Patents

Literature

78results about How to "Achieve primary crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

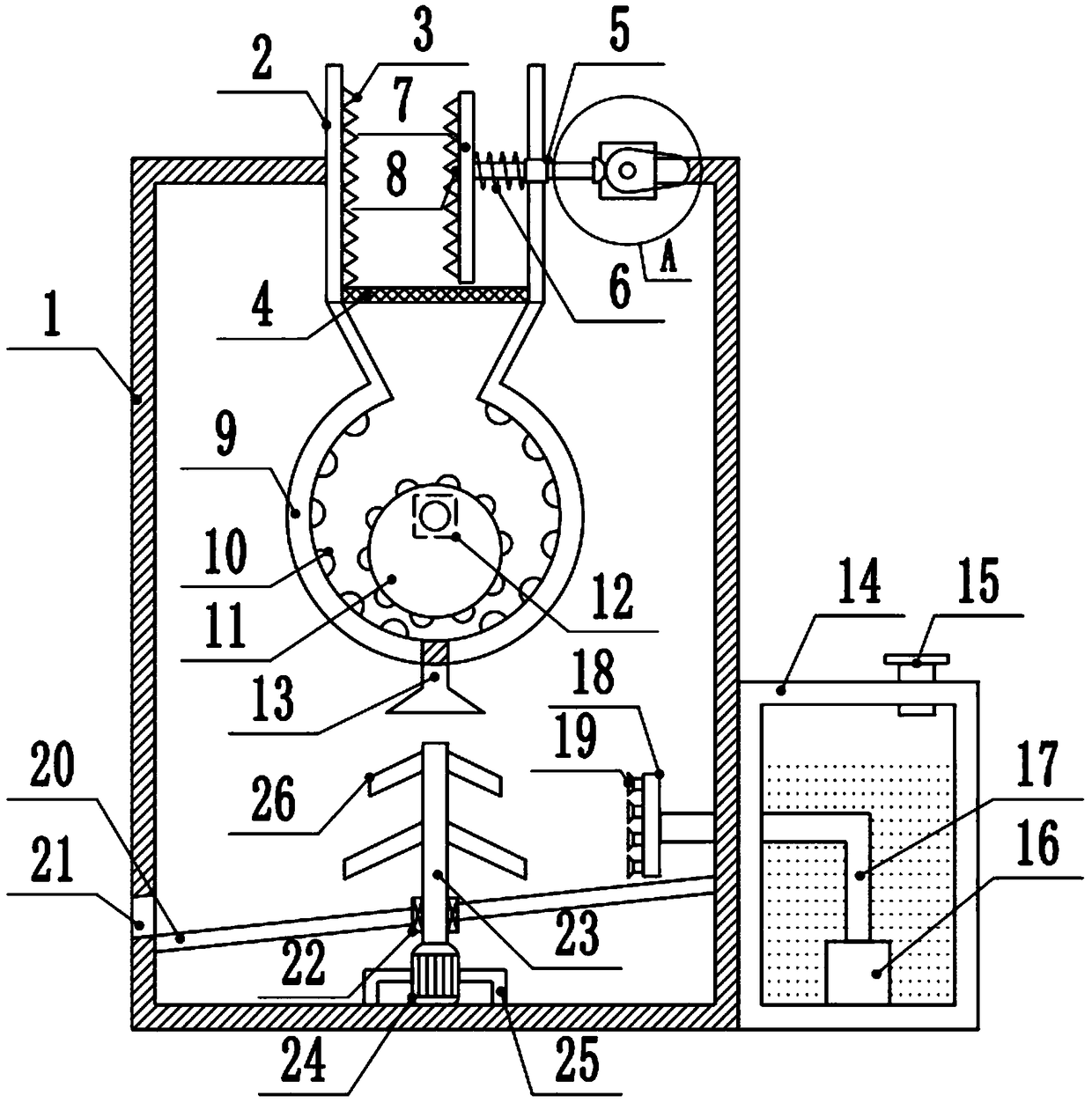

Fine grinding device for producing and processing powder cosmetics

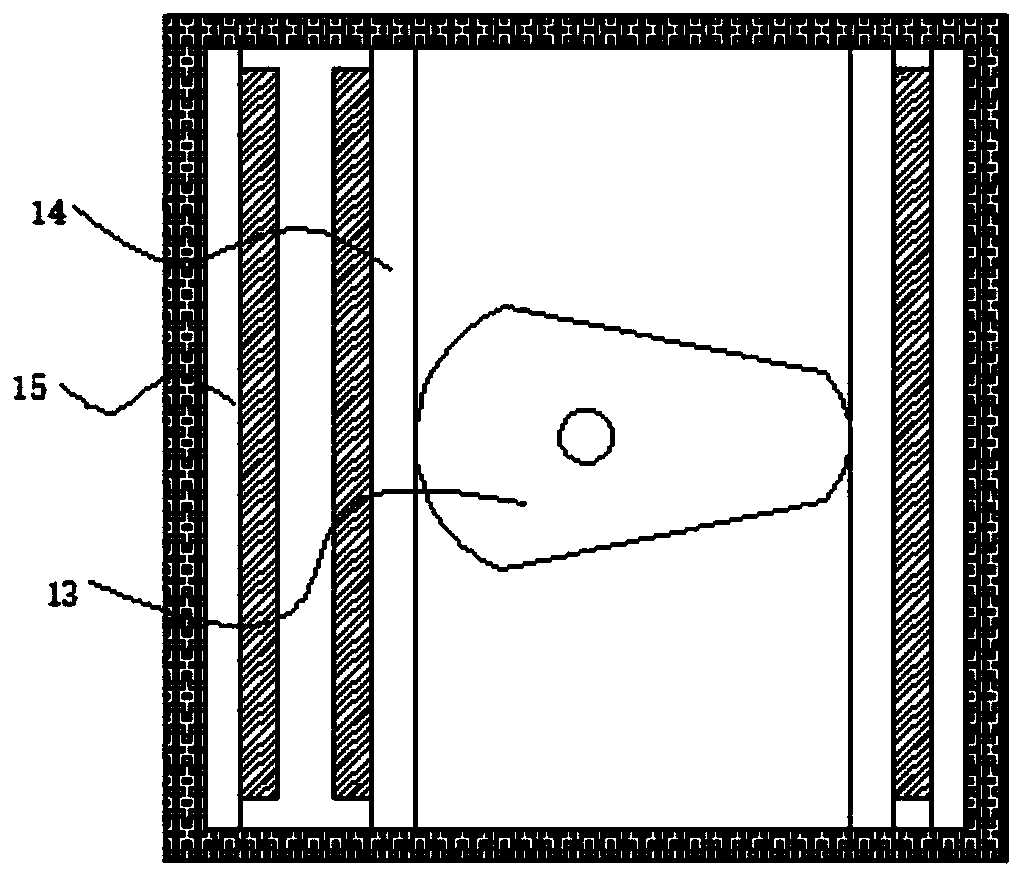

The invention discloses a fine grinding device for producing and processing powder cosmetics and relates to the field of cosmetics. The fine grinding device comprises a device box, wherein a crushingcylinder is fixedly connected with the interior of a middle part of an upper box body of the device box; a first pushing rod and a second pushing rod are in contact connection with the interiors of box bodies on the left side and the right side of the crushing cylinder; the right end of the first pushing rod and the left end of the second pushing rod are respectively fixedly connected with extrusion plates; crushing teeth are respectively fixedly mounted on the surfaces of the extrusion plates; the crushing teeth are in engaged connection with each other; the right end of the second pushing rod is fixedly connected with a second stop block; the outer surface of the right end of the second pushing rod is in contact connection with a spring; the other end of the spring is fixedly connected with the surface of the second stop block; the surface of the right side of the second stop block is in contact connection with a cam; the right rear part of the center of the cam is connected with a first motor. According to the fine grinding device, eccentric grinding rollers are capable of alternately and repeatedly rotating clockwise and counterclockwise so as to grind, so that the raw materials of the cosmetics can be more fully and completely ground; the fine grinding device has better grinding effect and high practicability.

