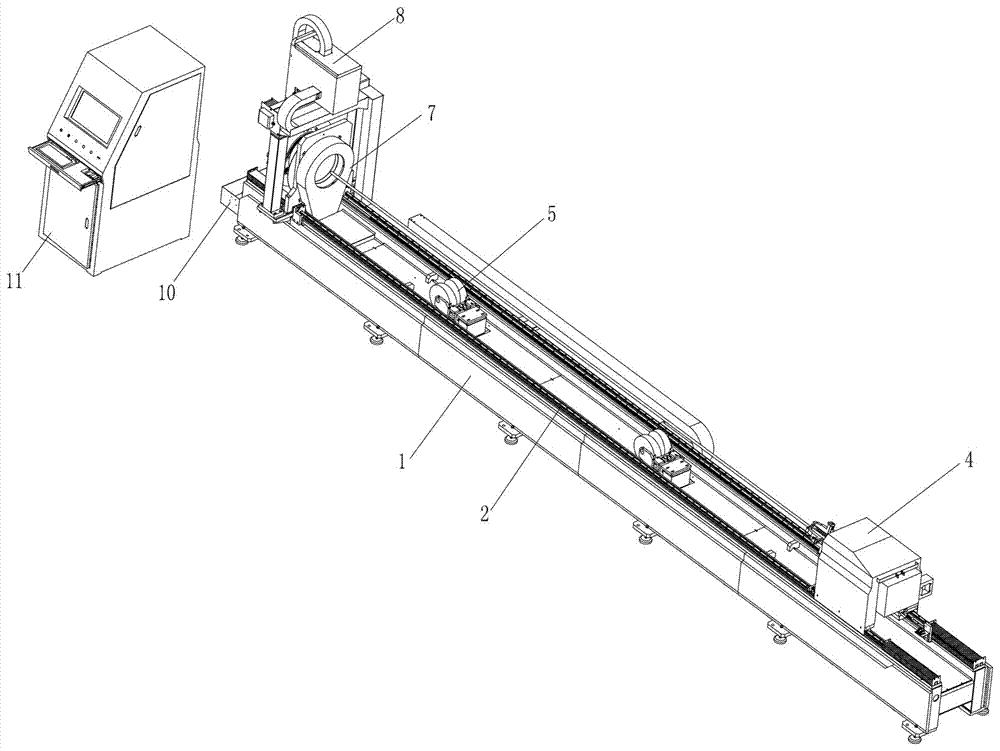

Novel integral type compact laser pipe cutting machine

A compact and integrated technology, applied in laser welding equipment, tubular objects, applications, etc., can solve problems such as complex structural design of pipe cutting machines, problems of pipe clamping adaptability, and inability to flexibly adjust pipe diameters, etc., to achieve improved Cutting efficiency and cutting quality, improving cutting quality, fast and convenient effect of receiving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing:

