Method for preparing fracturing fluid thickener with self-destruction effect

A fracturing fluid thickener and self-destruction technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of unsatisfactory use effect of gel fracturing fluid, reservoir damage, etc., to overcome the damage The effects of poor time control, reduced matrix damage, strong suspension and transport ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

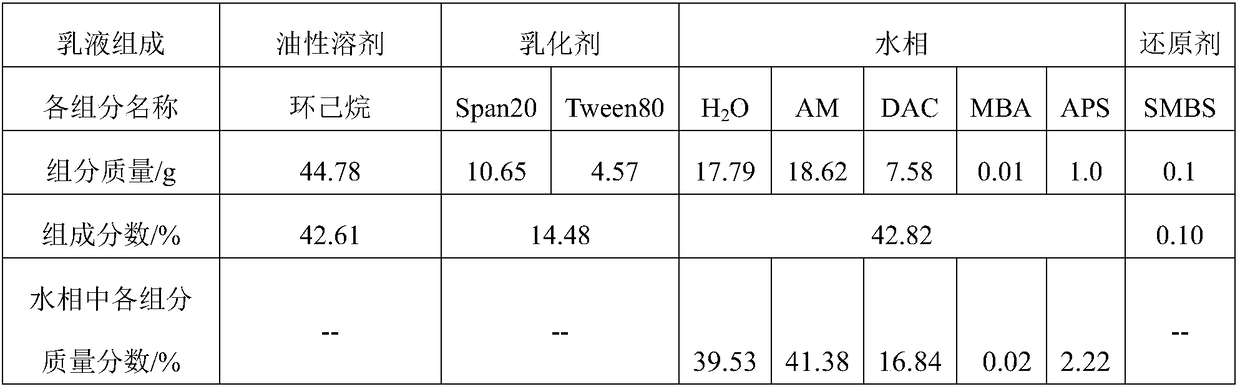

Embodiment 1

[0027] First prepare the sodium sulfite aqueous solution whose mass concentration is 10wt%, and then prepare the ammonium persulfate solution whose mass concentration is 20wt%. Weigh 44.78g of cyclohexane, add emulsifier prepared by 10.65g of Span20 and 4.57g of Tween80, heat to 30°C and shake to form a uniform solution, which is the oil phase, and transfer it to a constant temperature water bath at 20°C In a four-neck flask with a stirring bar, stir and pass N 2 Deoxygenation; then 18.62g of acrylamide (AM), 7.58g of acryloyloxyethyltrimethylammonium chloride (DAC), 0.01g of methylenebisacrylamide (MBA), and 13.79g of water were prepared into an aqueous monomer solution, Take 5g of 20wt% ammonium persulfate (APS) solution and add it into the aqueous monomer solution, and shake until a uniform and transparent solution is formed, which is the aqueous monomer phase. Then, quickly add the aqueous monomer phase into the four-necked flask equipped with the oil phase, and stir even...

