Flexible circuit board rubberizing mechanism, rubberizing device and flexible circuit board production device

A flexible circuit and board sticking technology, which is applied in the direction of circuit board tool positioning, printed circuit, printed circuit manufacturing, etc., can solve problems such as low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

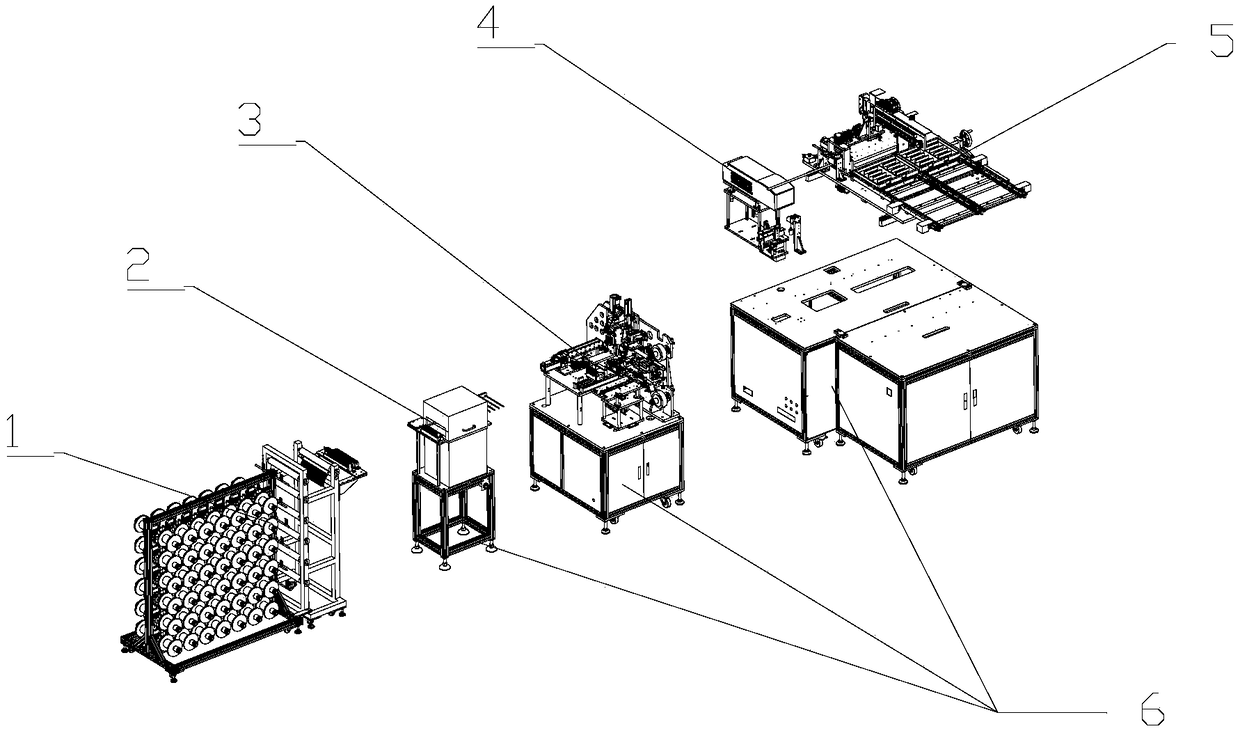

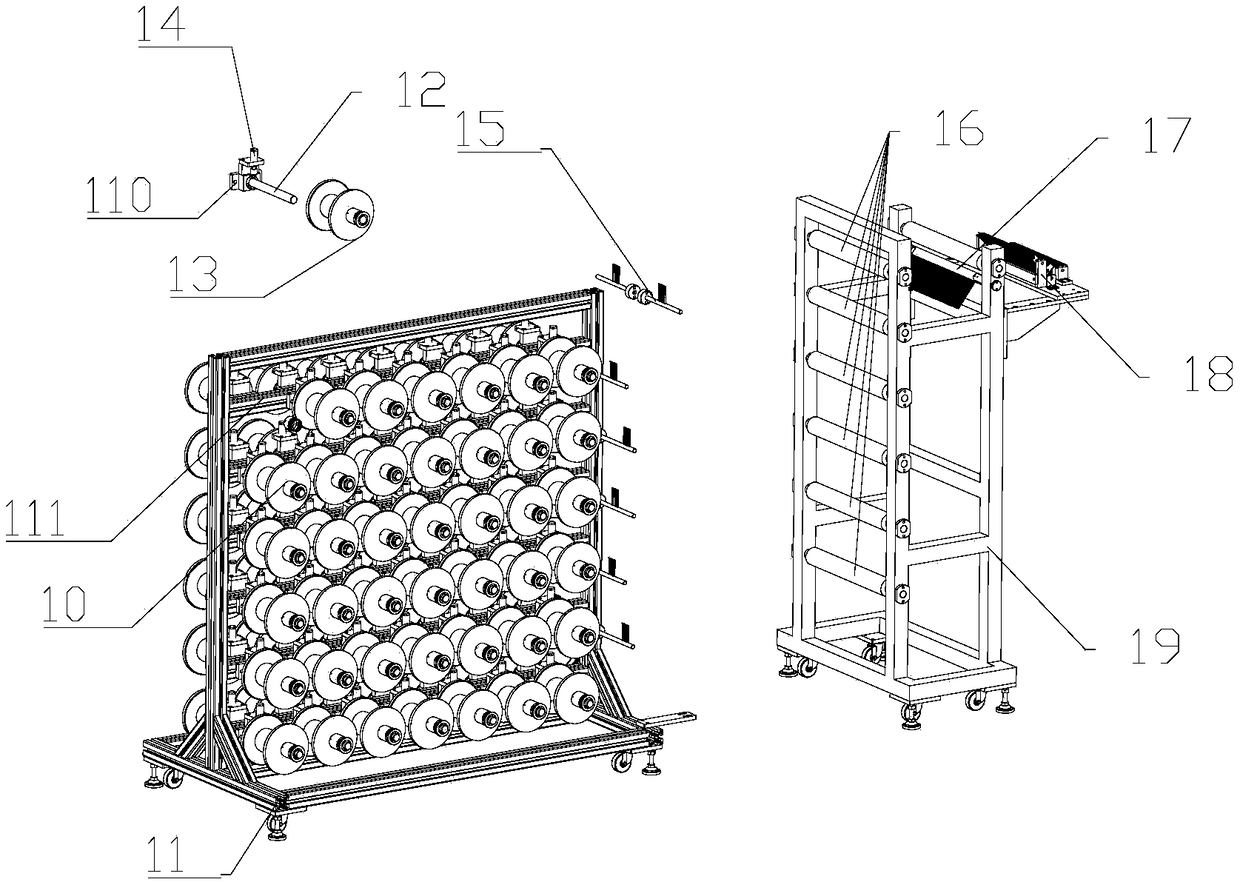

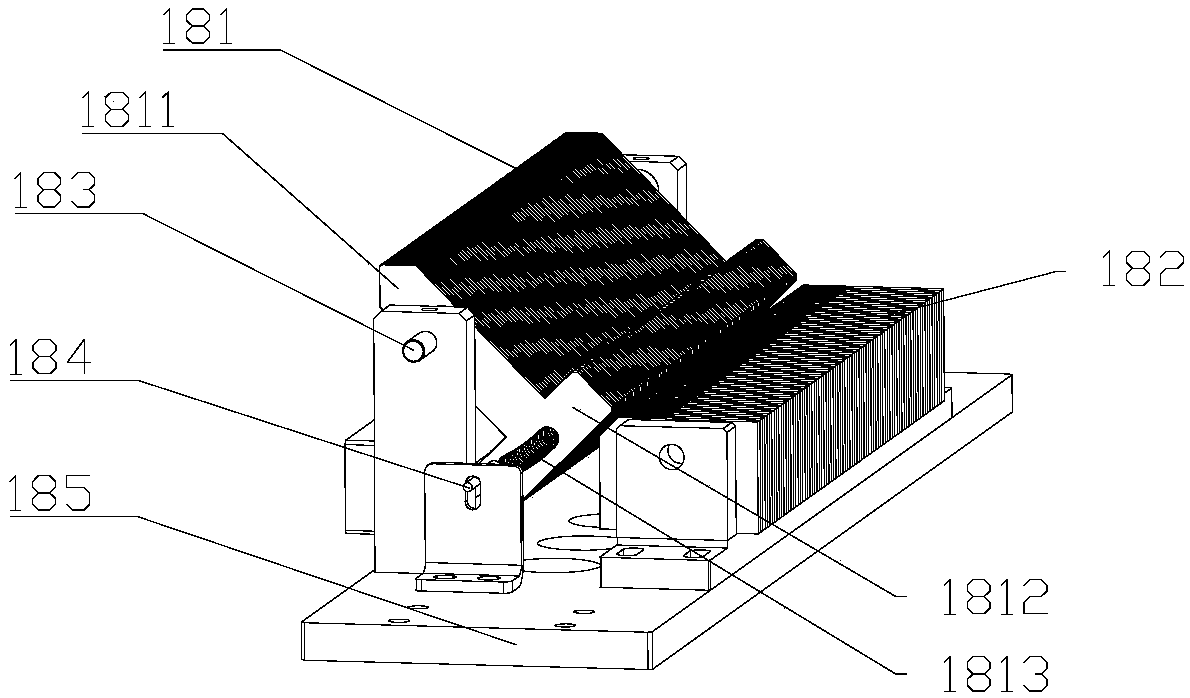

[0040] Combine below Figure 1-Figure 21 The present invention is further described.

[0041] Such as Figure 1-Figure 21 The flexible circuit board production equipment shown includes a wire feeding and feeding device 1 , a wire ultrasonic cleaning device 2 , a gluing device 3 , a laser cutting and peeling device 4 , a wire arranging, cutting and receiving device 5 and a frame 6 . Wire feeding and feeding device 1, wire ultrasonic cleaning device 2, gluing device 3, laser cutting and peeling device 4 and wire arranging, cutting and receiving device 5 are connected in sequence, and wire ultrasonic cleaning device 2, gluing device 3, laser cutting and peeling The device 4 and the cable cutting and receiving device 5 are installed on the frame 6 .

[0042] The feeding wire feeding device 1 is used for sorting wire rods and feeding them into the wire rod ultrasonic cleaning device 2, and the wire rods are copper enameled wires with a wire diameter of 0.3-1 mm. The wire rod ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com