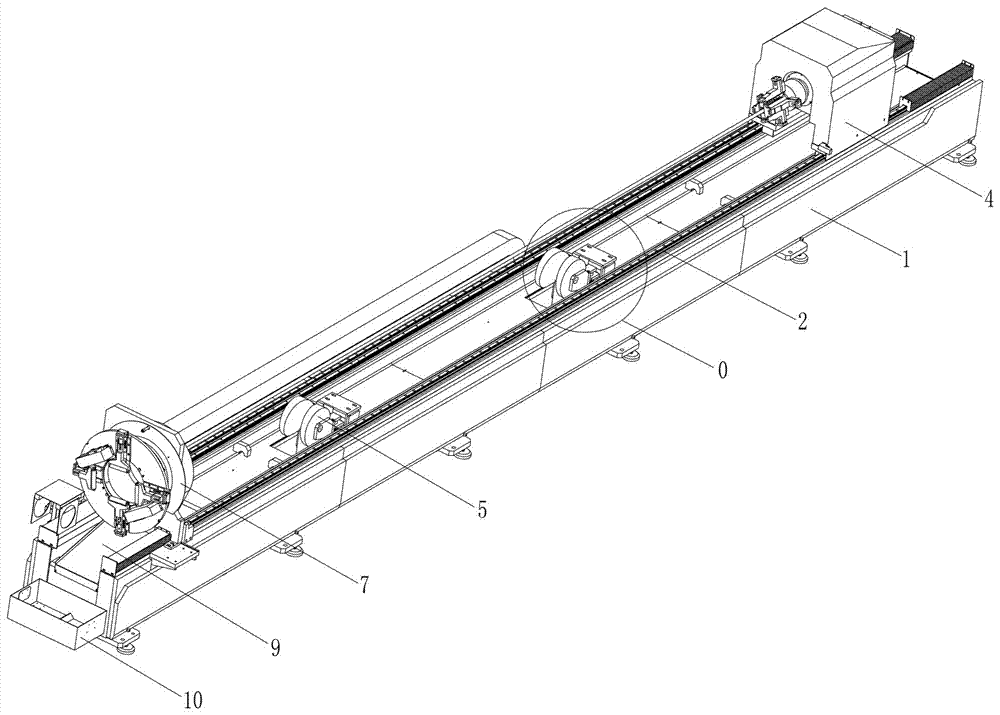

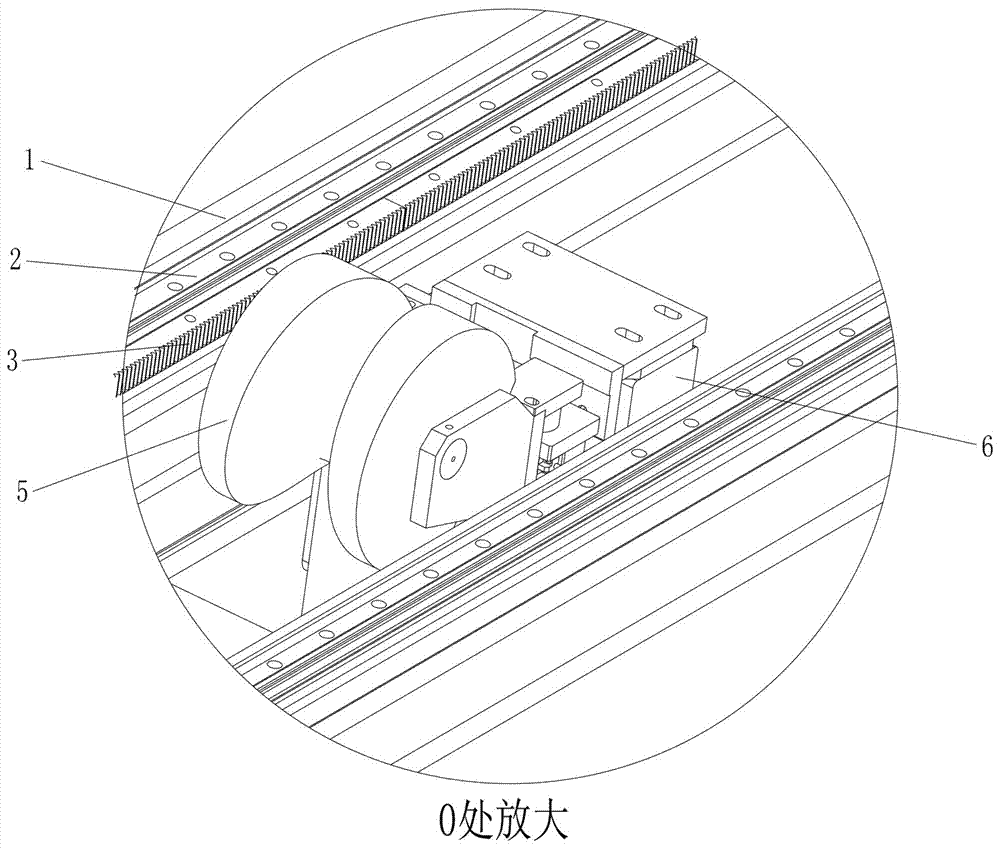

[0045] Such as Figure 1 to Figure 15 As shown, the technical solution adopted by the present invention is as follows: a new type of integrated compact laser pipe cutting machine, including a machine tool 1, a guide rail 2, a first clamping mechanism 4, a variable-diameter auxiliary support mechanism 5, and a second clamping mechanism 7 , cutting mechanism 8 and material box 10, wherein, above-mentioned machine tool 1 is a strip structure, and machine tool 1 is placed on the horizontal plane; Above-mentioned guide rail 2 comprises two, and two guide rails 2 are respectively arranged on the front and rear sides of machine tool 1 along the side direction of machine tool 1 The above-mentioned first clamping mechanism 4 is arranged on the rear end of the machine tool 1, and is slidably embedded on the guide rail 2. On the first clamping mechanism 4, one end of the pipe body to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com