Owner:张玉娥

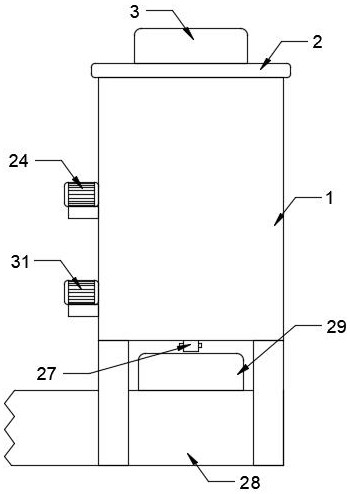

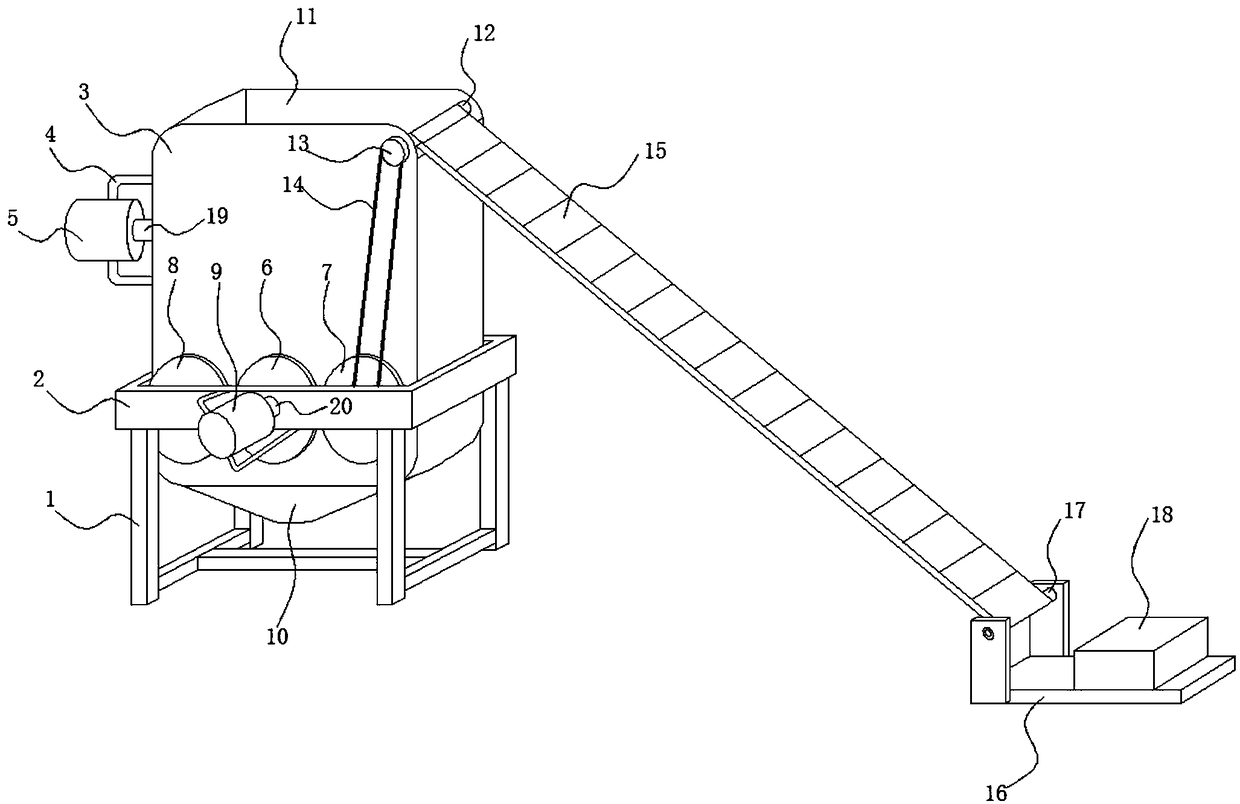

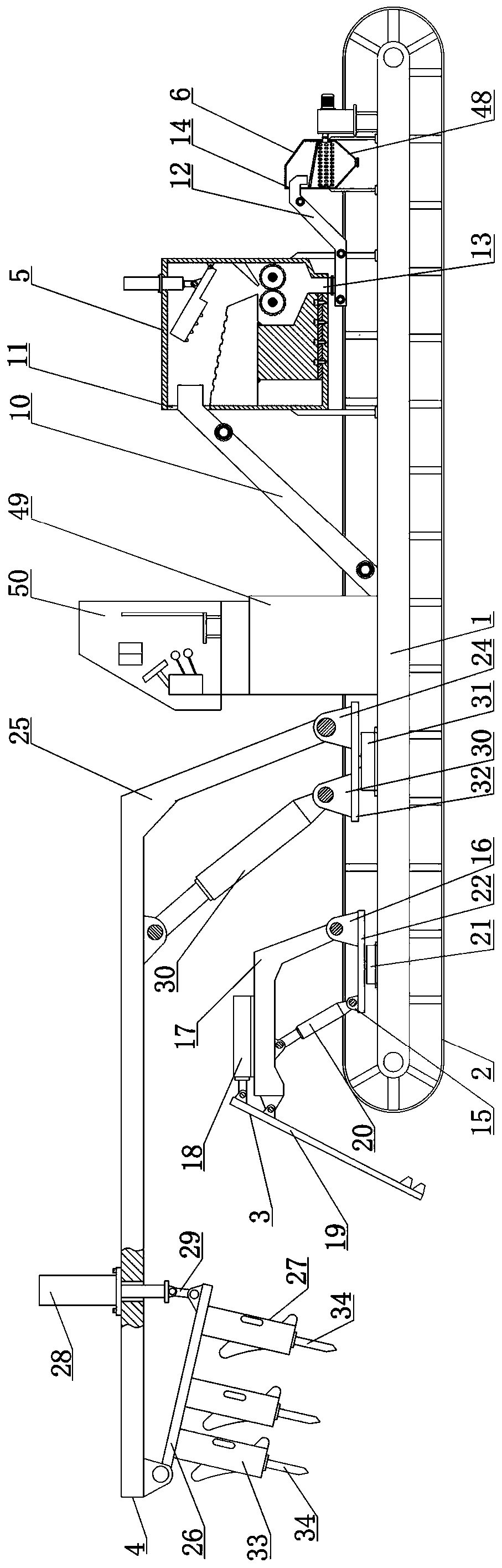

Crushing, stirring and lifting device for construction

InactiveCN107127038ASimple and reasonable designEasy to operatePackagingGrain treatmentsQuality assuranceBuilding material

The invention discloses a crushing and stirring lifting device for building construction, which comprises a bottom frame, a shock-absorbing layer and a base. A second crushing box is provided, the lower end of the second crushing box is provided with a feeding channel, the lower end of the feeding channel is provided with a first conveying cylinder, the right end of the first conveying cylinder is provided with a conveying port, and the lower right end of the conveying port is provided with a second Two delivery cylinders. This device realizes double crushing and mixing of building materials, ensures the quality of material crushing and mixing, and realizes the lifting of materials from low to high, which brings great convenience to construction and can greatly reduce the labor intensity of workers , which is conducive to improving the efficiency of construction. The shock absorbing mechanism and the shock absorbing layer have a good shock absorbing and buffering effect, which can reduce the vibration caused by the equipment during operation, protect the device, and prolong the service life of the device. .

