Automatically lockable cable rewinding structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

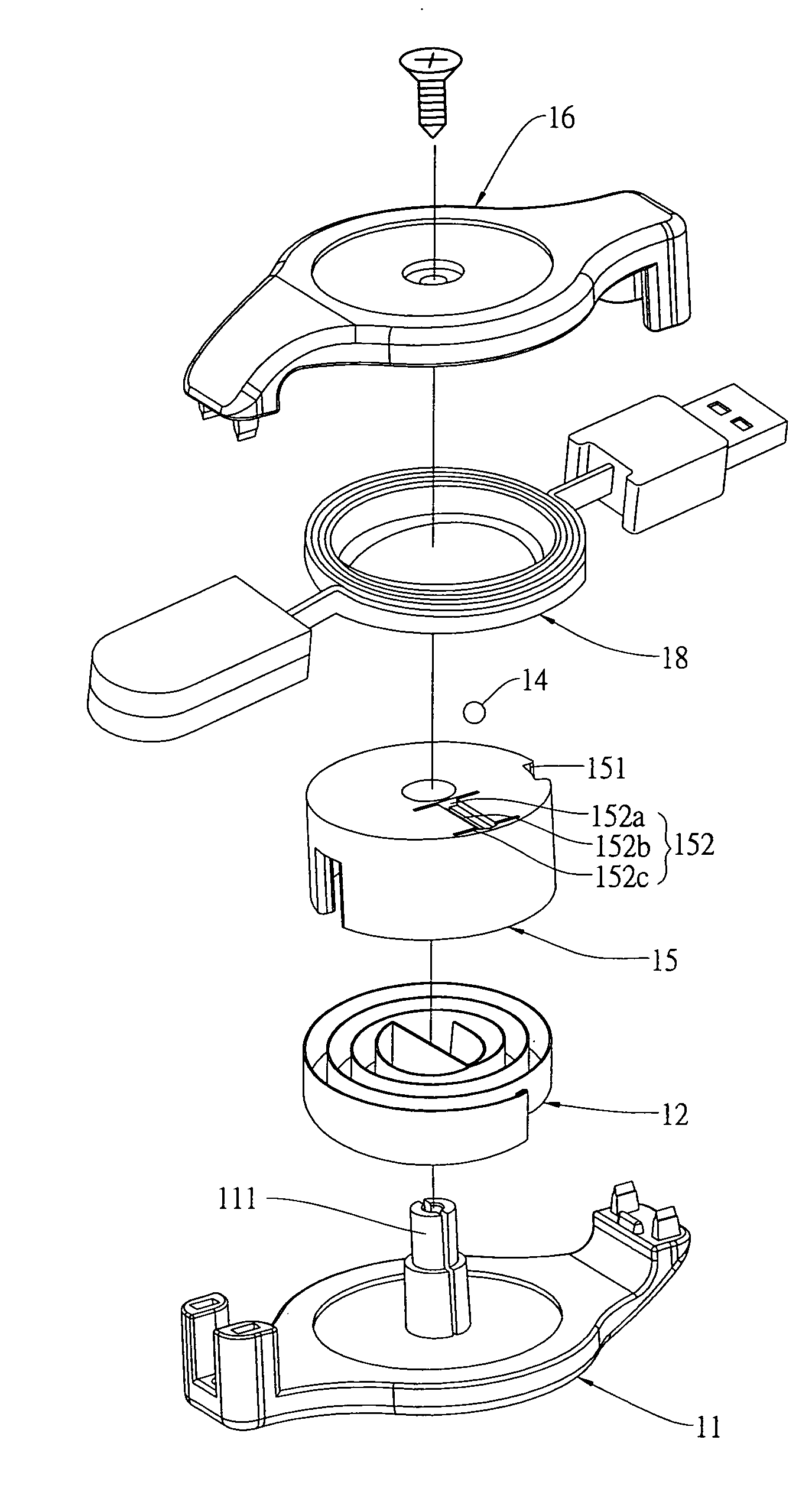

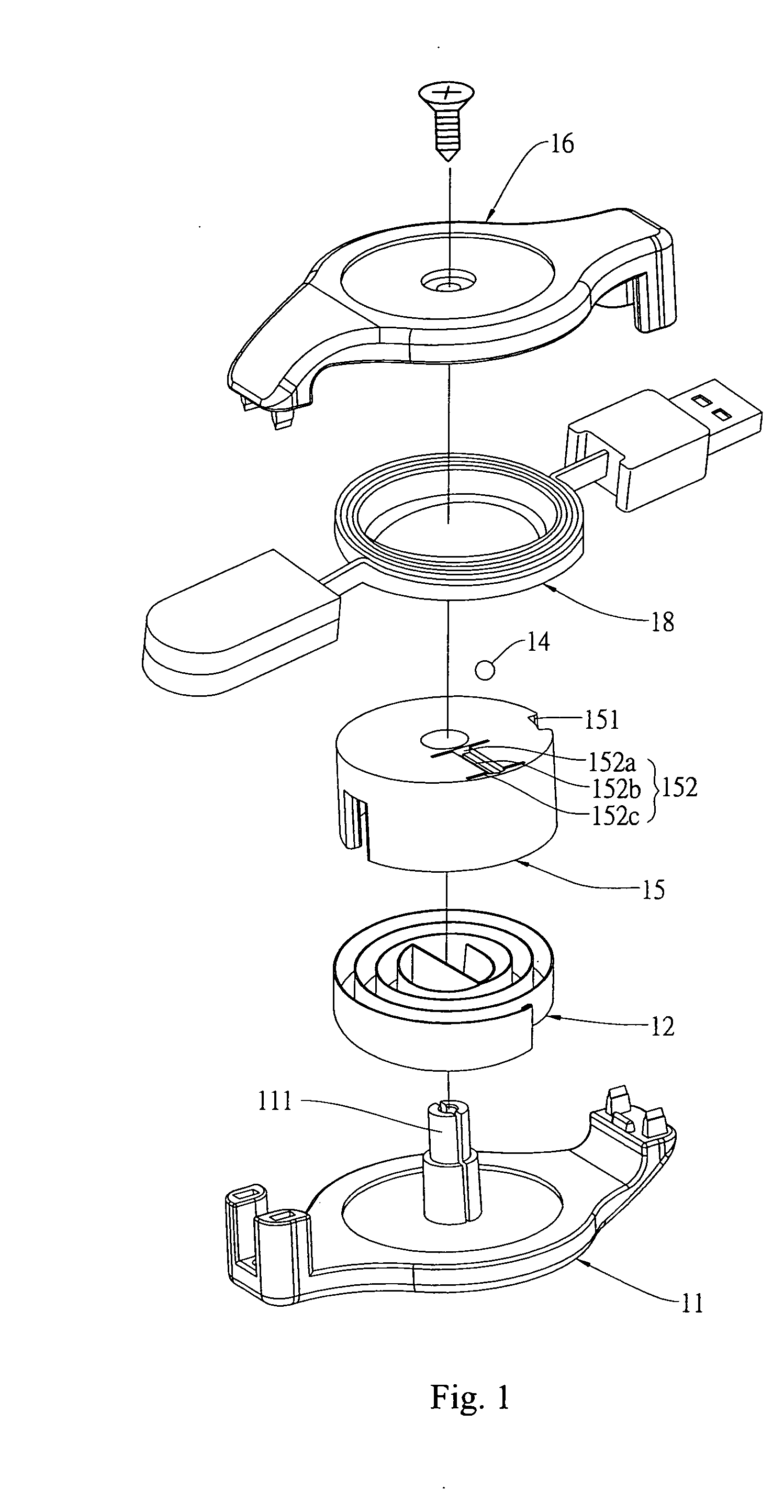

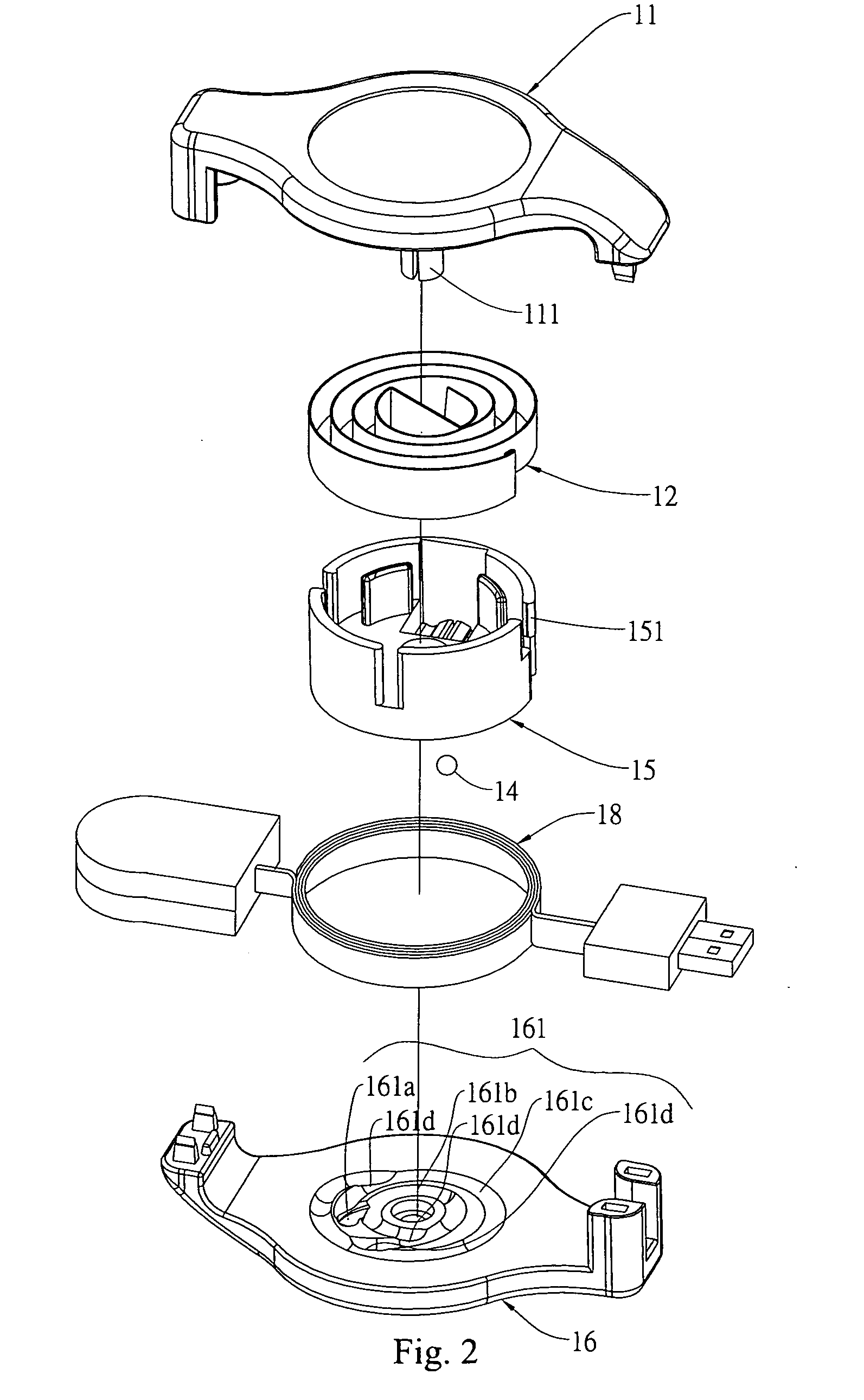

[0038]With the above arrangements, the automatically lockable cable rewinding structure according to the present invention is able to successfully lock or rewind the cable 18 through the following operating procedures.

[0039](a) Pull Procedure 1:[0040]Please refer to FIGS. 1, 2, and 4A at the same time.

[0041]It is noted the cable 18 can be pulled out of the assembled upper and lower cases 11, 16 in two opposite directions. When the cable 18 is pulled out in two opposite directions, the working member 15 is caused to turn counterclockwise, and the rolling element 14 is caused to move in the inner path section 161b.

[0042](b) Pull Procedure 2:[0043]Please refer to FIGS. 1, 2, and 4B at the same time. When the cable 18 is kept pulling out to turn the working member 15 counterclockwise, the rolling element 14 would move from the inner path section 161b through the transition sections 161d into the outer path section 161c. At this point, the limiting recess 152 at the bottom of the workin...

third embodiment

[0062]With the above arrangements, the automatically lockable cable rewinding structure according to the present invention is able to successfully lock or rewind the cable 38 through the following operating procedures.

[0063](a) Pull Procedure 1:[0064]Please refer to FIGS. 7, 8, and 10A at the same time. It is noted the cable 38 can be pulled out of the assembled upper and lower cases 31, 36 in only one direction. When the cable 38 is pulled out at an end thereof, the working member 35 is caused to turn counterclockwise, and the rolling element 34 is caused to move in the inner path section 352b.

[0065](b) Pull Procedure 2:[0066]Please refer to FIGS. 7, 8, and 10B at the same time. When the cable 38 is kept pulling out in the same direction to turn the working member 35 counterclockwise, the rolling element 34 would move from the inner path section 352b through the transition sections 352d into the outer path section 352c. At this point, the limiting recess 362 at the bottom of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com