Medical cotton swab machine

A technology of cotton swab machine and machine base, which is applied in the direction of tampons, absorbent pads, and medical equipment, etc., which can solve the problems of poor hygiene conditions of cotton swabs, inability to achieve appropriate and timely supply, and easy cross-infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

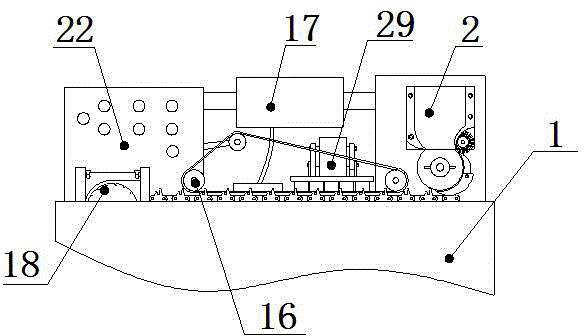

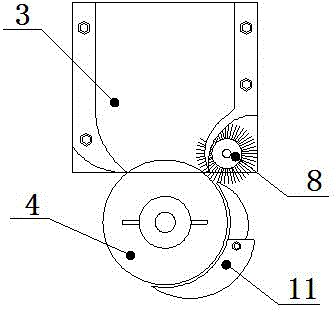

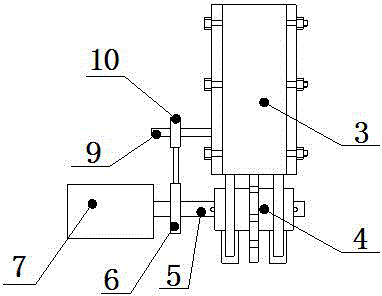

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 with Figure 13Shown, a kind of medical cotton swab machine, it comprises machine base 1, and the upper side of described machine base 1 right part is provided with unloading device 2, and described unloading device 2 is provided with hopper 3, and described material The bottom of the box 3 is connected with a blanking row wheel 4, the blanking row wheel 4 is connected with an output shaft 5, the outer wall of the output shaft 5 is sleeved with a chain wheel A6, and the input end of the output shaft 5 is connected with Motor A7, the upper right part of the blanking row wheel 4 is connected with the brush body 8 matched with the blanking row wheel 4, the brush body 8 is connected with the material box 3, and the brush body 8 is connected with the transmission shaft A9. The outer wall of the drive shaft A9 is...

Embodiment 2

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 with Figure 13 Shown, a kind of medical cotton swab machine, it comprises machine base 1, and the upper side of described machine base 1 right part is provided with unloading device 2, and described unloading device 2 is provided with hopper 3, and described material The bottom of the box 3 is connected with a blanking row wheel 4, the blanking row wheel 4 is connected with an output shaft 5, the outer wall of the output shaft 5 is sleeved with a chain wheel A6, and the input end of the output shaft 5 is connected with Motor A7, the upper right part of the blanking row wheel 4 is connected with the brush body 8 matched with the blanking row wheel 4, the brush body 8 is connected with the material box 3, and the brush body 8 is connected with the transmission shaft A9. The outer wall of the drive shaft A9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com