Patents

Literature

116results about How to "Realize feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printing antenna with baseplate integrated waveguide feeder

ActiveCN101075702ASealing is simple, convenient and economicalTo achieve the purpose of sealingRadiating elements structural formsRadarEngineering

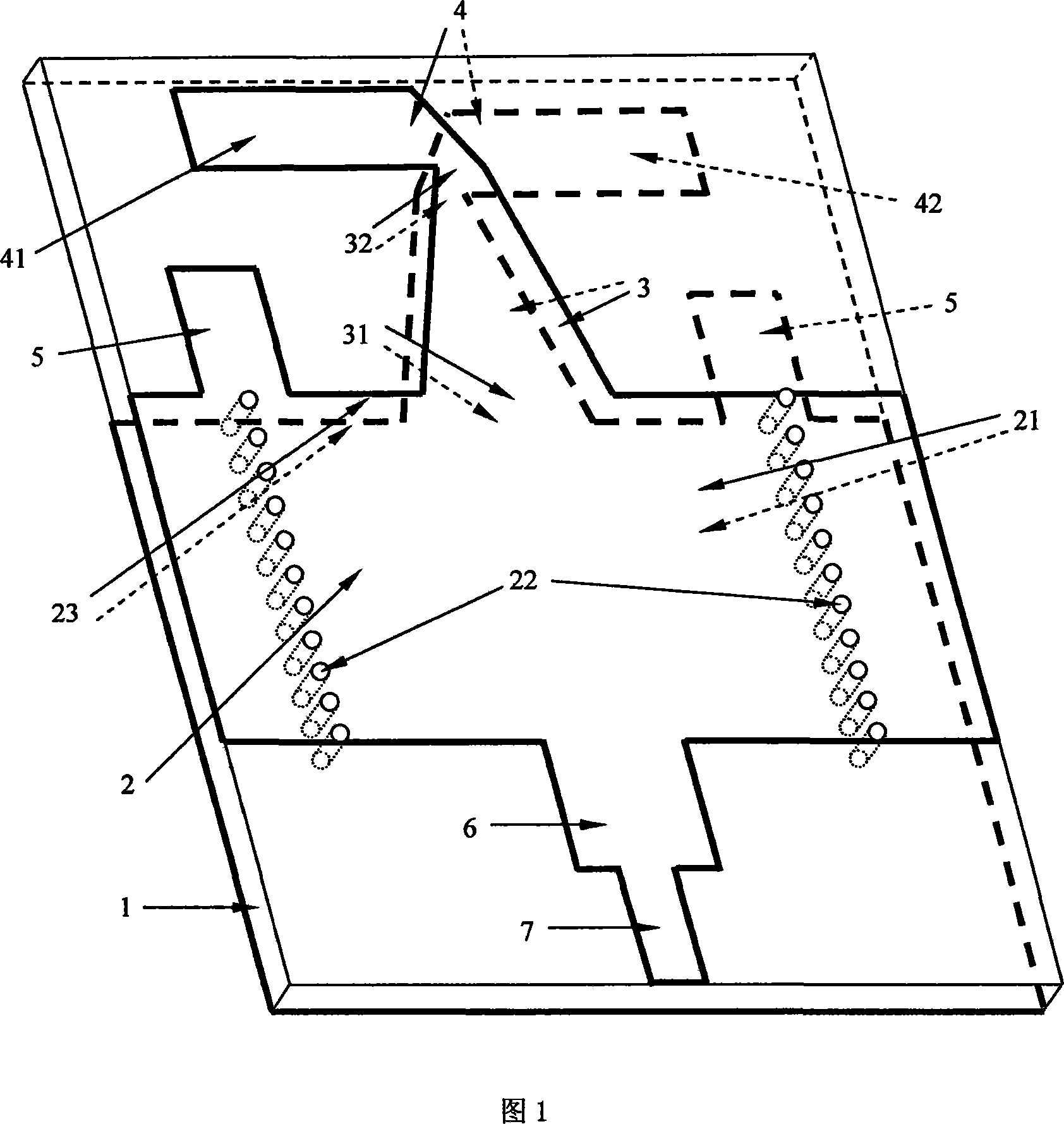

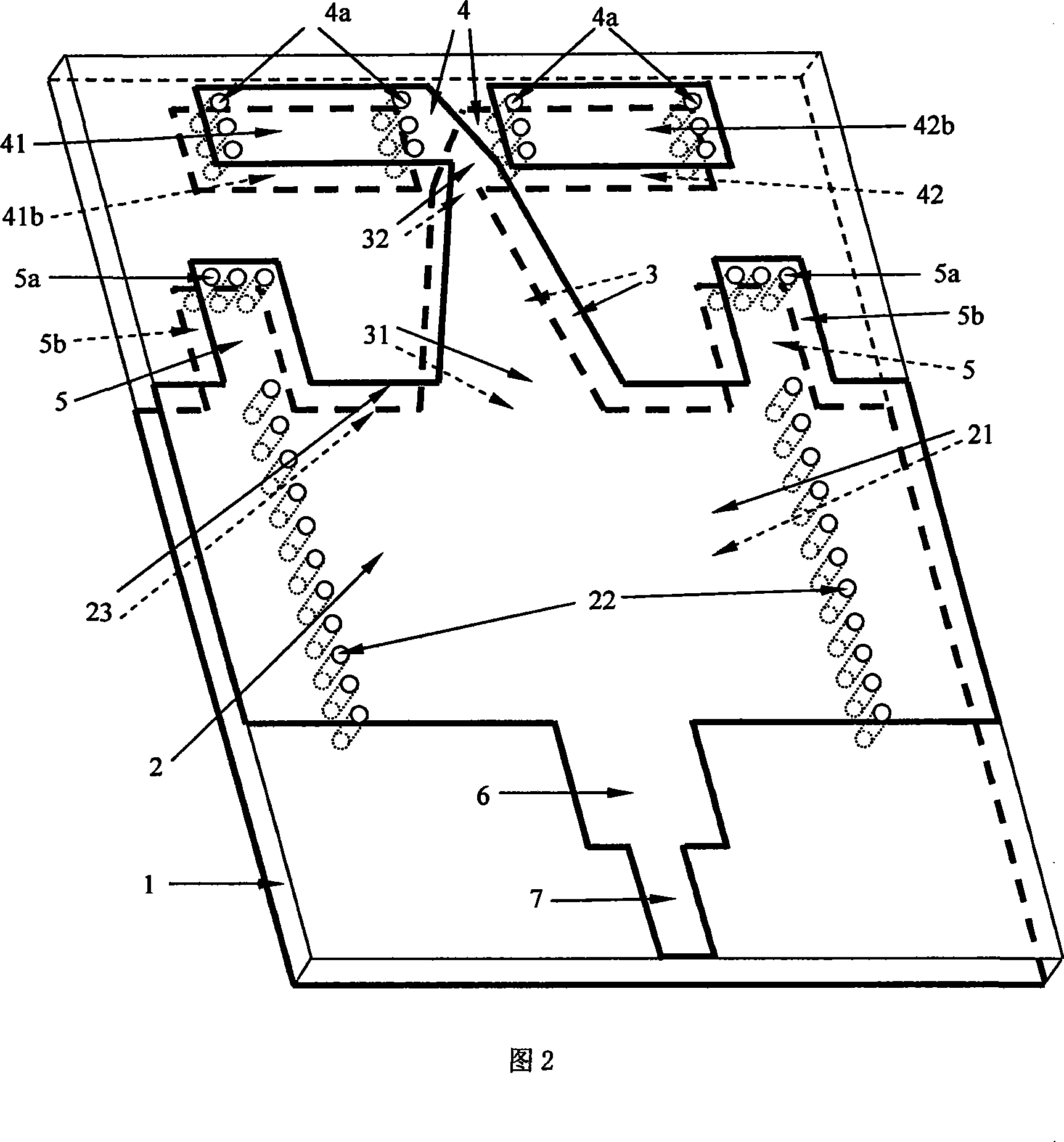

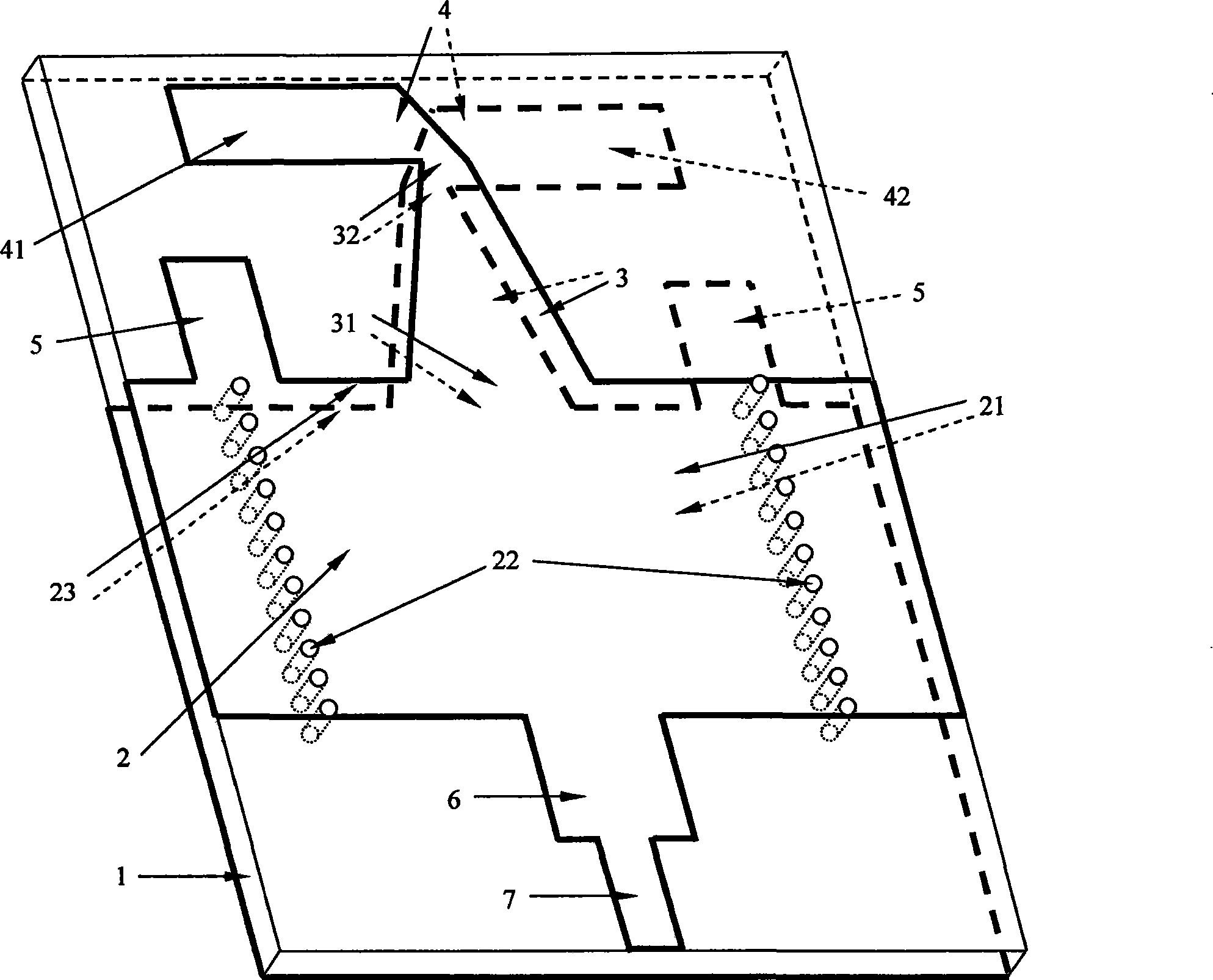

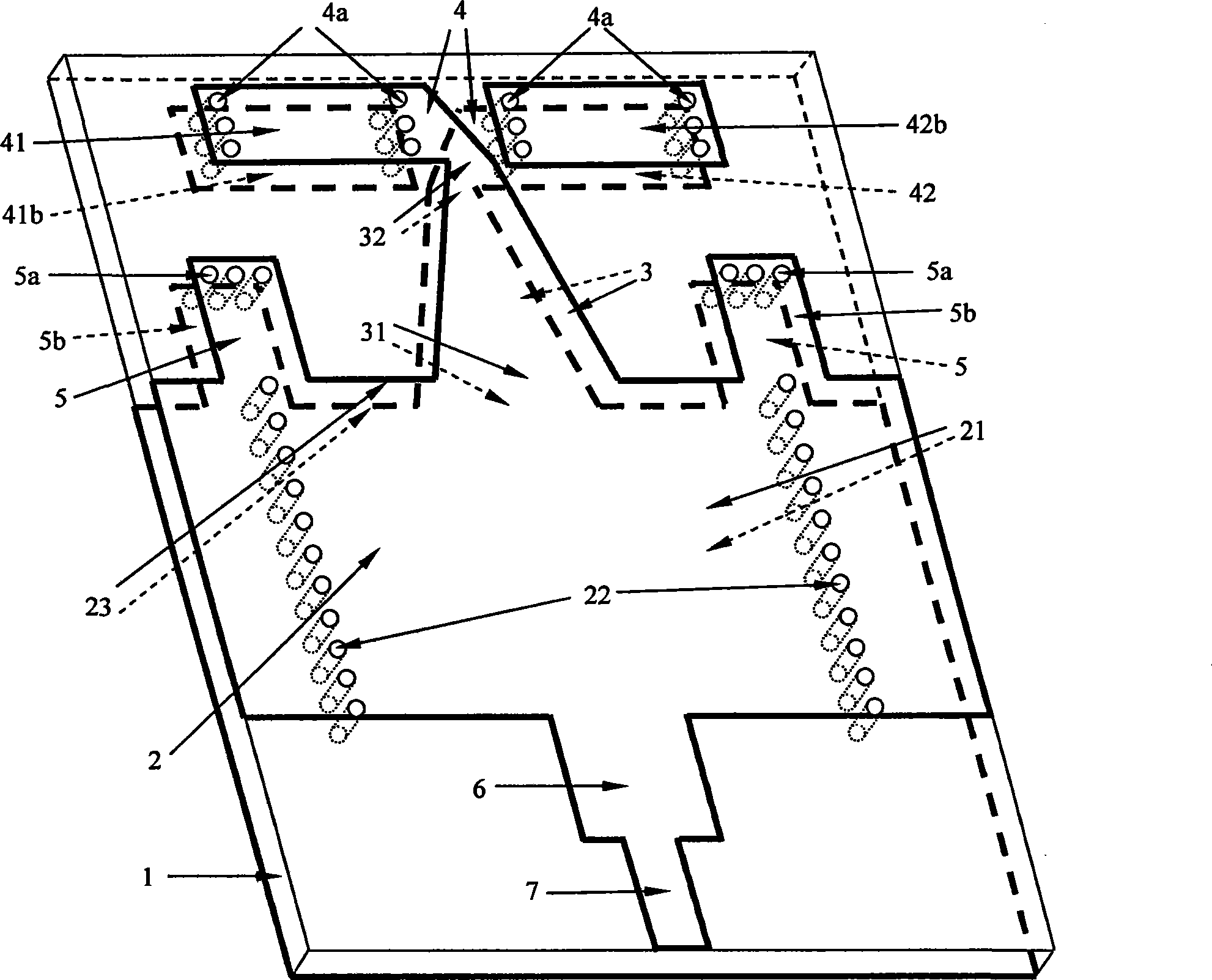

A chip integrated waveguide feeding print antenna is composed by a chip with its two metal sides being transfixed with metal through holes in array. The two metal sides are in axial symmetry. There is an intergrading section to one side of the waveguide centerline on two surface of the chip linking with transmission line. To the outer end of the intergrading section links a vibrator antenna. To the opposite side of the intergrading section on the waveguide links a micro-strip intergrading commutator linking with micro-strip transmission line.

Owner:南京易太可通信技术有限公司

Printing antenna with baseplate integrated waveguide feeder

ActiveCN101075702BSealing is simple, convenient and economicalTo achieve the purpose of sealingRadiating elements structural formsRadarEngineering

A chip integrated waveguide feeding print antenna is composed by a chip with its two metal sides being transfixed with metal through holes in array. The two metal sides are in axial symmetry. There is an intergrading section to one side of the waveguide centerline on two surface of the chip linking with transmission line. To the outer end of the intergrading section links a vibrator antenna. To the opposite side of the intergrading section on the waveguide links a micro-strip intergrading commutator linking with micro-strip transmission line.

Owner:南京易太可通信技术有限公司

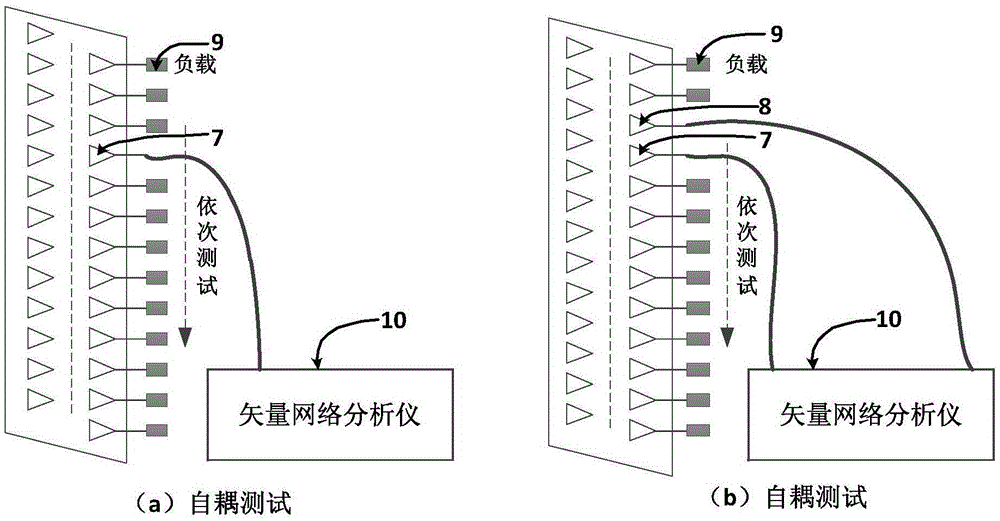

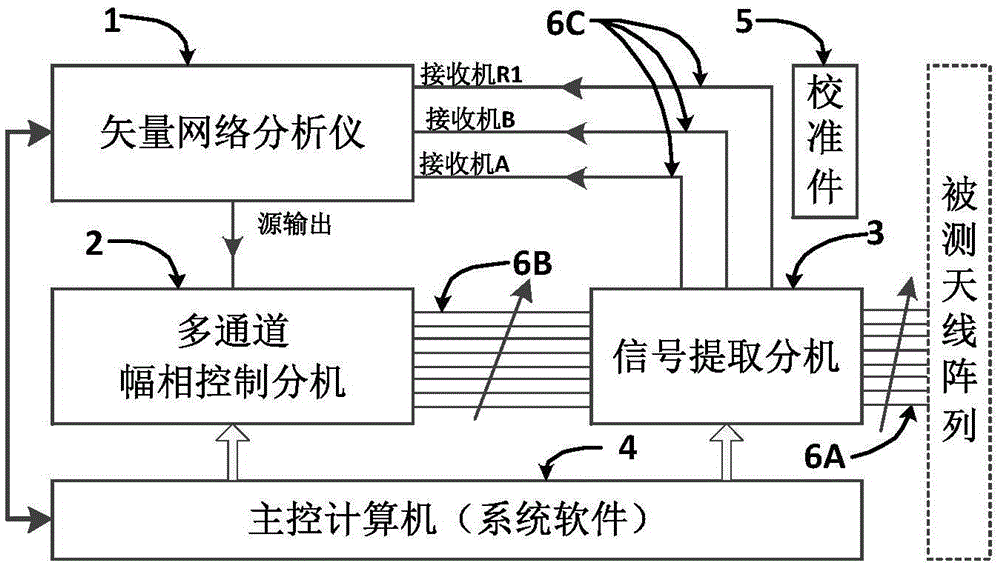

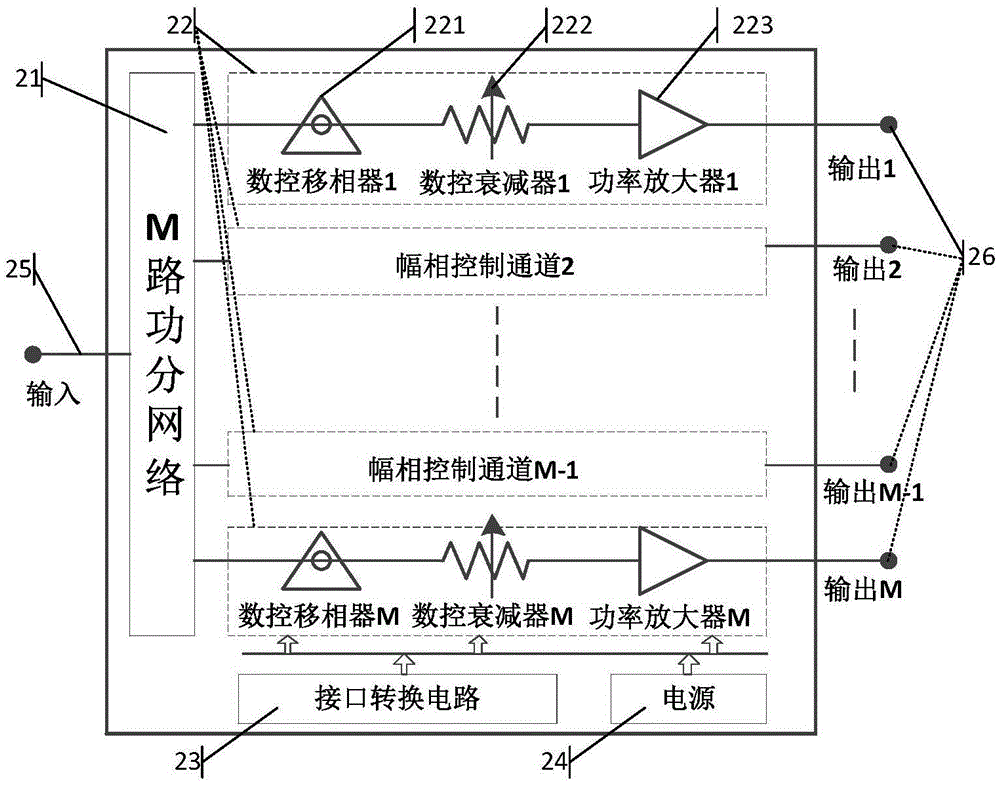

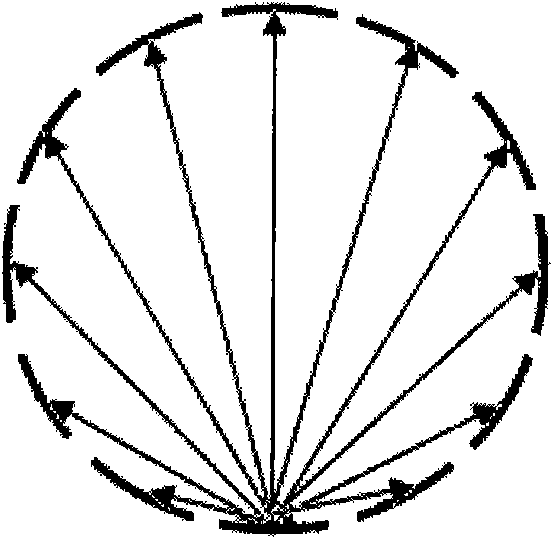

Active reflection coefficient test system and method of phased array antenna

The invention discloses an active reflection coefficient test system and method of a phased array antenna. The test system comprises a vector network analyzer, a multichannel amplitude phase control auxiliary unit, a signal extraction auxiliary unit, a master control computer, a calibration member and an amplitude-stabilizing phase-stabilizing cable, wherein the vector network analyzer is configured to generate test excitation signals and receive reference, reflection and monitoring signals; the multichannel amplitude phase control auxiliary unit is configured to convert one path of excitation signals into M paths, control the amplitudes and phases of the M paths of signals independently, and output M paths of amplitude and phase controllable excitation signals; and the signal extraction auxiliary unit is configured to realize straight-through output of the M paths of amplitude and phase controllable excitation signals, carry out reference coupling, monitoring coupling and reflection coupling extraction on the M paths of amplitude and phase controllable excitation signals, and implement switching control and selective output. The test system can directly test the active reflection coefficient of the antenna unit needless of calculation, the test process is concise, manual operation is less, and the test result is highly correct.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

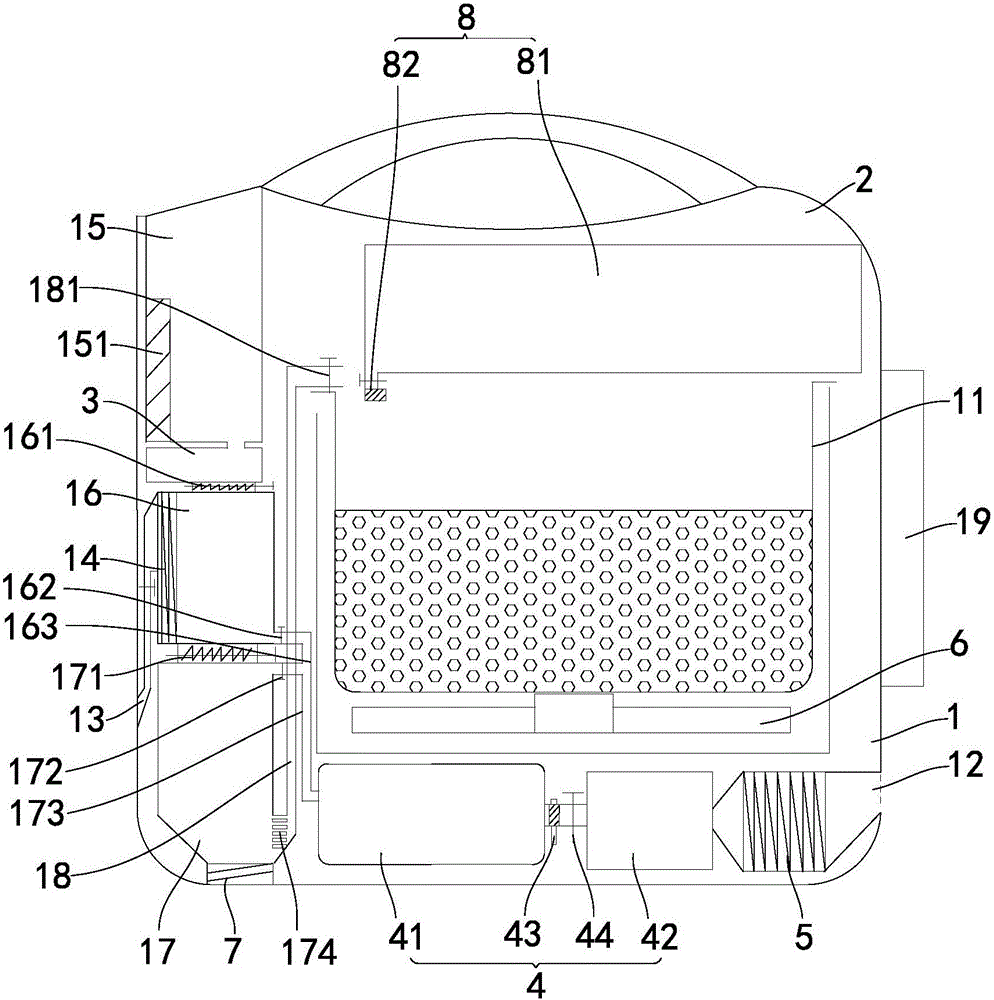

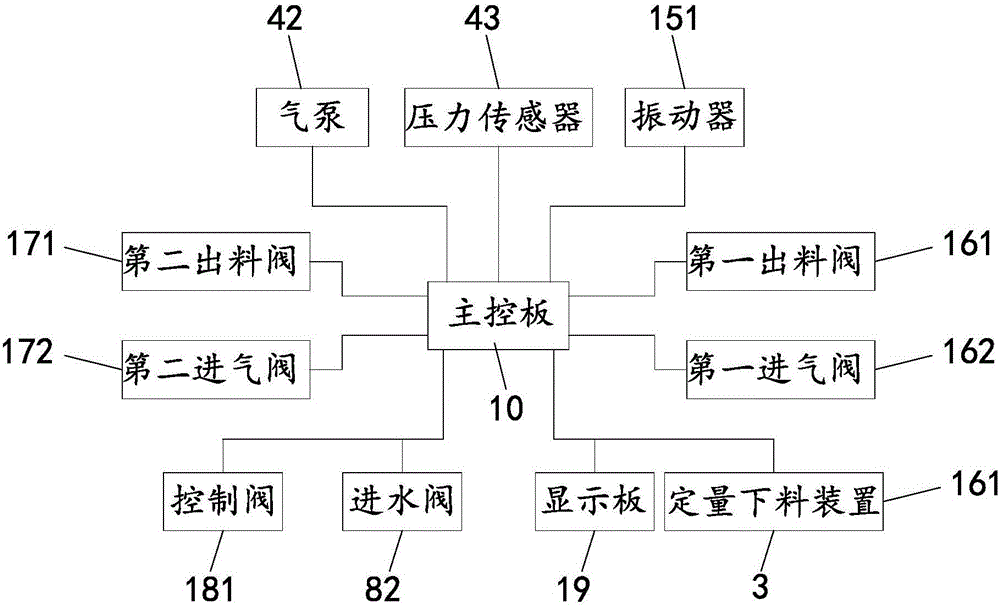

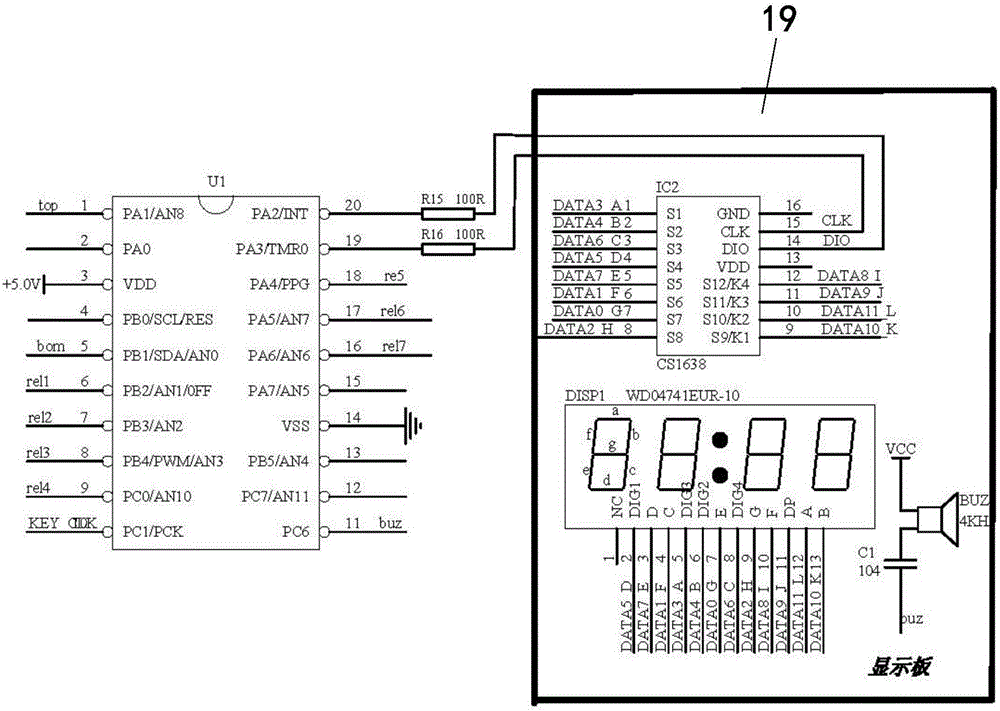

Control method of intelligent electric rice cooker

InactiveCN105768849ARetain nutritionAvoid churnVessels with intergral heatingEngineeringNutrient loss

The invention discloses a control method of an intelligent electric rice cooker, belongs to the field of kitchen cooking appliances, and solves the problems that an existing electric rice cooker causes cost loss and rice nutrient loss due to the use of water to wash rice. The intelligent electric rice cooker comprises a pot body, a cover, an inner pot and a control unit and also comprises a storage chamber, a washing chamber connected with the storage chamber and an air supply device connected with the washing chamber, and the control method at least comprises the steps: feeding: conveying material into the washing chamber from the storage chamber; washing: supplying air to the washing chamber from the air supply device so as to blow-wash the material in the washing chamber; discharging: conveying the material to the inner pot from the washing chamber. The embodiment of the invention is applicable to rice cooking, porridge making and cooking of other five cereals with electric rice cookers.

