Intelligent turnover device for welding and processing main beam of bridge crane

An overhead crane and processing intelligence technology, applied in welding equipment, auxiliary devices, metal processing equipment, etc., can solve the problems of low welding efficiency, large main beam volume, waste of resources, etc., to improve bearing capacity, safe and reliable rotation, The effect of reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

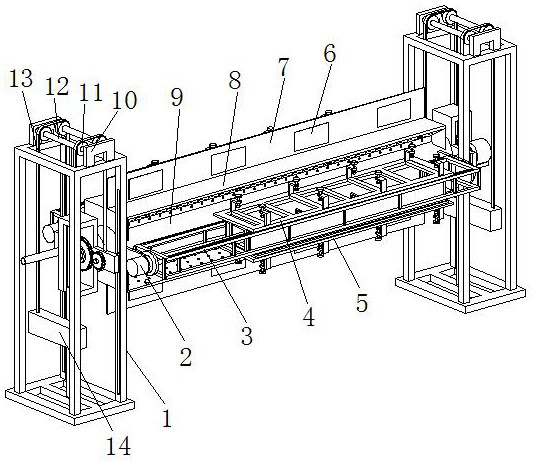

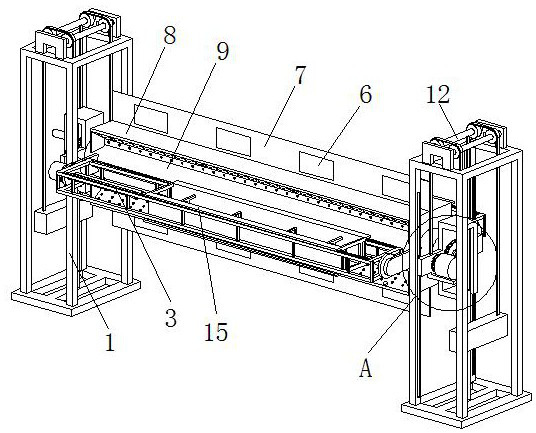

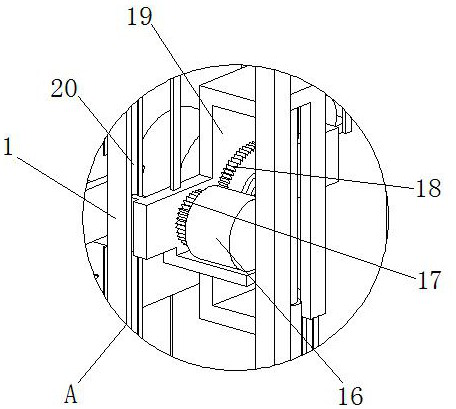

[0032] see Figure 1-9 , the present invention provides a technical solution: an intelligent turning device for welding and processing the main girder of a bridge crane, including a turning supporting frame 1, a turning frame 3, a smoke absorbing cover 8, a transposition roller 9, an adjusting carriage 15 and a smoking The connecting pipe 41 and the inside of the transposition drum 9 are hollow structures. The interior of the transposition drum 9 is provided with an inner partition 36, and the inner partition 36 divides the inner cavity of the transposition drum 9 into a smoking room I 33 and a smoking room II 34. The inner right side of the bit drum 9 is provided with a three-way connecting pipe 39, and the two inlets of the three-way connecting pipe 39 communicate with the smoking room I33 and the smoking room II34 respectively, and the two inlet pipes of the three-way connecting pipe 39 are provided with solenoid valves. 38. The opening and closing of the three-way connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com