Anti-friction bearing

A rolling bearing and rolling element technology, applied in rolling contact bearings, bearings, bearings in rotating motion, etc., can solve problems such as damage, unfavorable bending of guiding and retaining elements, and achieve the effect of simple and safe installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

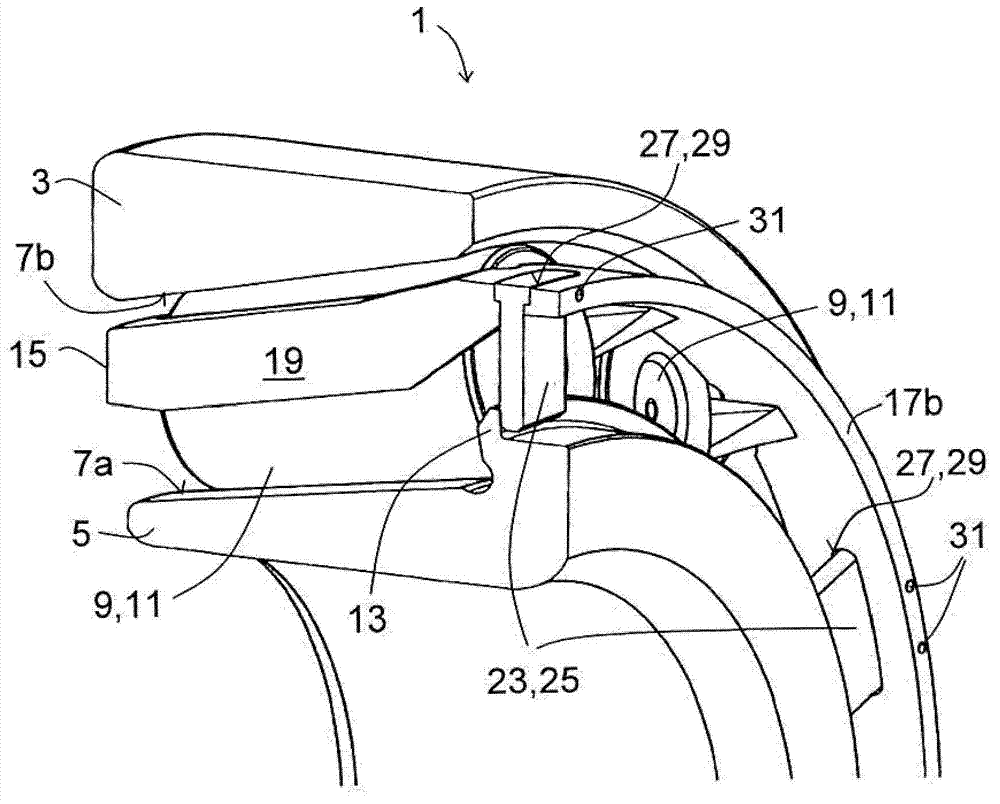

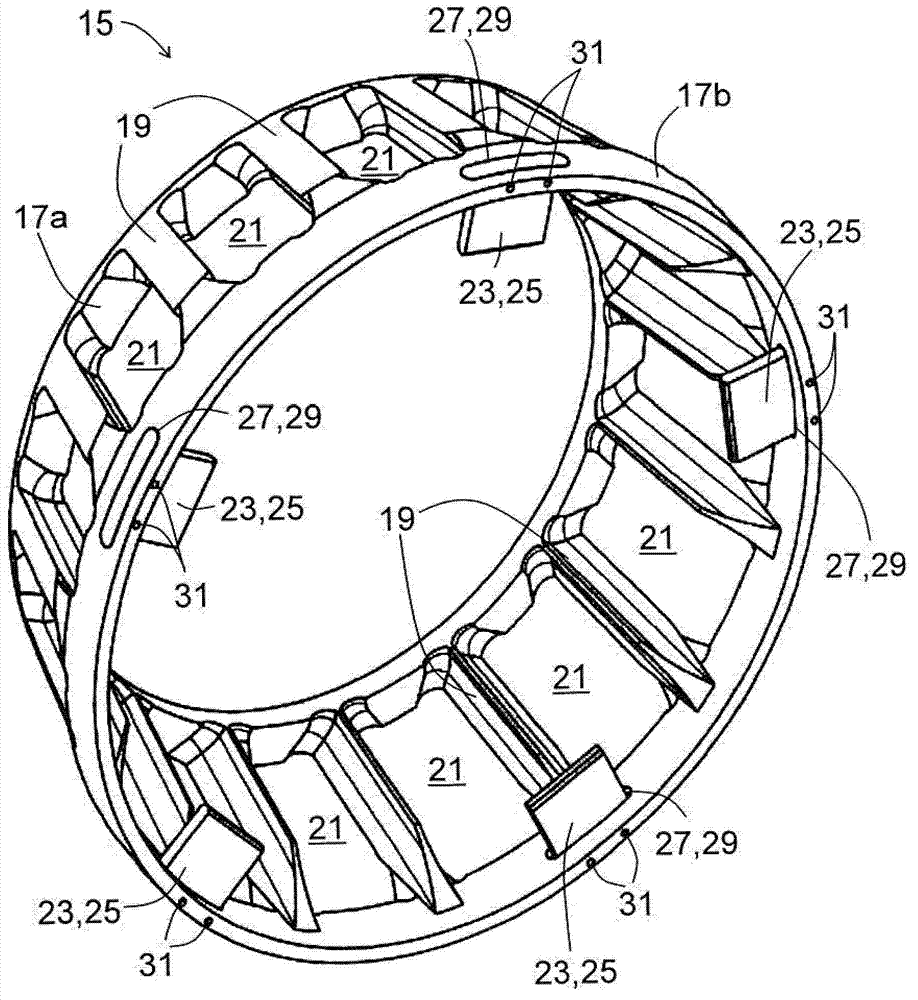

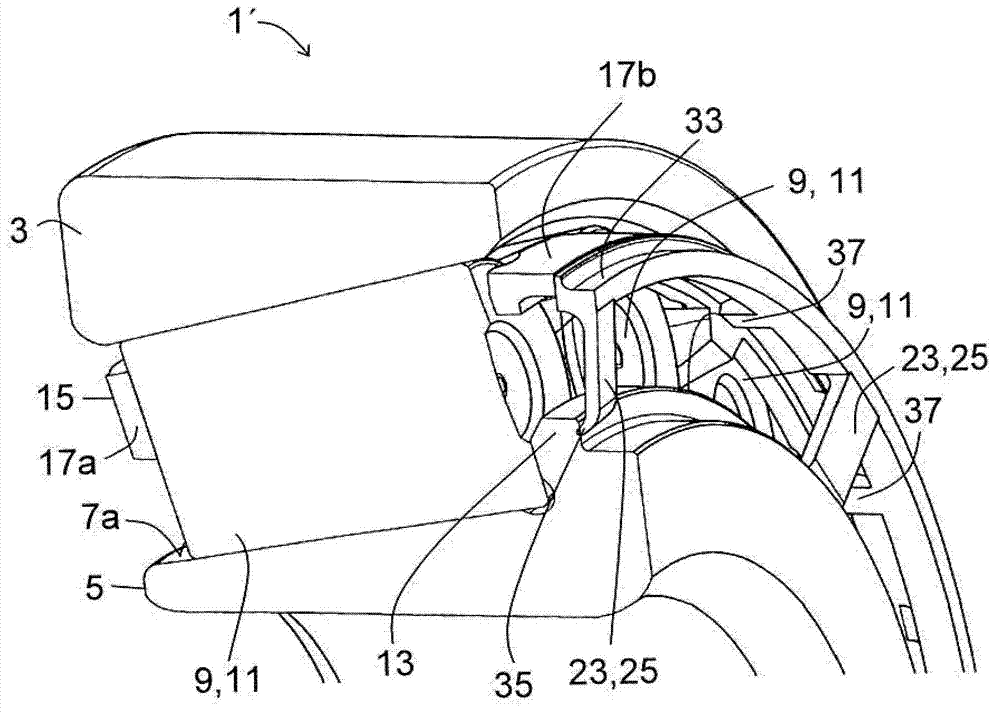

[0026] figure 1 Accordingly, a rolling bearing 1 is shown, which is designed here as a tapered roller bearing. The rolling bearing 1 comprises a bearing outer ring 3 and a bearing inner ring 5 into which several raceways 7a, 7b are introduced. A plurality of conical rolling elements 9 are arranged between the raceway 7a of the bearing inner ring 5 and the raceway 7b of the bearing outer ring 3, figure 1 You can see two of them.

[0027] The tapered rollers 11 roll on the raceways 7a, 7b of the bearing rings 3, 5 . In order to guide the rolling of the tapered roller 11 on the raceway 7a, 7b, on the side of the raceway 7a of the bearing inner ring 5 (in figure 1There is a very large rib 13 on the structure on the right side in the middle. The rib 13 extends from the bearing inner ring 5 radially outwards towards the bearing outer ring 3 . The bearing outer ring 3 is designed without ribs in this exemplary embodiment. In addition, the bearing inner ring 5 has no ribs on its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com