Owner:HONGYANG HOME APPLIANCES

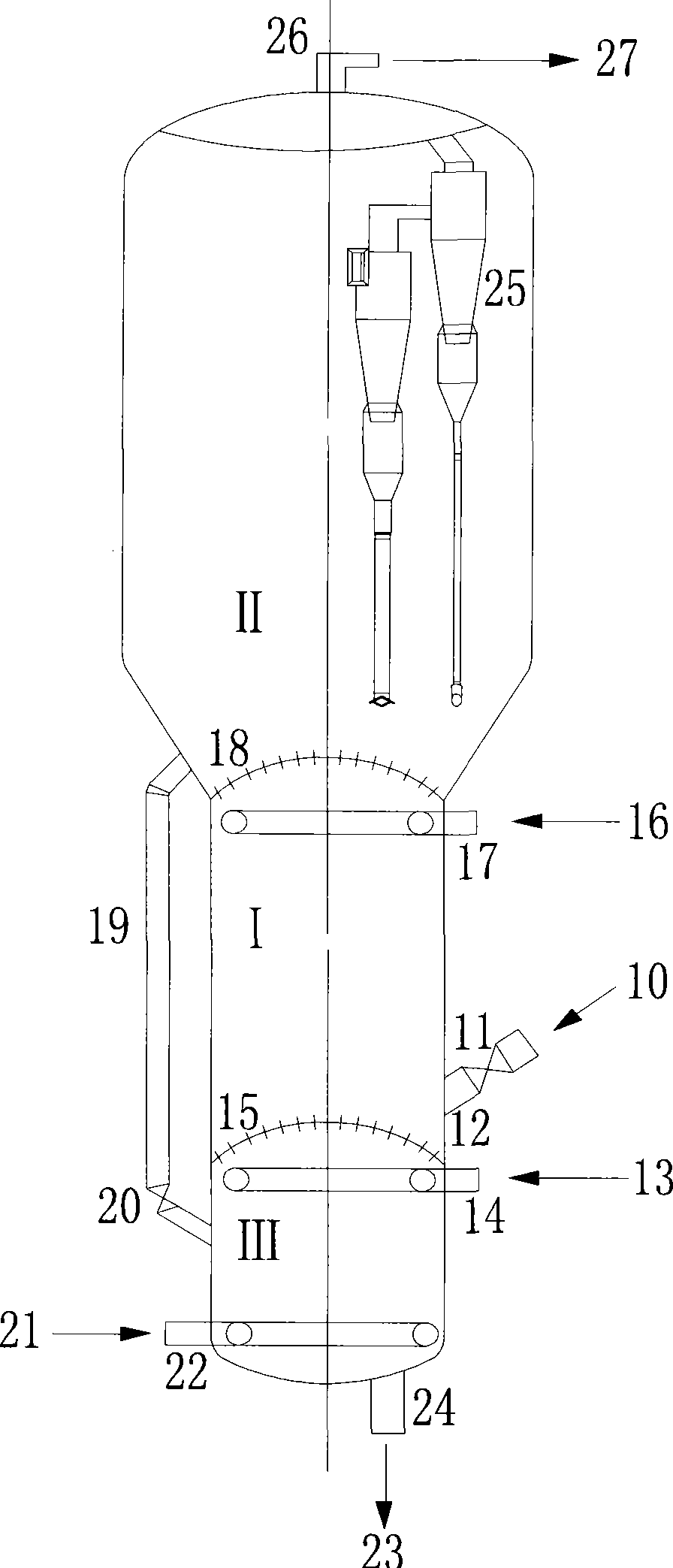

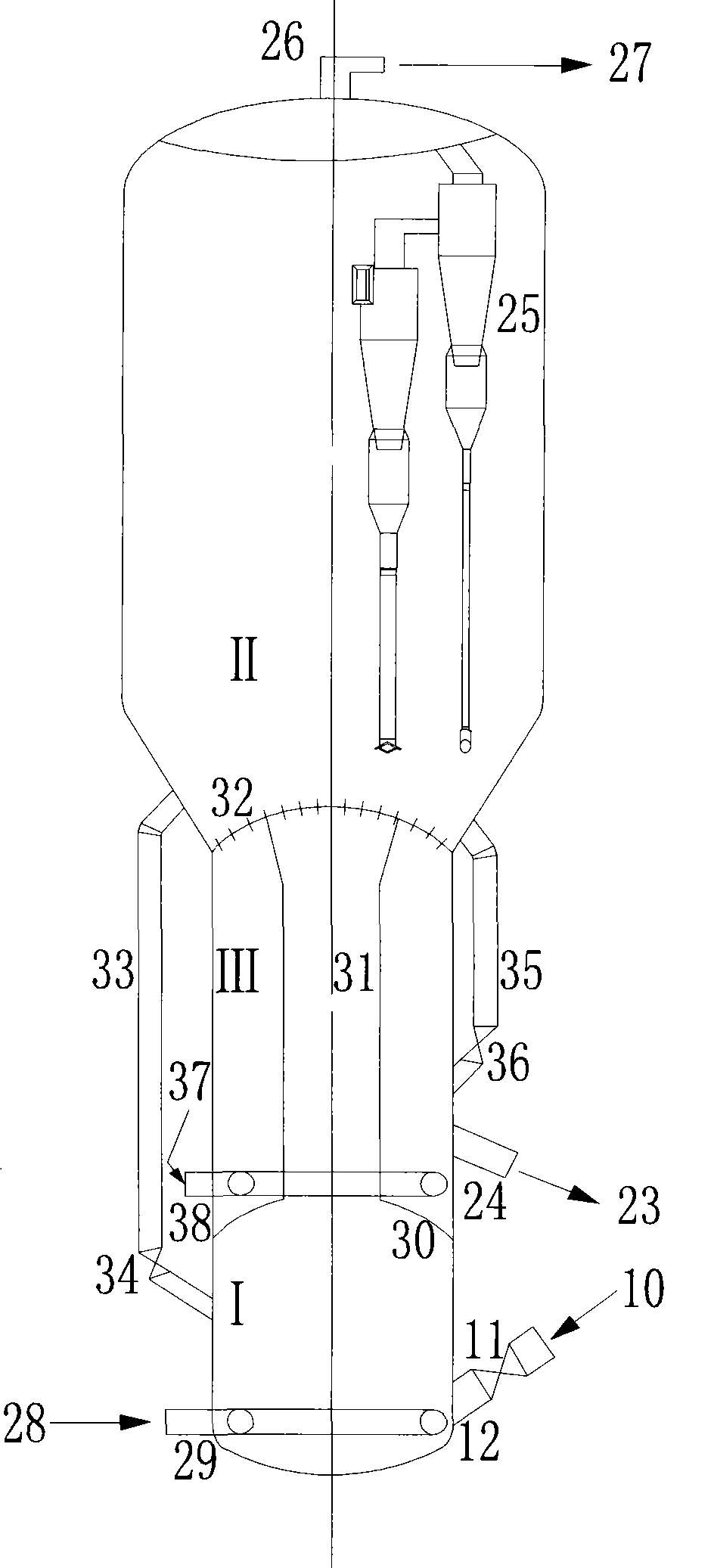

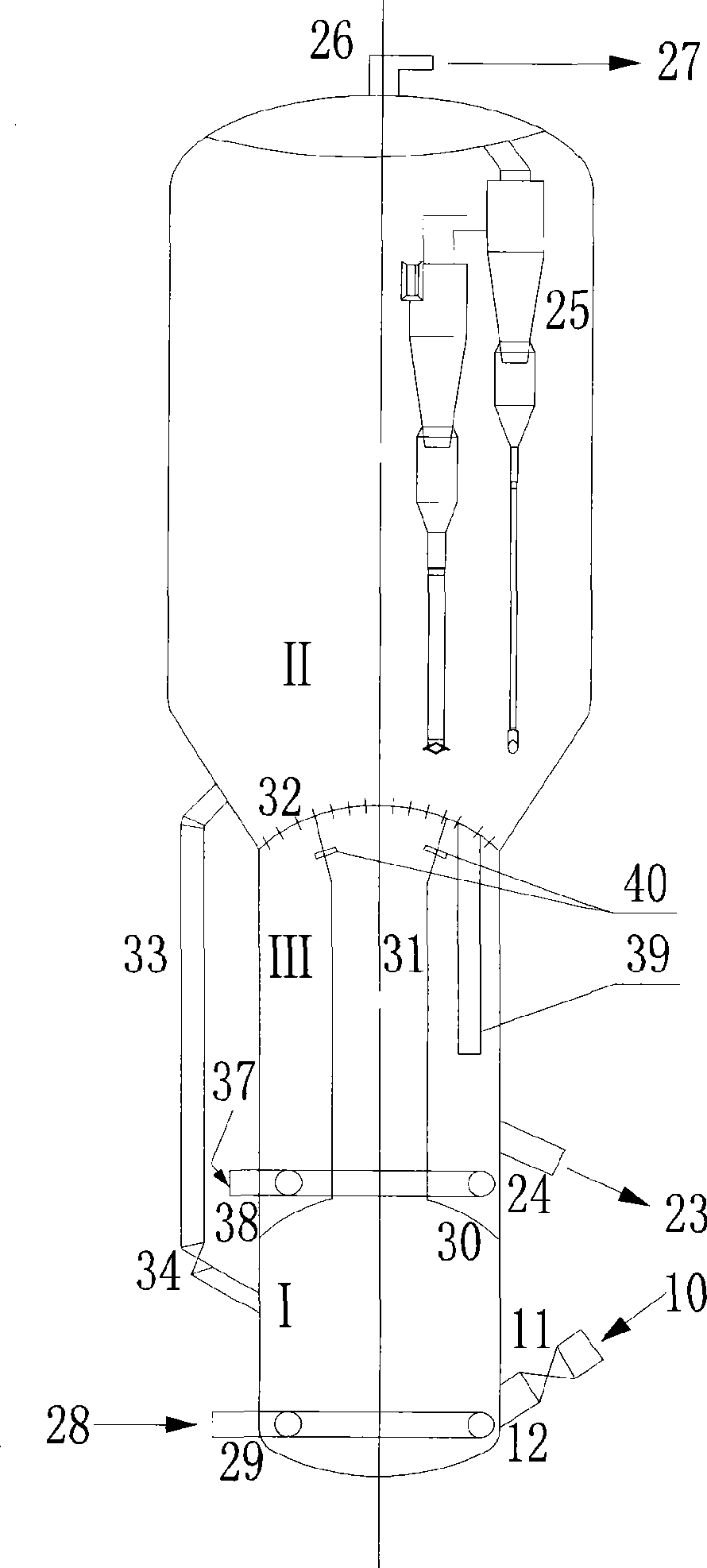

Catalyst multistage regeneration method and device

InactiveCN101391234AIncreased average chemical kinetic speedPromote regenerationCatalyst regeneration/reactivationRegenerative processLine tubing

The invention introduces a catalyst multi-section regeneration method and an apparatus, firstly, a spent catalyst enters a first section regenerator, and is in contact reaction with oxygen-containing gases in the first section regenerator, a second section regenerator and a third section regenerator sequentially, oxygen-containing regeneration flue gas of the first section enters the second section for continuous utilization, and the fresh compressed air is input to the third section for regeneration reaction, so as to complete the whole regenerative process. The fresh compressed air can also be supplemented to the first section regeneration reaction or the second section regeneration reaction, and the catalyst can also reflux to other sections for regeneration. The regeneration apparatus is composed of a first section turbulent bed regenerator, a second section turbulent bed regenerator and a third section turbulent bed regenerator in series connection, a distribution plate or a baffle and a catalyst standpipe are arranged, and all the regenerators are in coaxial arrangement. The invention adopts the multi-section counter-current regeneration, increases the average chemical kinetics speed, strengthens the regenerative process, saves the oxygen-containing gas usage, and reduces the production expense; and realizes the feeding of the spent catalyst from the bottom part or the middle part of each regenerator, lowers the height of the corresponding catalytic conversion device, shortens the oil-gas pipe-line, and reduces the construction investment.

