Maggot material separation multi-dimensional vibrating screen with material feeding and discharging device

A technology of feeding and discharging, vibrating screen, applied in the direction of solid separation, filter screen, grille, etc., can solve the problem of lack of separation technology of maggot manure and fly maggot, and no rapid development, so as to improve the screening efficiency and ensure the stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

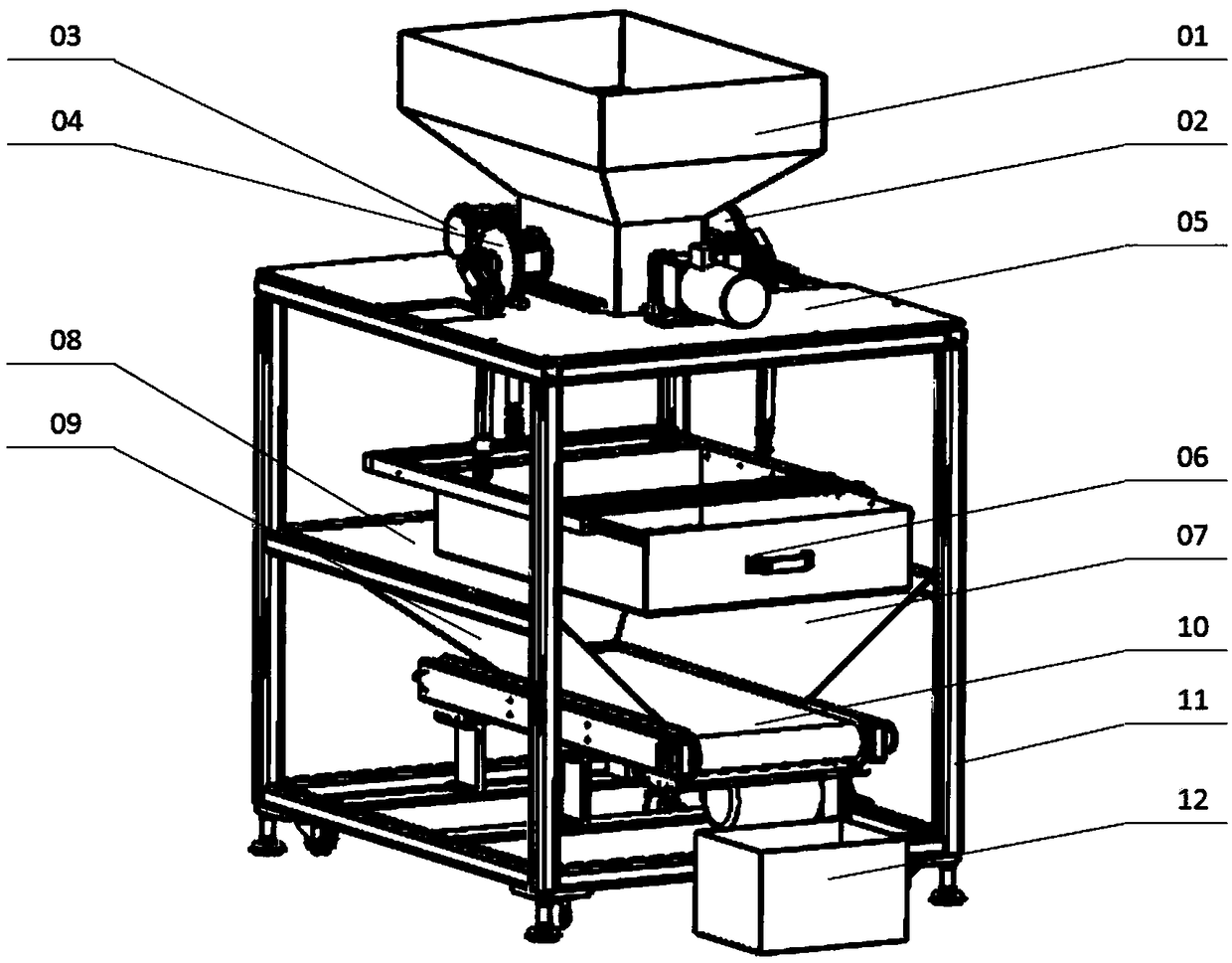

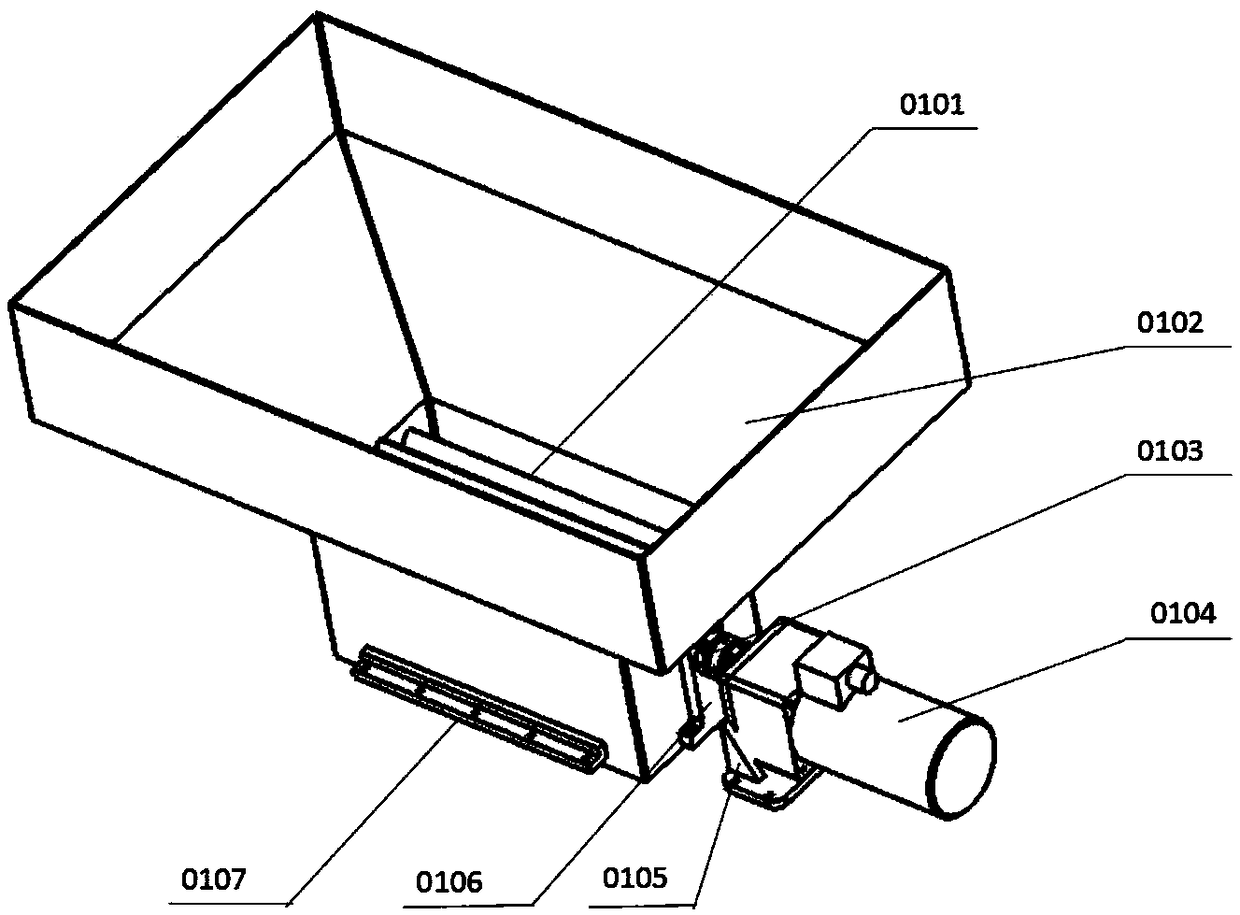

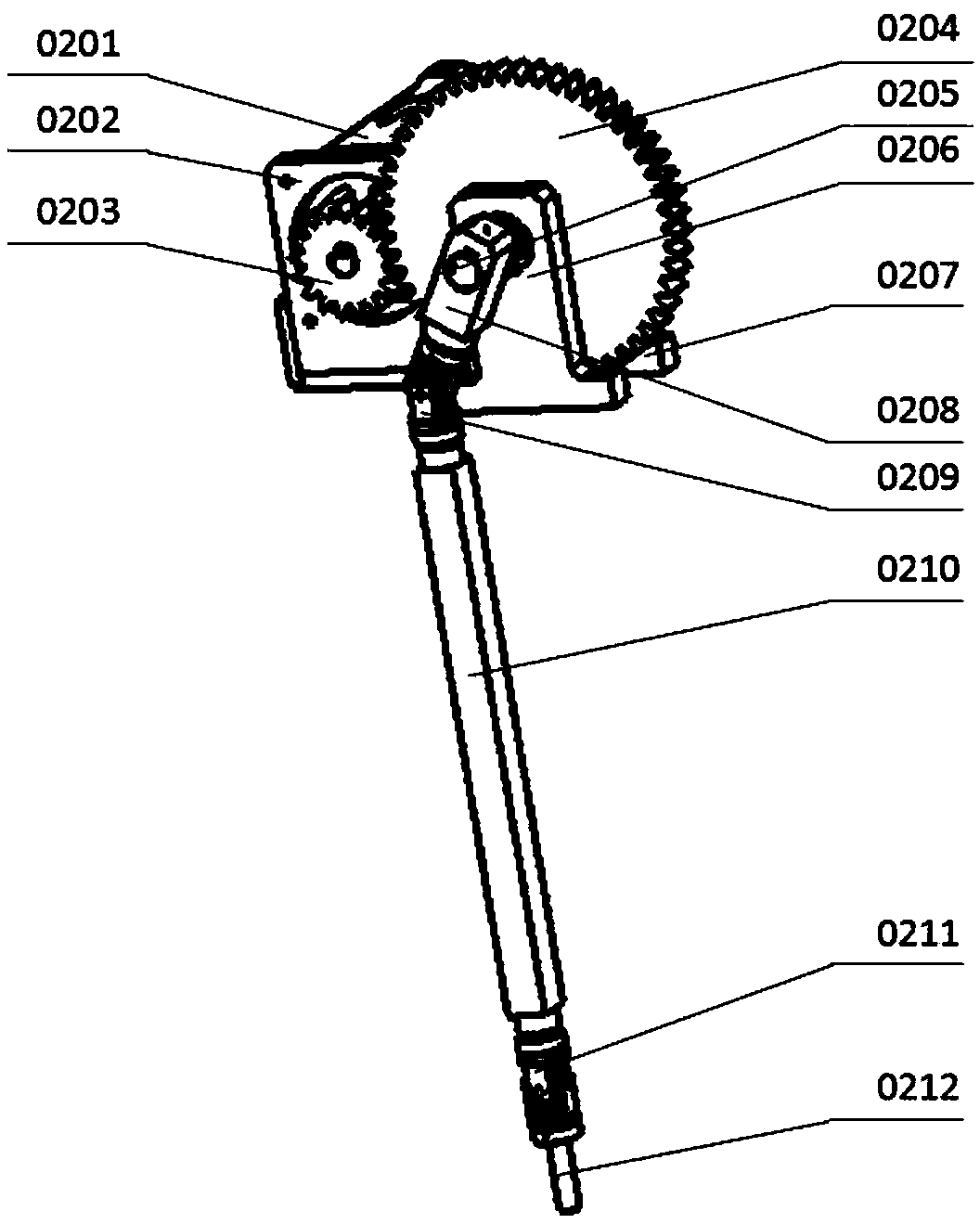

[0043] combined with figure 1 Shown is a maggot material separation multidimensional vibrating screen with a feeding and discharging device according to the present invention. The maggot material separating multidimensional vibrating screen with a feeding and discharging device includes a storage bin assembly 01, a first branch chain 02, a second The second branch chain 03, the third branch chain 04, the vibrating screen plate 05, the screen frame assembly 06, the first baffle 07, the second baffle 08, the third baffle 09, the belt conveyor assembly 10, the frame 11 and the connection Material box 12. The storage bin assembly 01 is fixed to the center of the vibrating screen plate 05 by screws; the first branch chain 02, the second branch chain 03 and the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com