Organic amine wet flue gas desulphurization and desorption system with high-efficiency and low-energy consumption

A wet flue gas desulfurization, organic amine technology, applied in separation methods, chemical instruments and methods, dispersed particle separation and other directions, can solve the problems of high energy consumption, low desorption efficiency, large steam consumption, etc. The effect of reducing sulfur dioxide content and reducing the amount of heating steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

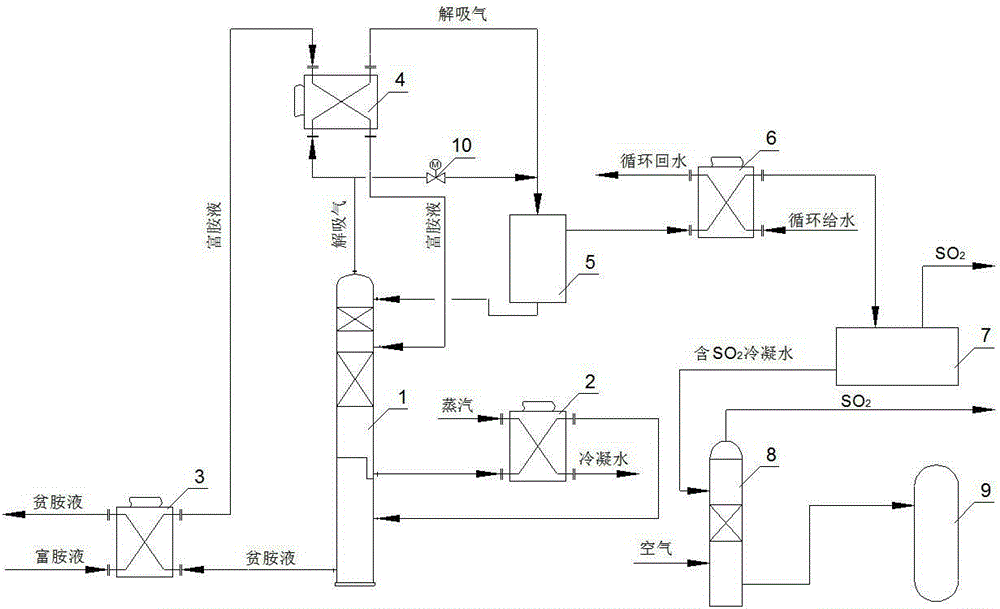

[0025] see figure 1 , the structure of this embodiment is described as follows:

[0026] A high-efficiency and low-energy organic amine wet flue gas desulfurization desorption system includes a desorption tower 1, a poor-rich amine liquid heat exchanger 3, a rich amine heater 4, a desorption tower 8, and an amine liquid purification system 9. In the desorption tower 1 A condensing cooler 6 and a separator are arranged in series between the desorption tower 8, and a reboiler 2 is arranged in the crude distillation section of the desorption tower 1.

[0027] The separator includes a primary separator 5 and a secondary separator 7; the condensation cooler 6 is located between the primary separator 5 and the secondary separator 7; the primary separator 5 is connected to the desorption tower 1, and the primary separator 5 A rich amine heater 4 is provided between the desorption tower 1 ; the secondary separator 7 is connected to the desorption tower 8 .

[0028] The rich amine li...

Embodiment 2

[0033] The structure of this embodiment is the same as that of Embodiment 1.

[0034] The working principle of this embodiment is described as follows:

[0035] The flow from the absorption tower is 220m 3 / h The rich amine liquid with a temperature of 40.7°C, after heat exchange between the poor and rich amine liquid heat exchanger 3 and the lean amine liquid, the temperature rises by 73.6°C, and then it is sent to the rich amine heater 4 to raise the temperature to 99.1°C for the second time, and then enters SO 2 Desorption tower; contains SO 2 The high-temperature saturated steam has a temperature of 111°C, is cooled and condensed in the rich amine heater, and the temperature drops to 100°C, and enters the primary separator 5 after heat exchange. The liquid is reused and sent to the liquid distributor in the rectification section, and the packing layer in the rectification section is mixed with SO 2 steam exposure. The kettle temperature was 113°C. The steam consumpti...

Embodiment 3

[0037] The structure of this embodiment is the same as that of Embodiment 1.

[0038] The working principle of this embodiment is described as follows:

[0039] The flow from the absorption tower is 308m 3 / h The rich amine liquid with a temperature of 42°C, after the heat exchange between the poor and rich amine liquid heat exchanger 3 and the lean amine liquid, the temperature rises by 71.4°C, and then it is transported to the rich amine heater 4 to raise the temperature to 98.2°C for the second time, and then enters SO 2 Desorption tower; contains SO 2 The high-temperature saturated water vapor has a temperature of 109°C, is cooled and condensed in the rich amine heater, and the temperature drops to 100°C, and enters the primary separator 5 after heat exchange. The liquid is reused and sent to the liquid distributor in the rectification section, and the packing layer in the rectification section is mixed with SO 2 steam exposure. The temperature in the bottom of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com