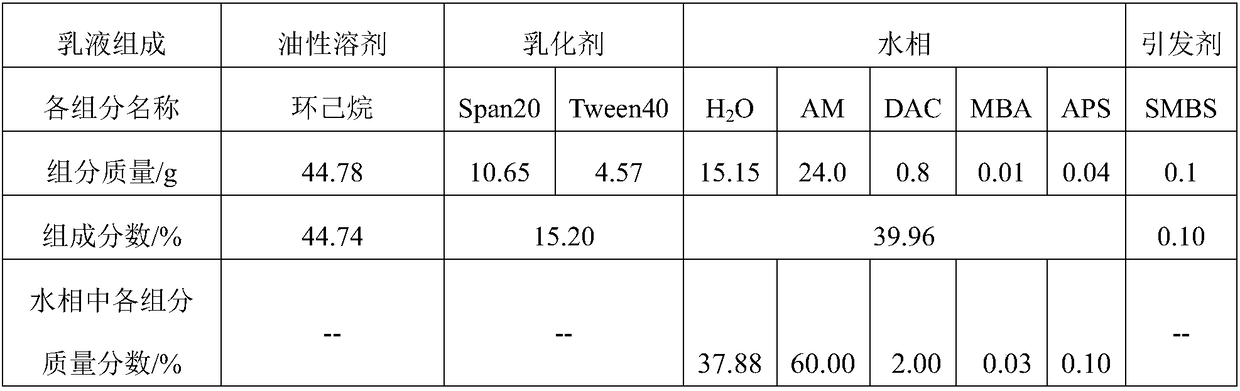

Embodiment 2

[0032] First prepare the sodium sulfite aqueous solution whose mass concentration is 10wt%, and then prepare the ammonium persulfate solution whose mass concentration is 20wt%. Weigh 44.78g of cyclohexane, then add emulsifier prepared by 10.65g of Span20 and 4.57g of Tween40, heat to 30°C and shake to form a homogeneous solution, which is the oil phase, and transfer it to a 10°C constant temperature water bath In a four-neck flask with a stirring bar, stir and pass N 2Deoxygenation; then 24.0g of acrylamide (AM), 0.8g of acryloyloxyethyltrimethylammonium chloride (DAC), 0.01g of methylenebisacrylamide (MBA), and 14.99g of water were prepared into an aqueous monomer solution, Take 0.2g of 20wt% ammonium persulfate (APS) solution and add it into the monomer aqueous solution, shake until the homogeneous transparent solution is the monomer aqueous phase. Then, quickly add the aqueous monomer phase into the four-necked flask equipped with the oil phase, and stir evenly at 400 r / mi...

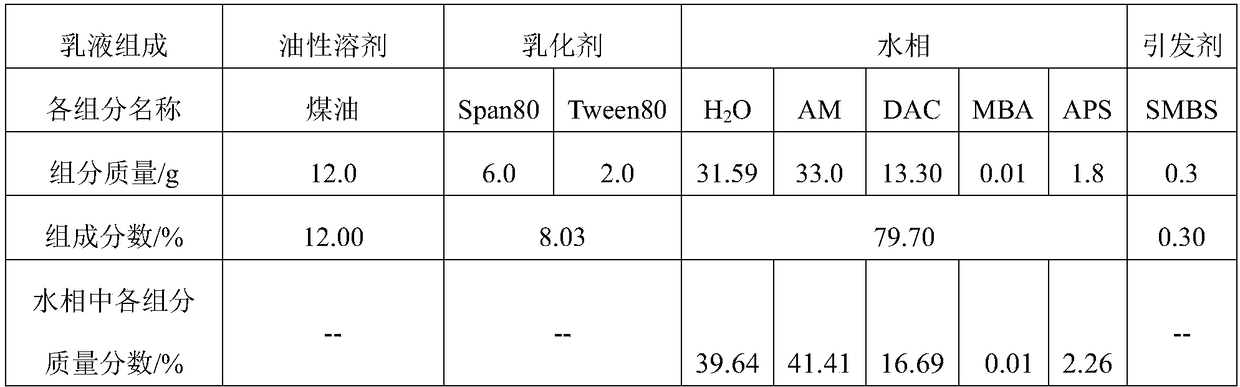

Embodiment 3

[0037] First prepare the sodium sulfite aqueous solution whose mass concentration is 10wt%, and then prepare the ammonium persulfate solution whose mass concentration is 20wt%. Weigh 12g of kerosene, add the emulsifier prepared by 6g Span80 and 2g Tween80, heat to 30°C and shake to form a uniform solution, which is the oil phase, and transfer it to a 20°C constant temperature water bath with a stirring bar. In a four-neck flask, stir and pass N 2 Deoxygenation; then 33.00g of acrylamide (AM), 13.30g of acryloyloxyethyltrimethylammonium chloride (DAC), 0.01g of methylenebisacrylamide (MBA), and 24.39g of water were prepared into an aqueous monomer solution, Take 9g of 20wt% ammonium persulfate (APS) solution and add it to the monomer aqueous solution, shake until the homogeneous transparent solution is the monomer aqueous phase. Then, quickly add the aqueous monomer phase into the four-necked flask equipped with the oil phase, and stir evenly at 500 r / min to obtain an inverse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com