Vertical cylinder type vibration coal and gangue separator

A technology of coal gangue separation and separator, which is applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of high energy consumption, limited processing capacity, and increased difficulty in manufacturing and maintenance, so as to improve work efficiency and speed up processing. The effect of speed, industrial and mining adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with examples (accompanying drawings), but does not limit the present invention.

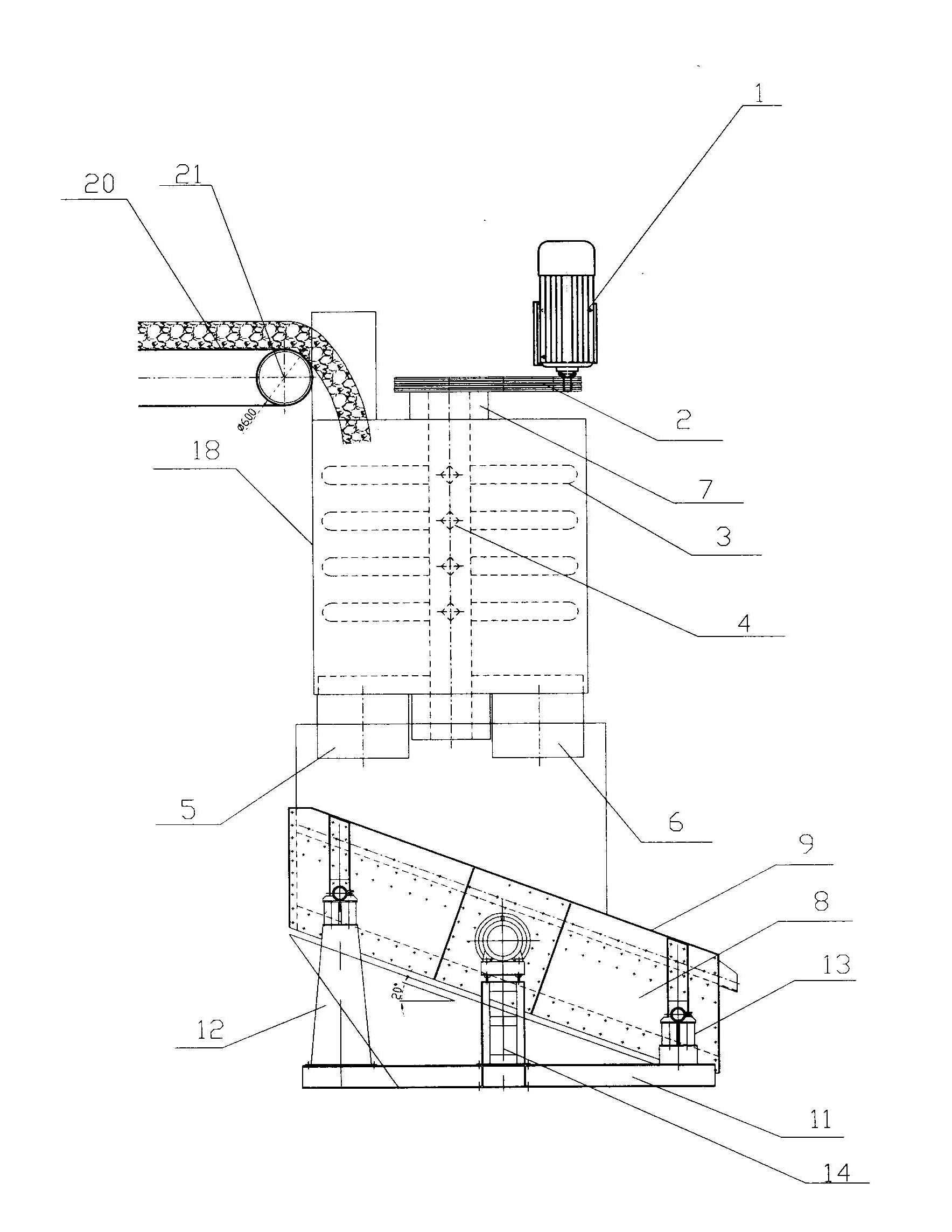

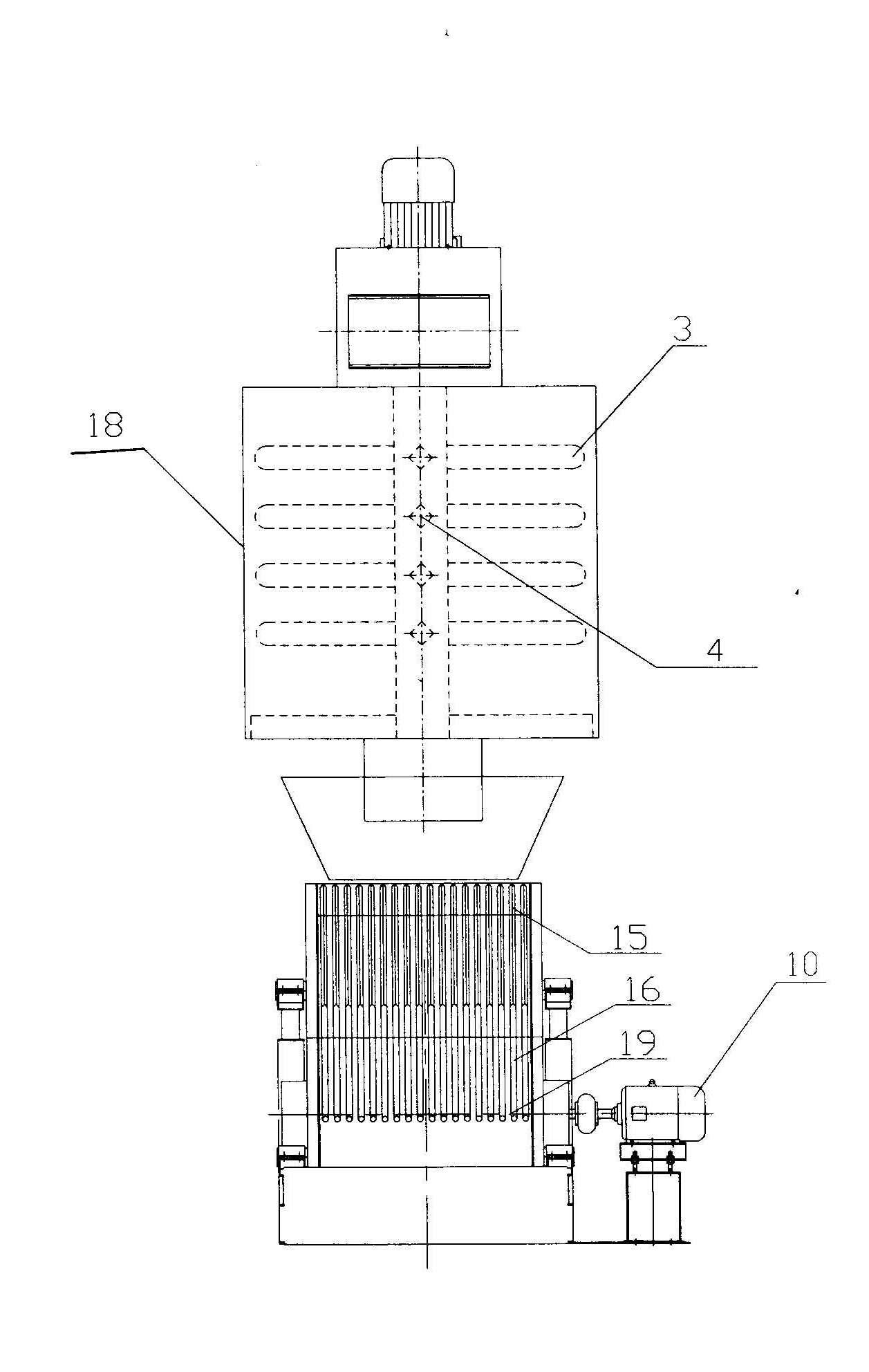

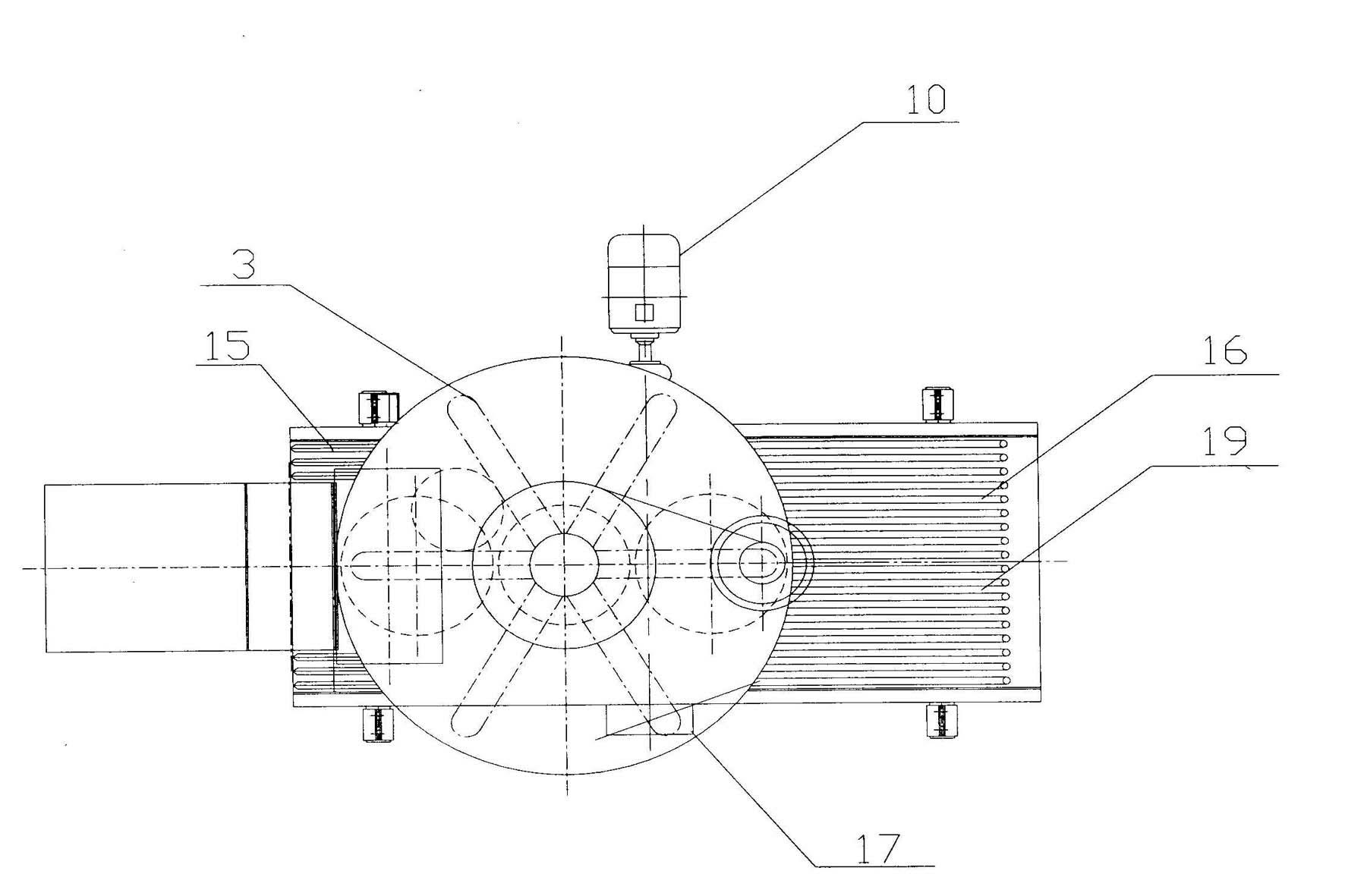

[0028] Such as figure 1 , 2 As shown in , 3, the vertical tube type vibrating coal and gangue separator of the present invention includes a vertically arranged coal and gangue separator cylinder 18, and a rotor shaft 4 driven by a power source installed in the cylinder in a coaxial manner with the cylinder And the crushing rotor 3 installed on the rotor shaft is composed of multiple layers and multiple strike bars arranged around the rotor shaft, the discharge port at the bottom of the cylinder, the feeding device arranged at the top of the cylinder, and the discharge port installed on the discharge The vibrating screen 8 below the mouth; the vibrating screen 8 includes the first frame 12, the middle frame 14 and the second frame 13 which are installed on the base 11 successively from high to low along the length direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com