Owner:蔡政伟

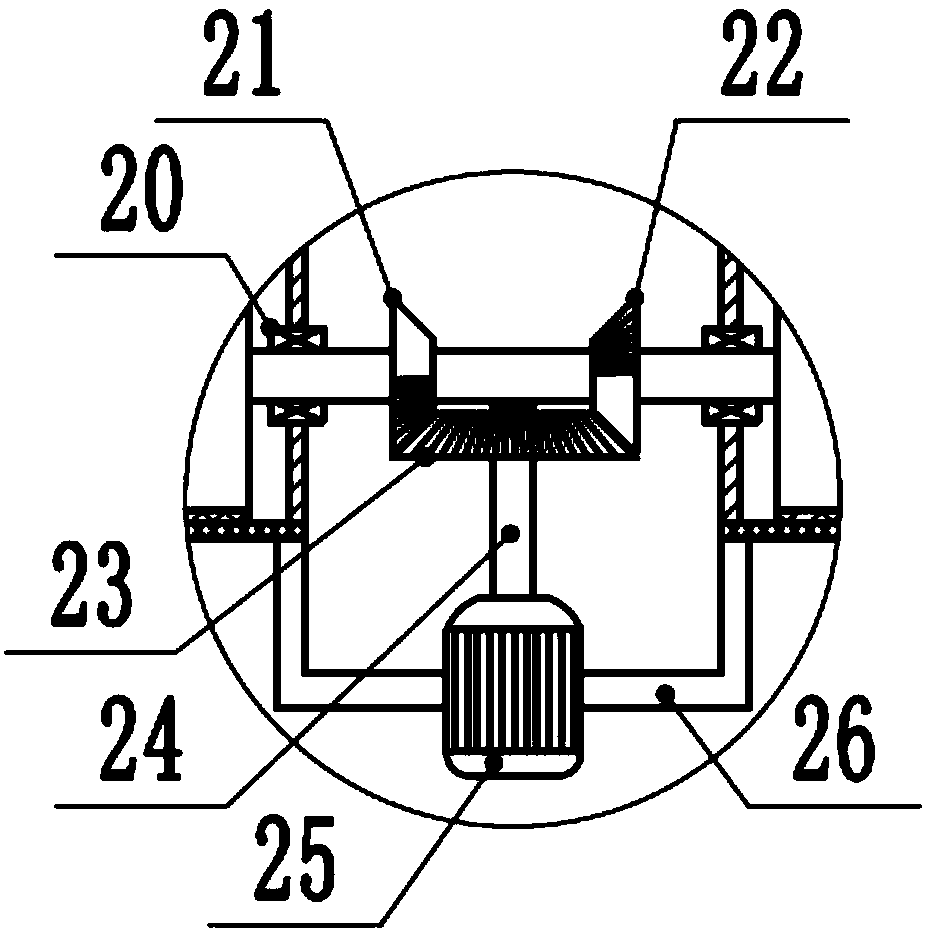

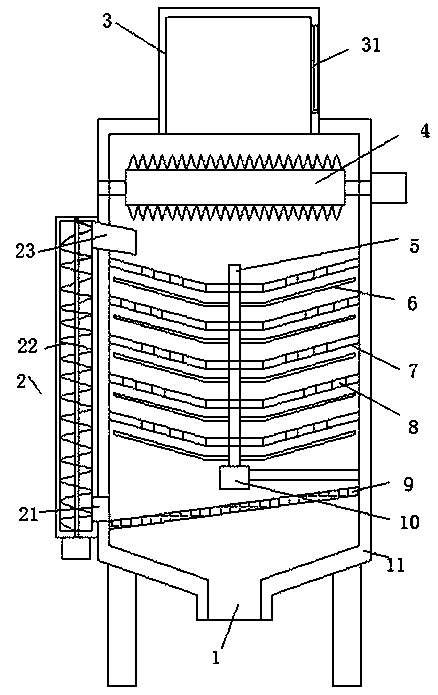

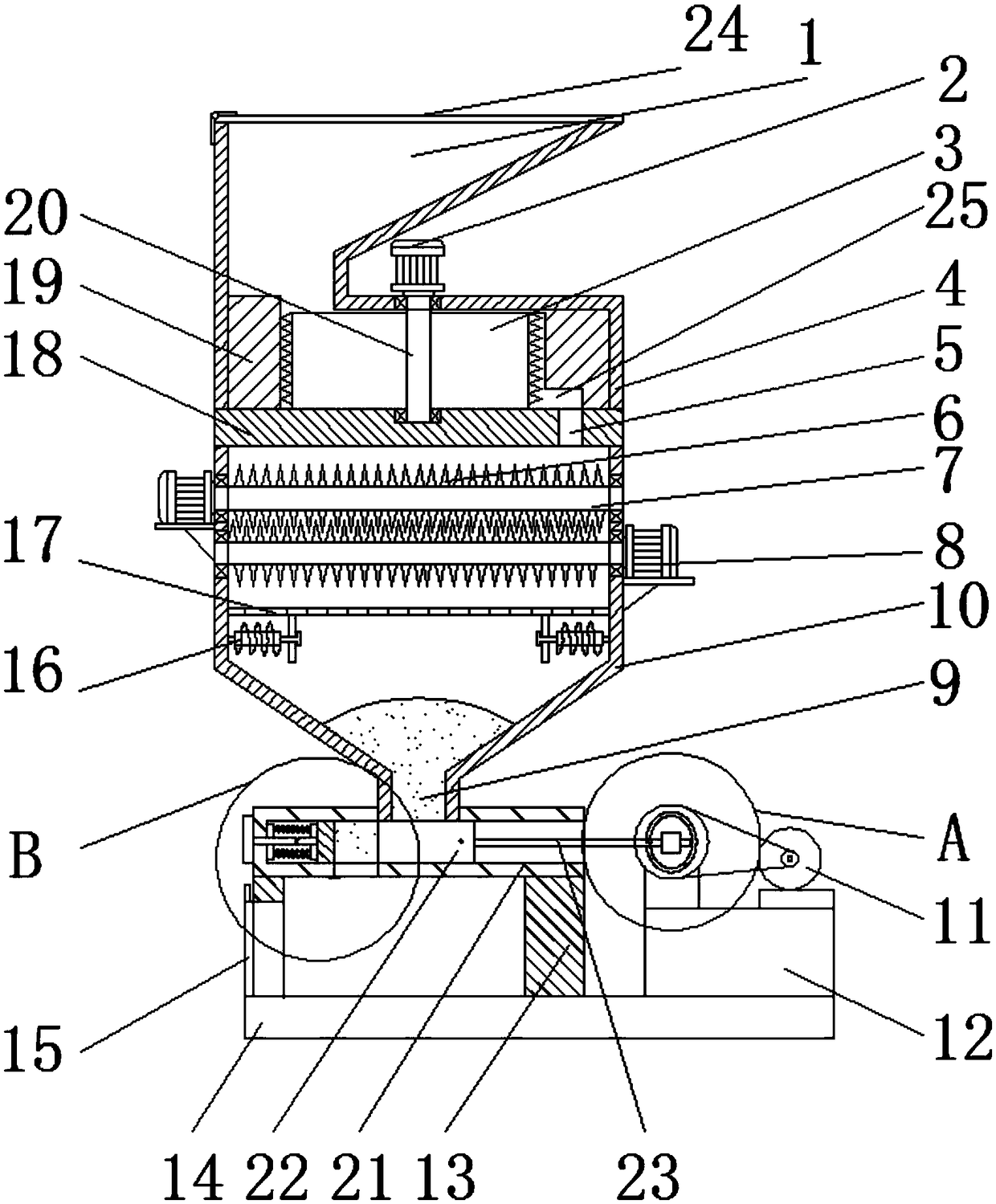