Owner:QINGDAO JINGRUN PETROCHEM ENG

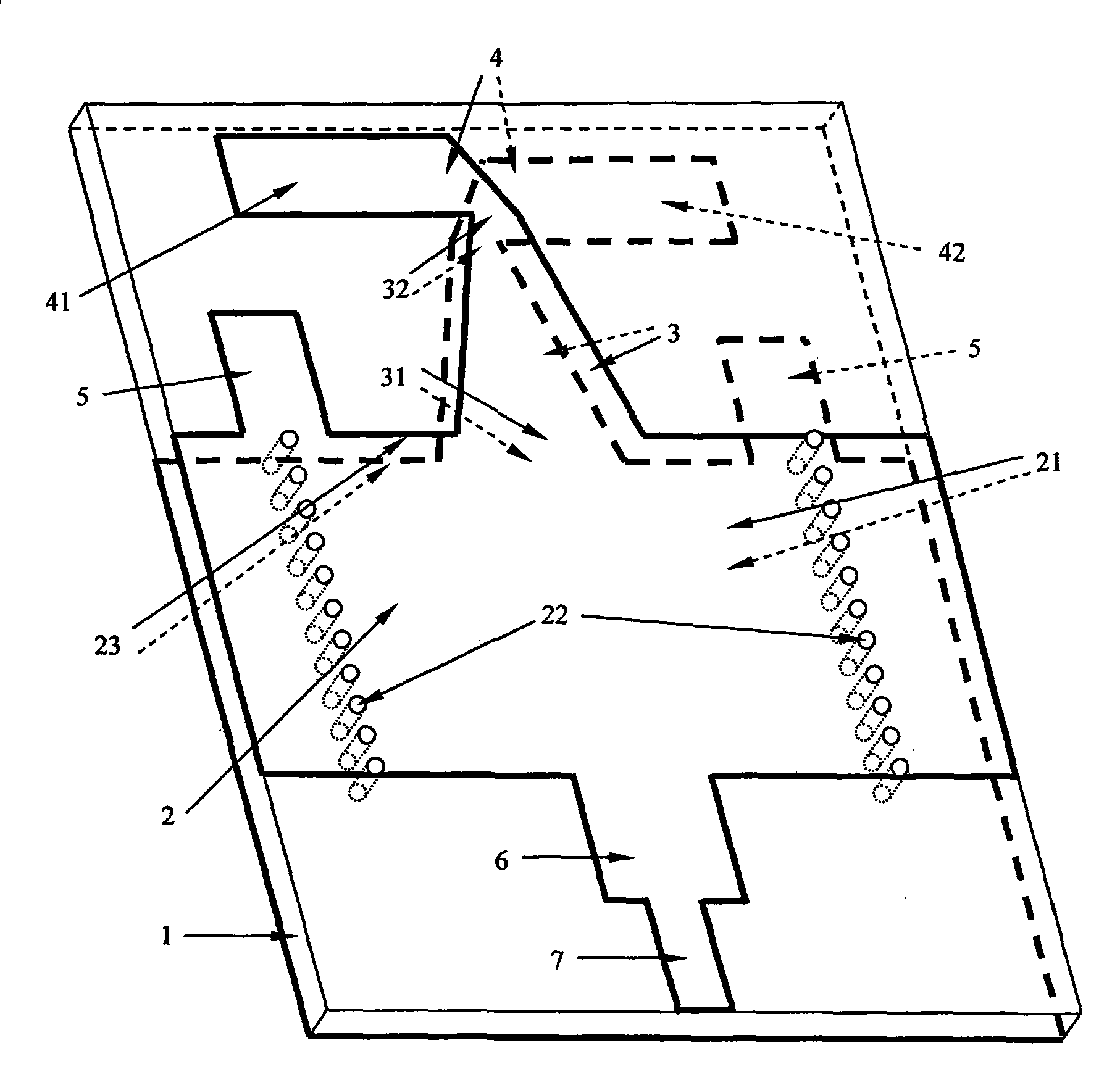

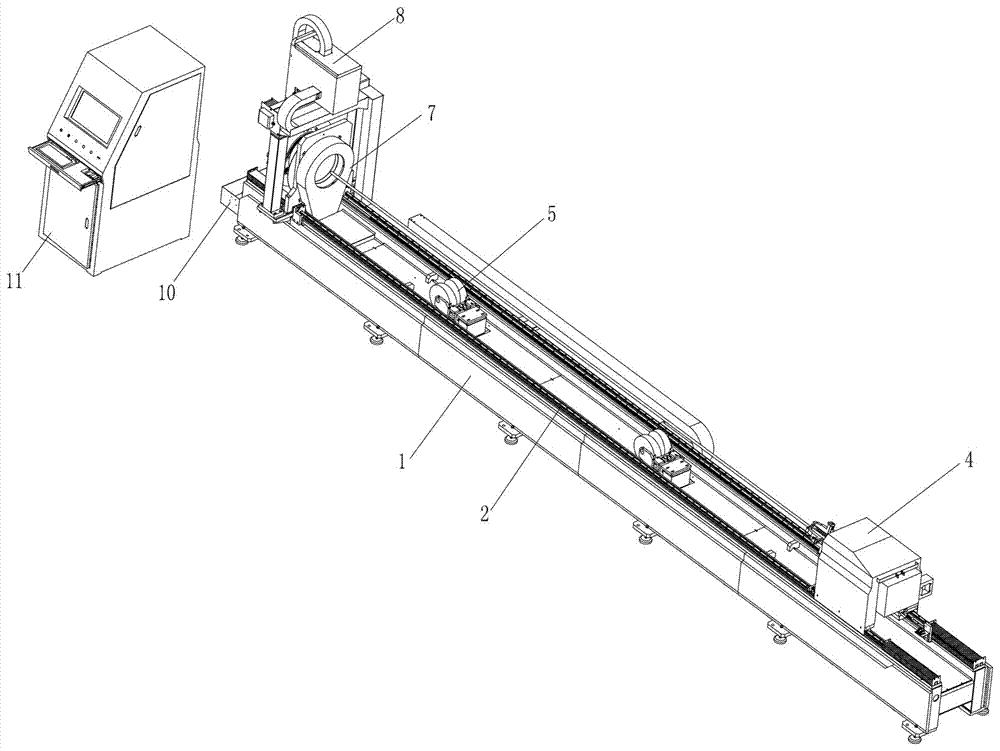

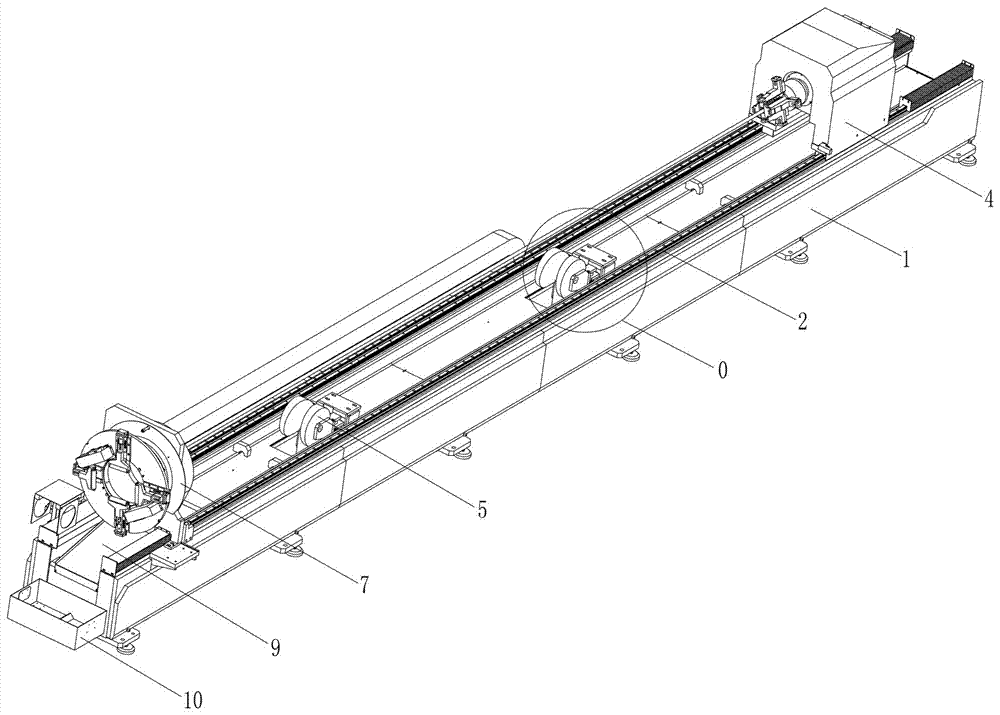

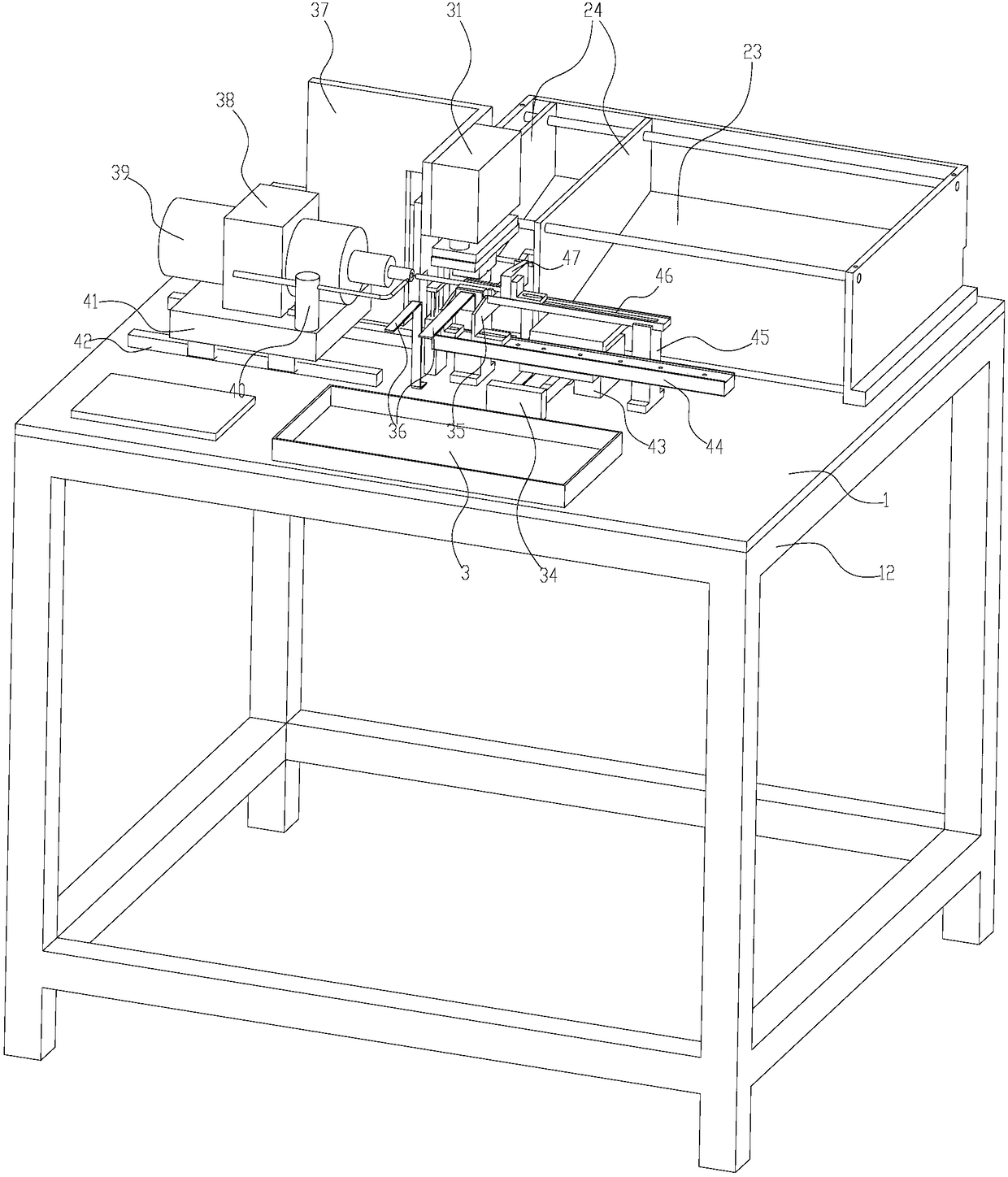

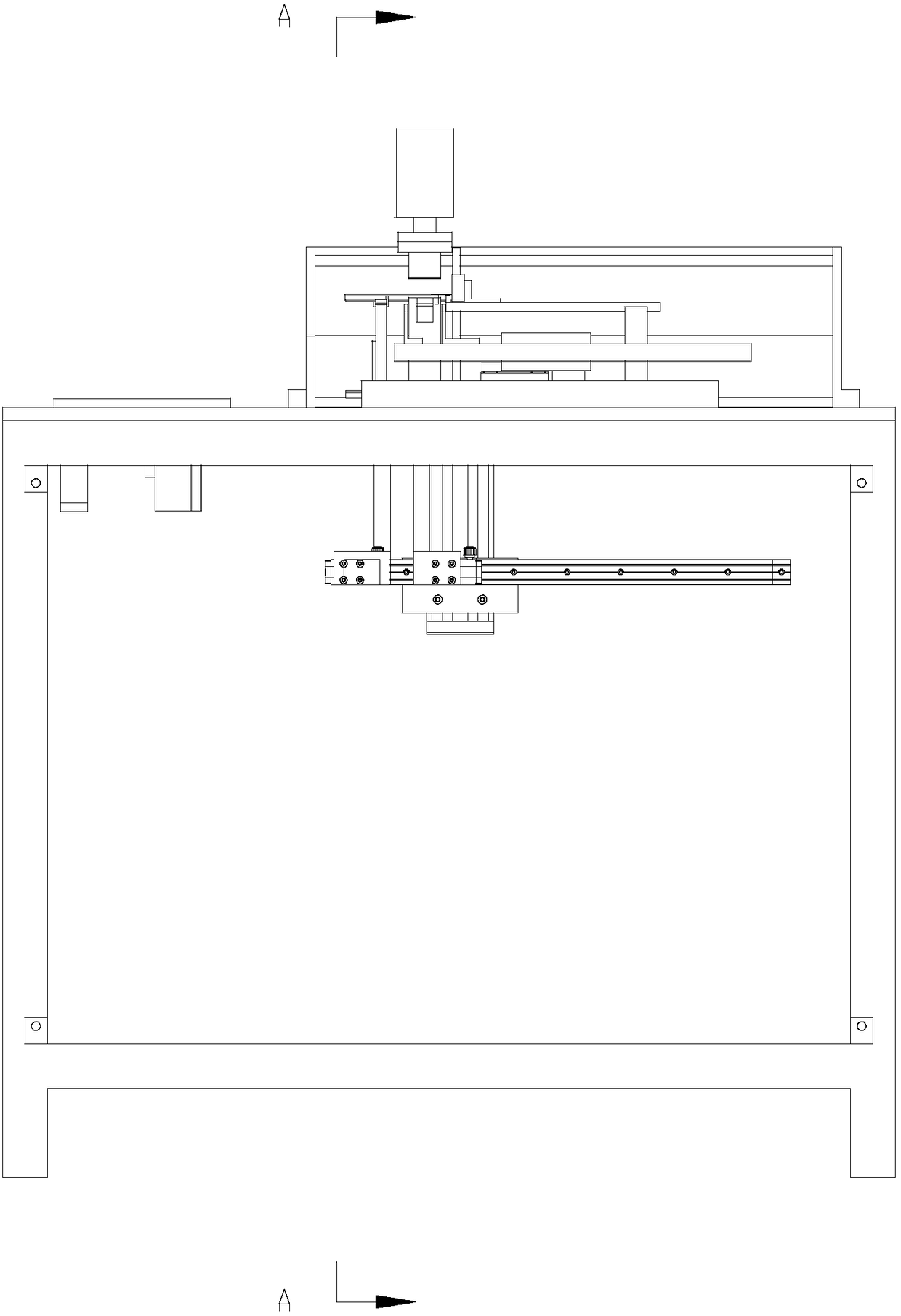

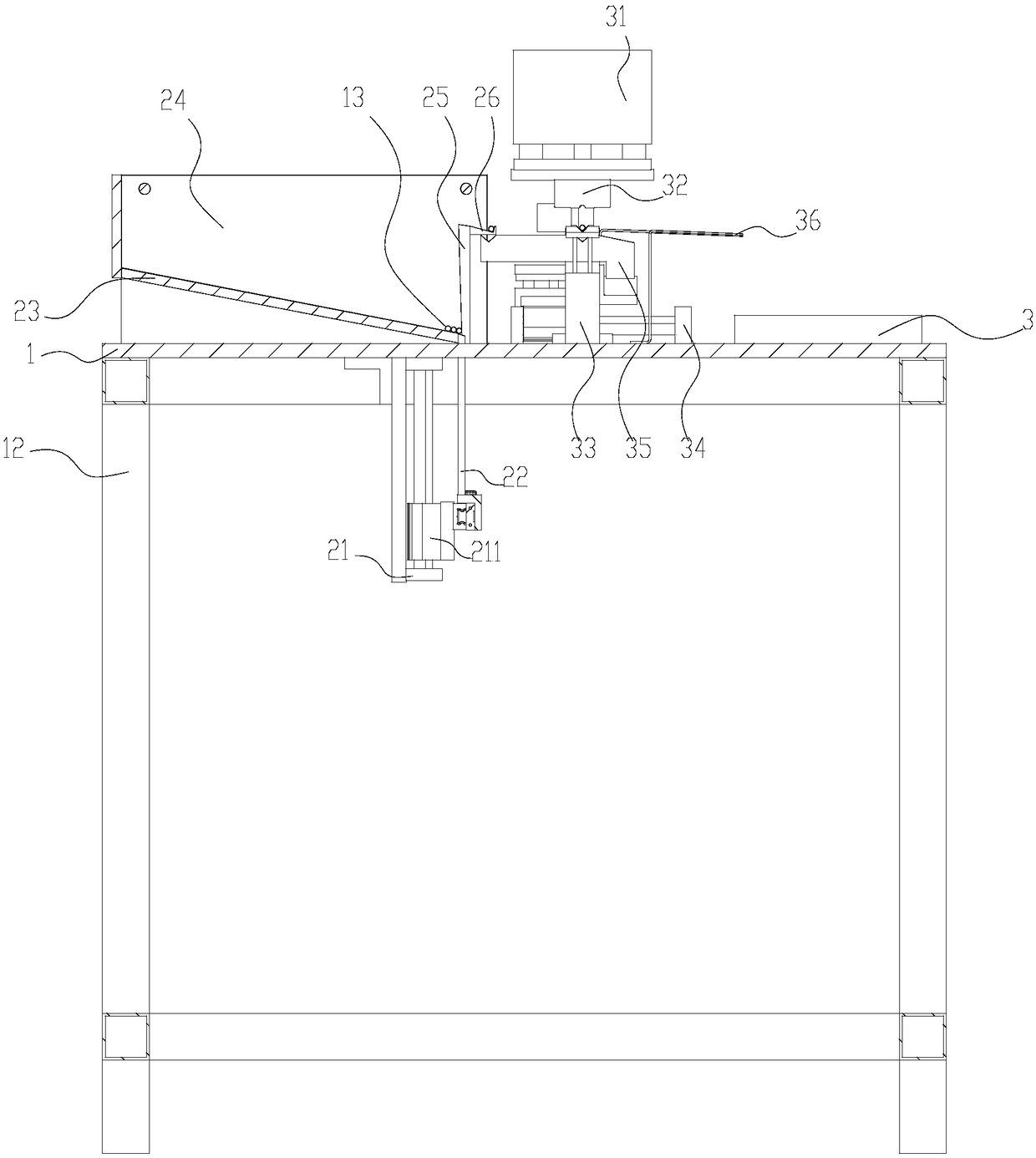

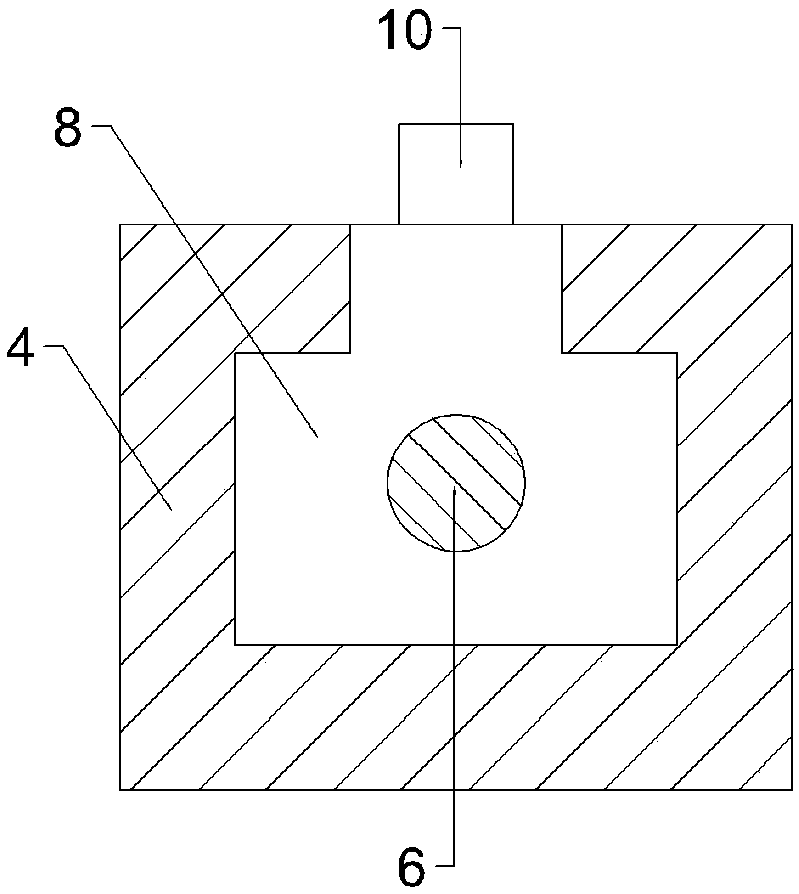

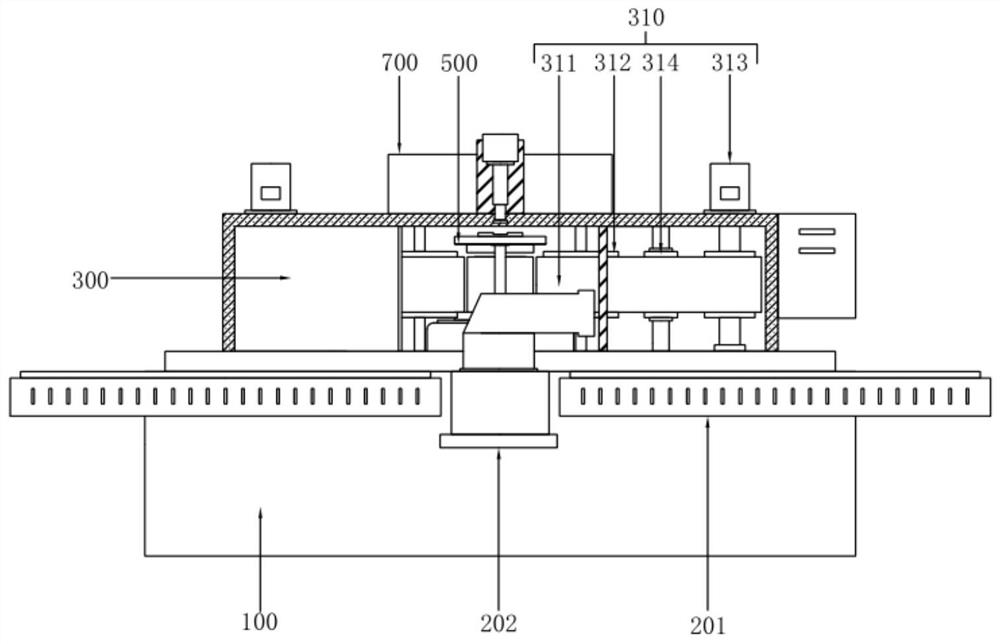

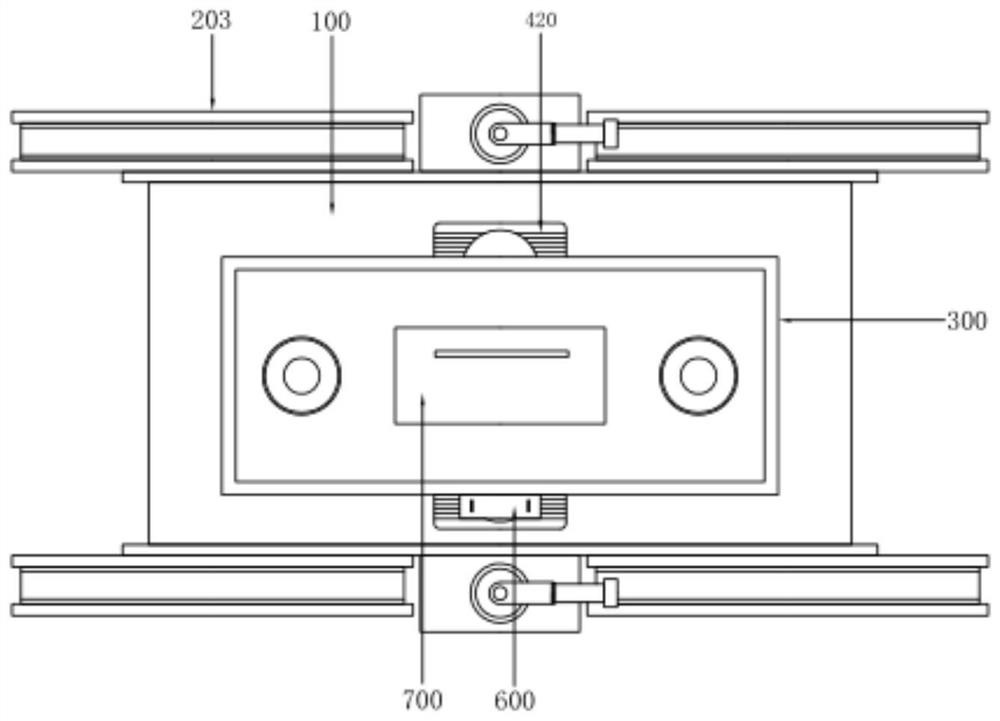

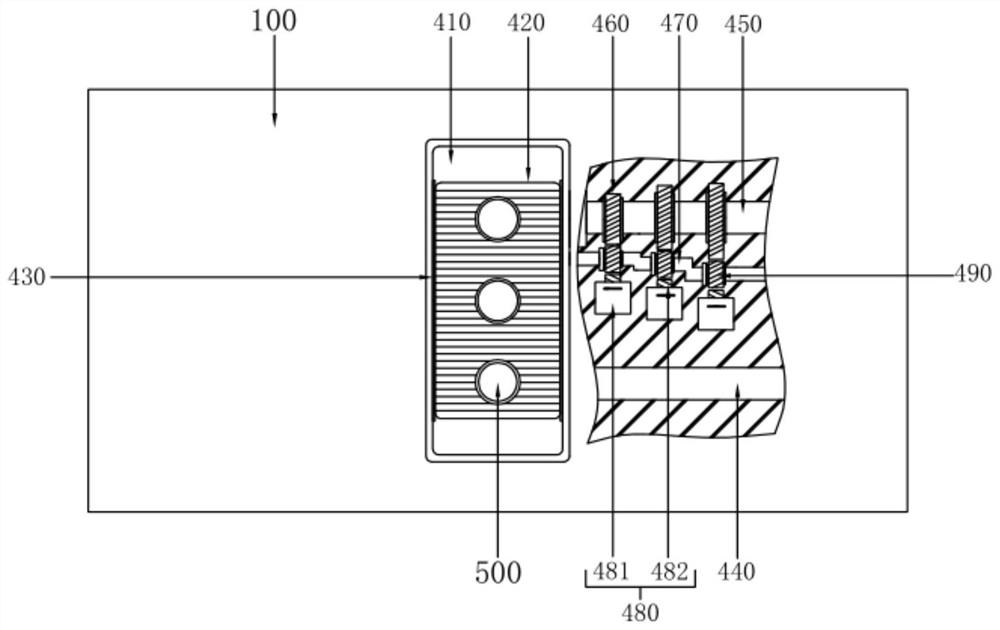

Novel integral type compact laser pipe cutting machine

InactiveCN107160035ACompact structureReduce space occupancyLaser beam welding apparatusTubular articlesEngineeringMachine tool

The invention discloses a novel integral type compact laser pipe cutting machine which comprises a machine tool, guide rails, a first clamping mechanism, reducing auxiliary supporting mechanisms, a second clamping mechanism, a cutting mechanism and a material box. The machine tool is of a strip-shaped structure. The two guide rails are arranged on the front side and the rear side of the machine tool correspondingly in the side edge direction of the machine tool. The first clamping mechanism is arranged at the rear end of the machine tool and embedded in the guide rails in a sliding manner. The first clamping mechanism clamps and fixes one end of a pipe body to be cut. At least two reducing auxiliary supporting mechanisms are arranged in the machine tool at intervals. The second clamping mechanism is fixedly arranged on the portion close to the front end of the machine tool. The second clamping mechanism fixes the other end of the pipe body to be cut. The cutting mechanism is arranged on the front side of the second clamping mechanism. The material box is arranged on the outer side of the front end of the machine tool. The novel integral type compact laser pipe cutting machine is compact in structure and small in space occupation rate, the pipe is driven to rotate to be cut at 360 degrees in the peripheral direction of the outer wall of the pipe body, and the cutting quality is effectively improved.

