Thin-wall pipe automatic material returning and clamping device

A technology of clamping device and thin-walled tube, applied in positioning device, feeding device, tangent device, etc., can solve problems such as complex structure, and achieve the effect of stable working process, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

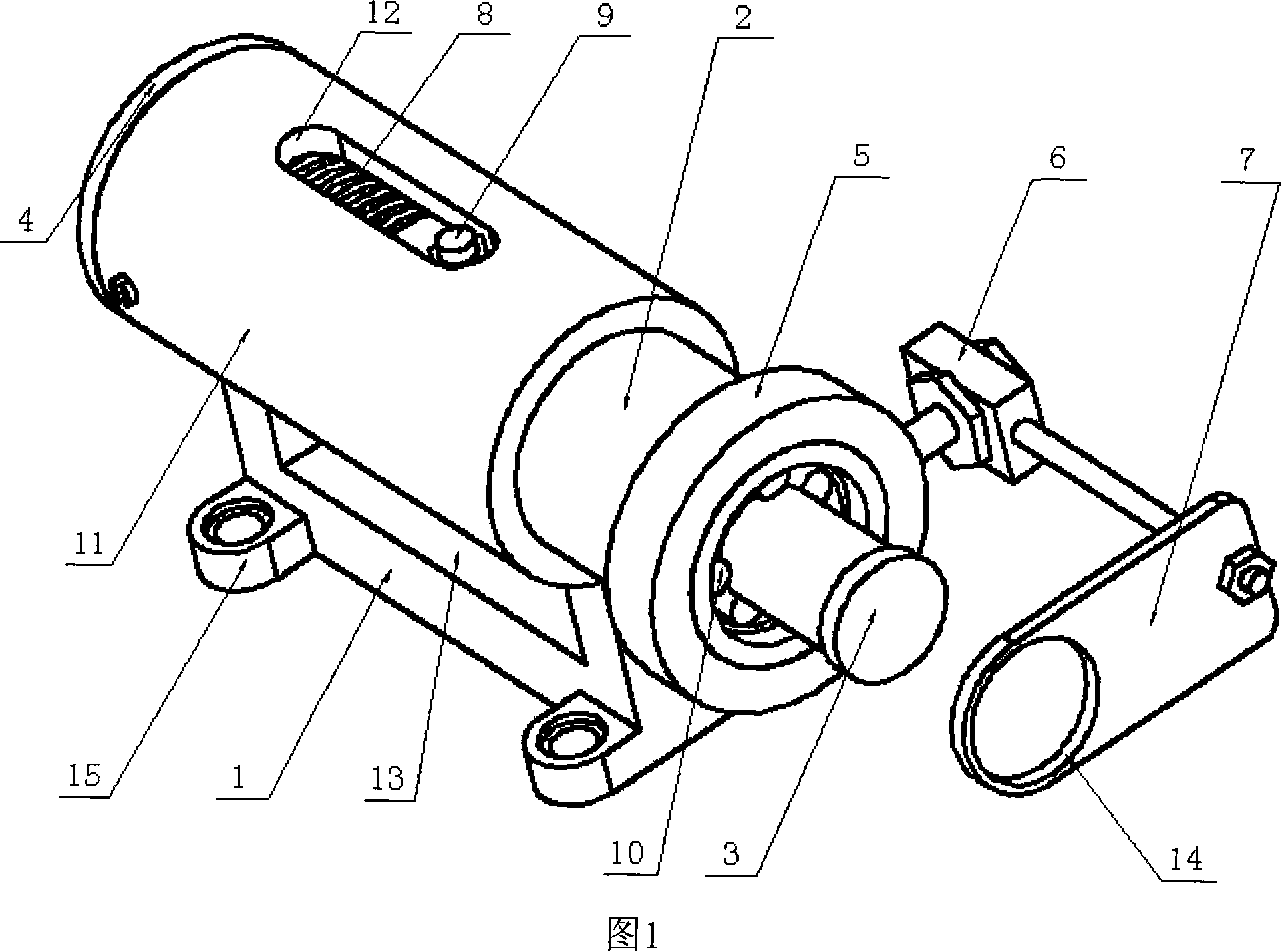

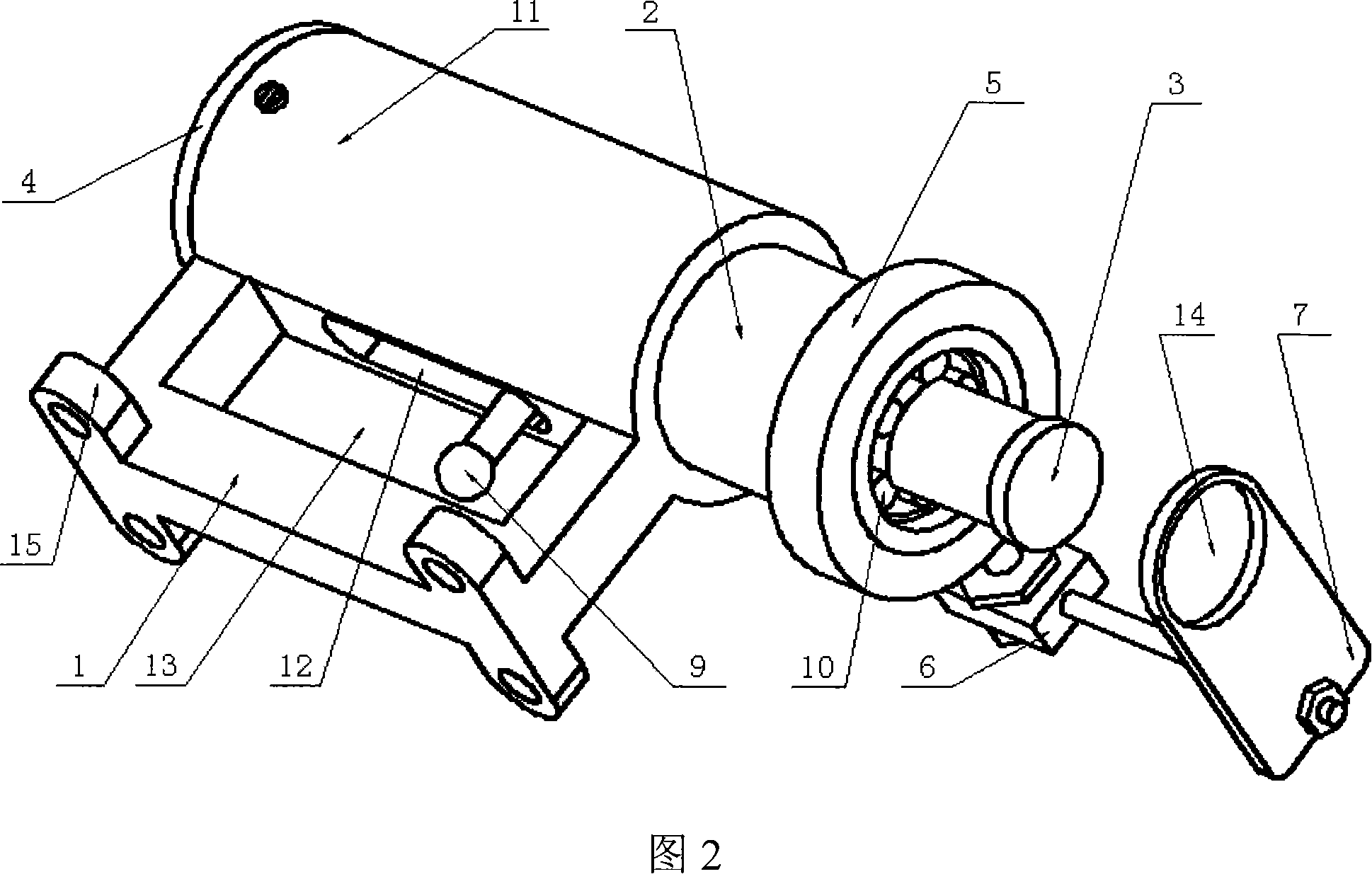

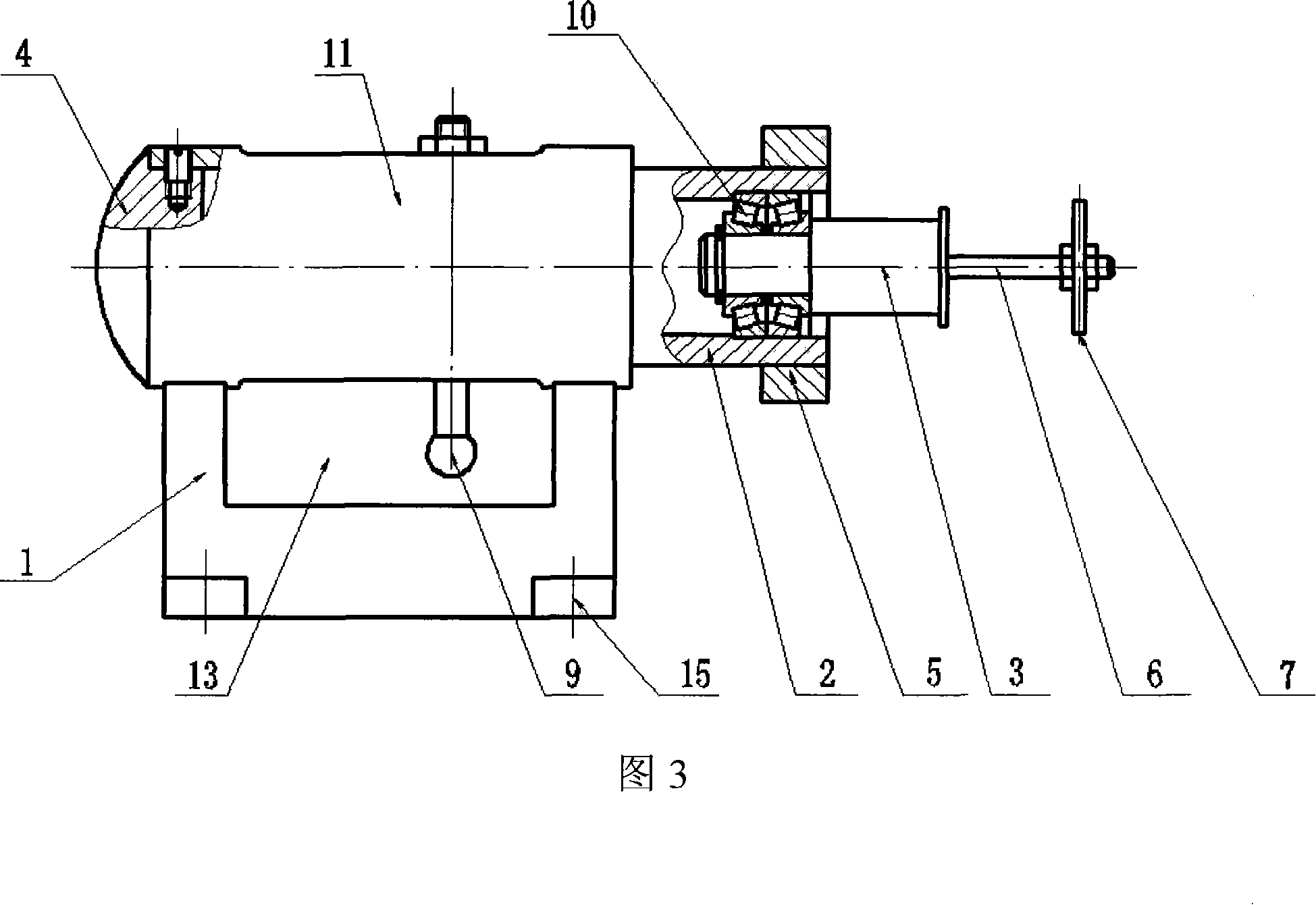

[0011] Embodiments of the present invention will be specifically described below with reference to FIGS. 1 to 3 .

[0012] As shown in Figure 1, Figure 2 and Figure 3, the thin-walled pipe material automatic return and clamping device mainly includes a support plate 1, an inner sliding cylinder 2, a material ejector 3, a clamping spring 8, an end cover 4, and a connecting ring 5, support rod 6, return sheet 7, connecting screw rod 9 and bearing 10. Wherein, the upper end of the support plate 1 is provided with an outer sleeve 11 with both ends open, and the upper and lower sides of the outer sleeve 11 are provided with keyway type through holes 12; the outer sleeve 11 is sequentially provided with end caps 4, The clamping spring 8 and the inner sliding sleeve 2 are fixedly connected to the tail end of the inner sliding sleeve 2 through the upper and lower keyway type through holes 12 of the outer sleeve 11 through the connecting screw 9, and the inner sliding sleeve 2 is limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com