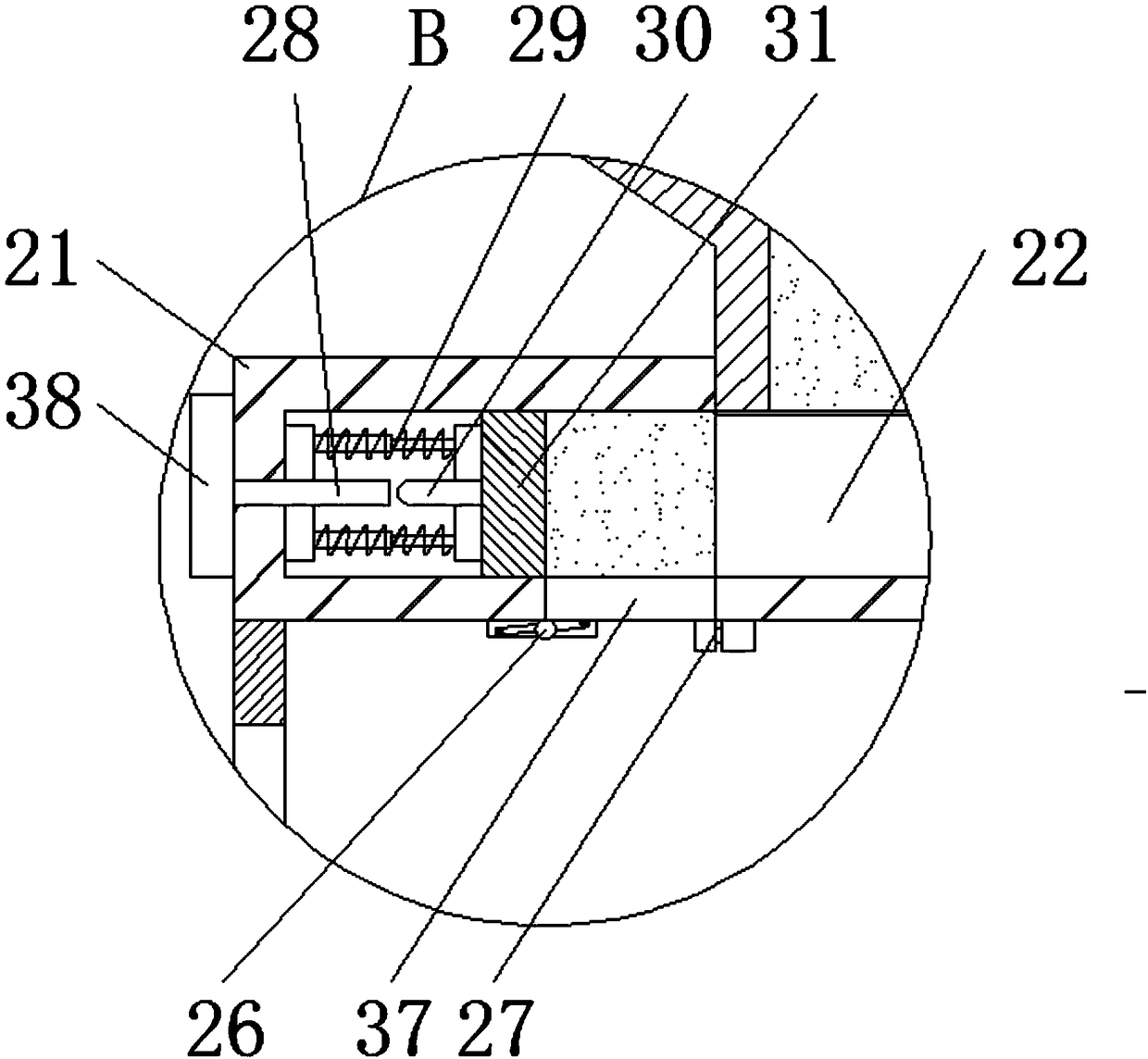

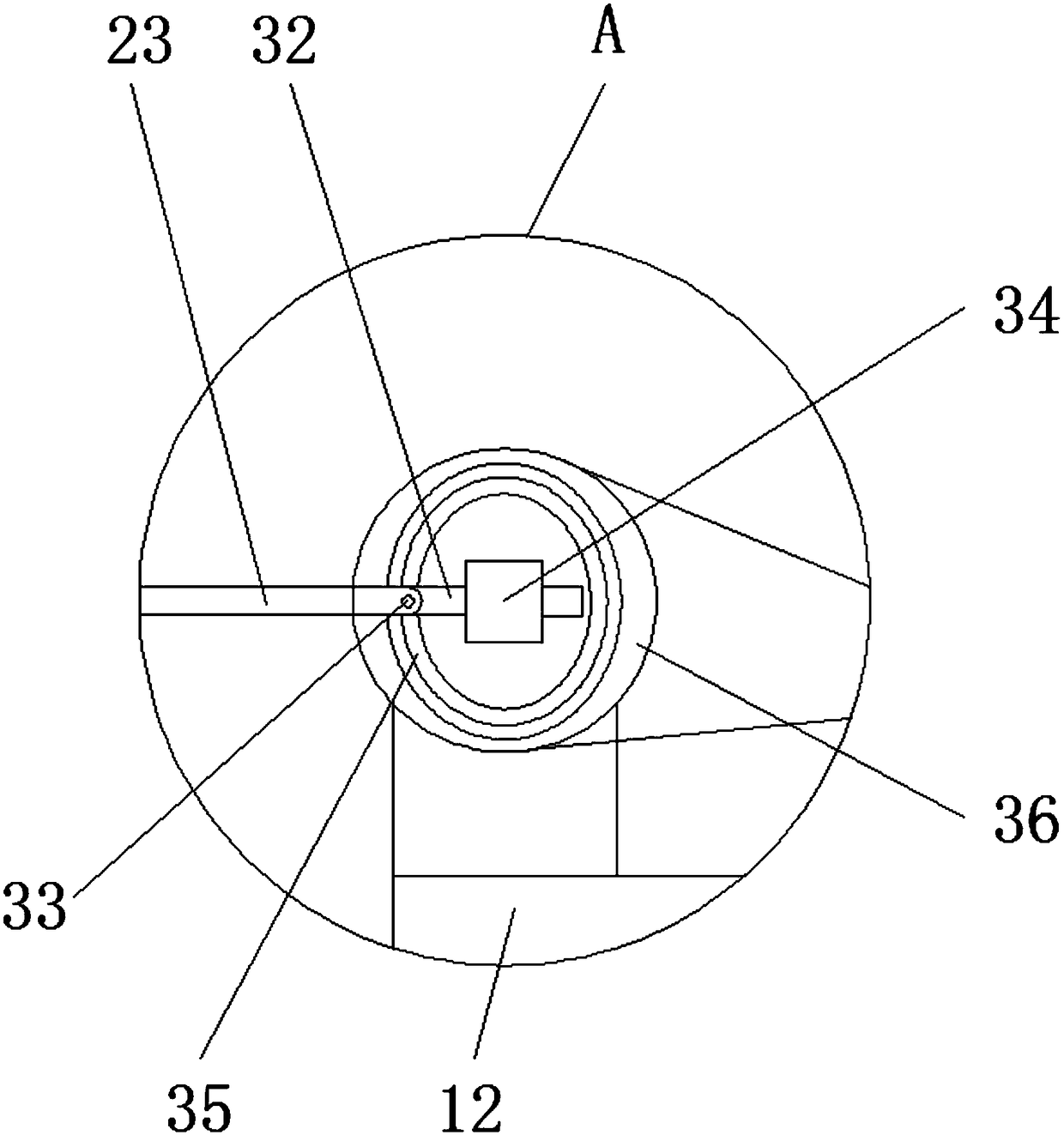

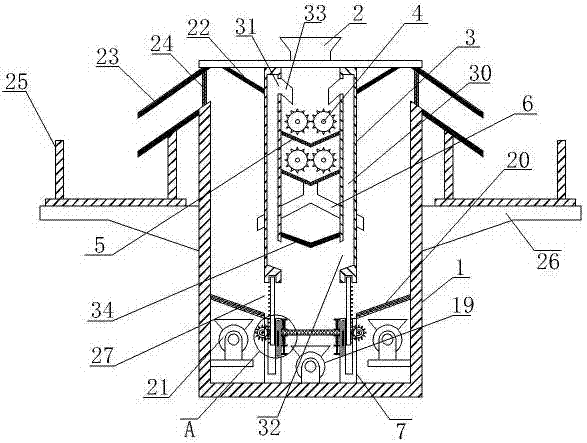