Owner:DONGGUAN GLORYSTAR LASER TECH

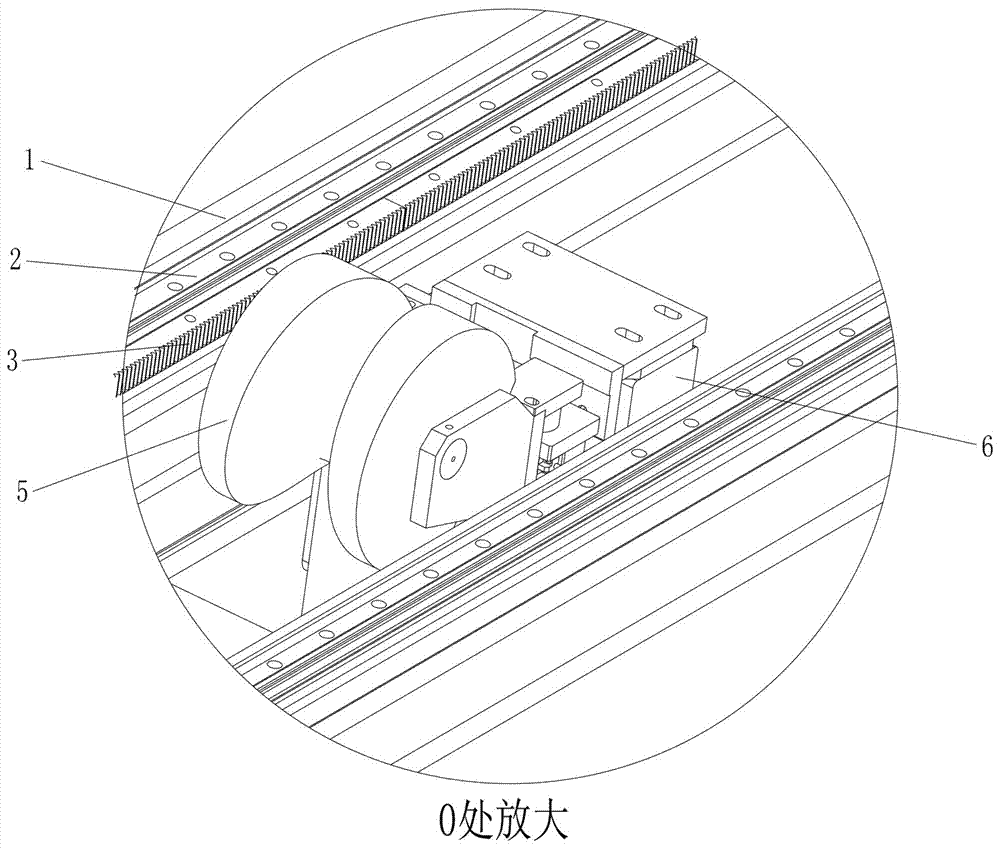

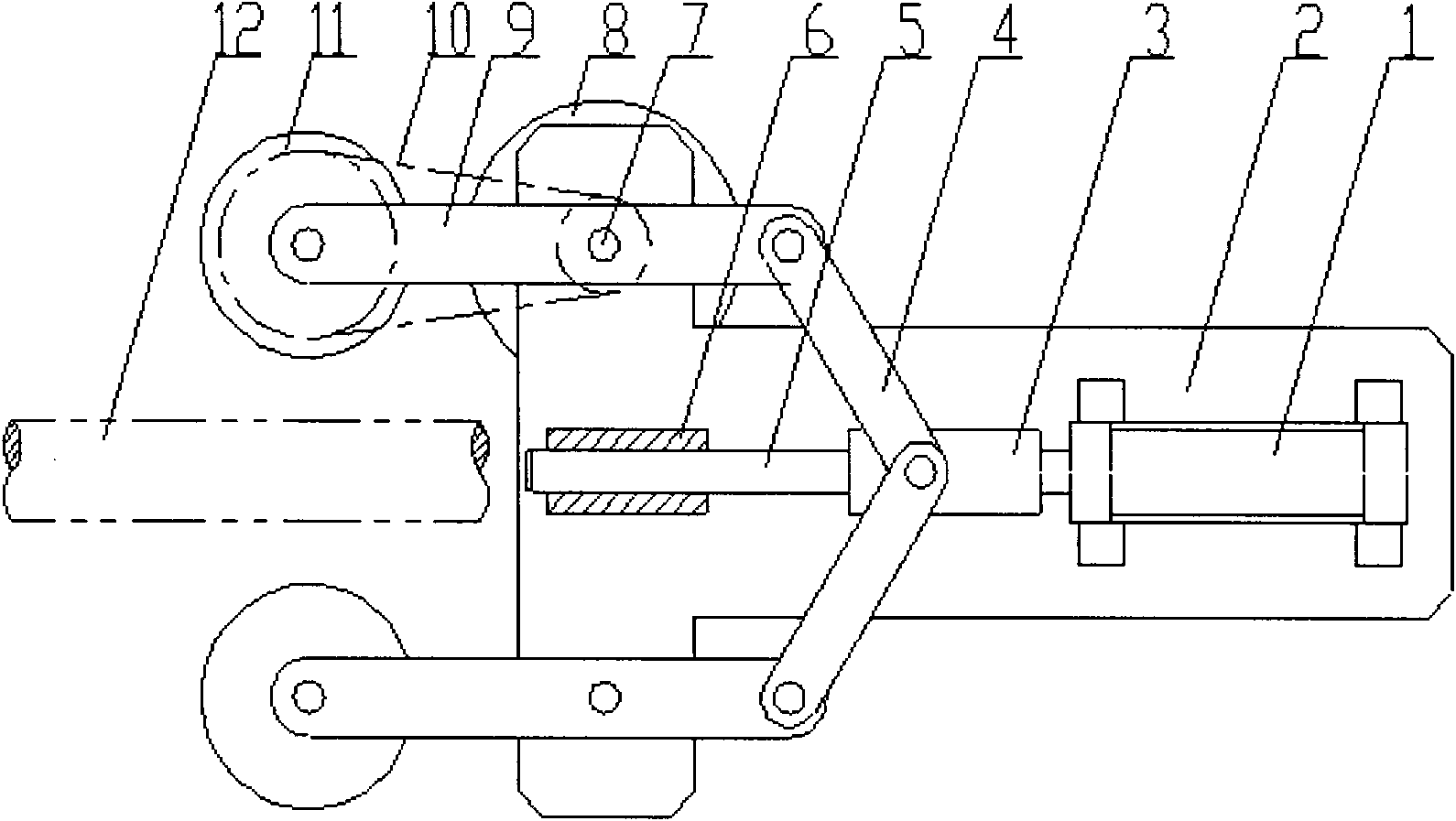

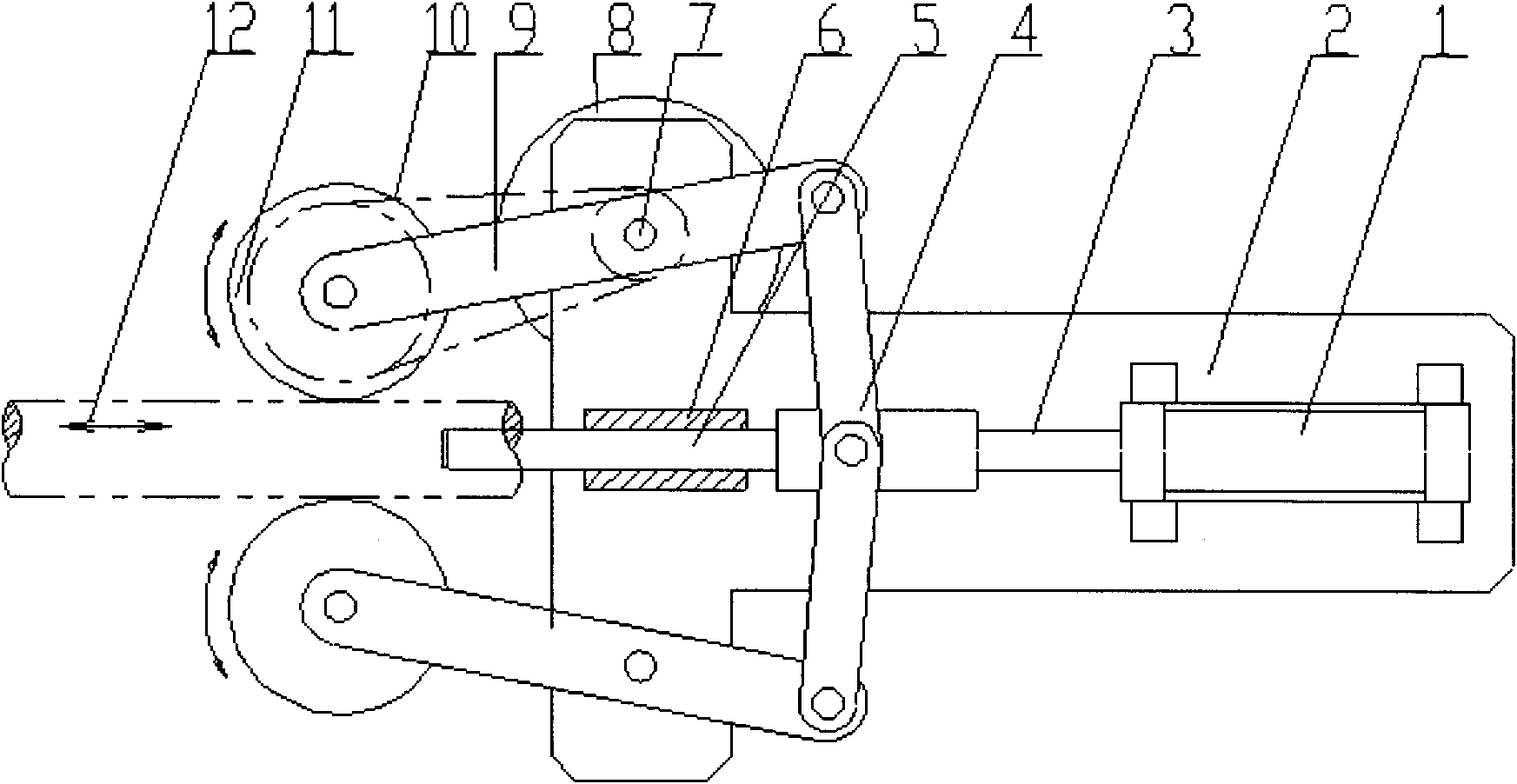

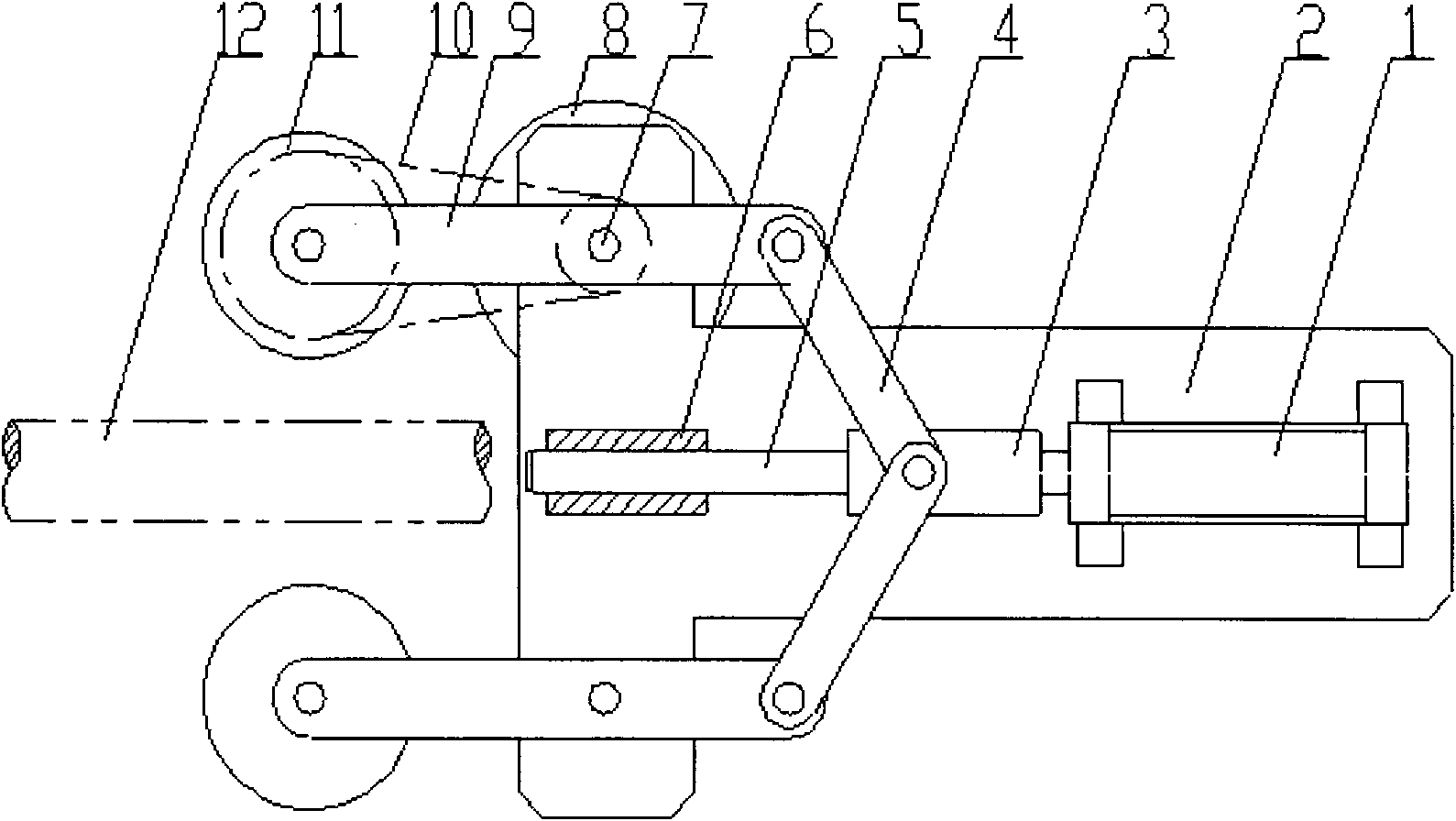

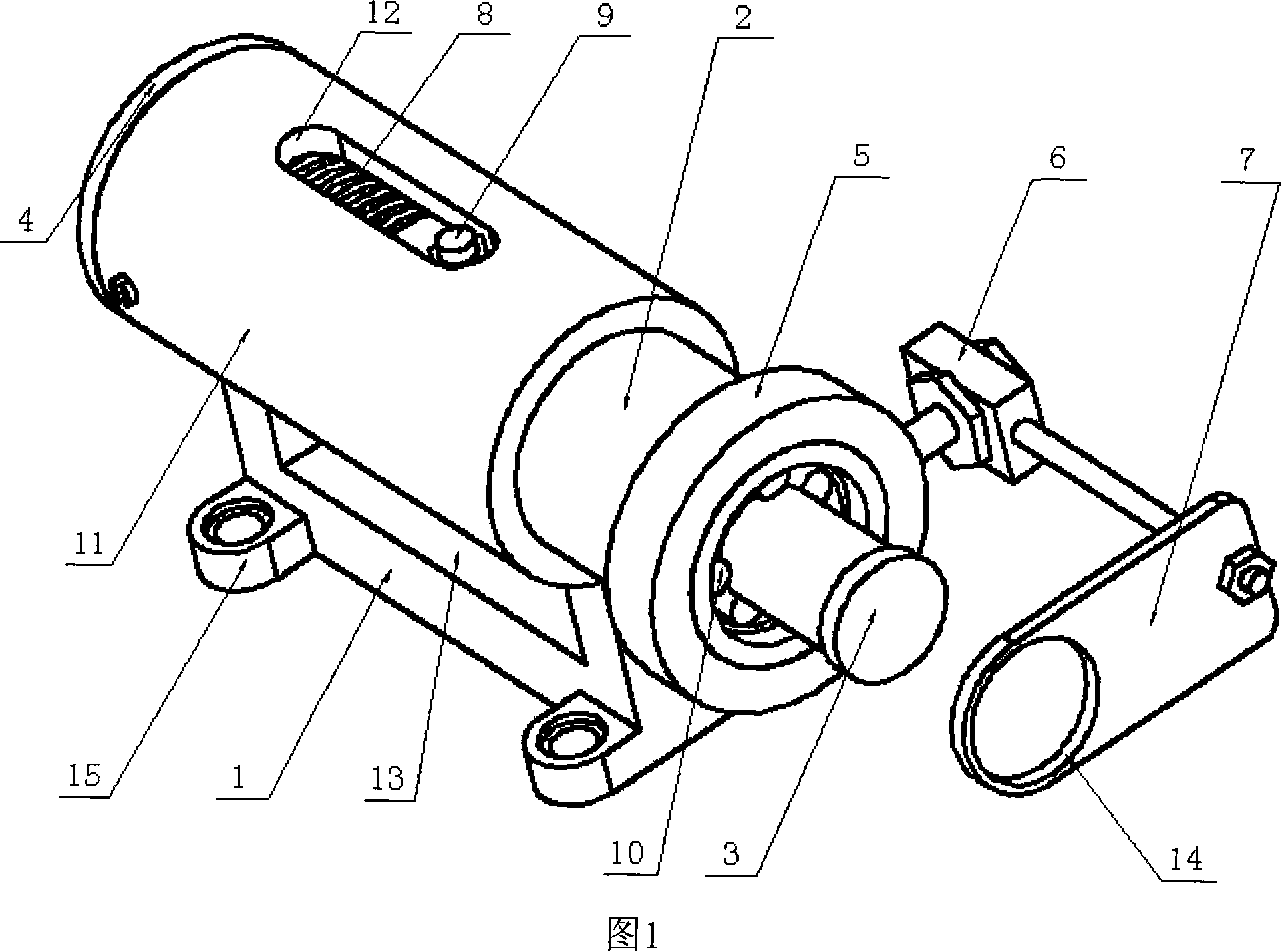

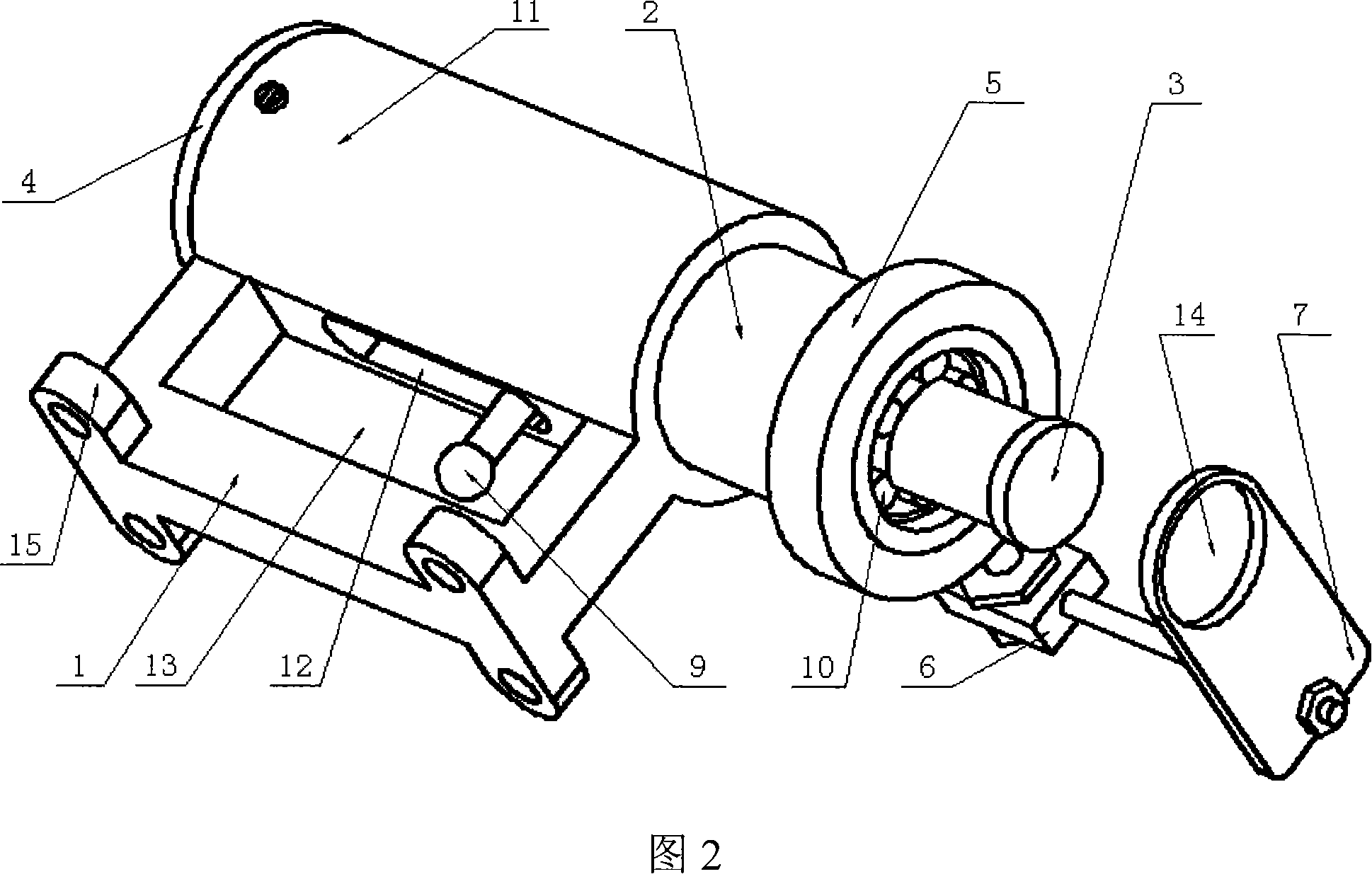

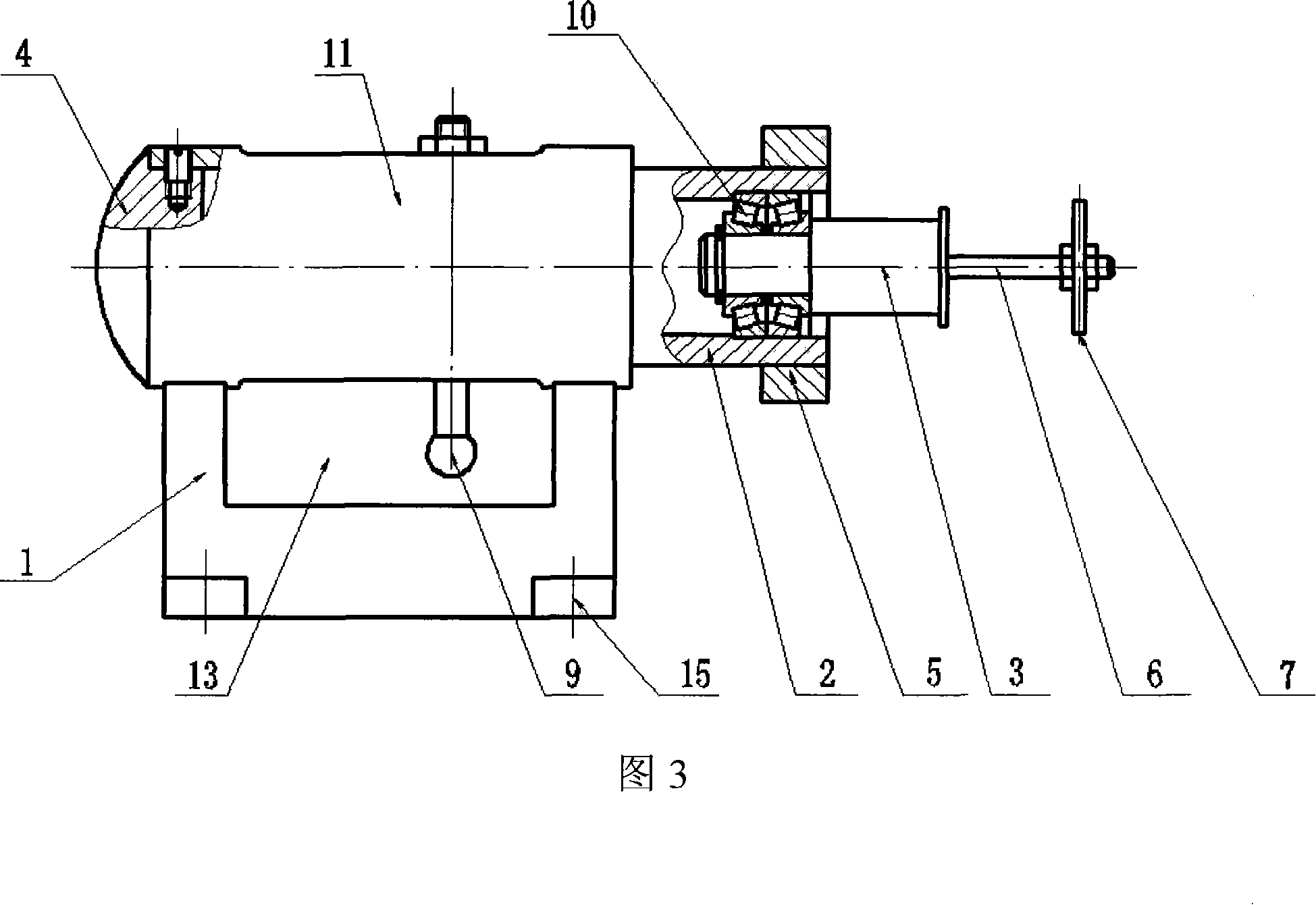

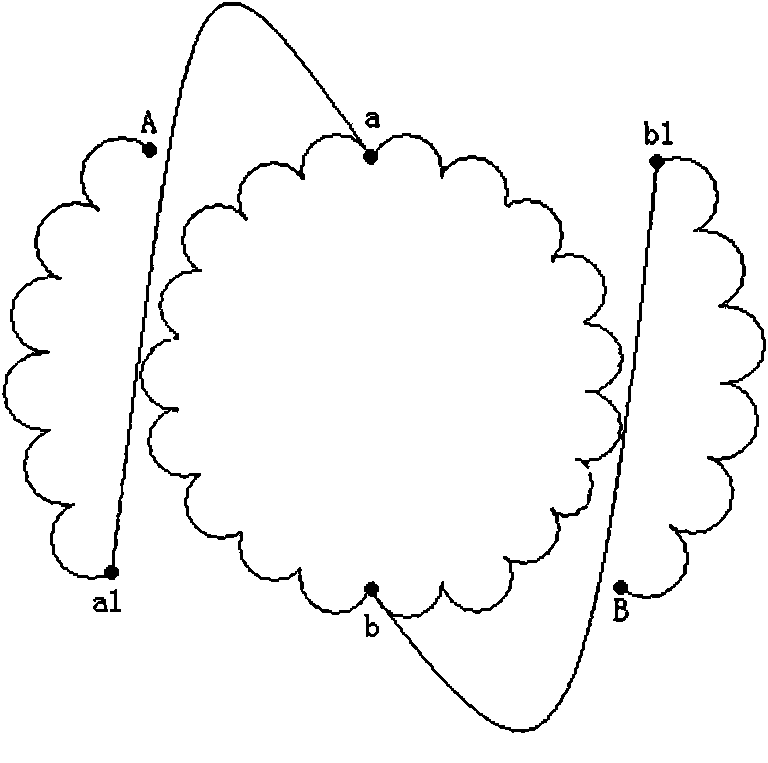

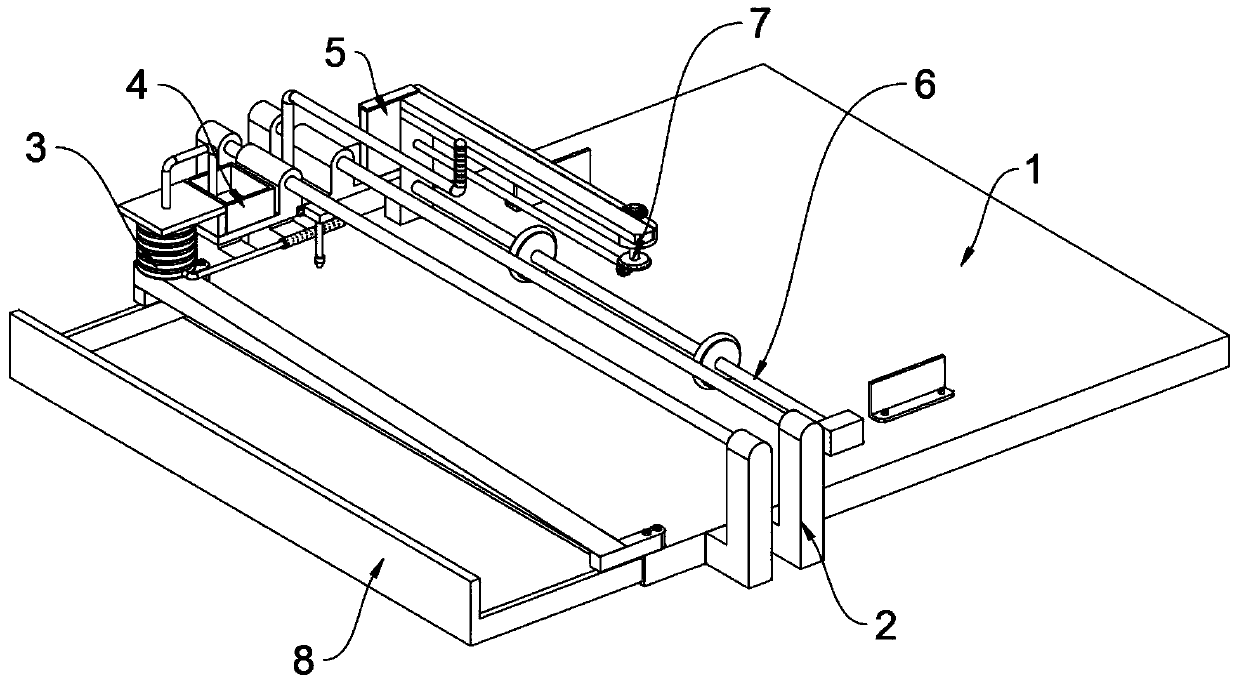

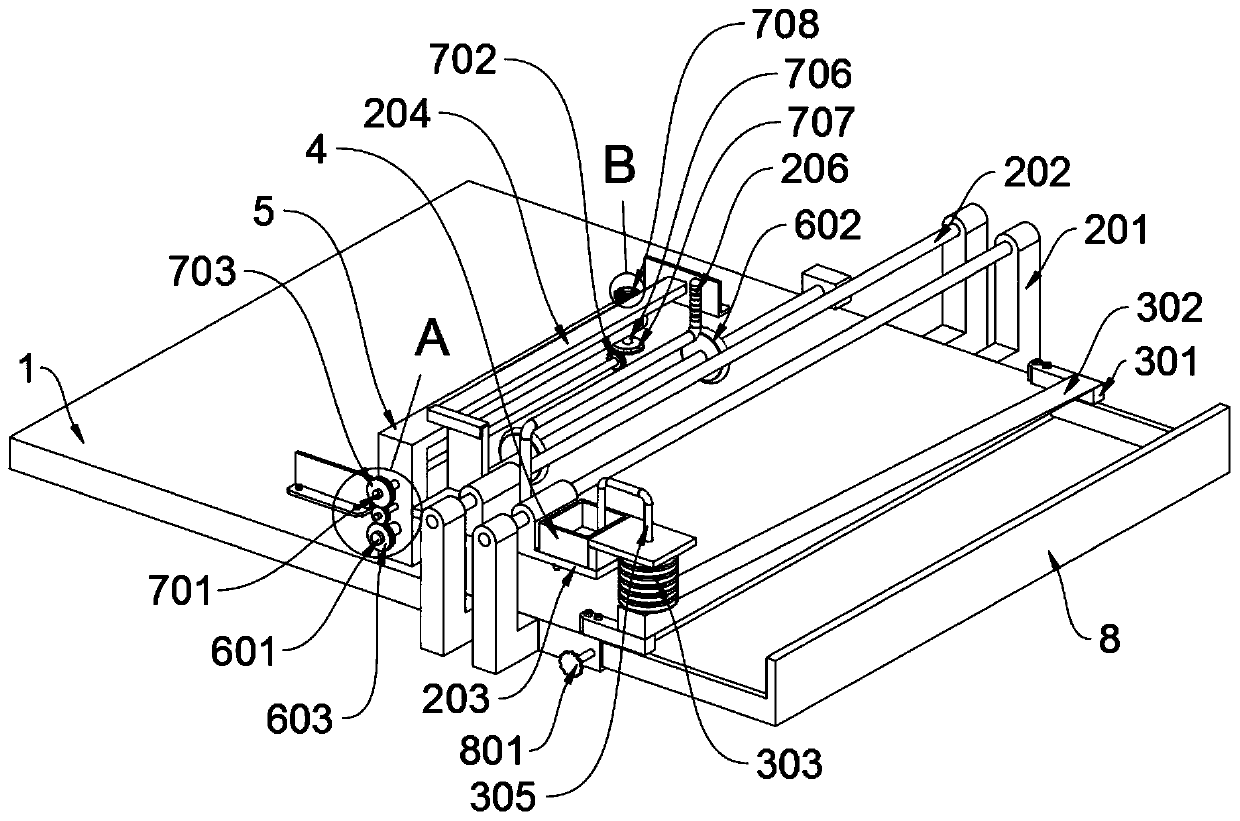

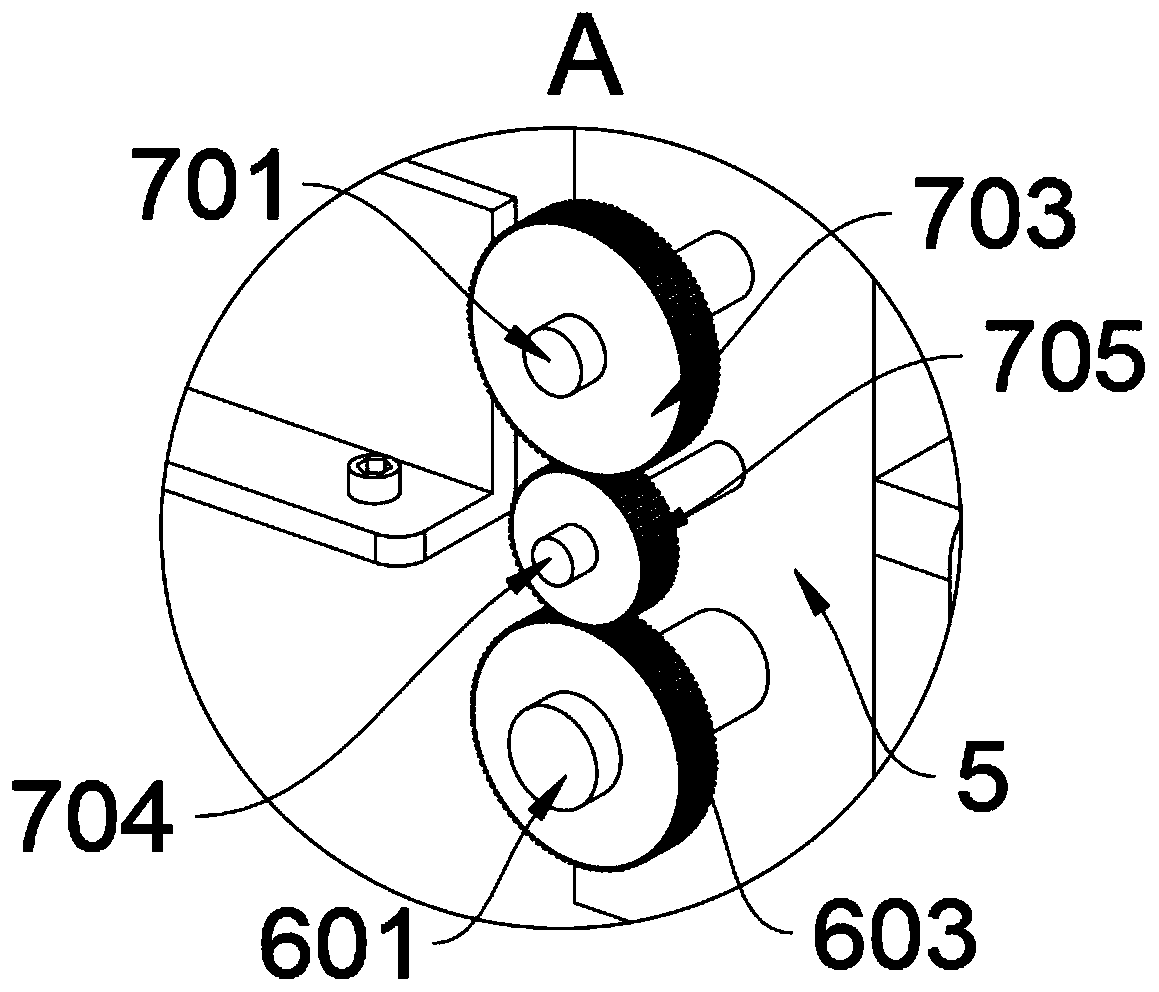

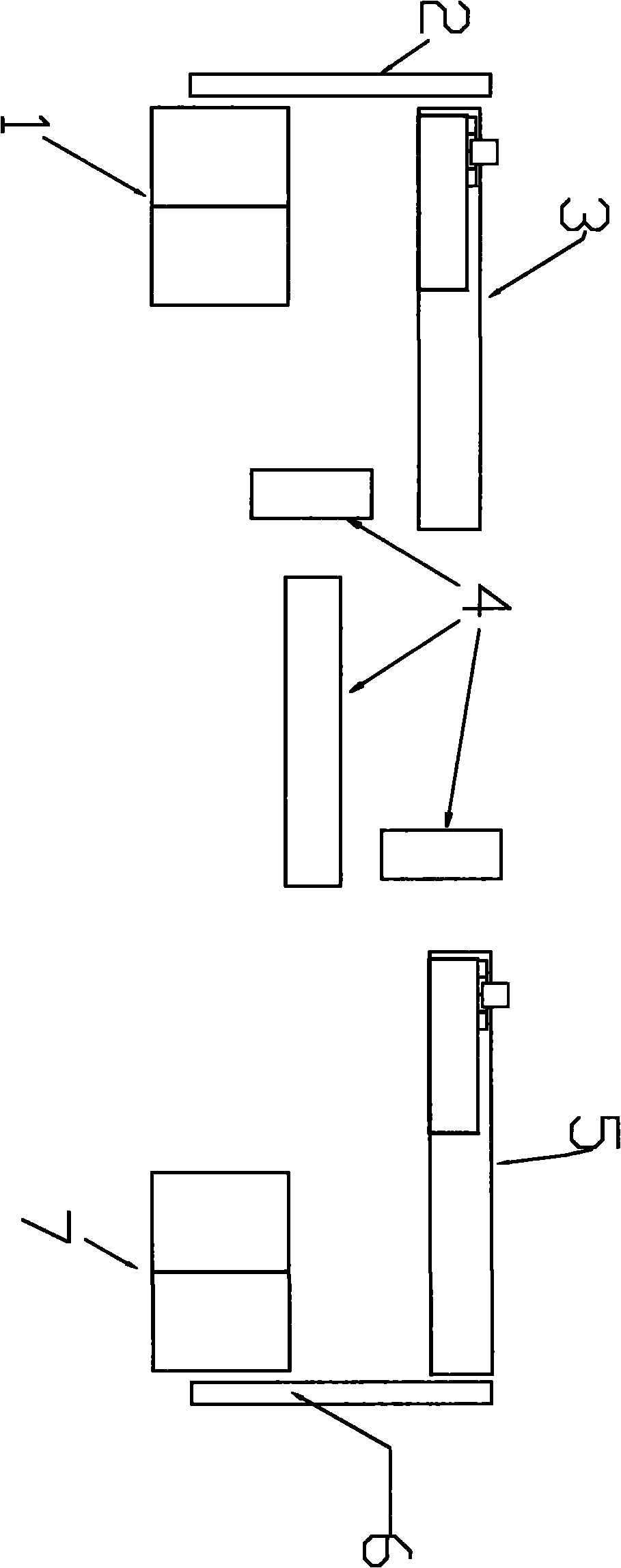

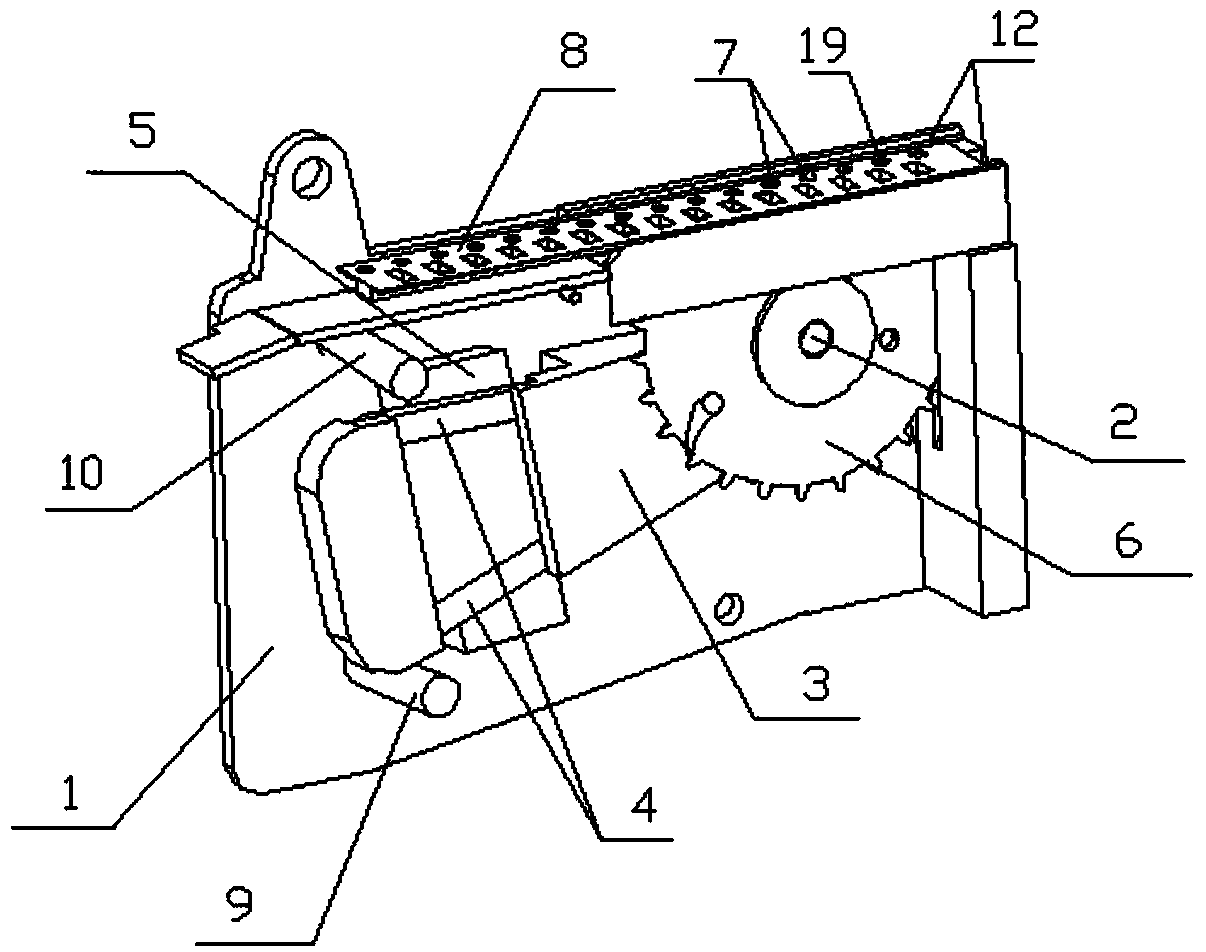

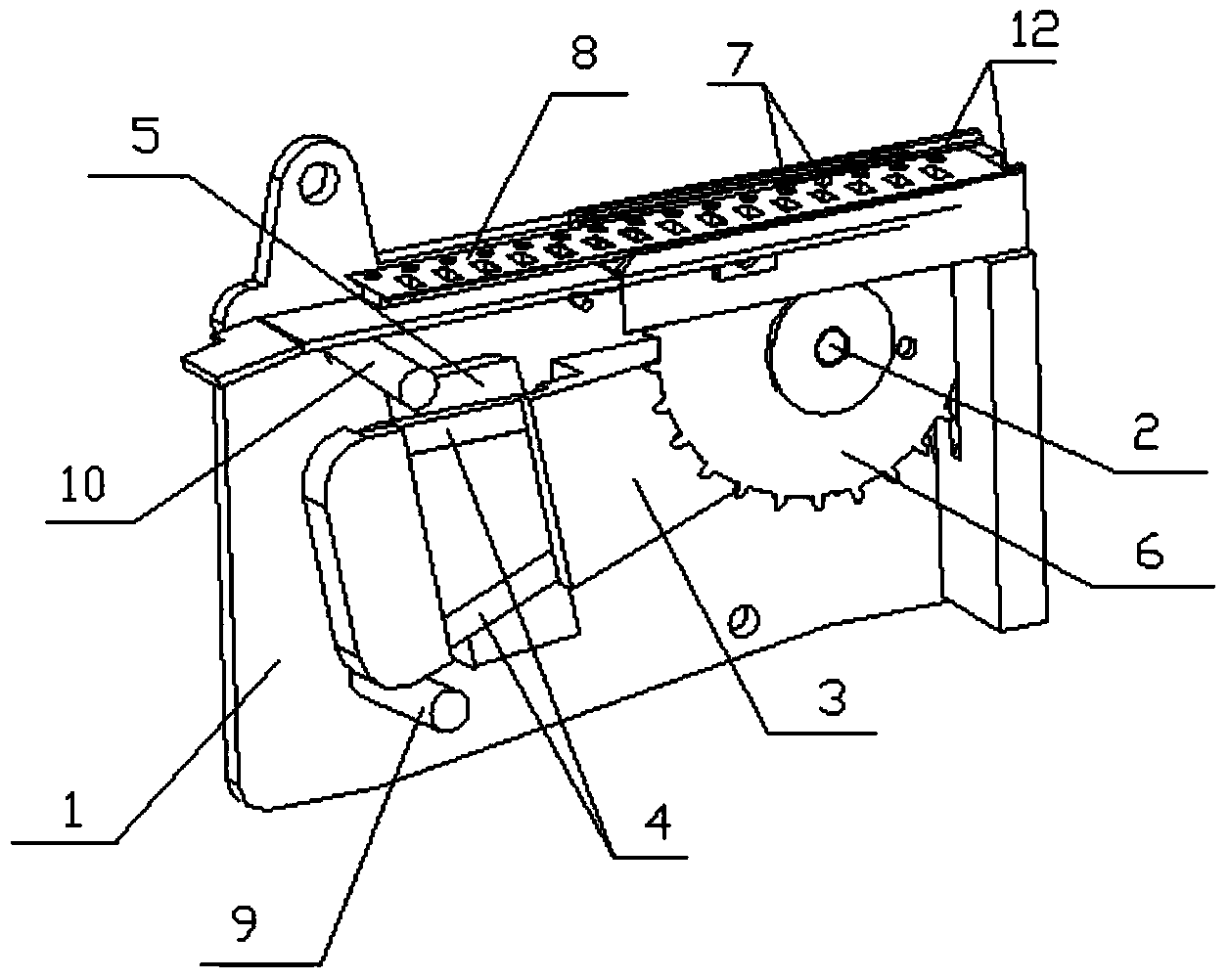

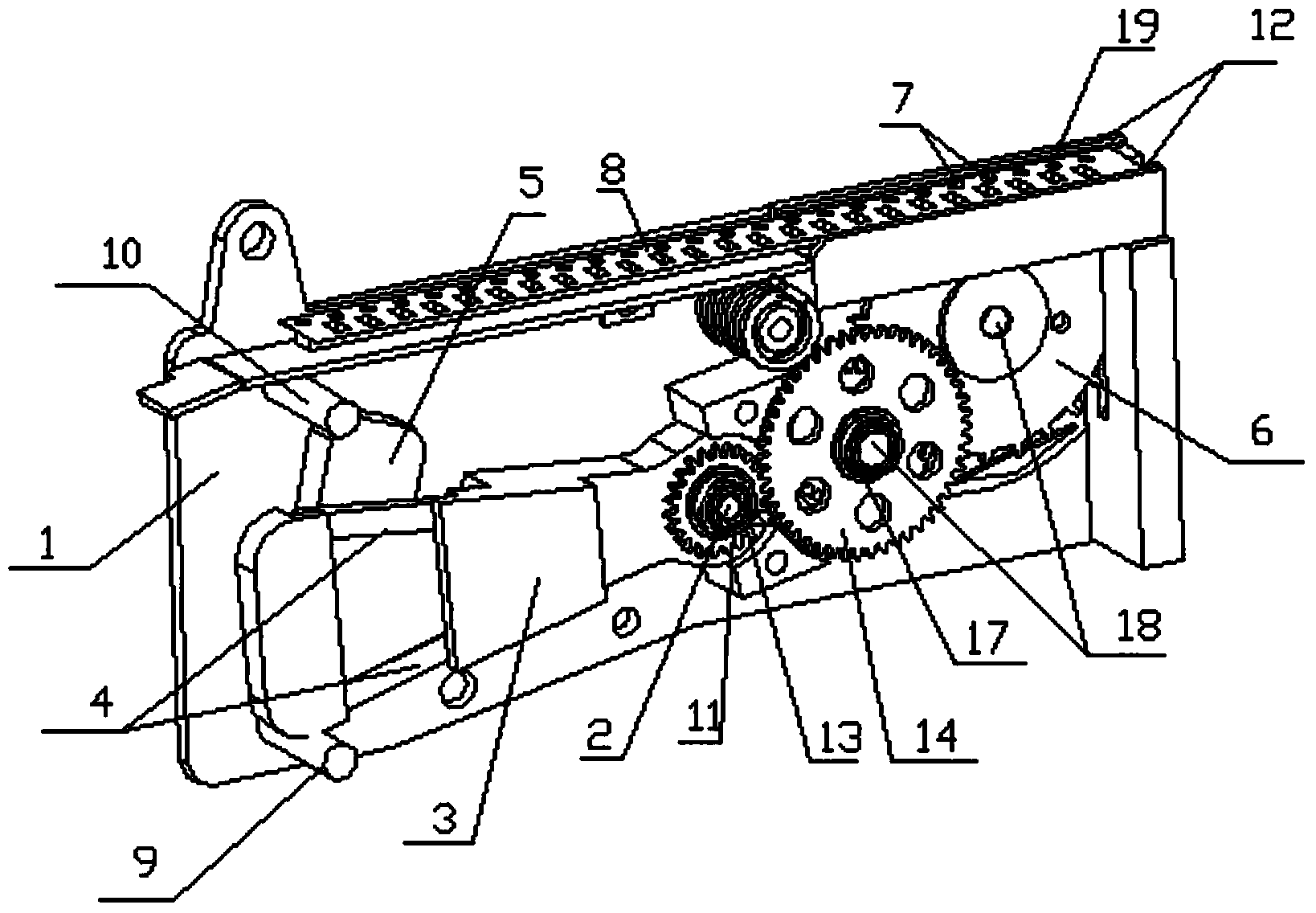

Automatic centering clamping feeding and discharging device

InactiveCN101898218ARealize feedRealize functionMetal-working feeding devicesPositioning devicesElectric machineryEngineering

The invention discloses an automatic centering clamping feeding and discharging device, which comprises a base. One end of the base is provided with a cylinder; a cylinder connector is movably connected with two connecting rods; the topmost end of the cylinder connector is connected with a guide rod; the guide rod passes through a guide sleeve which is fixed on the base; the two connecting rods are connected with two rocker arms through a hinge pin, and the rocker arms are fixed on the base; the tail ends of the rocker arms are provided with pinch rolls; the base is also provided with a motor; the center of a motor shaft of the motor is coincided with a rocker arm hinge pin; and the motor shaft is connected with the pinch rolls through a belt. The automatic centering clamping feeding and discharging device controls the opening and closing of the pinch rolls by using cylinder driving and matching with the connecting rods; and the pinch rolls can rotate positively or negatively so as torealize the function of feeding and discharging driven by the motor fixed at the rocker arm hinge pin, and an incoming material is centered and fed into finishing equipment automatically in a clampedmode and then is discharged automatically. The automatic centering clamping feeding and discharging device has the advantages of simple structure, flexible action, high production efficiency, convenient operation and the like.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Thin-wall pipe automatic material returning and clamping device

InactiveCN101121232ASimple structureEasy to operateThread cutting feeding devicesMetal-working feeding devicesOne shotBiomedical engineering

The present invention is an automatic material returning and clamping device for tubing of thin wall belonging to the technical field of machine manufacturing. The present invention mainly comprises a supporting plate (1), an internal sliding sleeve (2), a lifting head (3), a clamping spring (8), a material return slip (7) and a connecting screw (9). The supporting plate is equipped with an external sleeve and the clamping spring and internal sliding sleeve are equipped in the external sleeve and can slide in the external sleeve; the upper and lower surfaces of the external sleeve are equipped with a key through hole; the connecting screw is penetrated through the key through hole and connected with a sliding block; the connecting screw can move right and left in the key through hole; the internal sliding sleeve is a hollow cylinder with one open end; the lifting end of the lifting head (3) is processed into a mold corresponding to the tubing finished product. The present invention can realize automatic clamping; by processing the lifting head and knife end face into molds, one-shot molding of thin-wall tubing end face and side can be realized.

