Environmental-friendly iron sheet processing device for protective fence of road

A processing device and guardrail technology, applied in road safety devices, metal processing equipment, roads, etc., can solve the problems of low cutting efficiency, inability to realize automatic feeding in linkage, and poor structure, so as to improve the suction efficiency and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

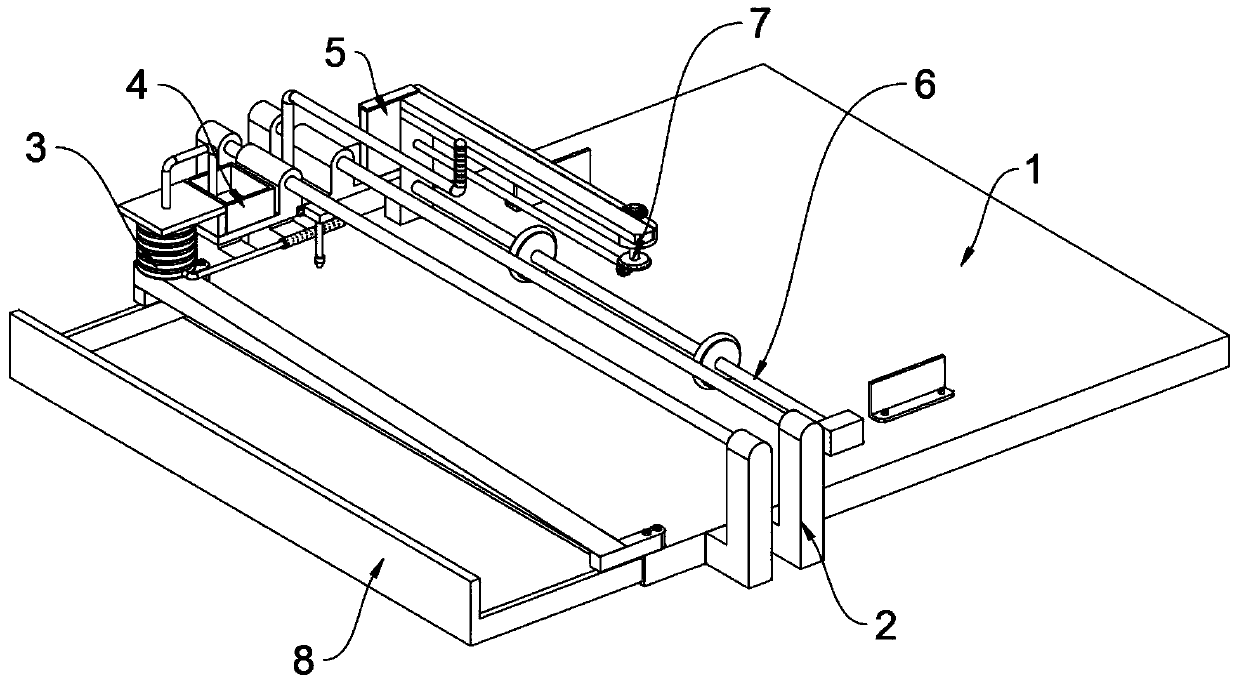

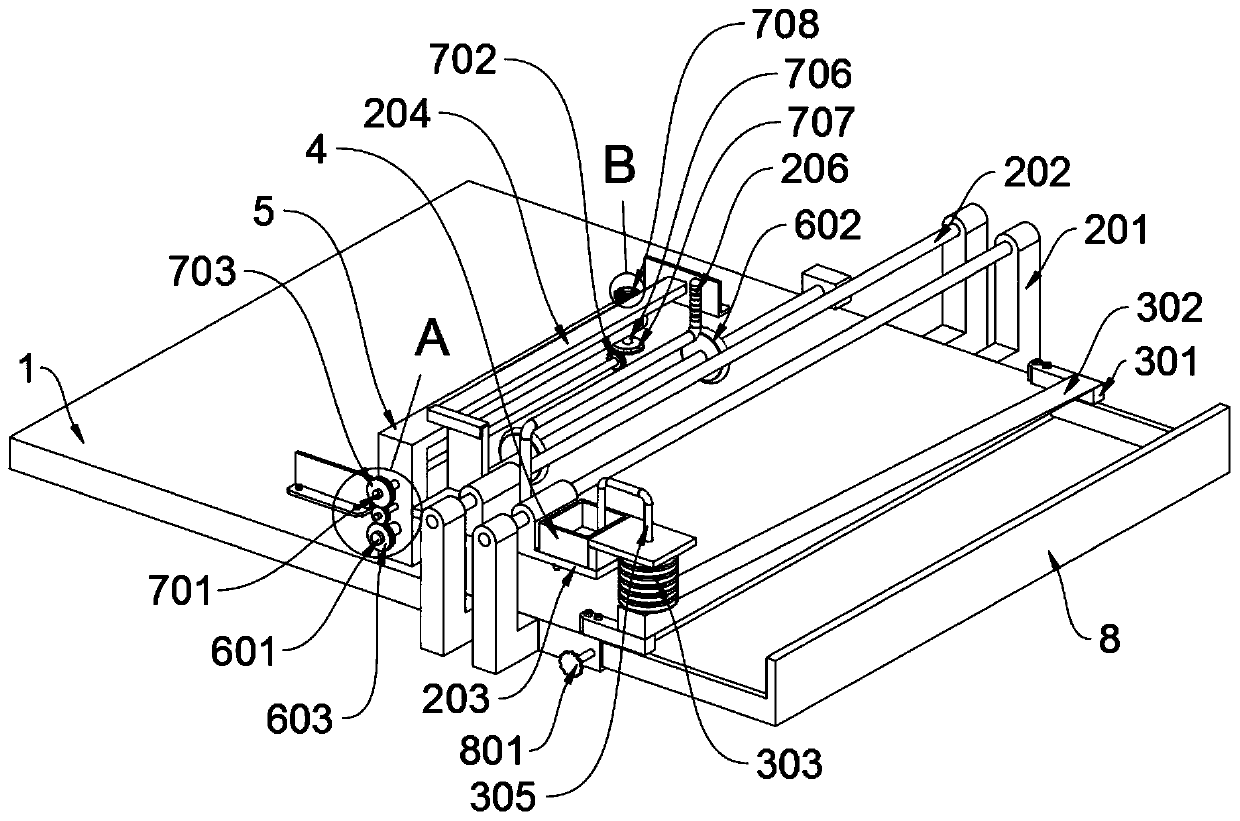

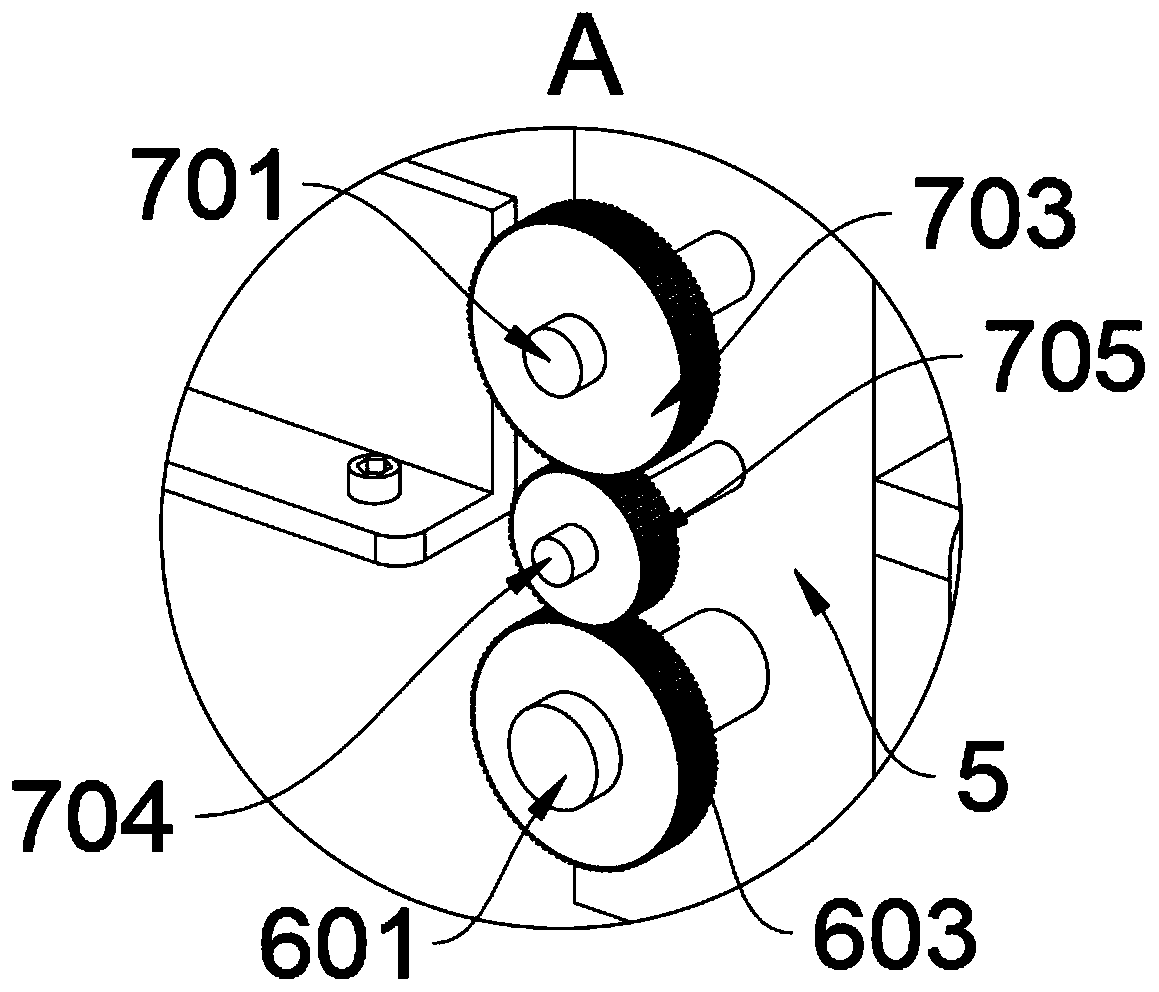

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034]The invention provides an environment-friendly iron sheet processing device for highway guardrails, which includes a base 1; a cutting structure 2 is installed on the base 1, and a gas collection structure 3 is installed on the cutting structure 2, and a filter box 4 is fixedly connected to the cutting structure 2 ; referenced as Figure 5 , the gas collection structure 3 includes a support base 301, a limit block 302, a compressed gas cylinder 303, an air suction pipe 304 and an exhaust pipe 305. There are two support bases 301, and the two support bases 301 are fixedly connected by bolts A limit block 302 is welded on the top surface of the base 1 and the top surfaces of the two support seats 301; the compressed gas cylinder 303 is fixedly connected to the bottom surface of the sliding seat 203, and the compressed gas cylinder 303 is provided with an air suction pipe 304 and an exhaust pipe. Tube 305; the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com