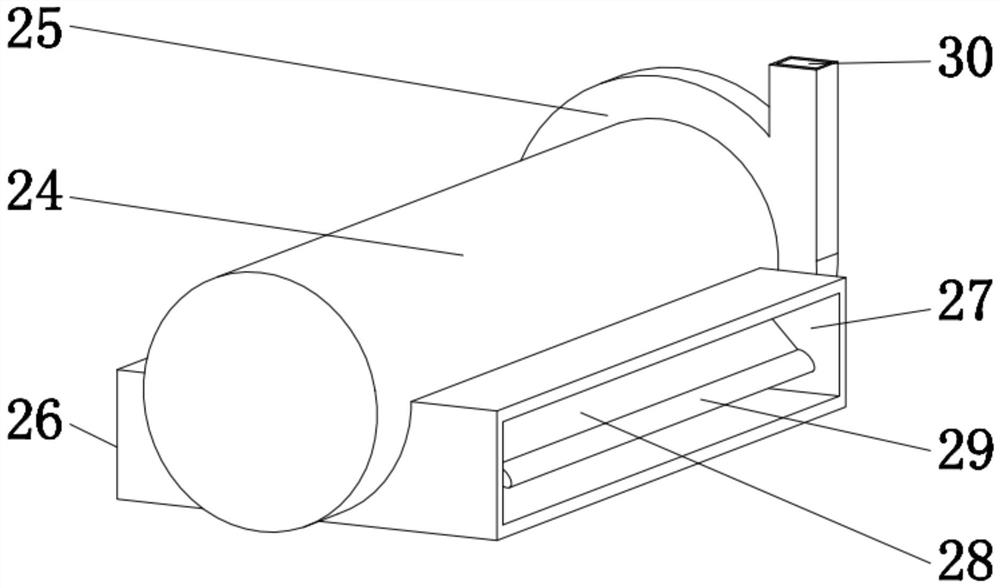

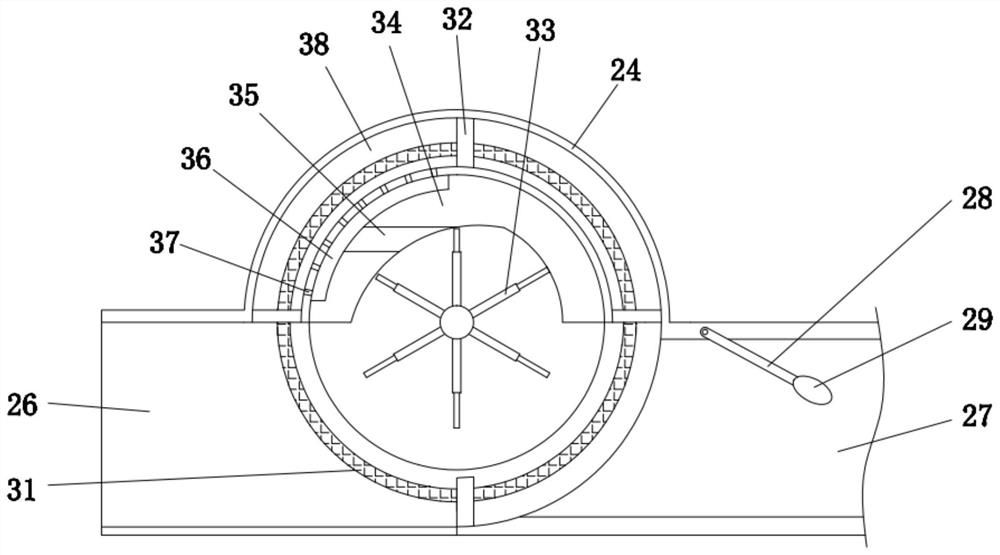

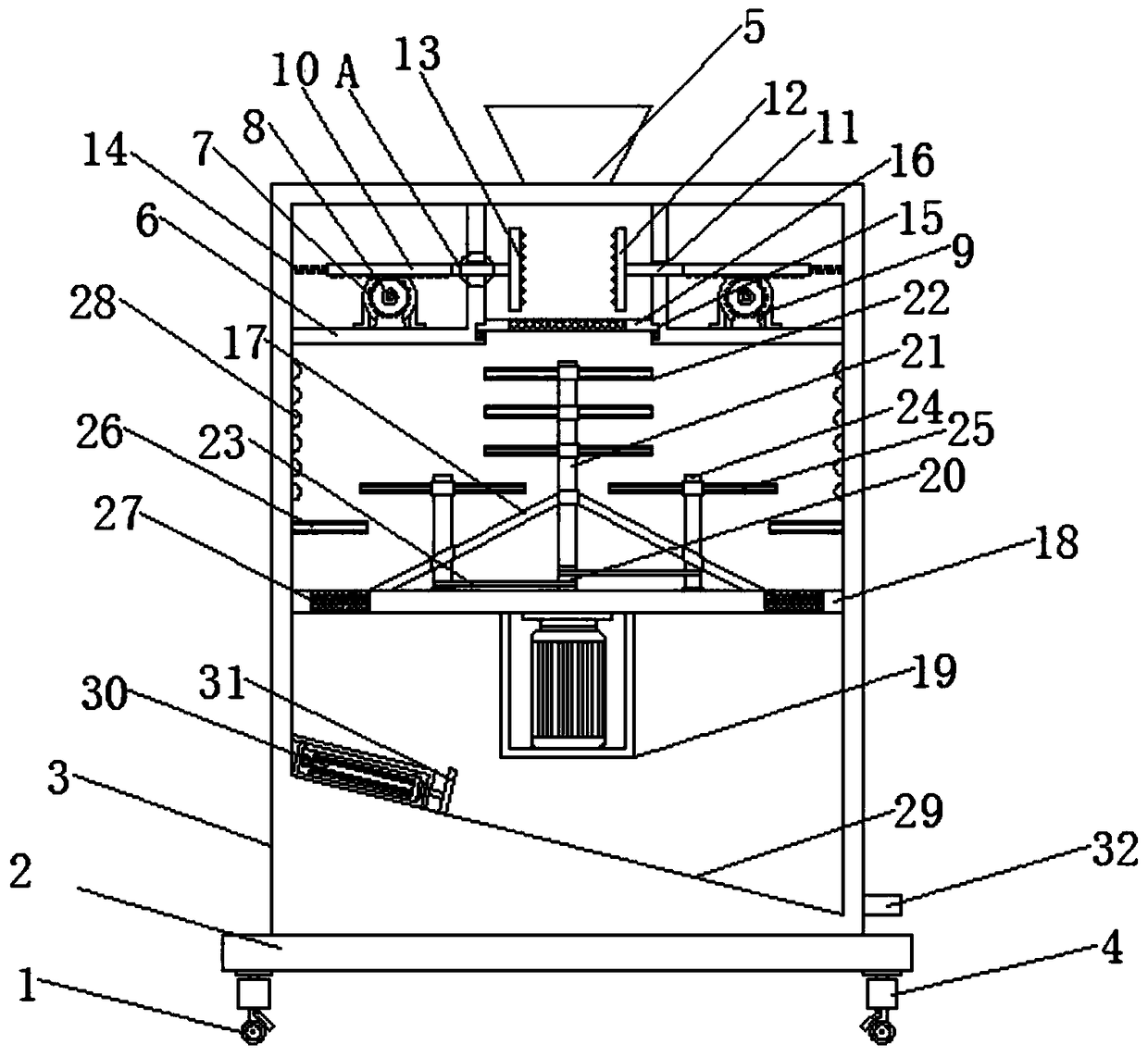