Owner:BEIJING UNIV OF TECH

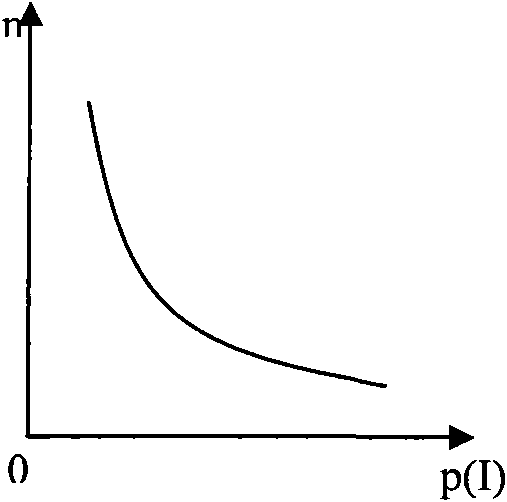

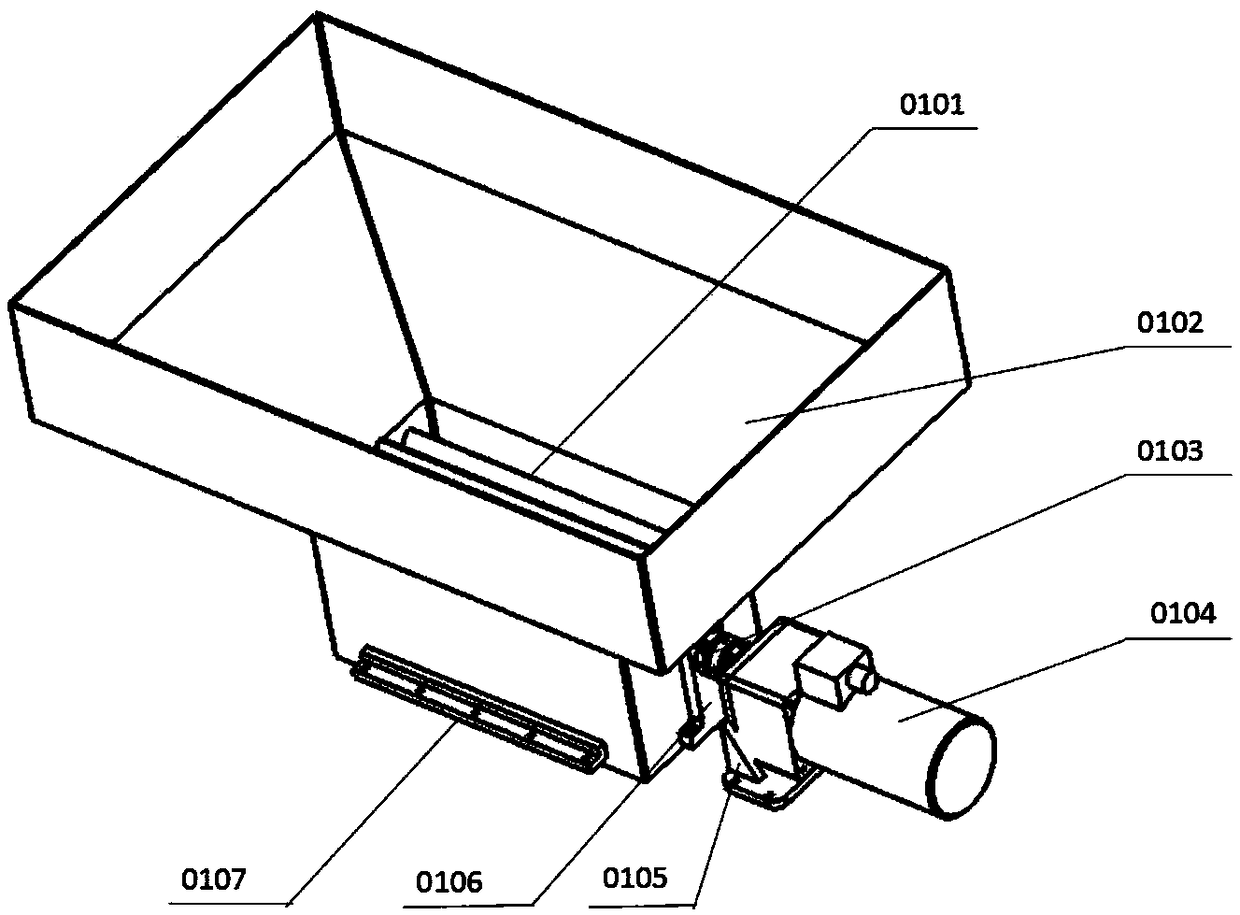

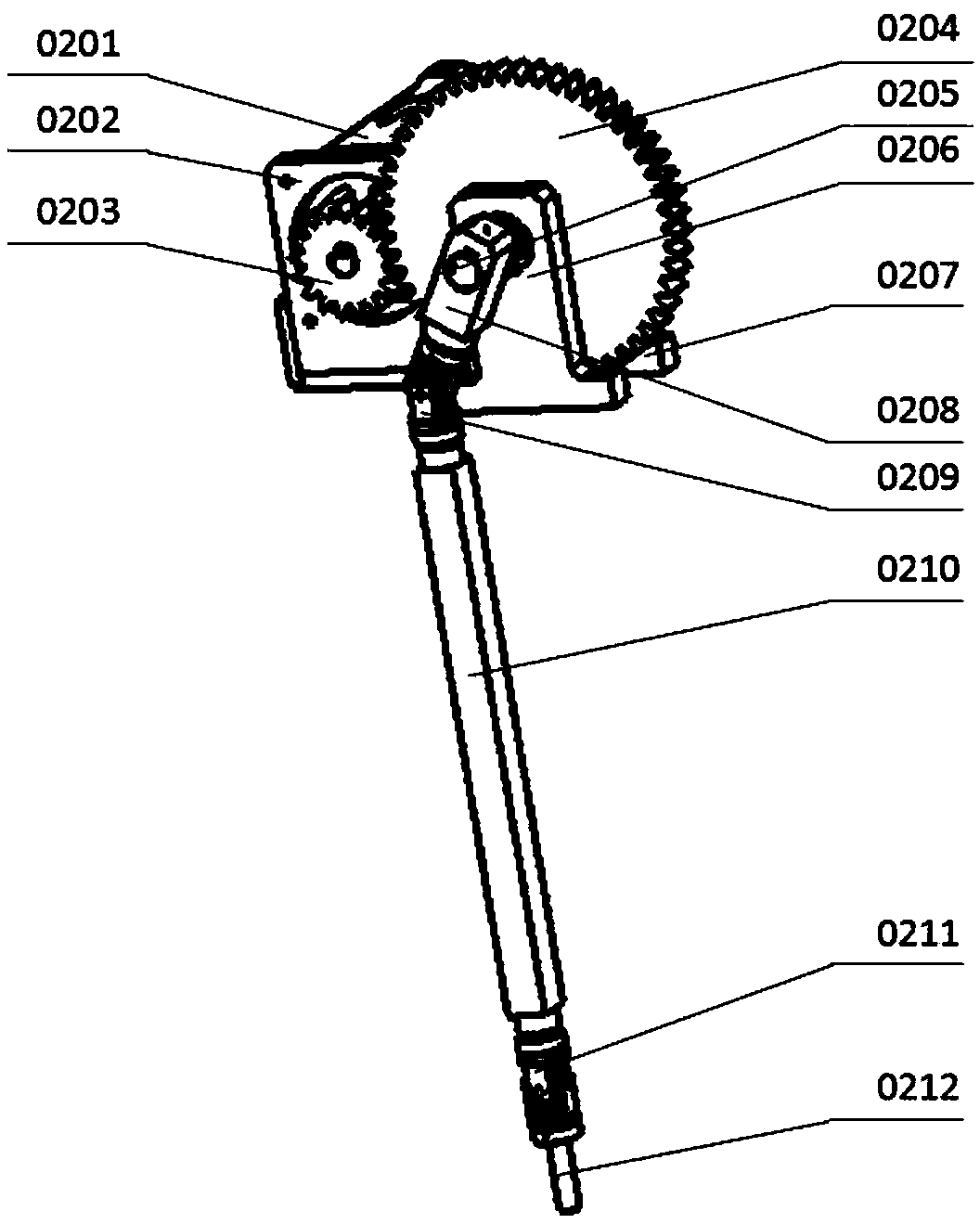

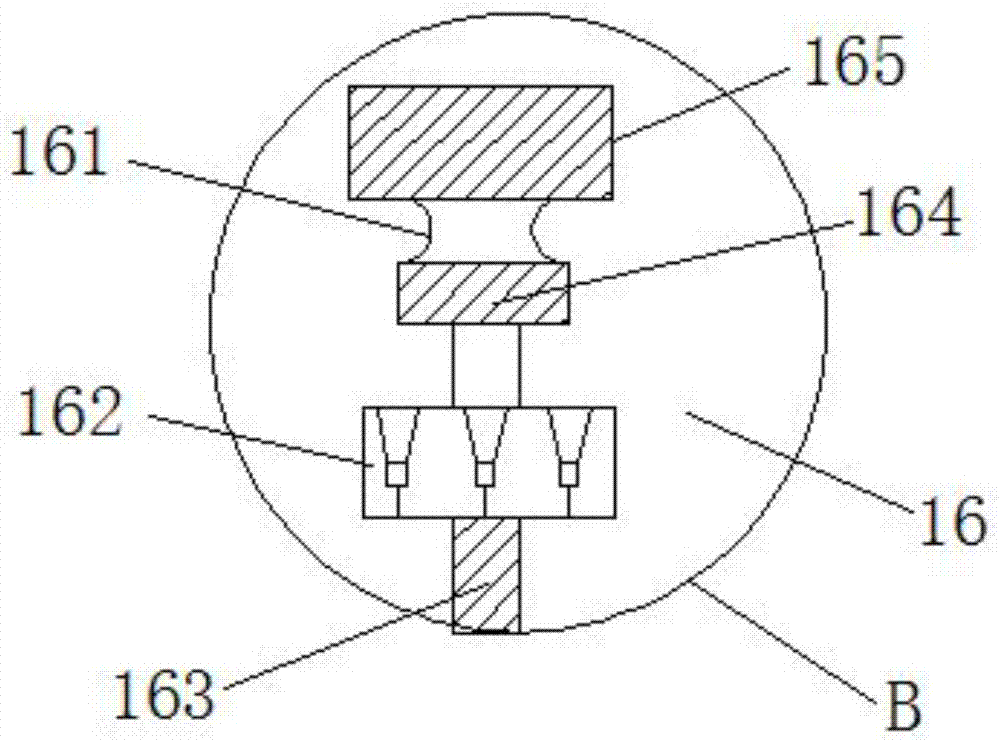

Automatic rotary compression necking device of metal tube

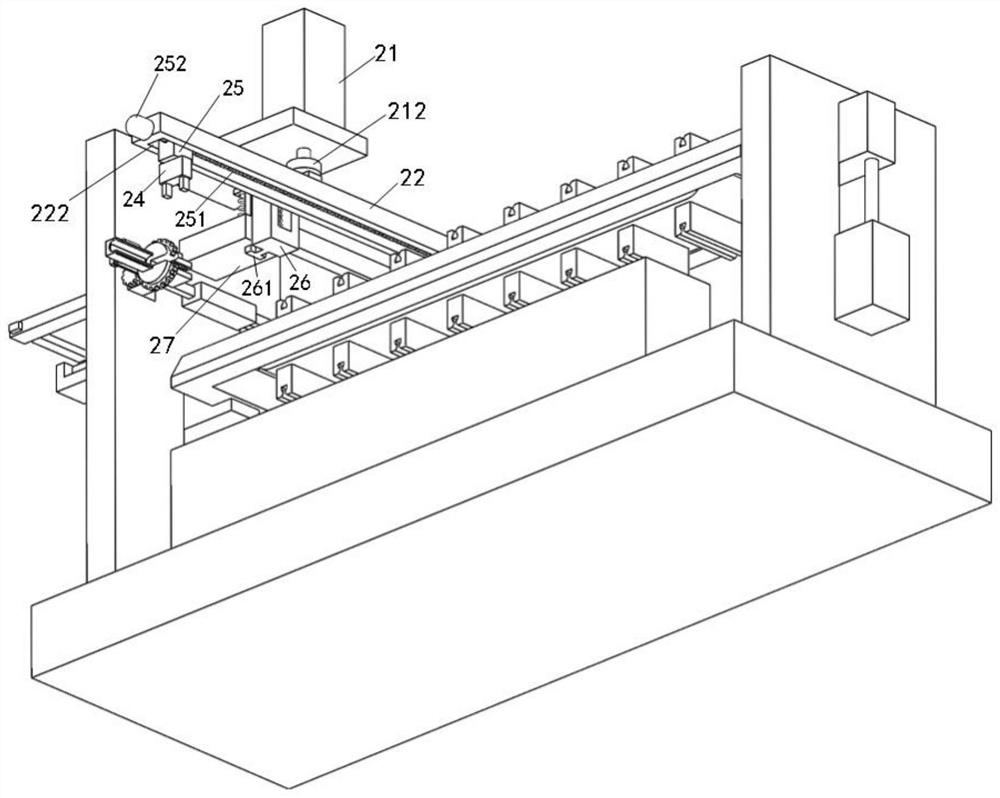

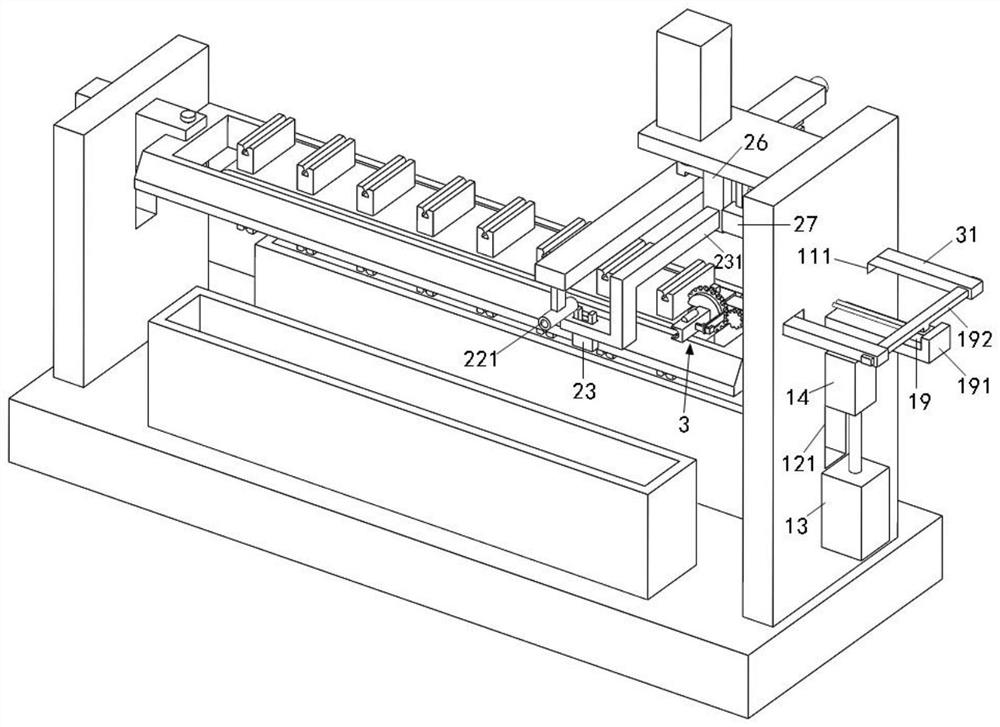

PendingCN108555165AAdjustable lengthPrecise control of necking speedMetal-working feeding devicesPositioning devicesControl systemEngineering

The invention discloses an automatic rotary compression necking device of a metal tube. The device comprises a machine frame, a hopper mechanism, a necking mechanism, a conveying mechanism and a control system, wherein the machine frame is provided with a tabletop plate, and the hopper mechanism, the necking mechanism, the conveying mechanism and the control system are arranged on the machine frame; the hopper mechanism comprises a hopper, and the hopper comprises a hopper bottom plate, hopper middle plates, a hopper baffle plate and an L-shaped tube placing block; the necking mechanism comprises an electric spindle, a linear moving mechanism, a tube clamping mechanism, a lifting type supporting mechanism, a cooling device and a screw rod driving mechanism, and the screw rod driving mechanism uses a servo motor as power; the conveying mechanism comprises a material jacking mechanism, a Z-Y direction two-dimensional moving mechanism, a transmission rod and two conveying double-V rods, and two material jacking V-shaped grooves are formed in each conveying double-V rod in a spaced mode; and the control system comprises a touch screen and a PLC which are connected through circuits. Theautomatic rotary compression necking device for the metal tube is high in machining efficiency, good in quality, high in precision, suitable for necking machining of metal tubes with different lengths and machining parameters, simple to operate and high in automation degree.

Owner:SOUTH CHINA UNIV OF TECH +1

Dual-mode electric vehicle drive motor

InactiveCN101969258ADimensional structure influenceIncrease slot fill rateElectric machinesDC commutatorDrive motorElectric vehicle

The invention discloses a dual-mode electric vehicle drive motor which relates to the field of drive of various electric vehicles. A point on an armature of a series exciter is taken to confirm a reference point of an extension line on which the armature of the series exciter simultaneously becomes an armature of an alternating-current generator; an alternating-current boosting winding is distributed in an armature groove of the series exciter; one end of the boosting winding is connected to the reference point of the series exciter, and the other end is connected to a rectifying circuit; by the method, alternating current the amplitude value of which is higher than power supply voltage on the series exciter is directly obtained; controllable rectification is applied to the alternating current; and the rectified alternating current is directly fed to a power supply. The method realizes control on the rotating speed of the series exciter and efficient conversion on energy at work, and the series exciter also realizes the function of the alternating-current generator, therefore, a system comprises a set of independent series exciter loop and function and also comprises a set of independent alternating-current generator loop and function, and the two modes coexist and are mutually restricted and influenced to form the dual-mode motor.

Owner:孟庆良

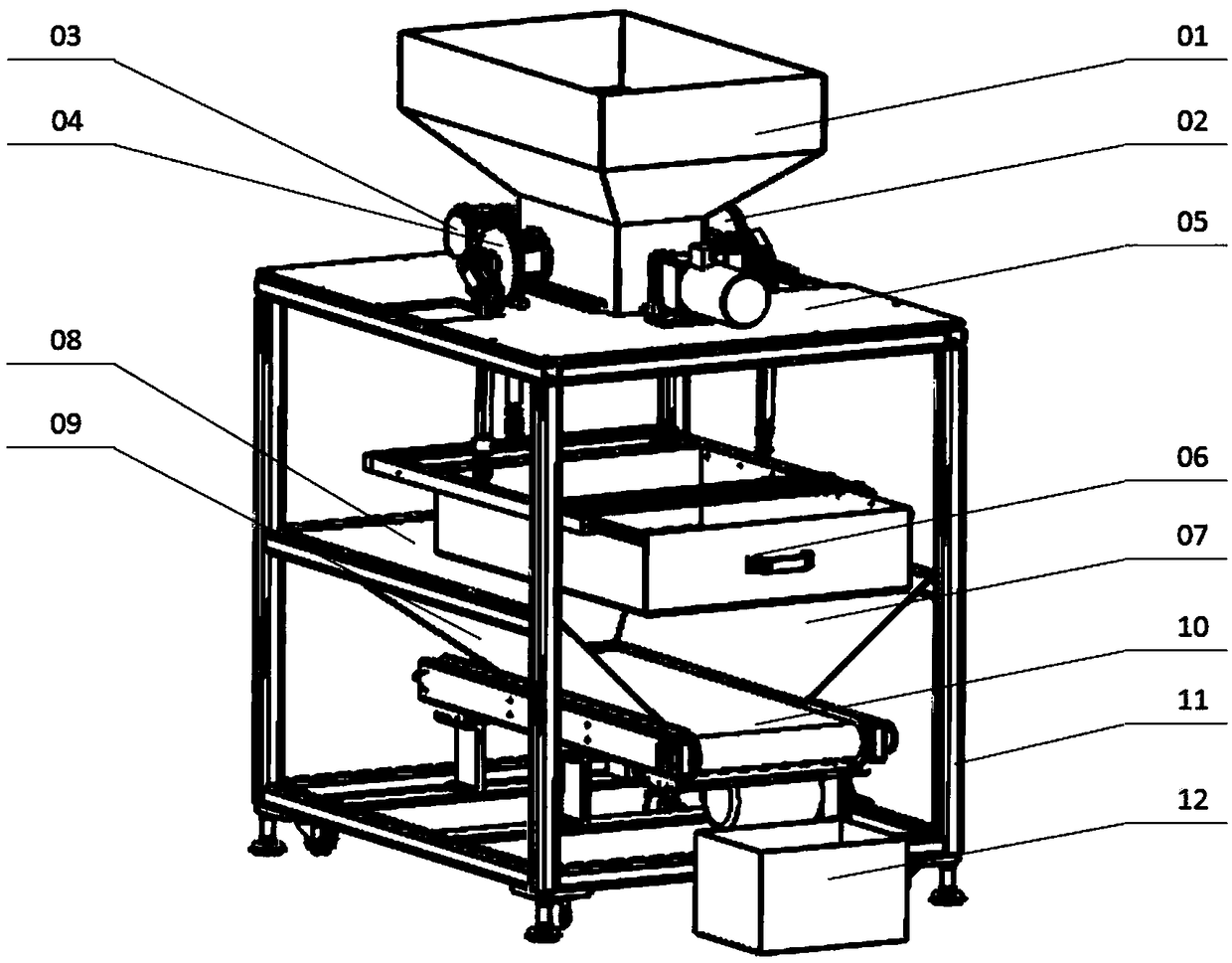

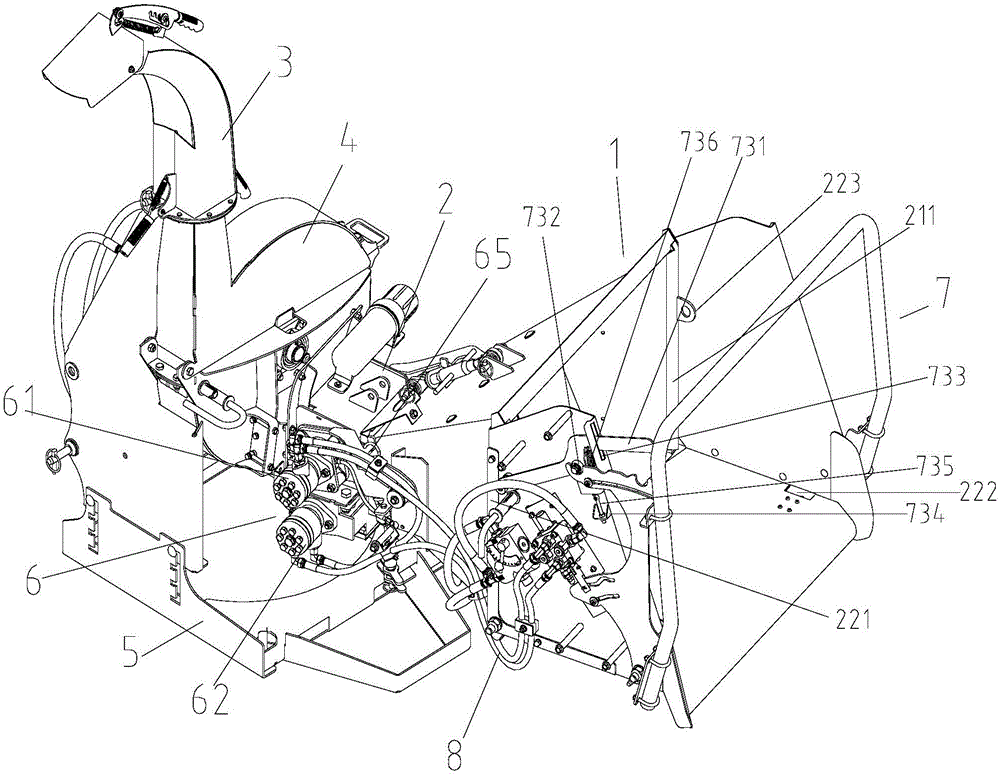

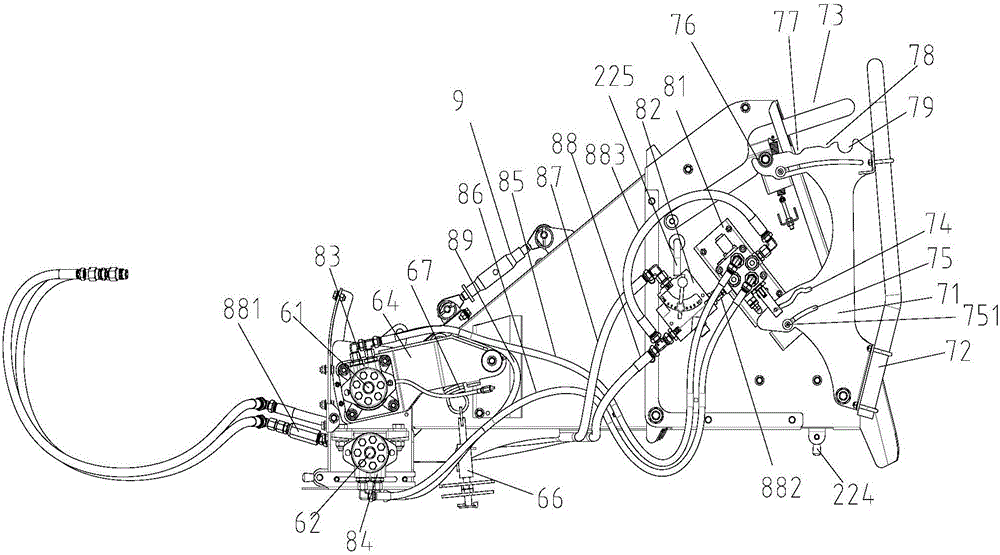

Maggot material separation multi-dimensional vibrating screen with material feeding and discharging device

The invention discloses a maggot material separation multi-dimensional vibrating screen with a material feeding and discharging device, and particularly relates to the field of vibrating screens. Thescreen comprises a material storage bin assembly, a first branch chain, a second branch chain, a third branch chain, a vibrating screen platen, a screen frame assembly, a first baffle, a second baffle, a third baffle, a belt conveying assembly, a rack and a material collection frame; a material falls into a screen frame of the vibrating screen; the three branch chains are connected with a power assembly through three rotating pairs, two-time rotation and one-time movement of the screen frame are simultaneously achieved through the rotating pairs, universal joints and screw rods respectively, the controllable mechanical separation of fly maggots and maggot manure is achieved at last, and the screening efficiency of separating a mixture of the fly maggots and a culture medium is improved; after screening is finished, the maggot manure fallen on a belt conveyor is collected into the material collection frame through the belt conveying assembly, the fly maggots remaining in the screen frame can be drawn out of a screen framework along with the screen frame, and the process of collecting the fly maggots is completed. The whole vibrating screen is small in spatial size, high in rigidityand stable and reliable in screening performance, and has practical significance for factory application.

Owner:JIANGSU UNIV

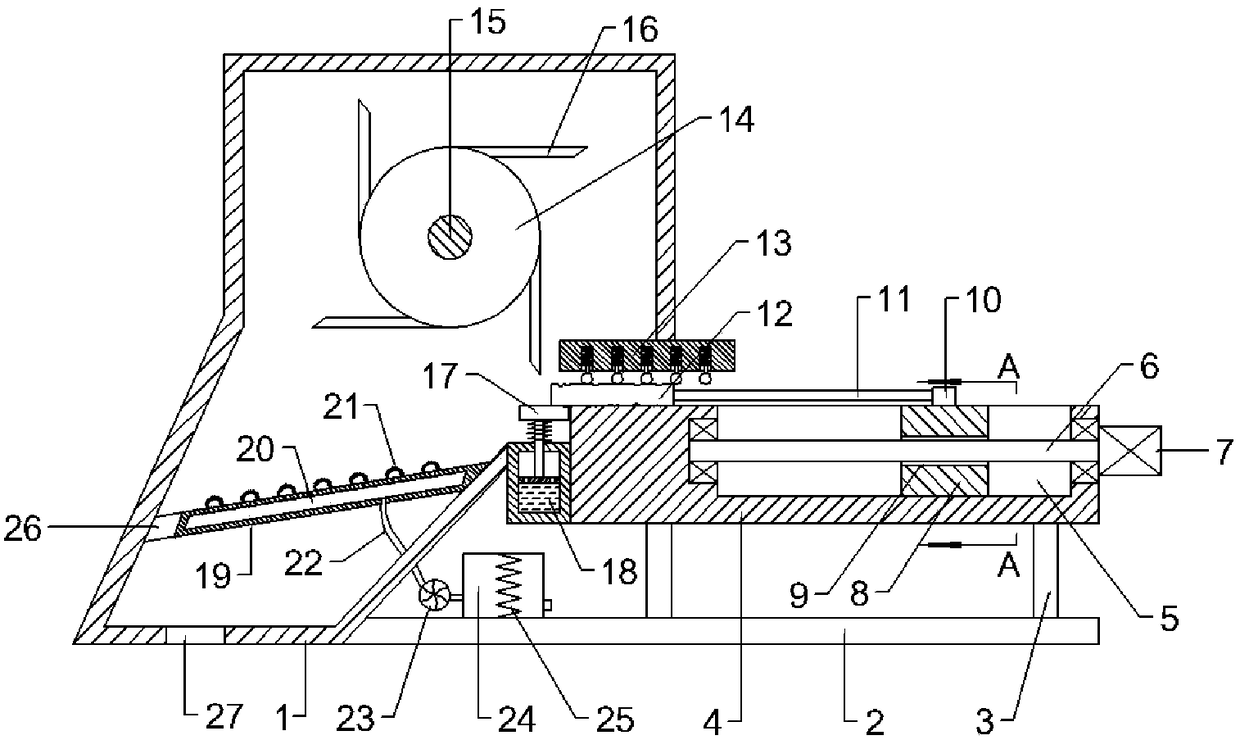

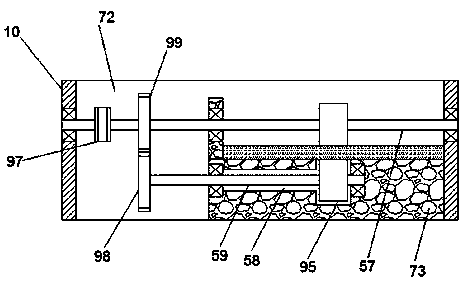

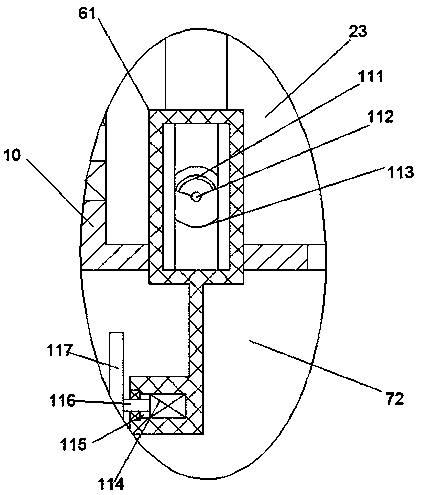

Ganoderma lucidum karst slicing and drying integration processing facility with bearing plate retreating function

InactiveCN108098873ARealize feedChange the length of the movementDrying gas arrangementsMetal working apparatusWork periodMotor drive

The invention provides a ganoderma lucidum karst slicing and drying integration processing facility with a bearing plate retreating function. The ganoderma lucidum karst slicing and drying integrationprocessing facility with the bearing plate retreating function comprises a shell. A base plate is fixedly connected with the lower side of the shell, and the upper side of the base plate is fixedly connected with a mounting plate through a plurality of supporting columns. The mounting plate is horizontally arranged. A moving groove is formed in the mounting plate, the opening of the moving grooveis upwards formed, a moving block is arranged in the moving groove, and a threaded through hole is formed in the moving block. The ganoderma lucidum karst slicing and drying integration processing facility with the bearing plate retreating function has the following advantages that a motor drives a threaded rod to rotate, the moving block which is matched with the threaded rod moves leftwards anddrives a push plate to move towards the left side through a mounting block, the push plate enables a piece of ganoderma lucidum karst to be moved towards the left side, and therefore feeding of the ganoderma lucidum karst is achieved; when feeding is conducted, intermittent power supply can be conducted on the motor, then the push plate can conduct intermittent movement, and therefore slicing isconveniently conducted; and the working time of the motor is adjusted to change the movement length of the push plate, and therefore adjustment of the slicing thickness can be achieved.

