and the lower side of a guide support at the output end of a guide air cylinder is sequentially and rotationally connected with a plurality of guide rotating rollers. According to the mechanism, the structural designis reasonable, the panels can be transferred and fed one by one, the panels can be stably and accurately overturned, the material loading and conveying automation degree of the panels is improved, andthe requirement for machining and using is met.

Owner:桐乡市川泰纺织科技有限公司

Automatically-controlled medical cotton swab machine

InactiveCN104887395AEvenly placedSimple structureMedical devicesMedical applicatorsAutomatic controlCompression device

The invention relates to an automatically-controlled medical cotton swab machine comprising a base. A discharge device is arranged on the base and is connected with a compression device A. The compression device A is connected with a conveying chain. A gluing device, a shaping device, a glue spraying device and a conveying device are sequentially connected to the conveying chain from right to left. The shaping device is connected with a smashing device. The automatically-controlled medical cotton swab machine has the advantages of simple structure, low operation cost, practicability, convenience, rapidness, automatic control and complete function.

Owner:崔怀鹤

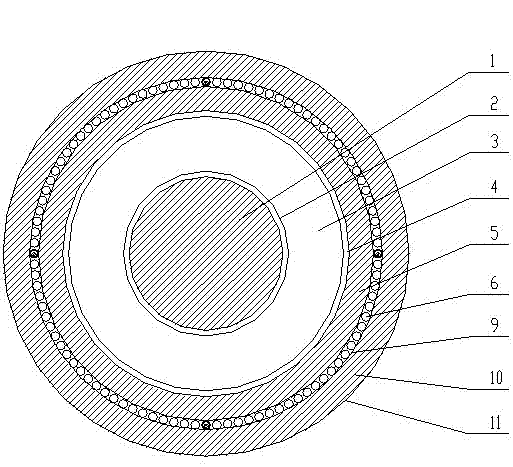

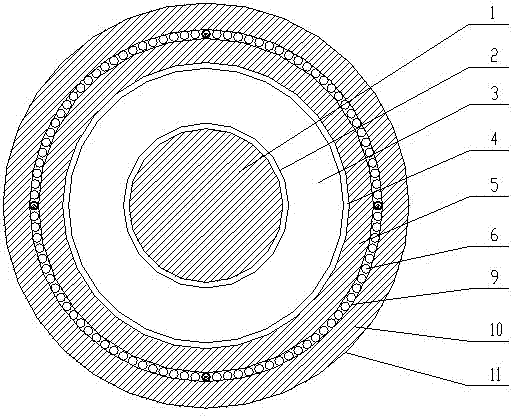

Intelligent ultrahigh-tension environment friendly crosslinking cable for power grid and preparation method thereof

InactiveCN102354563AGood environmental performanceEvenly placedPower cables with screens/conductive layersCable/conductor manufactureSteel tubeCopper tape

The invention discloses an intelligent ultrahigh-tension environment friendly crosslinking cable for a power grid and a preparation method thereof. The cable has a structure as follows: a semiconductive conductor shielding layer, an insulating layer and a semiconductive insulation shielding layer are arranged outside a conductor in sequence; a water-blocking and buffering isolating layer is lapped on the conductor; an armor layer is formed by a thick copper wire and multimode fibres with stainless steel tubes, which are uniformly placed in the thick copper wire; and an outer sheath and a graphite layer are arranged outside the armor layer in sequence. The intelligent ultrahigh-tension environment friendly crosslinking cable is armored by using the thick copper wire and overlapped, lapped and tightened reversely by using a soft copper strip so as to simultaneously play roles in metal shielding and metal armoring and bear high short-circuit current. The multimode fibres with the stainless steel tubes are uniformly placed in the armor layer of the thick copper wire, and the stainless steel tubes can play a favorable protection role for the fibres. The multimode fibres with the stainless steel tubes are uniformly placed so as to cause little influence to electric field distribution. In addition, a plastic sleeve of the cable provided by the invention, the outer sheath of the cable, and the like are made of halogen-free low-smoke material uniformly, therefore, the cable has favorable environment friendliness property.

Owner:YUANCHENG CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com