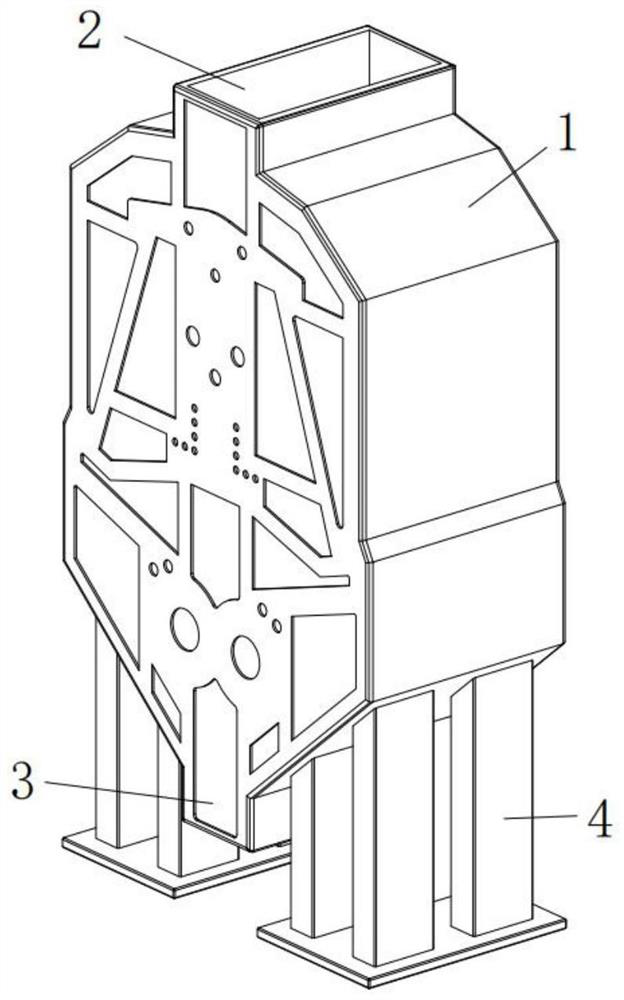

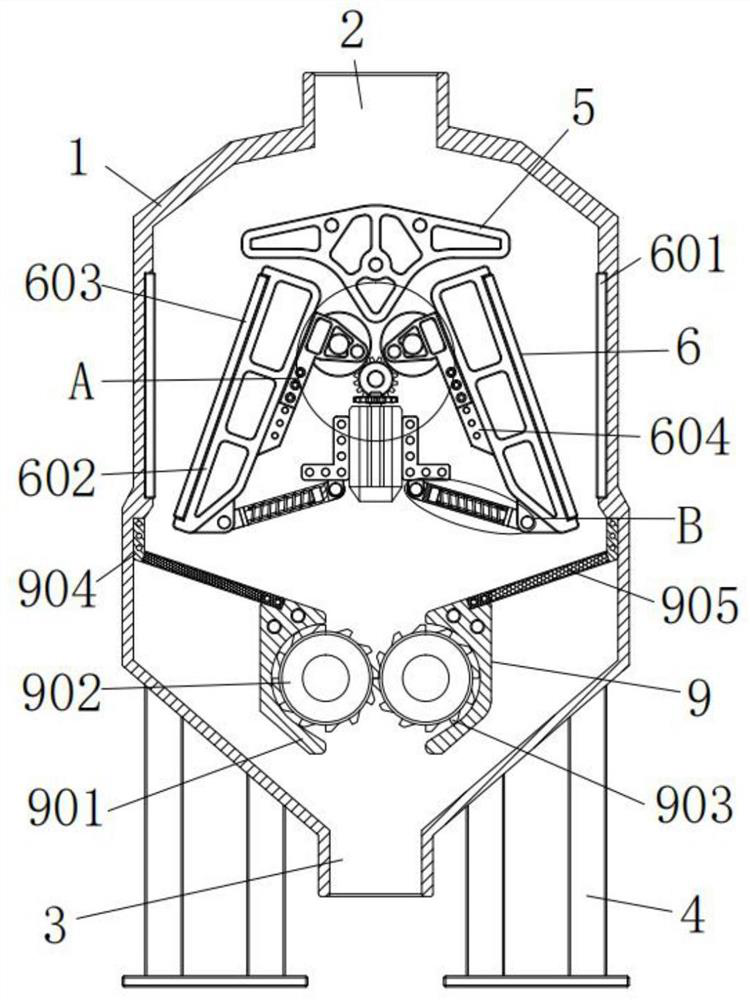

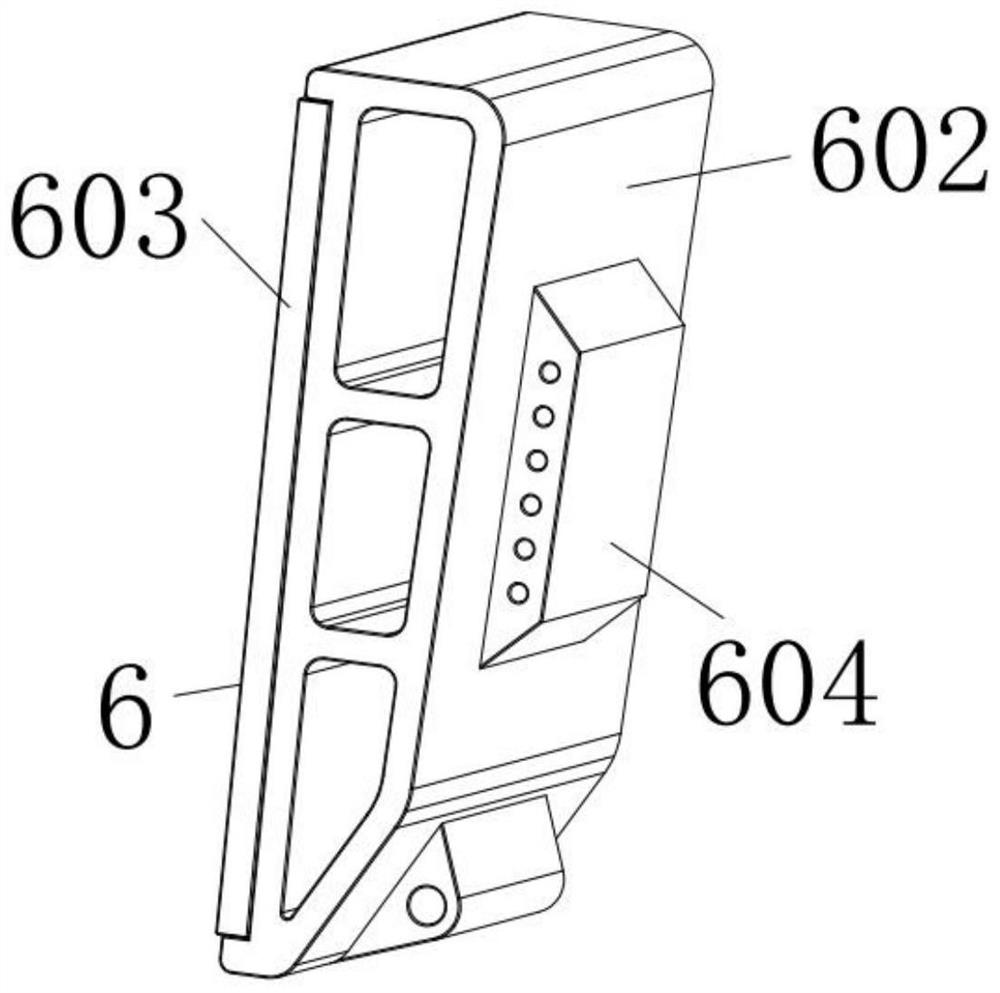

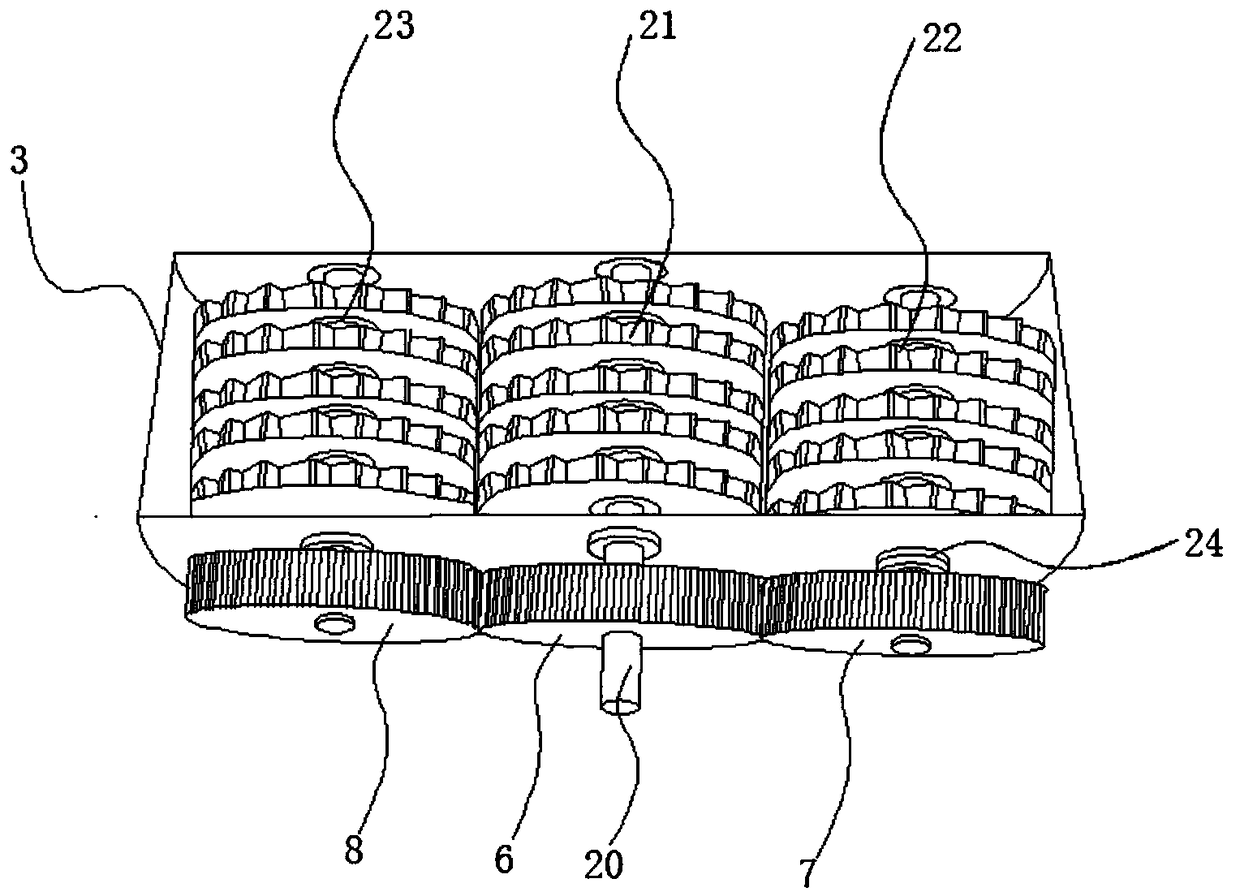