Owner:徐中春

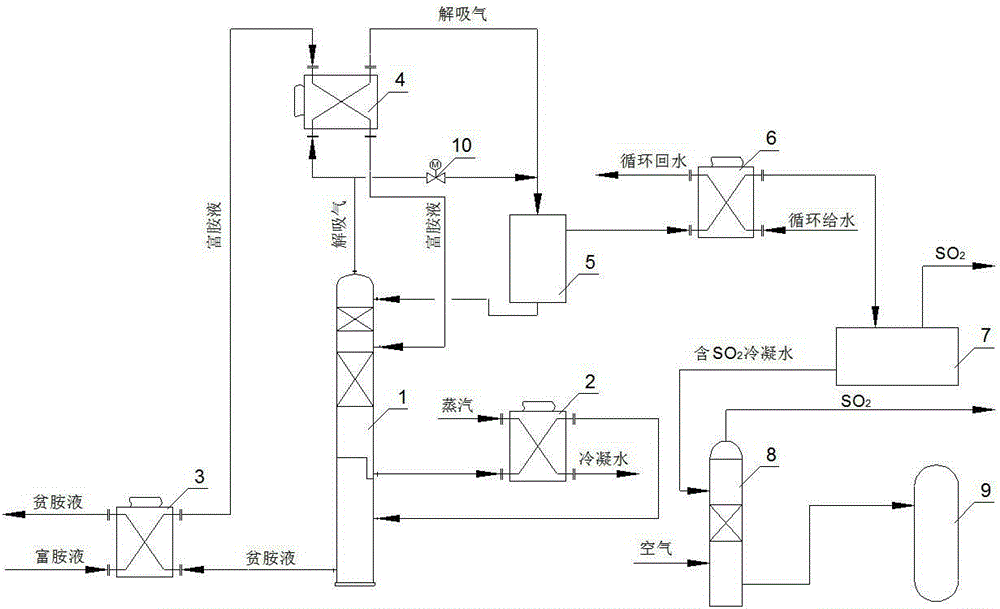

Organic amine wet flue gas desulphurization and desorption system with high-efficiency and low-energy consumption

ActiveCN105233689AReduce usageReduce cooling water consumptionDispersed particle separationReboilerChiller

The invention relates to an organic amine wet flue gas desulphurization and desorption system with high-efficiency and low-energy consumption. The desorption system comprises a desorber, a reboiler, a lean / rich amine liquid heat exchanger, a rich amine heater, a primary separator, a condensation cooler, a secondary separator, a desorption tower, an amine liquid purifying system and an electric regulating valve. A high-temperature saturated steam containing SO2 (desorbed gas for short) at the top of the desorber is directly used as a secondary heating medium of a rich amine liquid, so that the rich amine liquid entering the tower is at bubble point temperature; an integrated process system comprising step-by-step condensation cooling waste heat utilization of the high temperature desorbed gas, charging of the rich amine liquid at bubble point temperature, and backflow of a condensation liquid at bubble point temperature is used, so that effective reuse of the waste heat andreduced amounts of cooling water and heating steam are realized, the SO2 desorption efficiency of the desorber is improved, and the energy-saving effect is substantial.

Owner:TONGLING NON FERROUS METAL GROUP CORP +1

Perishable garbage biological disposal system and method for disposing perishable garbage by applying system

PendingCN108202078APromote growthWith heat preservation and moisturizingSolid waste disposalClimate change adaptationIntelligent environmentHermetia illucens

The invention discloses a perishable garbage biological disposal system. The system comprises a garbage pretreatment device, a garbage digestion device and an intelligent environment control device, wherein the garbage digestion device comprises an automatic feeding machine, an insect feeding machine, automatic deodorization equipment, a digestion bed surface, cleaning equipment, disinfecting equipment and automatic discharging equipment; the garbage pretreatment device comprises a barrel turning machine, a grinding machine, a material storage tank and deodorization spraying equipment; and theintelligent environment control device comprises a temperature sensor, a humidity sensor, an illumination sensor and a microcomputer control device. The invention further discloses a method for disposing the perishable garbage based on the perishable garbage biological disposal system. According to the perishable garbage biological disposal system and a method for disposing the perishable garbageby applying the system, a method for disposing the perishable garbage by using hermetia illucens is large in disposal capacity, short in disposal time and low in cost, so that the perishable garbageis digested, the objective of making perishable garbage be transformed into feed is achieved, economic benefits are increased, and sustainable development is facilitated.

Owner:浙江青草地环境科技有限公司

Environmental-friendly iron sheet processing device for protective fence of road

InactiveCN111468800AImprove suction efficiency and qualityRealize automatic absorptionGas flame welding apparatusRoadway safety arrangementsEnvironmental geologyStructural engineering

The invention relates to an environmental-friendly iron sheet processing device for a protective fence of a road, relates to the field of iron sheet processing, and solves the problems that the physical and psychological health of an operator is easily affected persistently as it is unable to absorb harmful gas generated by cutting the iron sheet automatically when the iron sheet is tailored, andthe iron sheet is relatively poor in structural property and relatively low in cutting efficiency as linkage for automatic feeding in a pushing, pulling and cutting process cannot be achieved. The environmental-friendly iron sheet processing device for the protective fence of the road comprises a base. A cutting structure is mounted on the base, and a gas collecting structure is mounted on the cutting structure. The bottom end surface of a compressed gas cylinder is in contact with the top end surface of a limiting block and the top end surface of the limiting block is of an inclined structurewhich is high on the left side and low on the right side. When a sliding seat is pulled to move rightward, the compressed gas cylinder is in a stretched inhaling state at the moment, so that exhaustgas generated by cutting is absorbed automatically in the cutting process.

Owner:刘加英

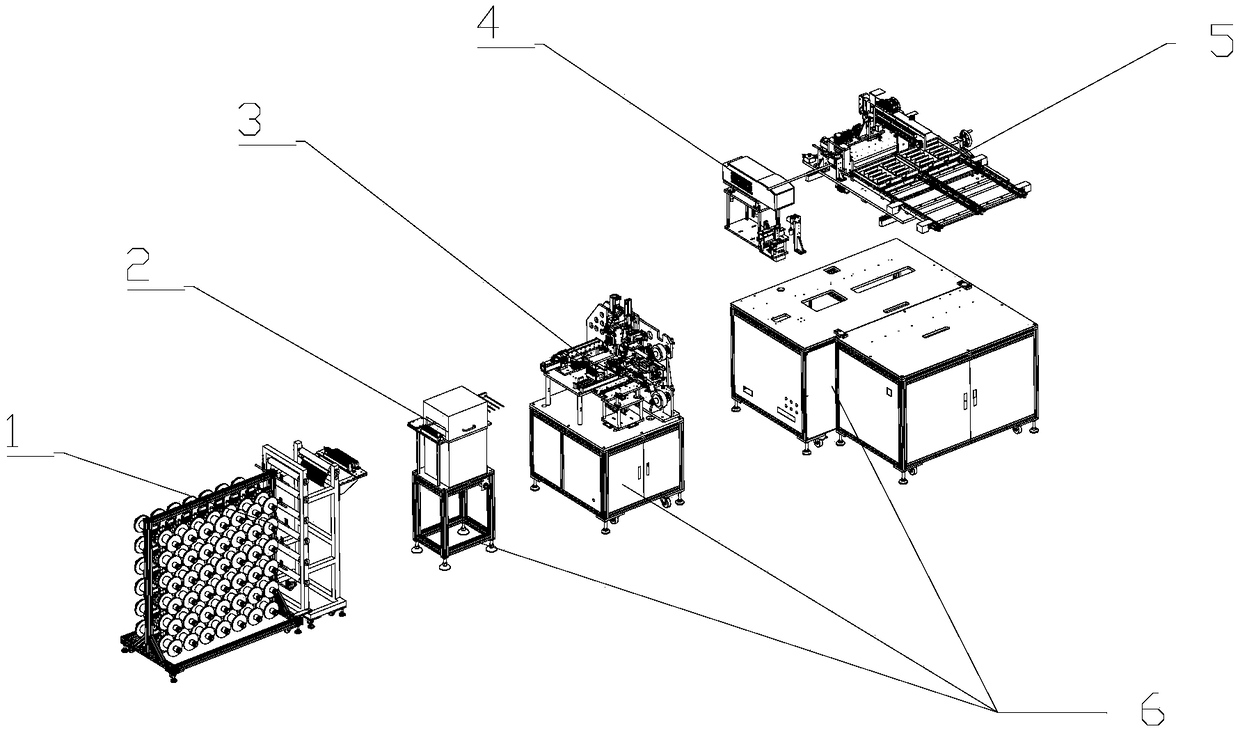

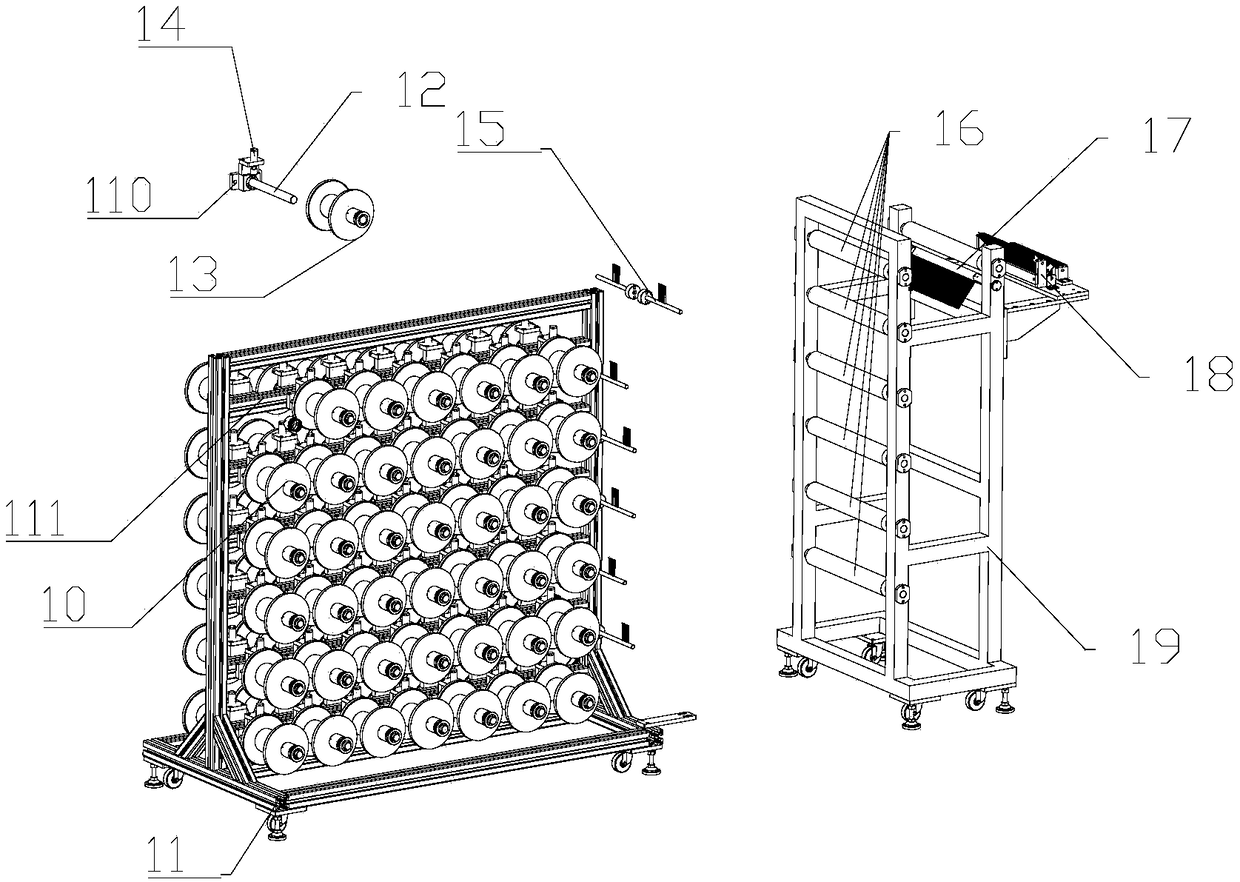

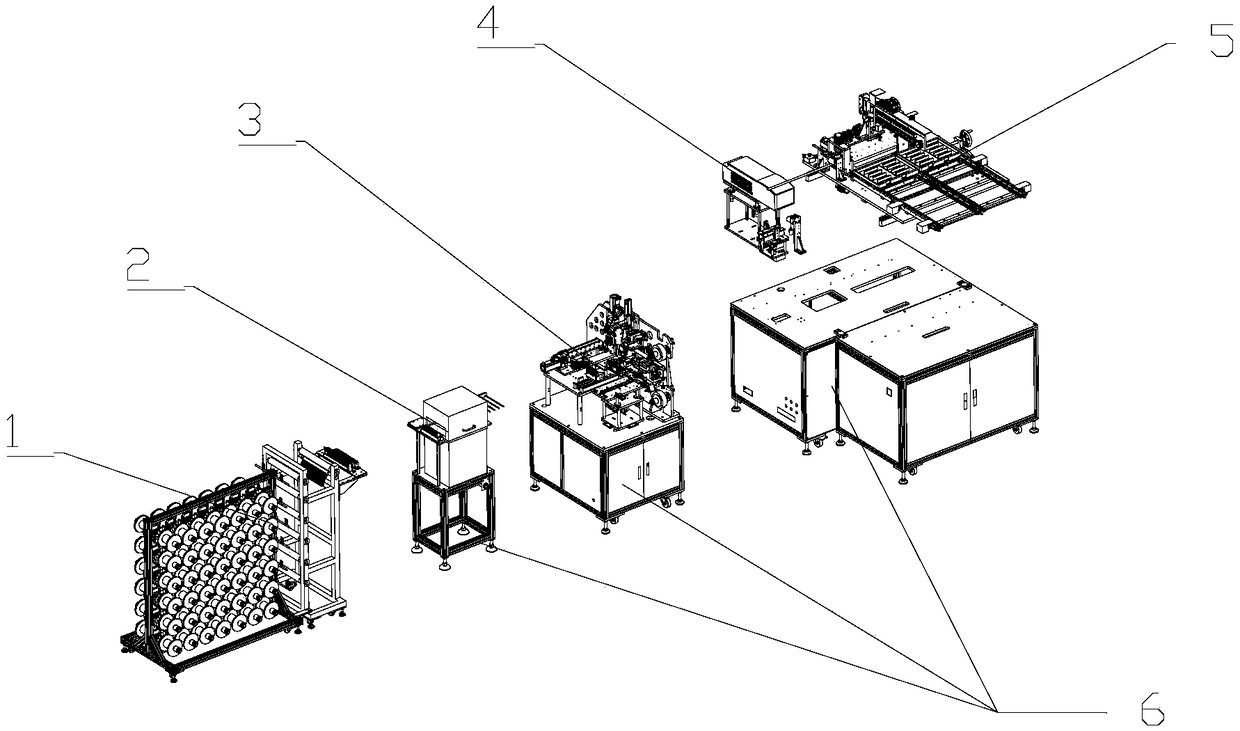

Battery forward and backward welding machine

InactiveCN102248282ARealize feedFully automatedWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryEngineering

The invention relates to a battery forward and backward welding machine, comprising a laser welding device and a welding table, wherein a battery front laser welding device and a back laser welding device are arranged on the welding table surface, a battery forward and backward turning and transmitting device is arranged between the two welding devices, a primary feeding device is arranged at one side of the front laser welding device, a feed bin is arranged at the front side of the primary feeding device, a secondary feeding device is arranged at one side of the back laser welding device, and a storage silo is arranged at the front side of the secondary feeding device. In the invention, the battery forward and backward turning and transmitting device is arranged, thus the front and back surfaces of a battery can be continuously welded by the same machine; and the primary feeding device, the secondary feeding device, the feed bin and the storage silo are arranged, the automation of charging, welding and feeding is realized, the efficiency is high, and the quality is stable.

Owner:ZHONGSHAN TIANMAO BATTERY

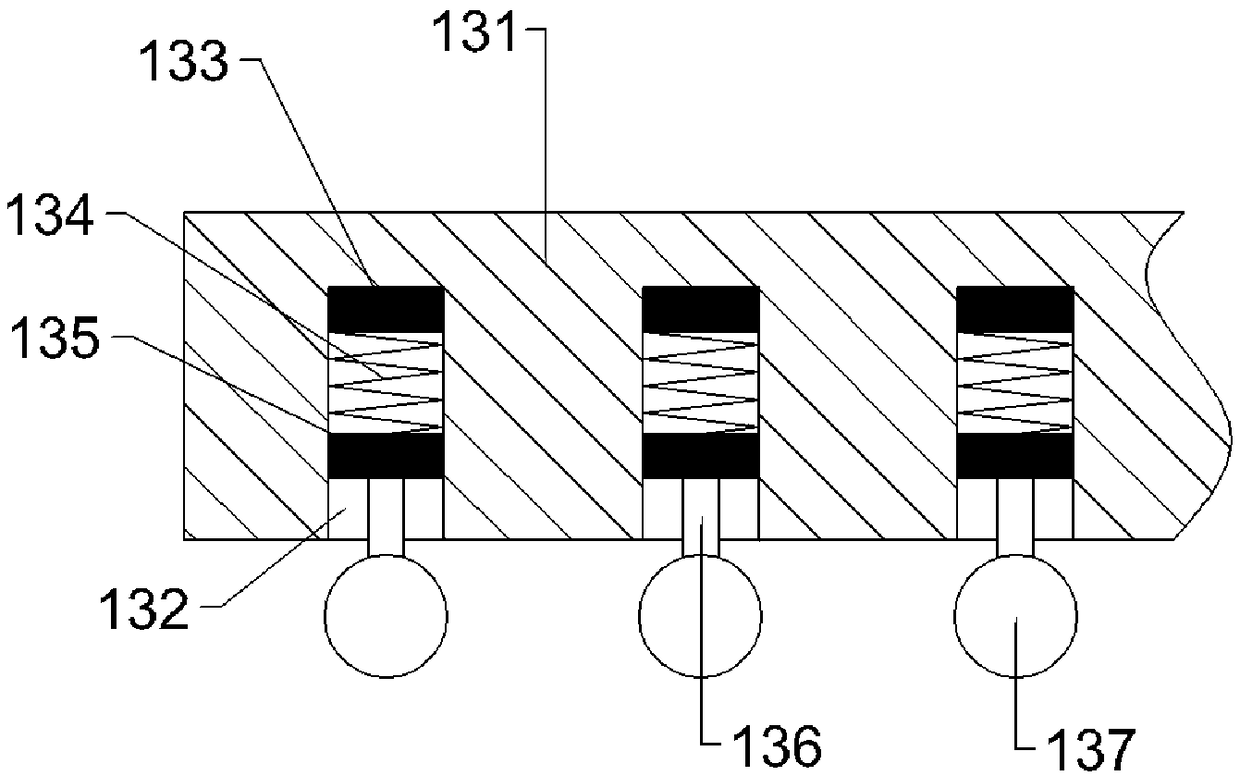

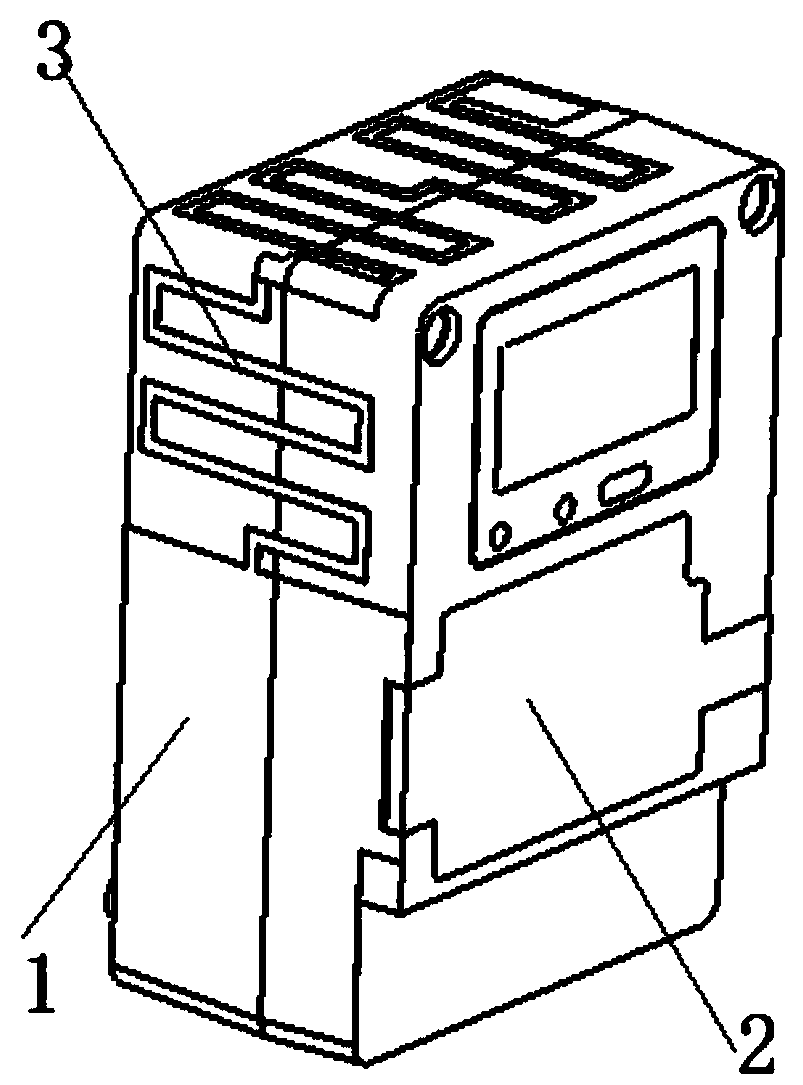

Material belt charging device of chip mounter

InactiveCN103747630ARealize feedEasy to controlPrinted circuit assemblingElectrical componentsEngineeringVoice coil

The invention provides a material belt charging device of a chip mounter. The material belt charging device of the chip mounter comprises the following parts of a swing type voice coil motor for providing powder, a shell and a mounting shaft which are used for fixing the position of the voice coil motor, and a charging wheel driven by the voice coil motor for charging of a material belt, wherein the charging wheel is provided with charging wheel matched with material belt holes. According to the material belt charging device of the chip mounter, as the swing type voice coil motor is adopted for providing power, the size and cost of the charging device are reduced and the material belt charging device is suitable for a small-sized desk chip mounter.

Owner:NEODEN TECH CO LTD

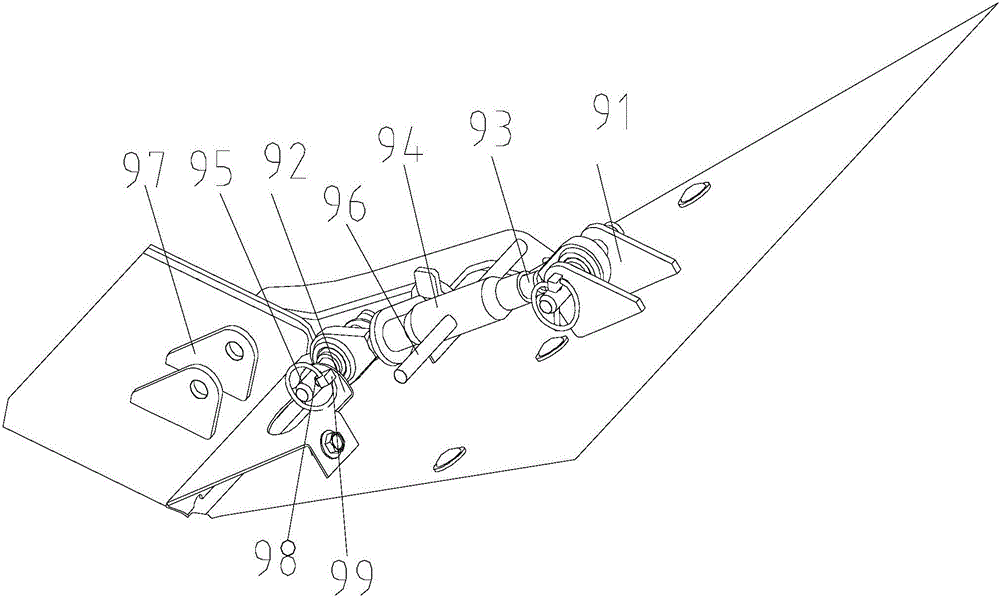

Flexible circuit board rubberizing mechanism, rubberizing device and flexible circuit board production device

InactiveCN109362186ARealize feedTo achieve the effect of finishing the wireCircuit board tools positioningNon-metallic protective coating applicationFlexible circuitsEngineering

The invention relates to the technical field of flexible printed circuit board production. A flexible circuit board rubberizing mechanism comprises a mounting board and a rubberizing action component,wherein the rubberizing action component comprises an adhesive paper feeding component, an adhesive paper clamping component, an adhesive paper shifting component and an adhesive paper cutting component. The flexible circuit board rubberizing mechanism has the advantage that adhesive paper can be automatically conveyed, clamped, stretched, sucked, cut and pasted onto a wire.

