Wood grinder

A technology of wood chippers and crushing chambers, which is applied in the direction of wood processing equipment, grain processing, and manufacturing tools, etc. It can solve the problems of reduced work efficiency, inconvenience, and increased workload, so as to avoid stuck and unable to work normally, improve Convenience and safety, and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

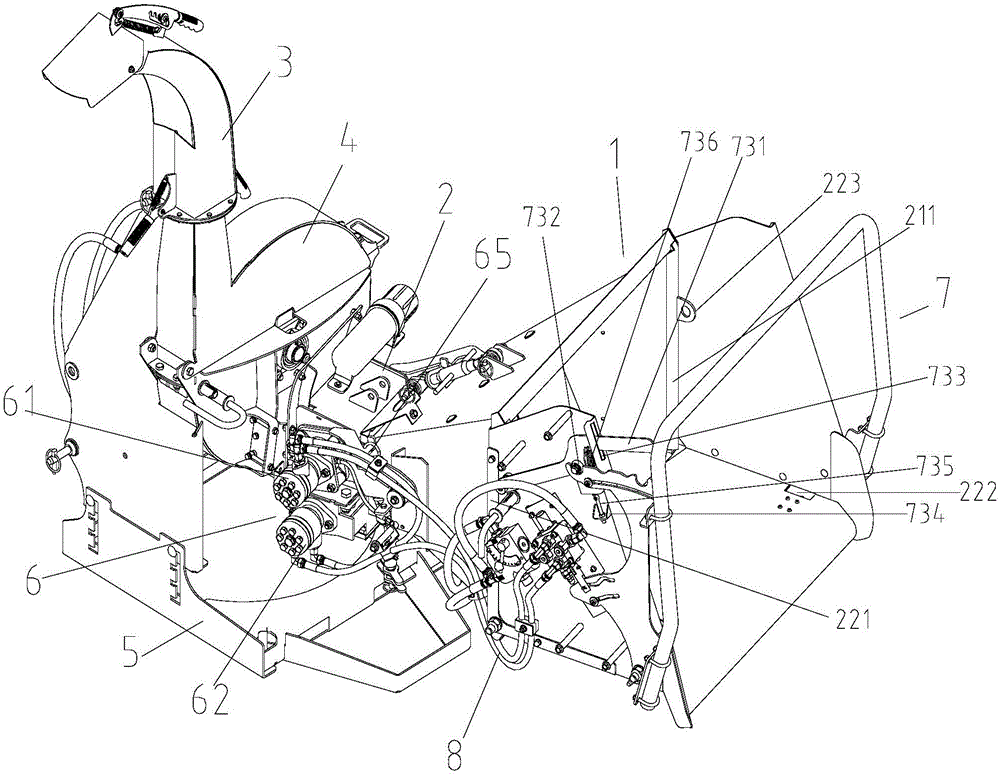

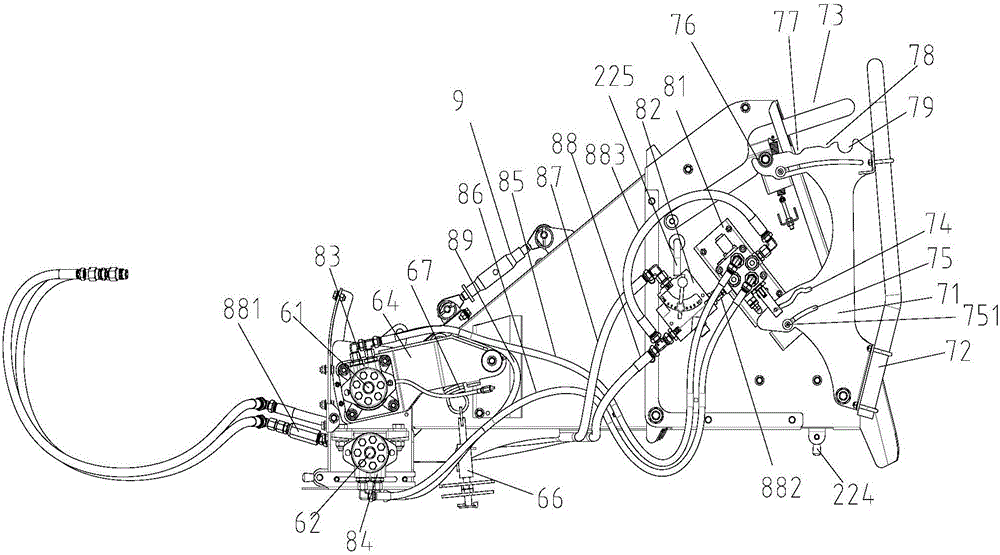

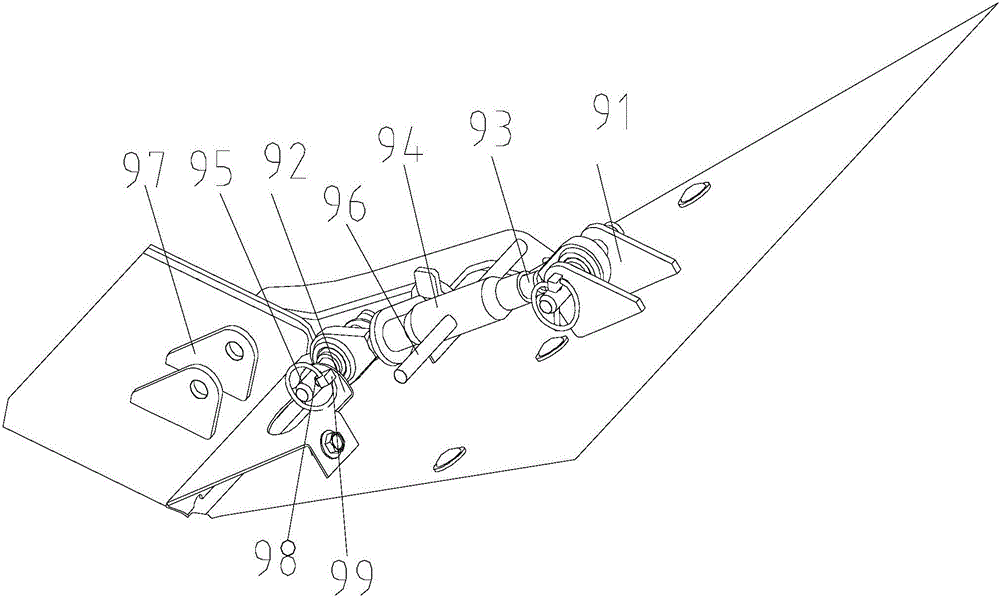

[0022] Such as Figure 1 to Figure 4 , a wood chipper, including a feed hopper 1, a crushing chamber 2, a discharge pipe 3, a cutter head mechanism 4 and a chassis 5, and the feed hopper 1, the crushing chamber 2 and the cutter head mechanism 4 are sequentially connected and installed on the chassis 5 Above, the discharge pipe 3 is installed on the cutter head mechanism 4, the feeding mechanism 6 is installed in the crushing chamber 2, the inlet of the feeding hopper 1 is provided with a joystick device 7 for controlling the feeding mechanism 6, and the outside of the feeding hopper 1 A hydraulic assembly 8 connecting the feeding mechanism 6 and the joystick device 7 is provided.

[0023] The feeding mechanism 6 includes an upper roller 61 and a lower roller 62 parallel to each other. The lower roller 62 is fixed on the crushing chamber 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com