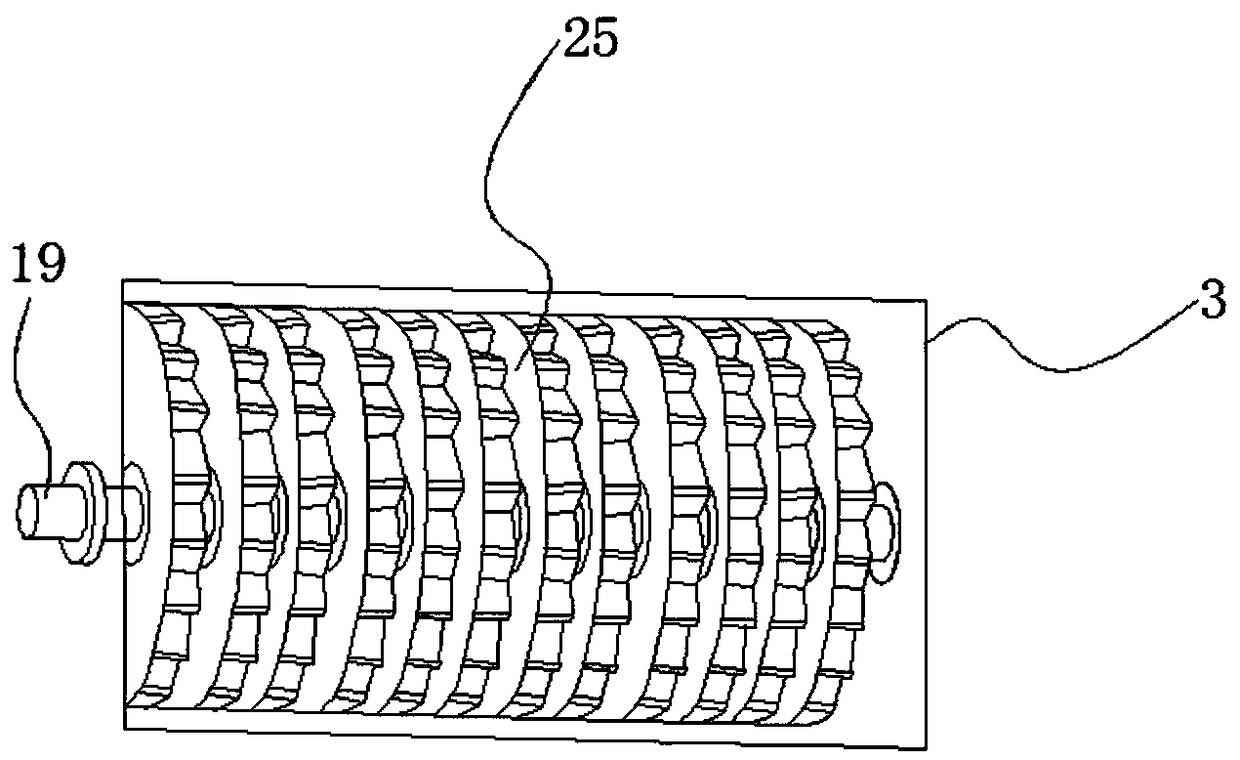

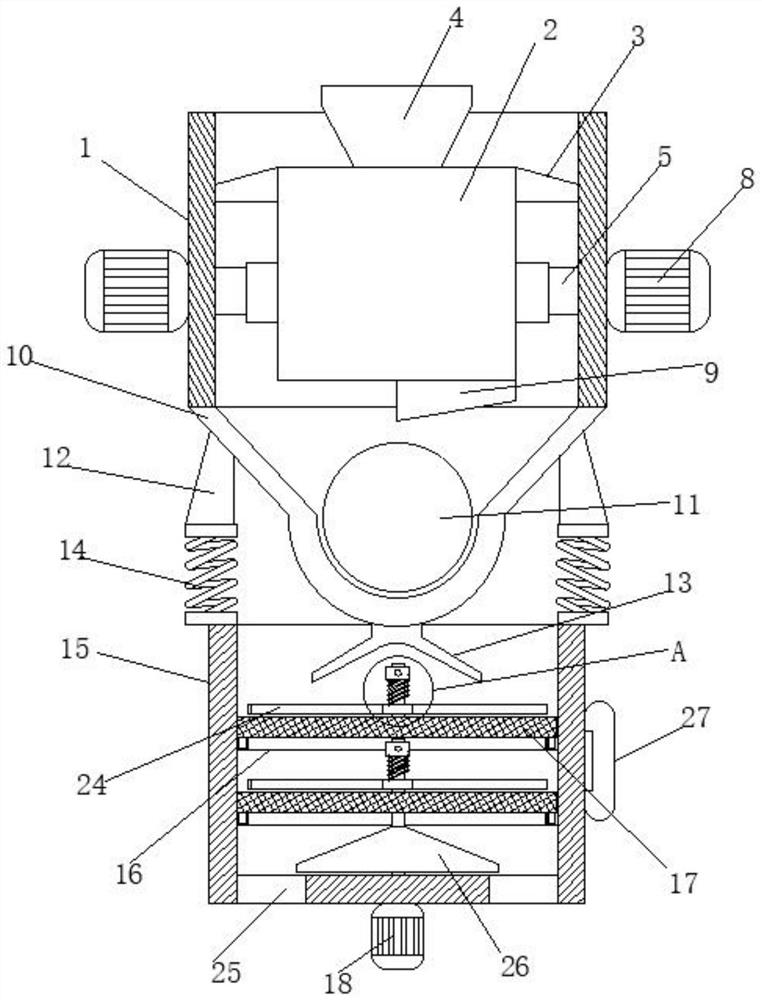

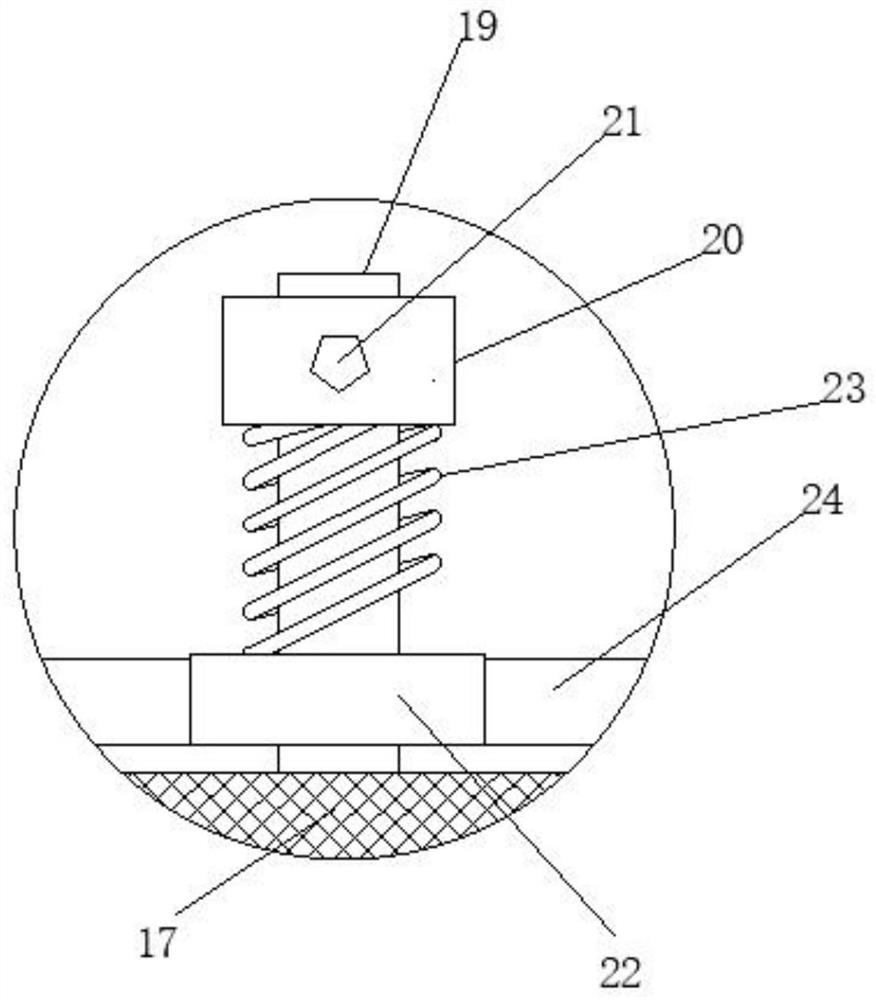