Owner:王朝火

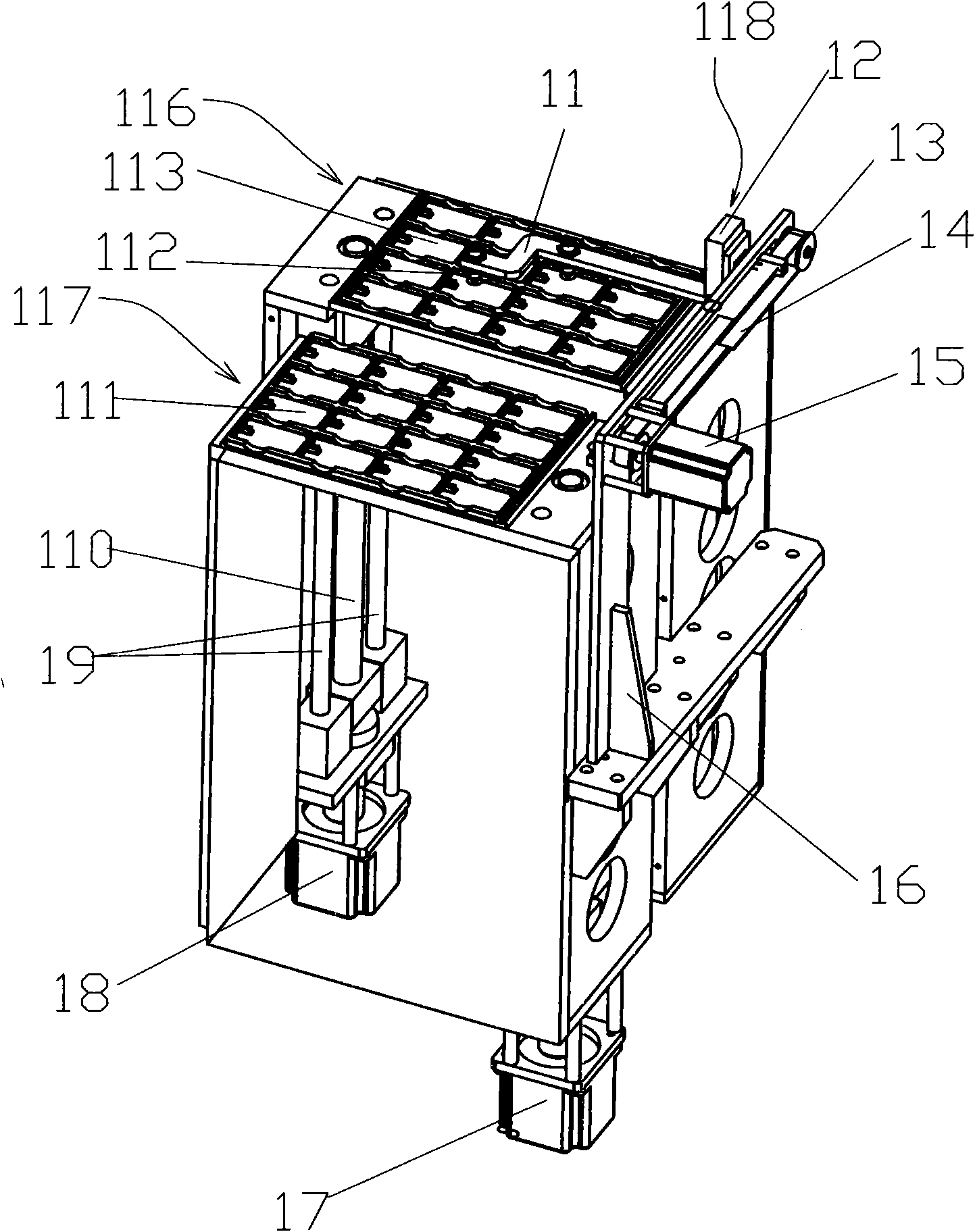

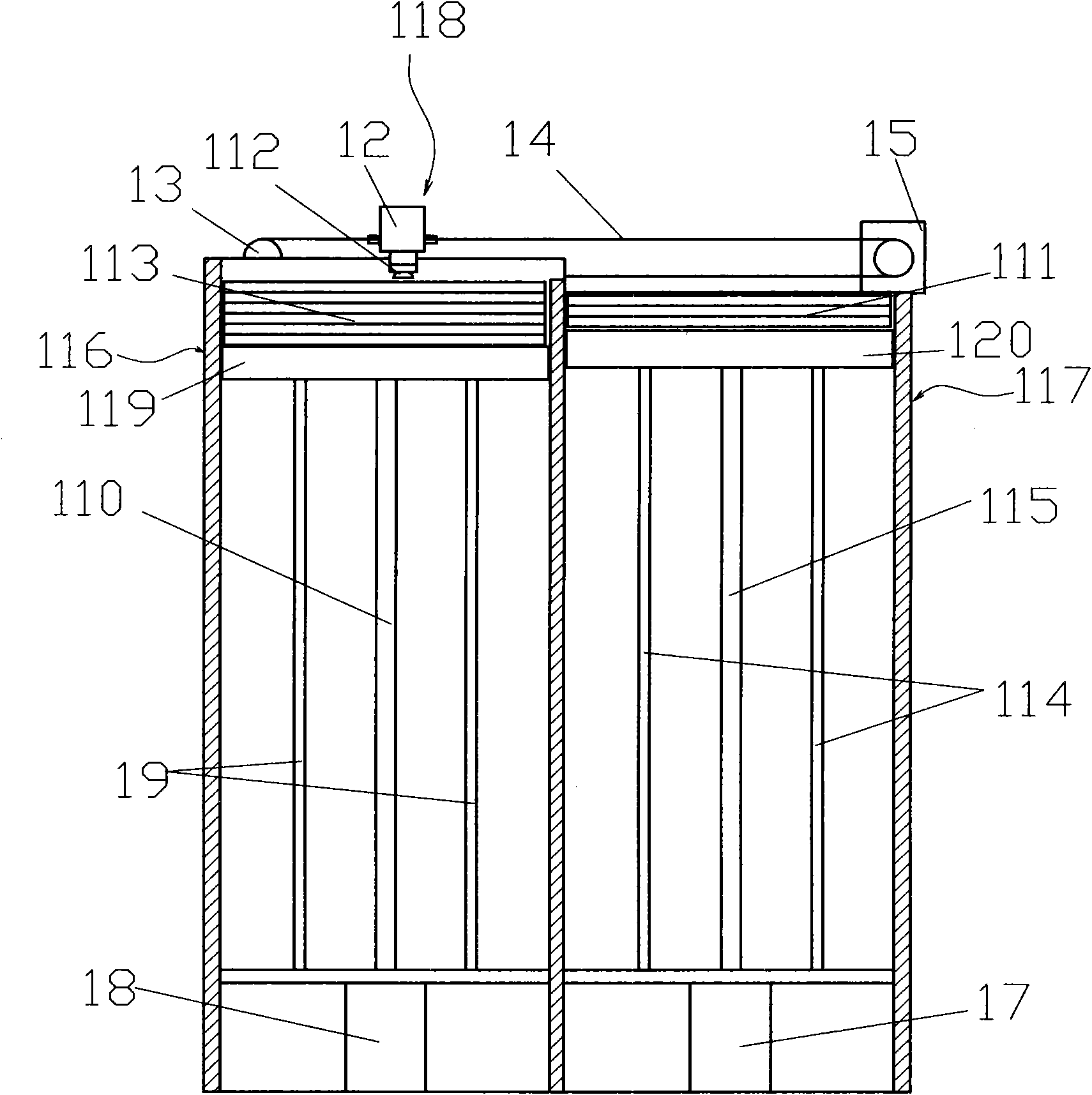

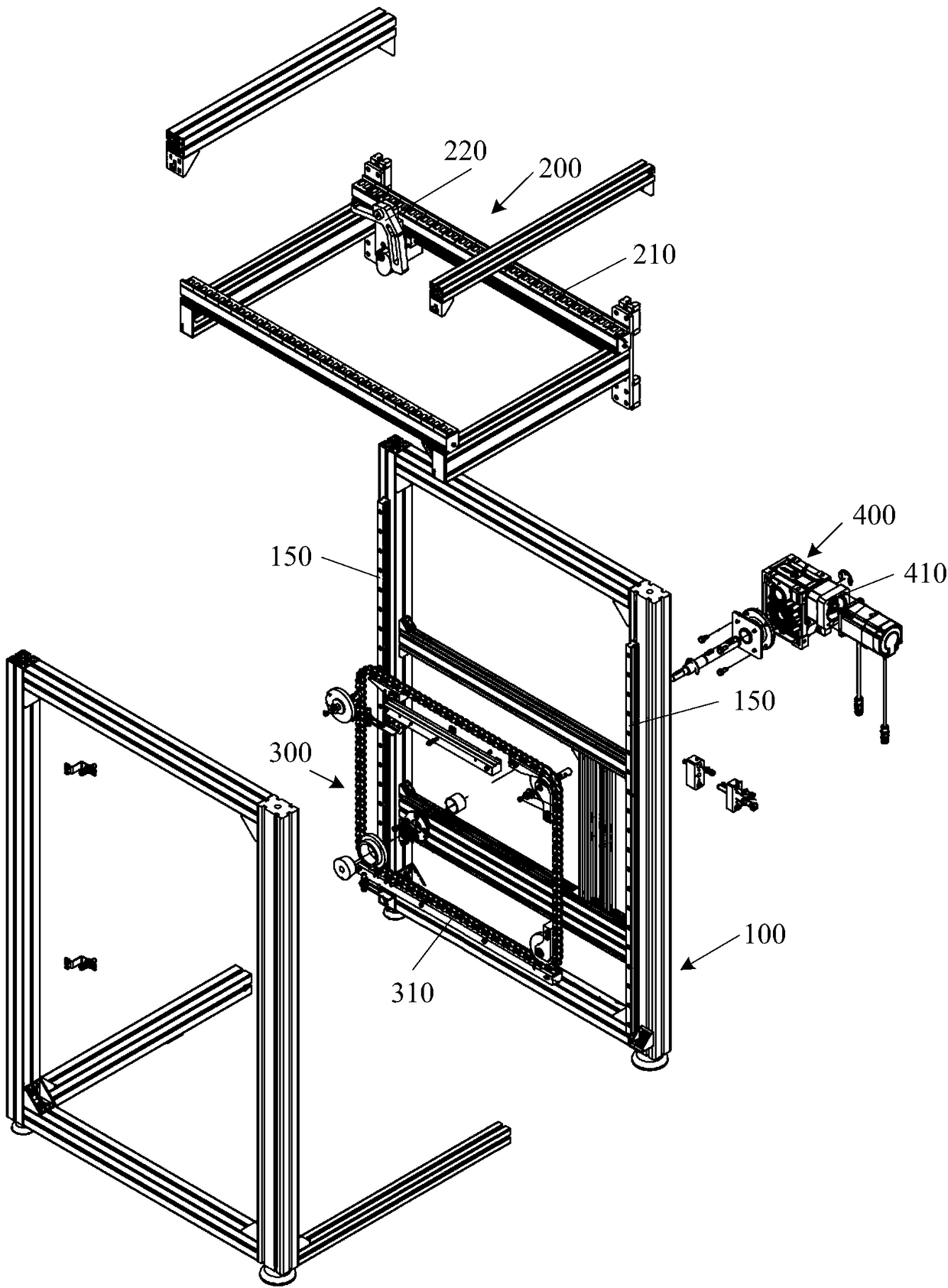

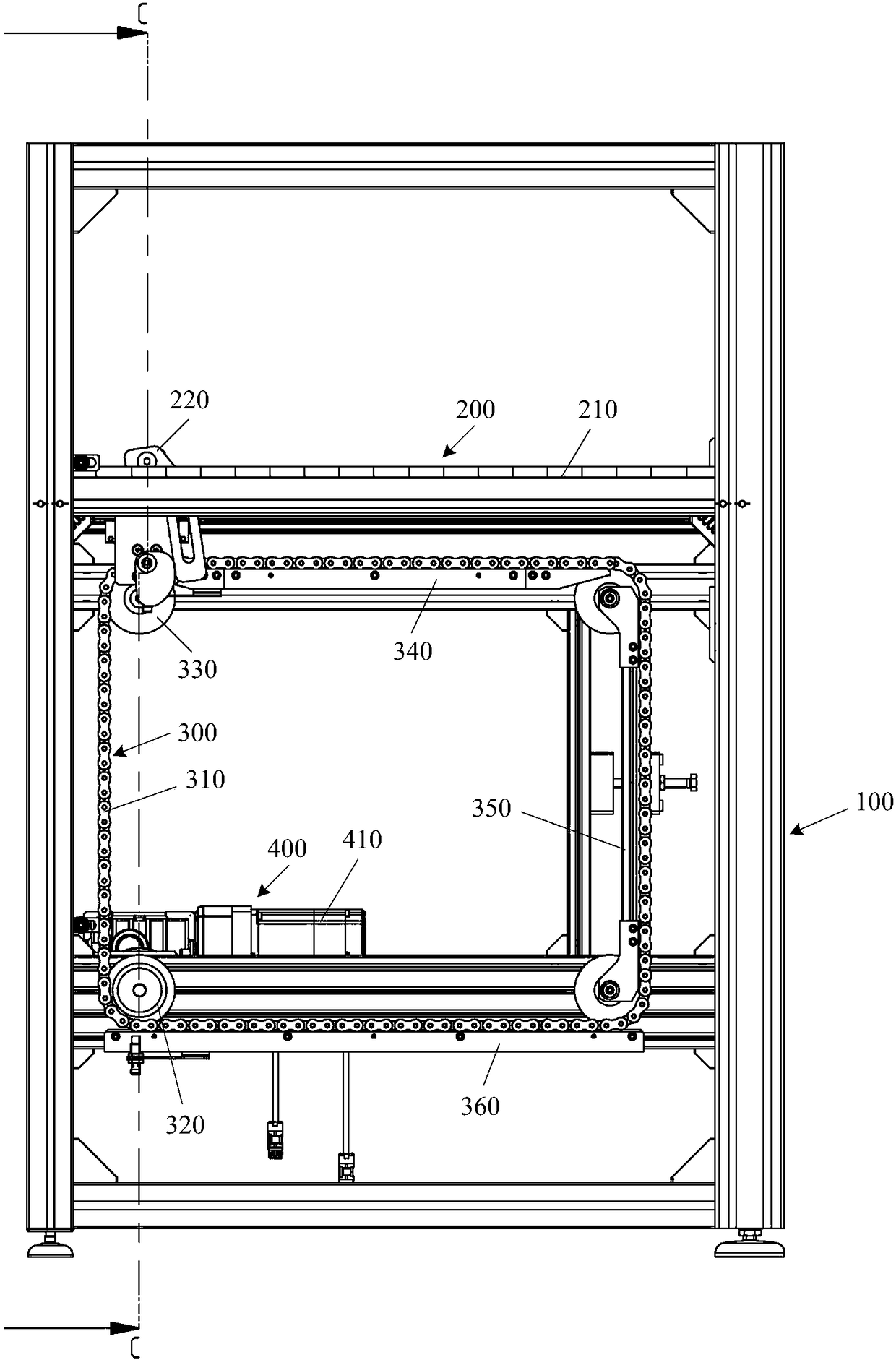

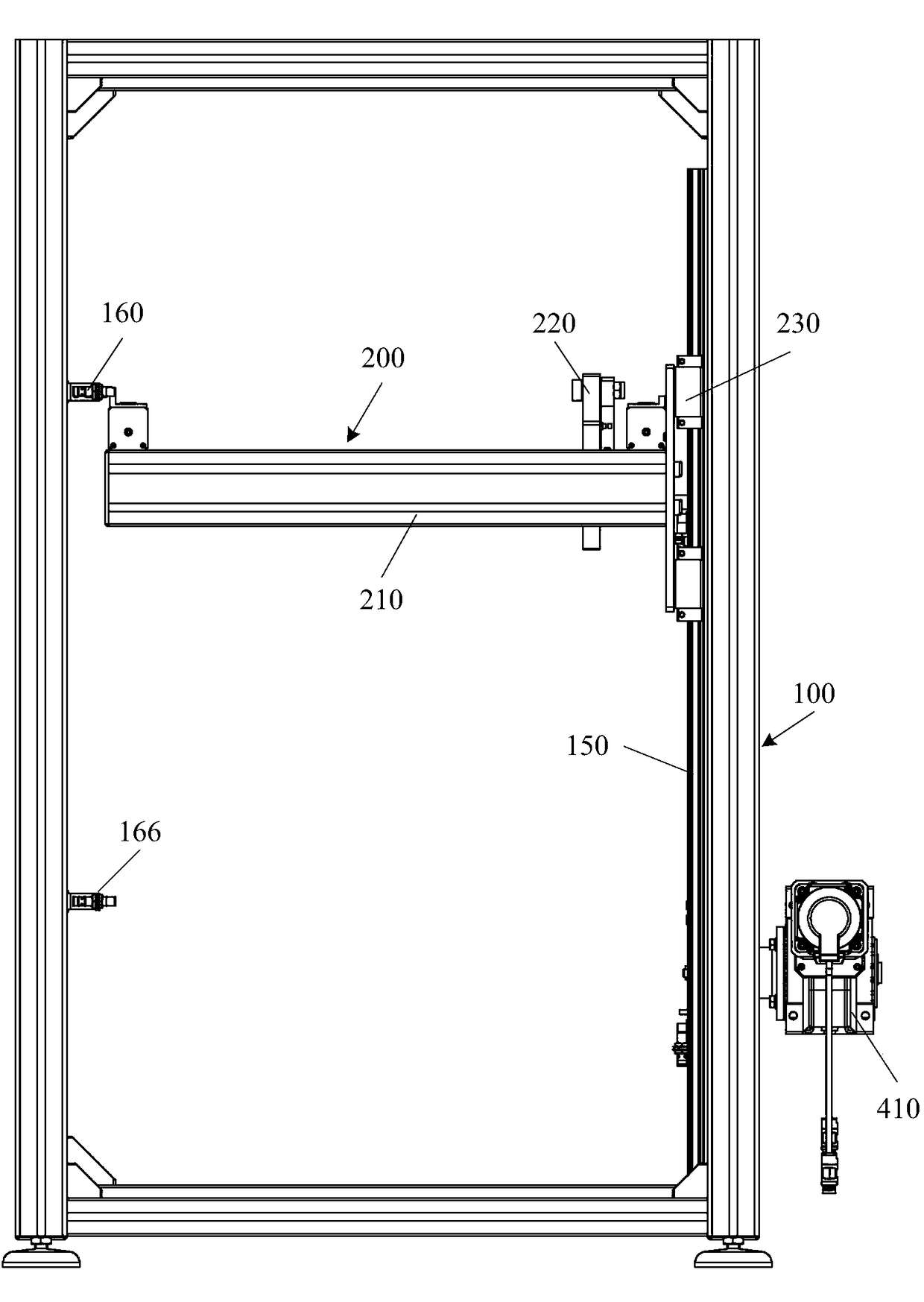

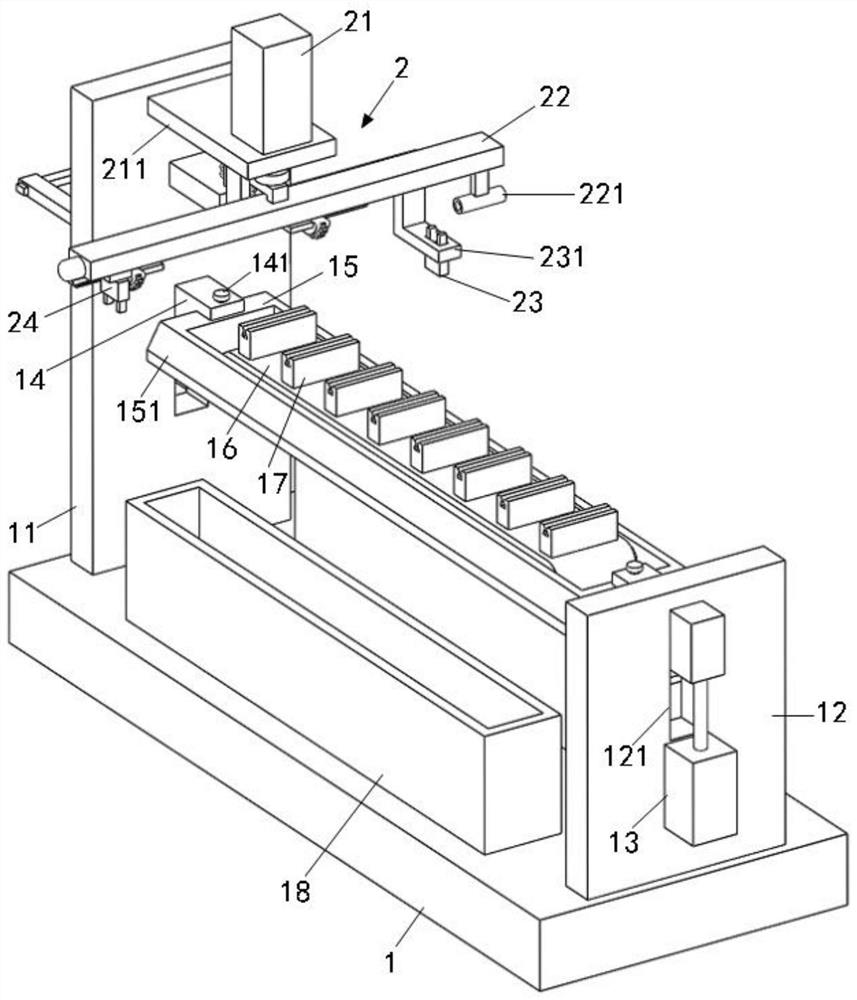

Lifting platform for lifting device and lifting device

The invention relates to a lifting platform for a lifting device. The lifting device comprises a machine frame, a driving device and a transmission device; the lifting platform comprises a frame and asliding assembly, wherein the frame comprises guide rails which are arranged horizontally; the sliding assembly comprises a mounting frame, a sliding block, a pushing / pulling component and a drivingshaft; the sliding block is mounted on the mounting frame and can move along the guide rails; the pushing / pulling component is pivotally mounted on the mounting frame through a pivot shaft to push andpull a material on the lifting platform; and the driving shaft can be fixedly connected with the transmission device, wherein the transmission device drives the driving shaft to move so that the sliding assembly moves in the horizontal direction of the frame and the frame moves in the vertical direction of the lifting device, and the driving shaft moves in the same direction in the moving processof the lifting device. The invention also relates to the lifting device comprising the lifting platform. According to the lifting platform for the lifting device and the lifting device, the service life can be prolonged and the structure can be simplified.

Owner:BOSCH REXROTH (XIAN) ELECTRIC DRIVES & CONTROLS CO LTD XIAN

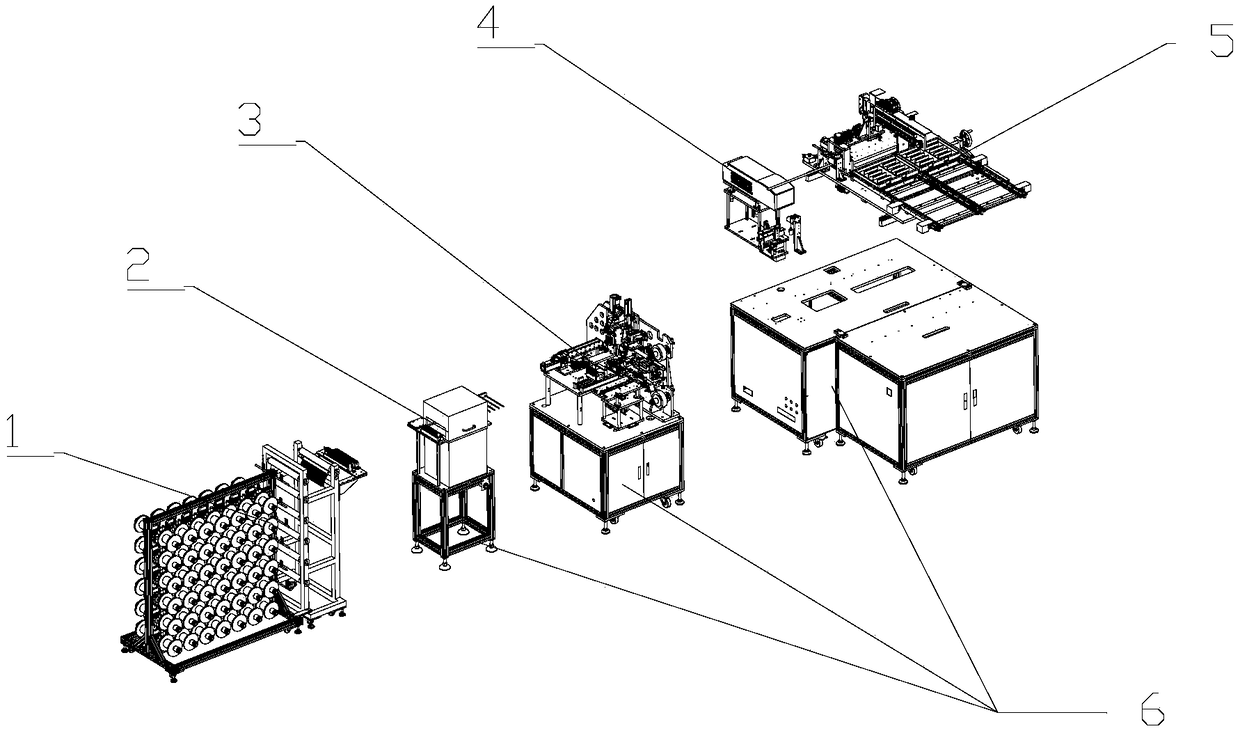

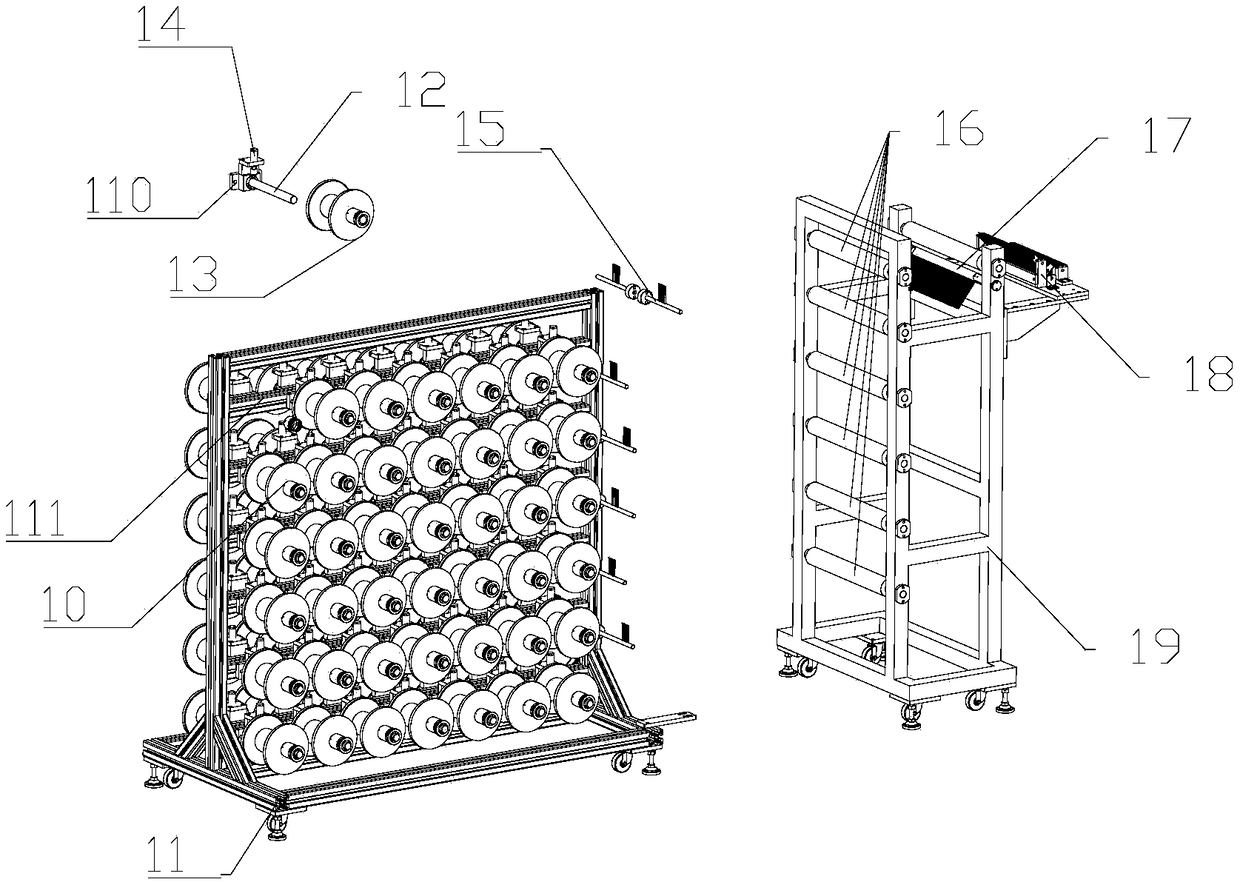

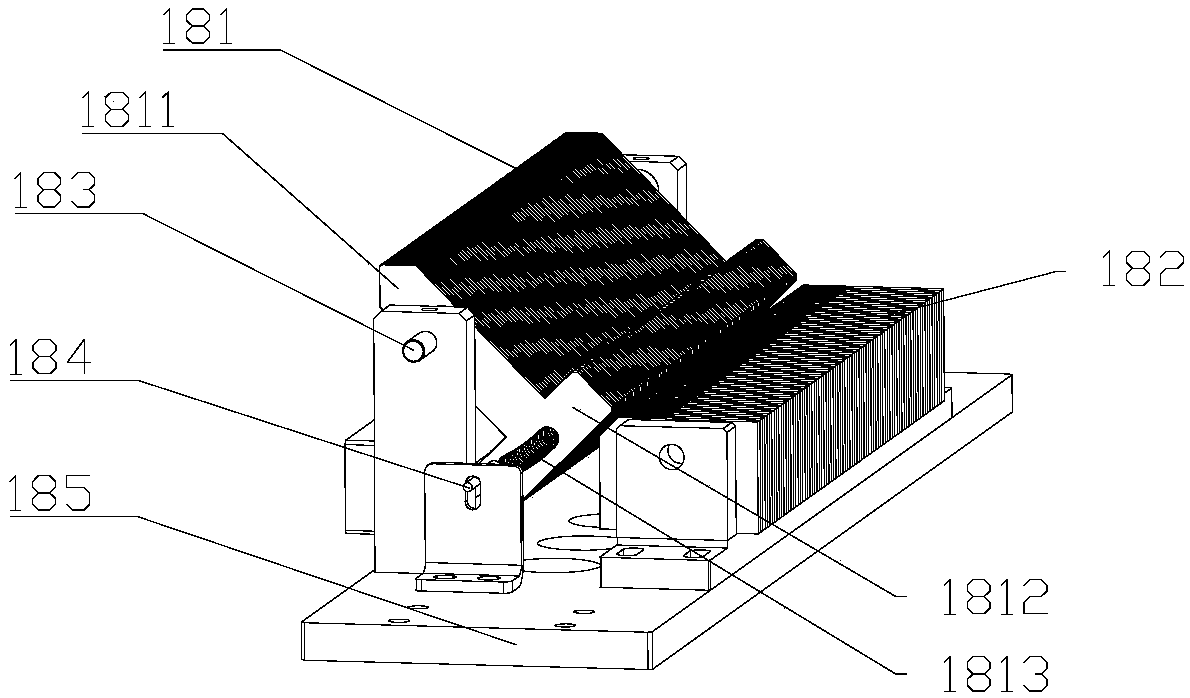

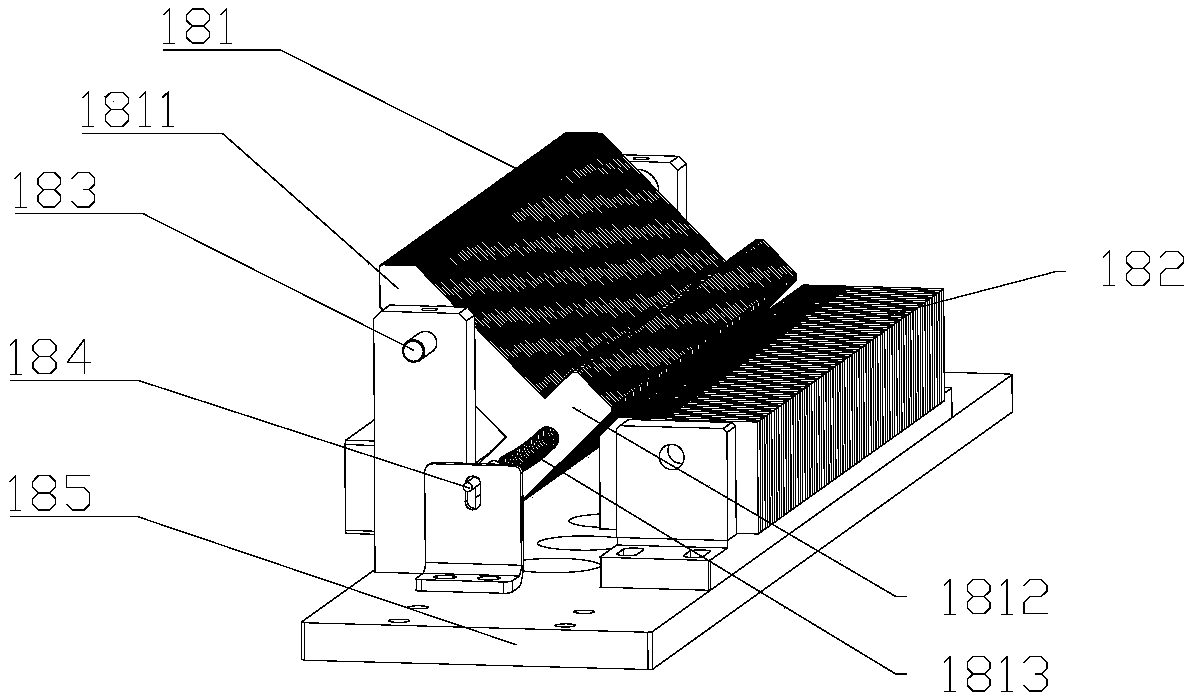

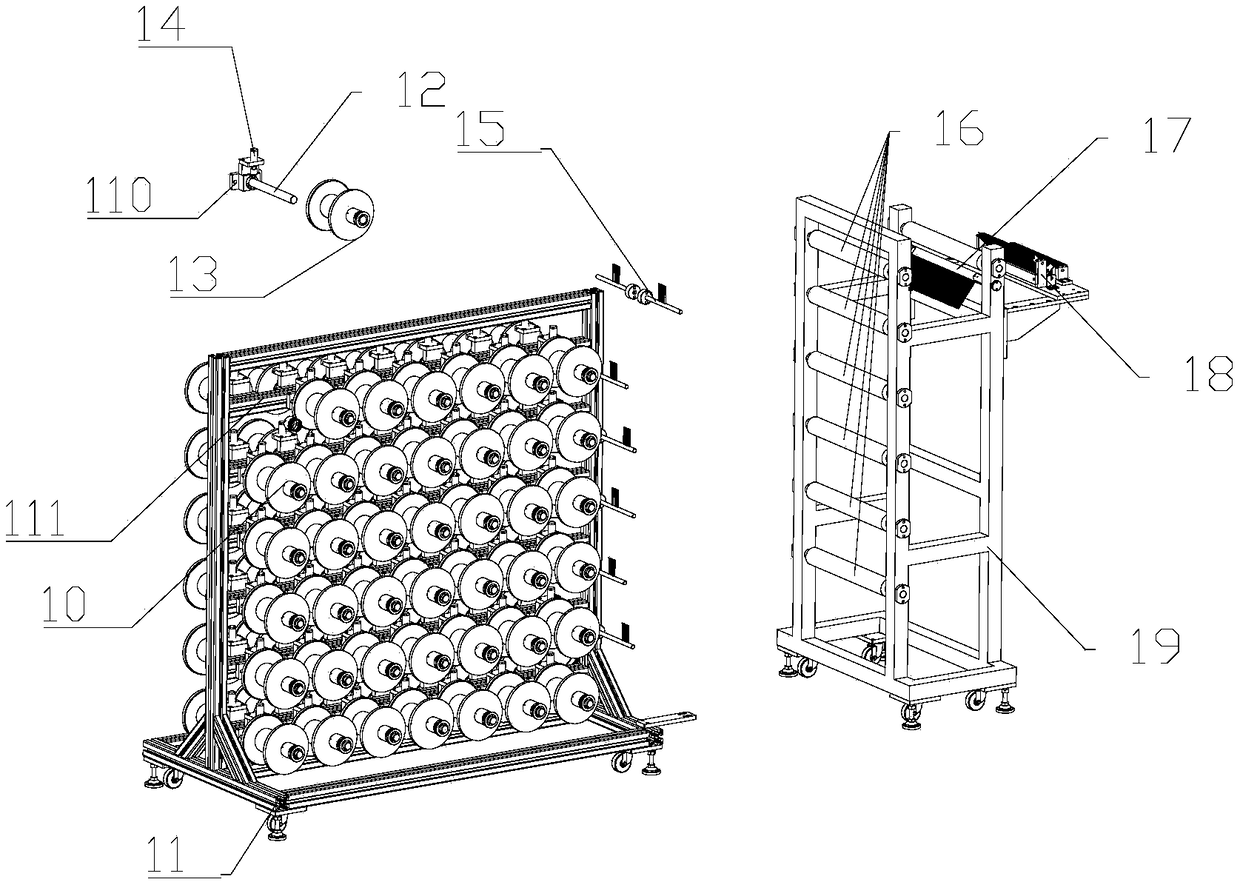

Woven rope belt with neat and firm rubber heads and production process thereof

ActiveCN113245125AGood strengthReduce the cross-sectional areaPretreated surfacesSevering textilesYarnRubber solvent

The invention discloses a woven rope belt with neat and firm rubber heads. The woven rope belt comprises a woven belt body and woven belt heads, wherein the woven belt body is formed by weaving a plurality of yarn bundles; the woven belt heads are firmly coagulated through environment-friendly rubber cement; and the surfaces of the woven belt heads are coated with colored rubber. According to the woven rope belt with the neat and firm rubber heads, the woven belt heads are coagulated by the rubber cement; rotary rubber coating seats rotate close to the belt heads in an elastic extrusion mode; the weaving degrees of the belt heads are further tighter in the state that the woven belt heads are tensioned; the formed rubber heads are better in strength and smaller in sectional areas; when the woven belt heads with the rubber cement are coated with the rubber raw material, the rubber raw material is not only in contact with the yarns and is also in contact with the rubber cement, so that the rubber raw material can be more firmly adhered to the woven belt heads and is not easy to fall off; the sectional areas of the belt heads of the woven rope belt are smaller than that of the belt body; the hardness of the belt heads is far greater than that of the belt body; and the woven rope belt has the advantages of easiness in perforation and long service life.

Owner:上海锦湾实业有限公司

Stirring machine convenient to clean

InactiveCN107297172AEasy to cleanEasy to useRotary stirring mixersTransportation and packagingMegasonic cleaningPulp and paper industry

The invention relates to the technical field of a stirring machine and discloses a stirring machine convenient to clean. The stirring machine convenient to clean comprises a pedestal; the upper surface of the pedestal is fixedly connected with a bracket; the top end of the bracket is fixedly connected with a stirring machine body; a discharging port is formed in the bottom of the stirring machine body; a spiral disk is mounted in the discharging port; one side of the internal part of the stirring machine body is rotationally connected with an observation door; the upper surface of the stirring machine body is fixedly connected with a motor box; one side of the motor box is fixedly connected with a switch which runs through and extends into the stirring machine body; and the other side of the motor box is fixedly connected with a supporting platform positioned on one side of the upper surface of the stirring machine body. According to the stirring machine convenient to clean, the top of a stirring shaft is fixedly connected with a rotating rod, the two ends of the rotating rod are fixedly connected with an ultrasonic cleaner, an output end of the ultrasonic cleaner is fixedly connected with a brush rod, and the surface of the brush rod is fixedly connected with a brush, so that the stirring machine can be cleaned.

Owner:HEFEI YAOSHI TONGHUI TECH CO LTD

Electric meter coupling antenna

PendingCN109524761ARealize space feedRealize feedAntenna supports/mountingsRadiating elements structural formsCouplingComputer module

The invention discloses an electric meter coupling antenna, which comprises a receiving antenna formed by an external antenna arranged on an outer electric meter case body and an internal antennas arranged in an internal module of an inner electric meter case body. The receiving antenna forms an LC loop by tuning inductance and feeding connection. The external antenna is a bending circuit arrangedat the side of the outer electric meter case body; and the internal antenna includes a radiation sheet body arranged in the inner electric meter case body. The electric meter coupling antenna has aninternal part and an external part; the external antenna is in close contact with the side of the outer electric meter case body; the internal antenna is in close contact with the surface of the internal module of the inner case body; and the external antenna and the internal antenna are spaced at a certain distance. The internal antenna is excited by the internal module to generate surface currents and a corresponding structure is designed at the meter case to meet the spatial impedance matching condition, so that the excited currents generated by the internal module generate induced currentsat the surface of the external antenna to realize spatial feeding. The antenna is combination of the internal part and the external part.

Owner:杭州易和互联软件技术有限公司

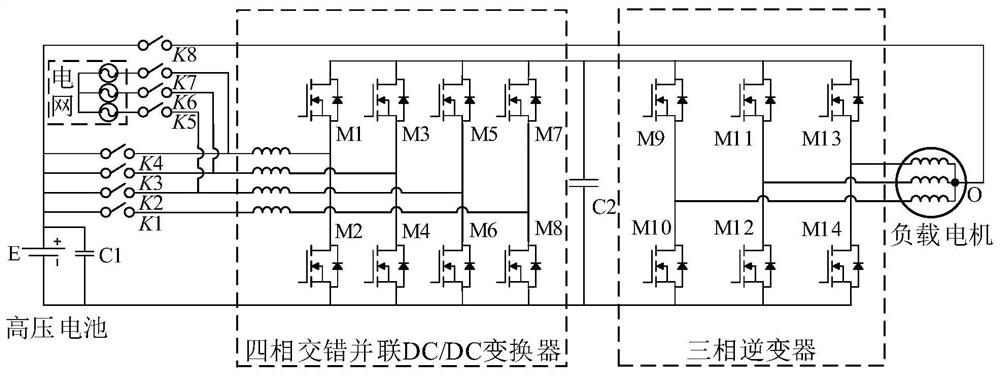

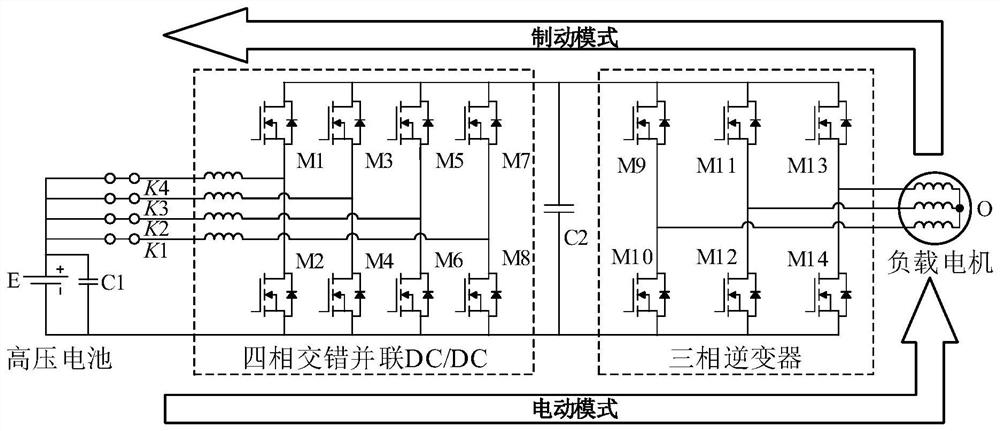

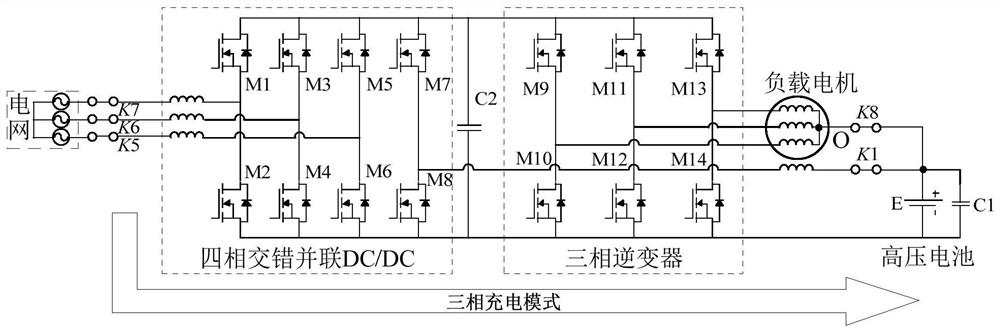

Electric vehicle traction-bidirectional charging system based on quadruple interleaved parallel DC/DC

ActiveCN111806267ASmall space volumeLow costCharging stationsAc-dc conversionMultiplexingElectrical battery

The invention discloses an electric vehicle traction-bidirectional charging system based on quadruple interleaved parallel DC / DC, belongs to the technical field of power electronics, and aims to solvethe problems of an existing electric vehicle. The electric vehicle traction-bidirectional charging system comprises a high-voltage battery, a quadruple interleaved parallel DC / DC converter, a three-phase inverter and a multiplexing control unit, the multiplexing control unit is switched among a vehicle driving mode, a three-phase charging mode, a single-phase charging mode, a single-phase V2G mode and a three-phase V2G mode, and the multiplexing control unit comprises switches K1 to K8. The two sets of systems share the same set of DC / DC converter.

Owner:HARBIN INST OF TECH

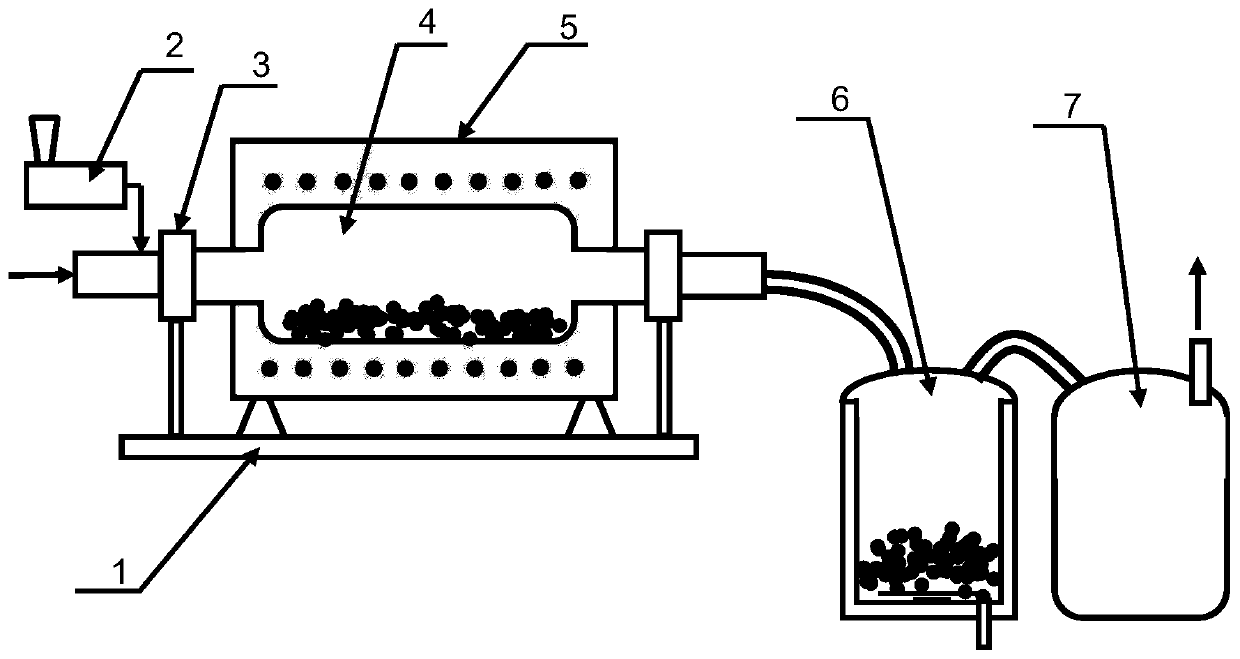

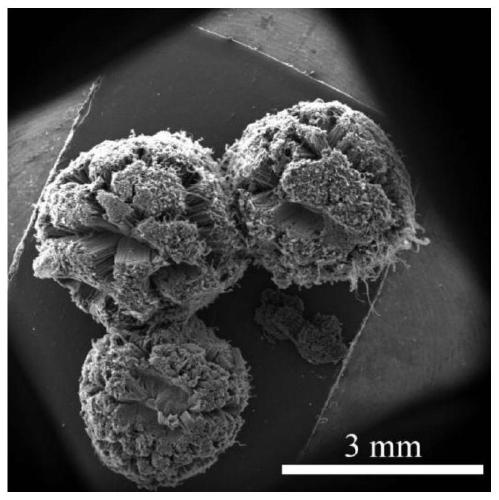

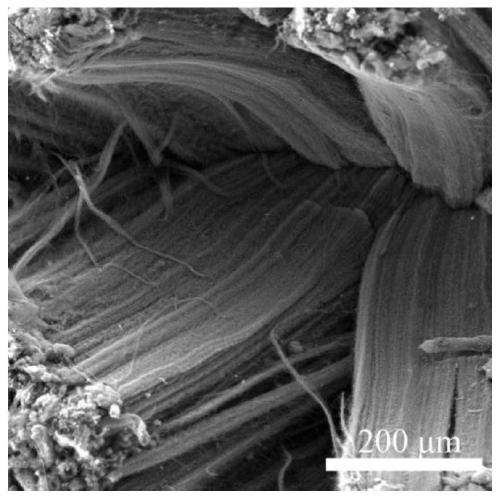

Device and method for preparing carbon nanotubes in batches

ActiveCN110451486AReduce energy consumptionImprove efficiencyCarbon compoundsCarbon sourceBatch production

The invention discloses a device and a method for preparing carbon nanotubes in batches. The device is composed of a tiltable tubular rotary furnace, a solid feeder, a solid powder separator, a powdercollector and an auxiliary system. The device and the method are based on a technology for preparing carbon nanotubes by floating catalytic chemical vapor deposition, inorganic ceramic beads adoptedas a collection carrier are placed in the high temperature zone of the tiltable tubular rotary furnace, and a carbon source and a catalyst are introduced for the growth of the carbon nanotubes; and after the growth is completed, a furnace body is tilted and rotated at the same time, the carbon nanotubes deposited on the tube wall of the rotary furnace are scraped off by the ceramic beads, enter the solid powder separator and are separated, and a carbon nanotube powder is brought into the powder collector by an inert gas current, and is collected to finally obtain the carbon nanotubes. The device and the method can realize continuous batch production of the carbon nanotube, solves the problem that carbon nanotube product is prone to deposit on the tube wall of the furnace under a stable gasfield distribution reaction condition, obtain the high-quality carbon nanotubes, can be easily amplified to realize industrialization, and have great economic values.

Owner:JIANGXI COPPER TECHNOLOGY RESEARCH INSTITUTE CO LTD

Flexible circuit board glue device and flexible circuit board production equipment

The invention relates to the production technical field of a flexible printed circuit board. A flexible circuit board gluing device comprising a frame, a first lead mechanism, a comb mechanism, a scraping and carding mechanism, a gluing mechanism and a glue pressing mechanism; The first lead mechanism is installed in the wire comb mechanism, and the wire comb mechanism, the wire scraping and carding mechanism, the glue sticking mechanism and the glue pressing mechanism are installed on the frame. The advantages of the flexible circuit board glue pasting device are that the wire feeding, wire finishing, glue pasting and compaction operations are automatically completed.

Owner:王朝火

High-gain circularly-polarized antenna

PendingCN112038761ARealize feedIncrease Radiation GainSimultaneous aerial operationsRadiating elements structural formsDielectric substrateEngineering

The invention discloses a high-gain circularly-polarized antenna. The high-gain circularly-polarized antenna comprises a metal box body, a first dielectric substrate and a second dielectric substratewhich are sequentially stacked from bottom to top, wherein a parasitic patch is arranged on the upper surface of the second dielectric substrate, a radiation patch is arranged on the upper surface ofthe first dielectric substrate, and the parasitic patch and the radiation patch are arranged face to face; the third dielectric substrate is arranged in the metal box body, and a Wilson power divideris arranged on the third dielectric substrate; an SMA coaxial connector is arranged on the side wall of the metal box body; a shunt port of the Wilson power divider is electrically connected with theradiation patch, and a combination port of the Wilson power divider is connected with the SMA coaxial connector to feed external equipment, so circularly-polarized wave radiation is realized; and theradiation patch is provided with a U-shaped gap. The high-gain circularly-polarized antenna provided by the invention has the characteristics of simple structure, high gain, small size and the like.

Owner:广州智讯通信系统有限公司

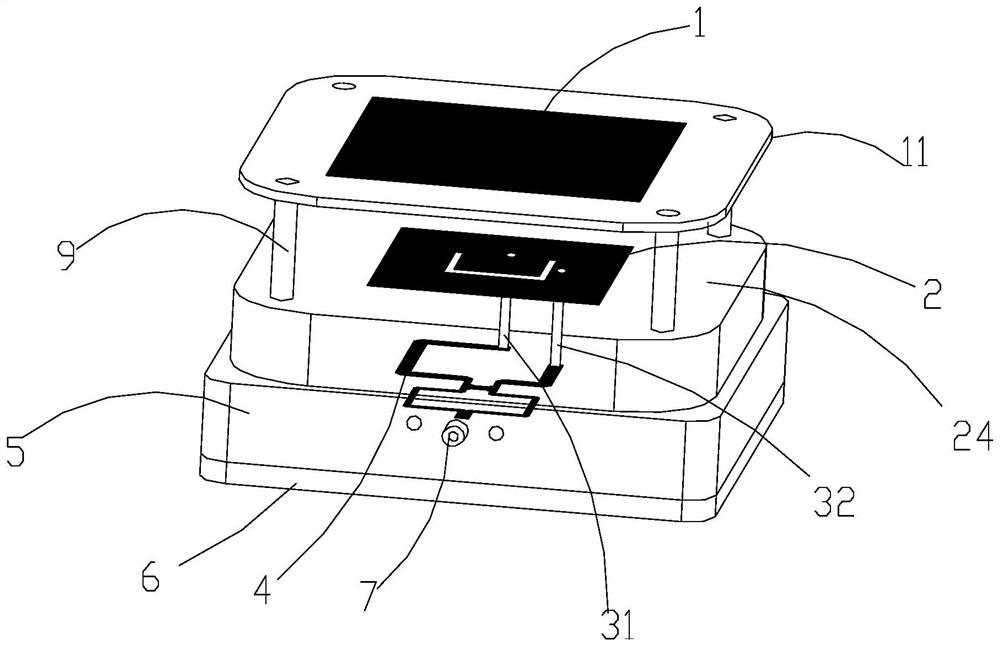

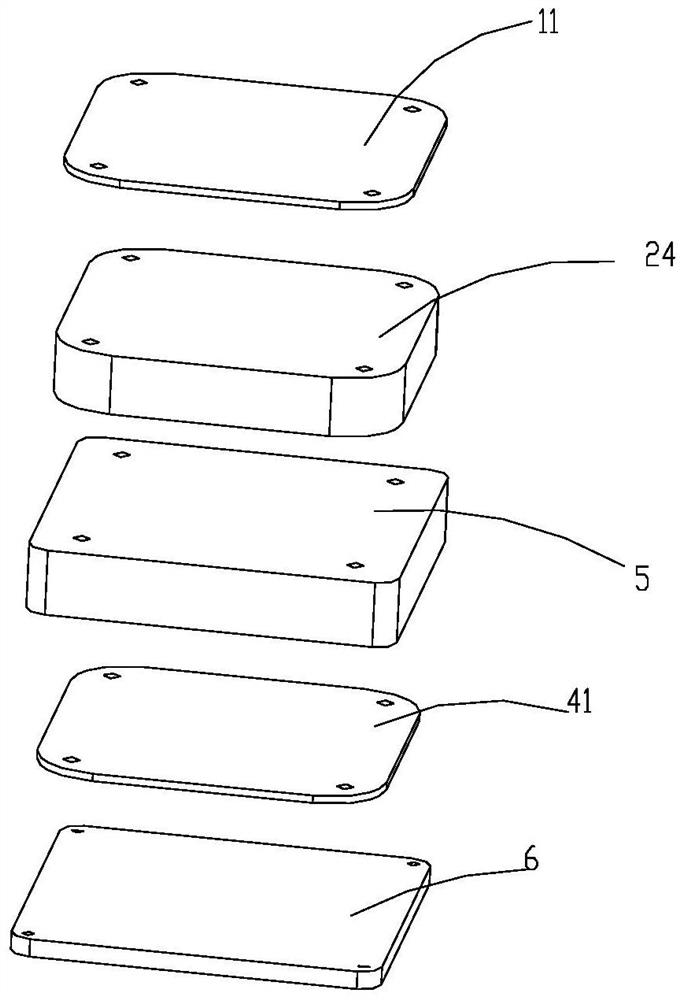

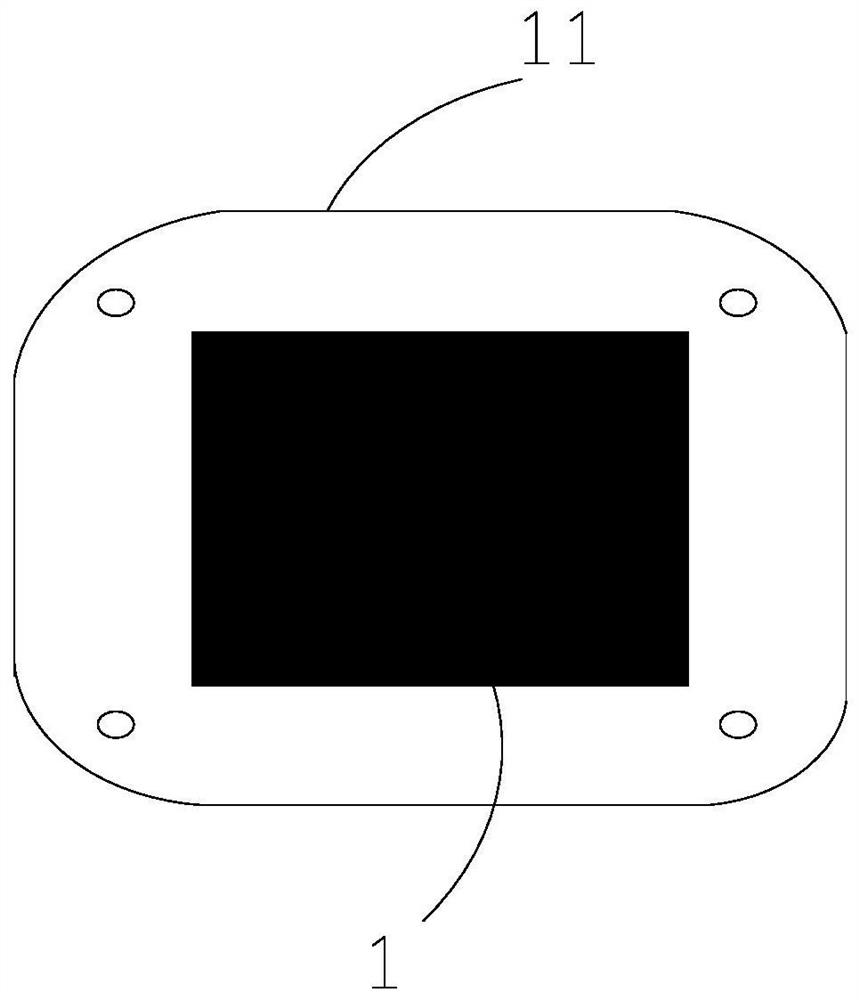

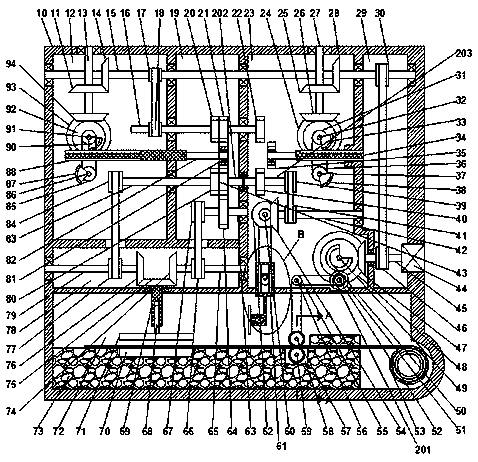

Metal sheet processing equipment and operation method thereof

InactiveCN109176029AEnsure safetyIncrease incomeShearing machinesFeeding apparatusMetal sheetEngineering

The invention discloses metal sheet processing equipment and an operation method thereof. The metal sheet processing equipment comprises a main box body and a cutting device arranged in the main box body. A first rotating cavity is arranged in the main box body, and a second rotating cavity located on the right side of the first rotating cavity is arranged in the main box body. A third rotating cavity located on the right side of the second rotating cavity is arranged in the main box body, and a motor cavity located on the right side of the third rotating cavity is arranged in the main box body. A fourth rotating cavity located on the lower side of the first rotating cavity is arranged in the main box body, and a stamping cavity which is located on the lower side of the fourth rotating cavity and provided with a forward opening is arranged in the main box body. A first rotating shaft is rotatably arranged on the top wall of the first rotating cavity, and a first bevel gear is fixedly arranged on the first rotating shaft. A fourteenth bevel gear is fixedly arranged at the lower end of the first rotating shaft, a second rotating shaft is arranged on the left wall of the first rotating cavity in a rotating mode, and the right end of the second rotating shaft is rotatably connected with the right wall of the motor cavity through the second rotating cavity, the third rotating cavity, and the motor cavity.

Owner:何杨波

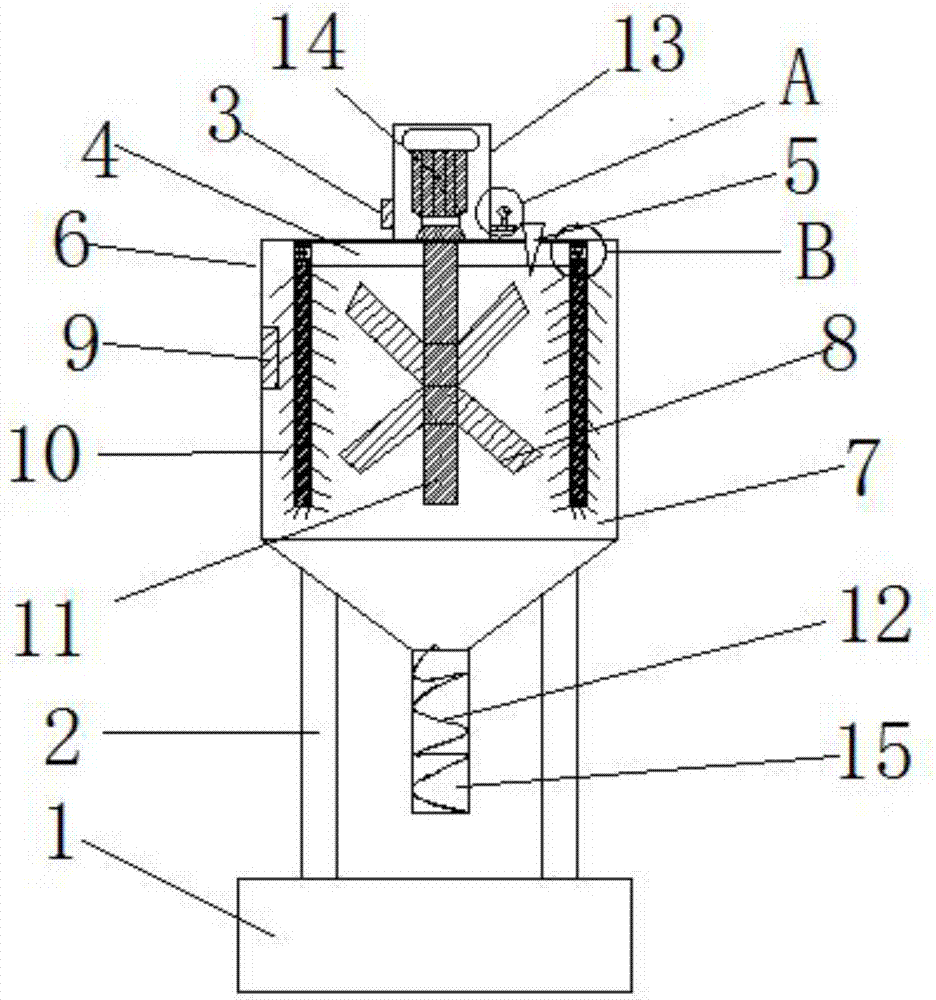

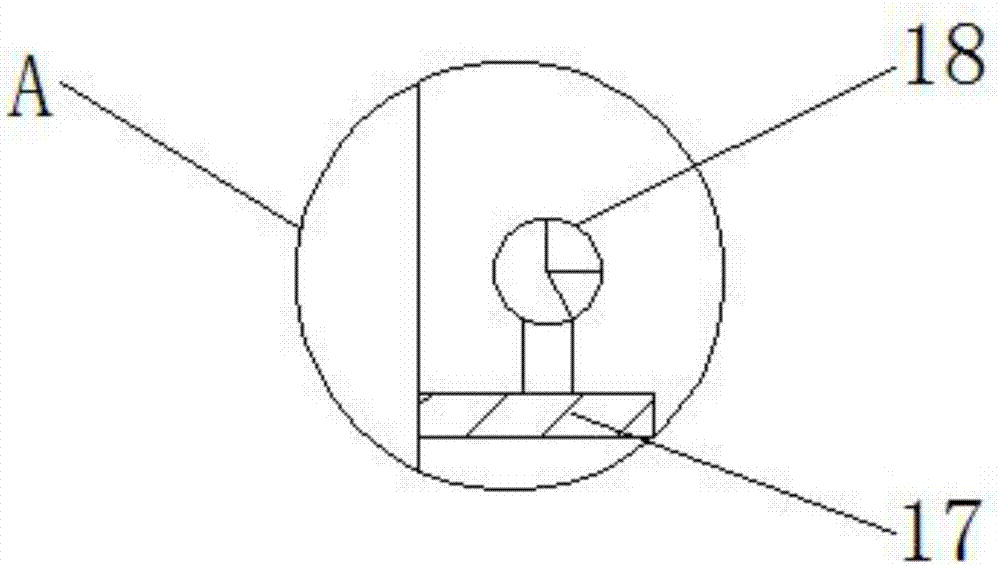

Wood grinder

ActiveCN105818237ARealize feedRealize material returnWood working apparatusGrain treatmentsWood grinderMechanical engineering

The invention relates to a wood grinder. The wood grinder comprises a feeding hopper, a grinding chamber, a discharging pipe, a cutter head mechanism and a base plate, wherein the feeding hopper, the grinding chamber and the cutter head mechanism are sequentially connected and are mounted on the base plate, the discharging pipe is mounted on the cutter head mechanism, a feeding mechanism is mounted inside the grinding chamber, an operation rod device for controlling the feeding mechanism is arranged at an inlet of the feeding hopper, and a hydraulic assembly for connecting the feeding mechanism with the operation rod device is arranged outside the feeding hopper. The wood grinder has the characteristics that the grinder is simple in structure, safe to use and the like.

Owner:常州汉森机械股份有限公司

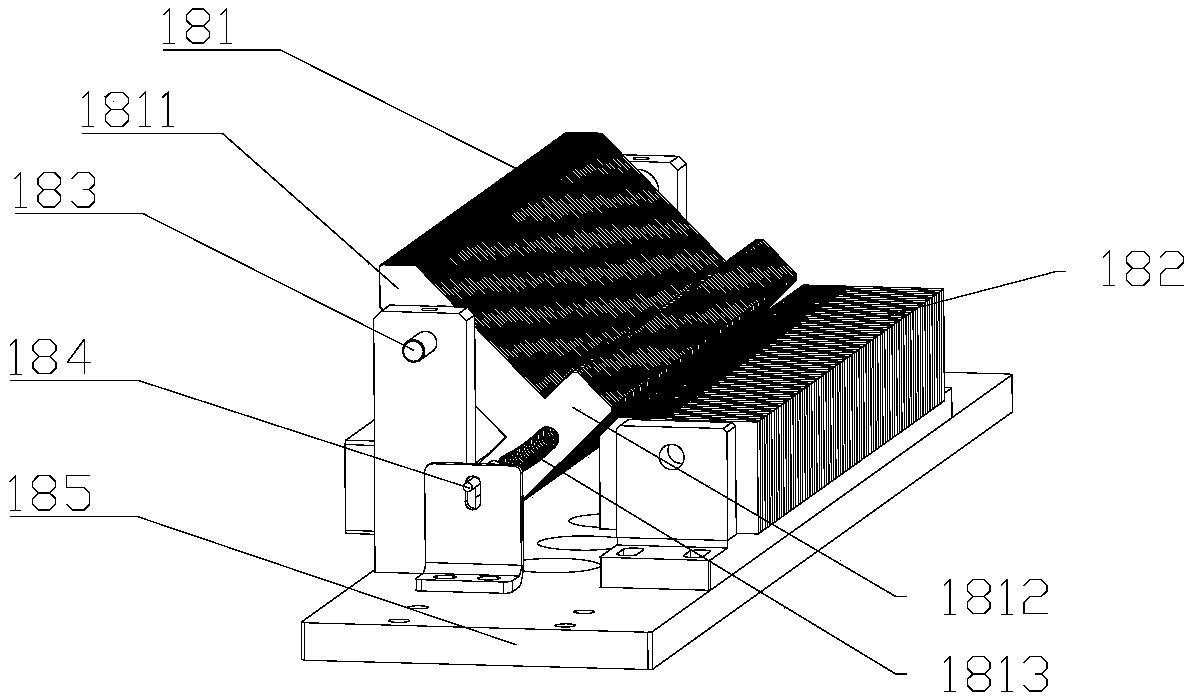

Flexible circuit board cable combing mechanism, rubberizing device and flexible circuit board production device

InactiveCN109362187ARealize feedTo achieve the effect of finishing the wireCircuit board tools positioningNon-metallic protective coating applicationFlexible circuitsFlexible electronics

The invention relates to the technical field of flexible printed circuit board production. A flexible circuit board cable combing mechanism comprises a fixed base, a movable base, a second cylinder, afirst linear track shifting component, a connecting channel strip, a combing seat, a locking handle, a third cylinder fixing seat, a third cylinder, a second linear track shifting component, a fixture piece holder, a fixture piece and a first photoelectric sensor component. The flexible circuit board cable combing mechanism has the advantage that flat cables with different widths can be combed.

Owner:王朝火

Automatic polishing lathe capable of adjusting speed of working table, capable of achieving batch production and high in safety

ActiveCN111660177ANo problems with over-grindingQuality improvementBelt grinding machinesGrinding/polishing safety devicesRobot handPolishing

The invention discloses an automatic polishing lathe capable of adjusting the speed of a working table, capable of achieving batch production and high in safety in the technical field of workpiece machining. A conveying assembly is arranged on the front side of the top face of a machining table. The conveying assembly comprises mechanical hands which are arranged on the front side and the rear side of the machining table and electronically controlled by equipment. Linear feeding and conveying mechanisms and linear discharging and conveying mechanisms are arranged on the left sides and the right sides of the mechanical hands at the front end and at the rear end. A protecting cover provided with a feeding and discharging opening in the side wall is arranged on the top face of the working table. Polishing assemblies are symmetrically arranged in an inner cavity of the protecting cover. A conveying assembly is arranged between the polishing assemblies. The conveying assembly is provided with a workpiece limiting assembly. A locking assembly is arranged at the front end of the protecting cover. According to the automatic polishing lathe, the speed of the working table can be adjusted properly according to the difference between machined workpiece materials, thus the better machining quality is achieved, meanwhile, the polishing lathe can adapt to batch production, and the automaticpolishing lathe is high in machining efficiency and high in safety.

Owner:SHANDONG JIU XIN MACHINE TOOL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com