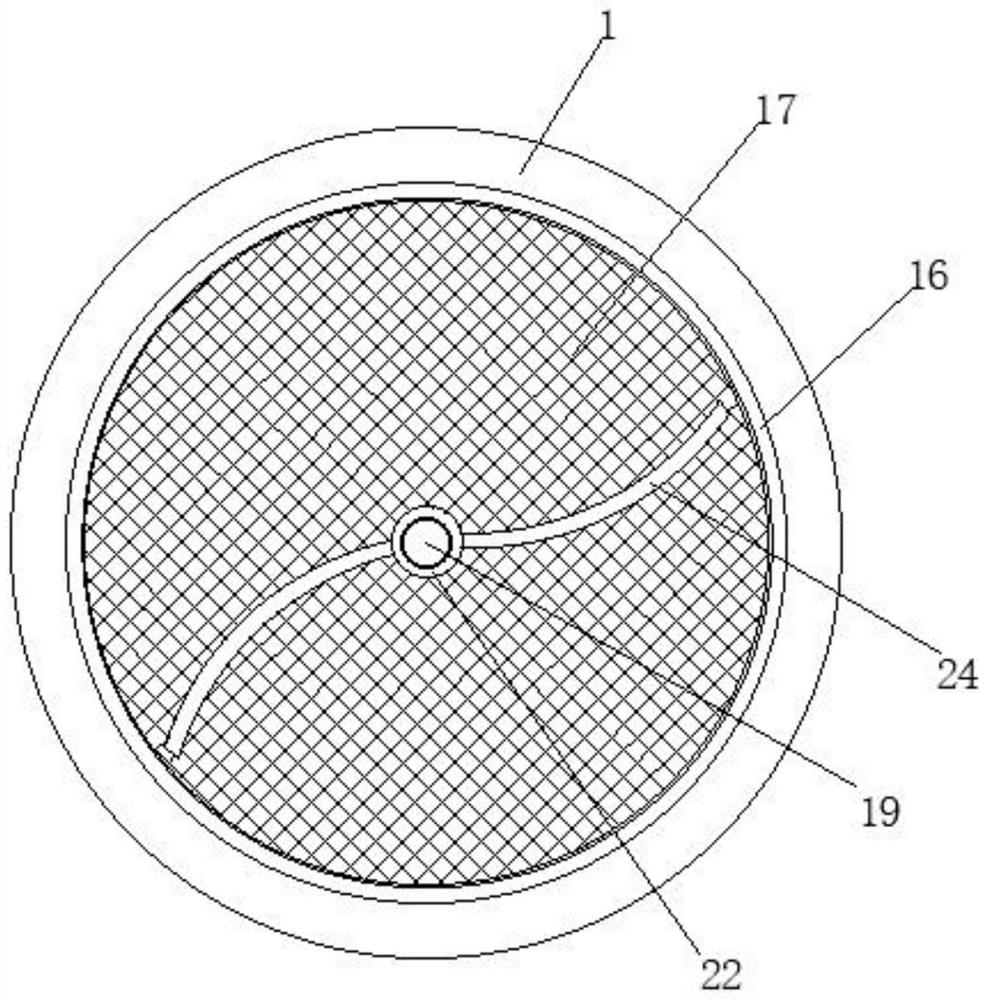

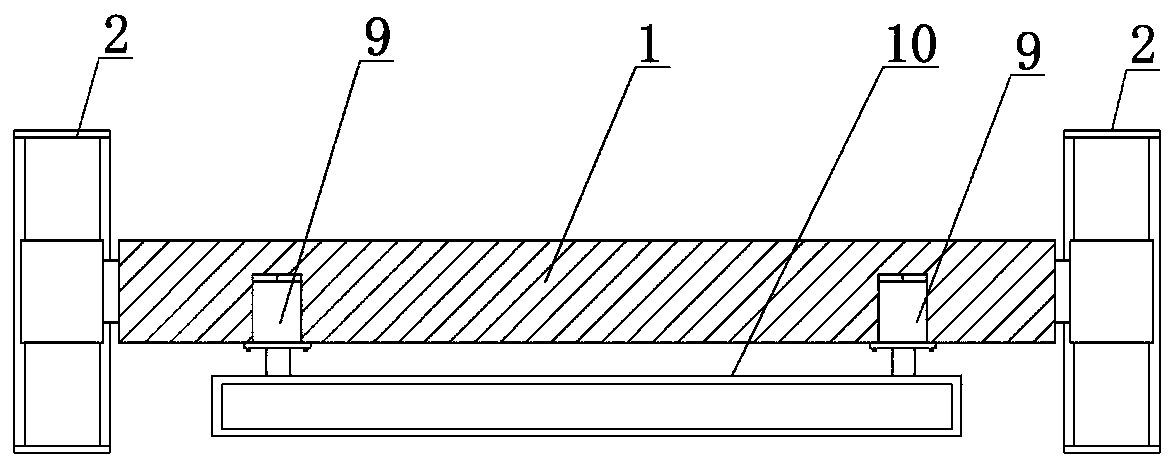

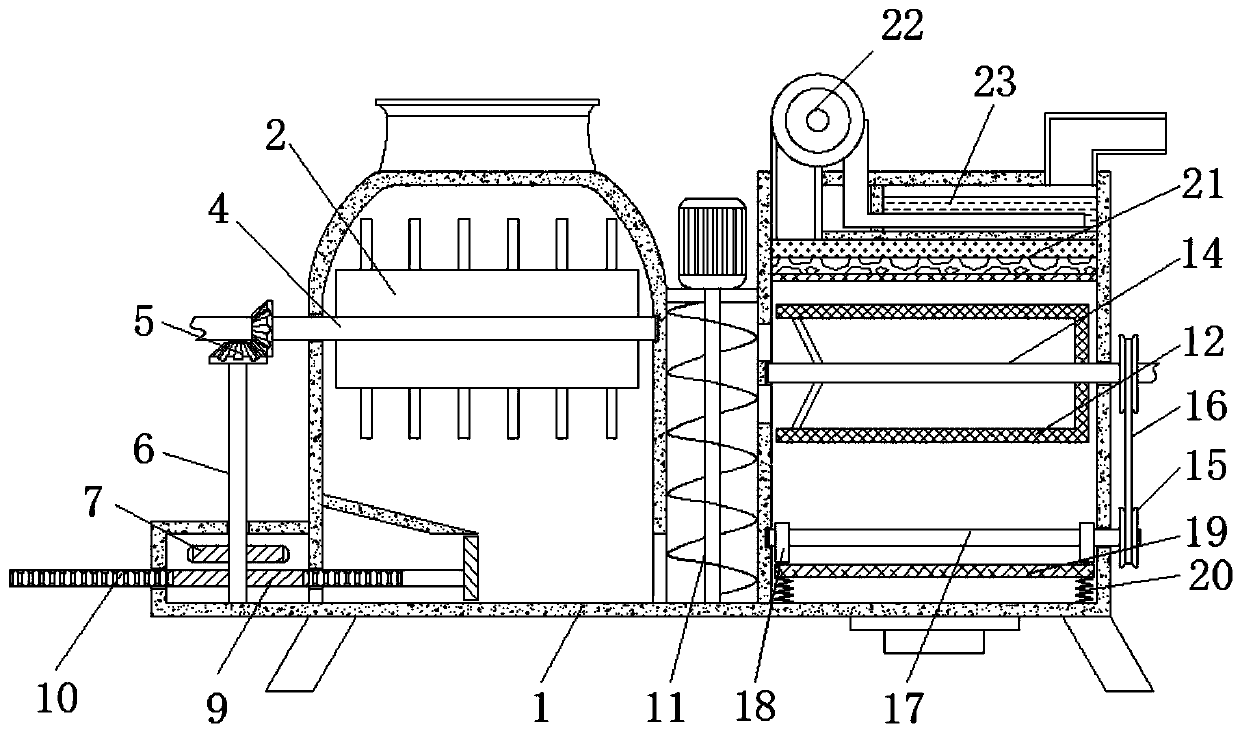

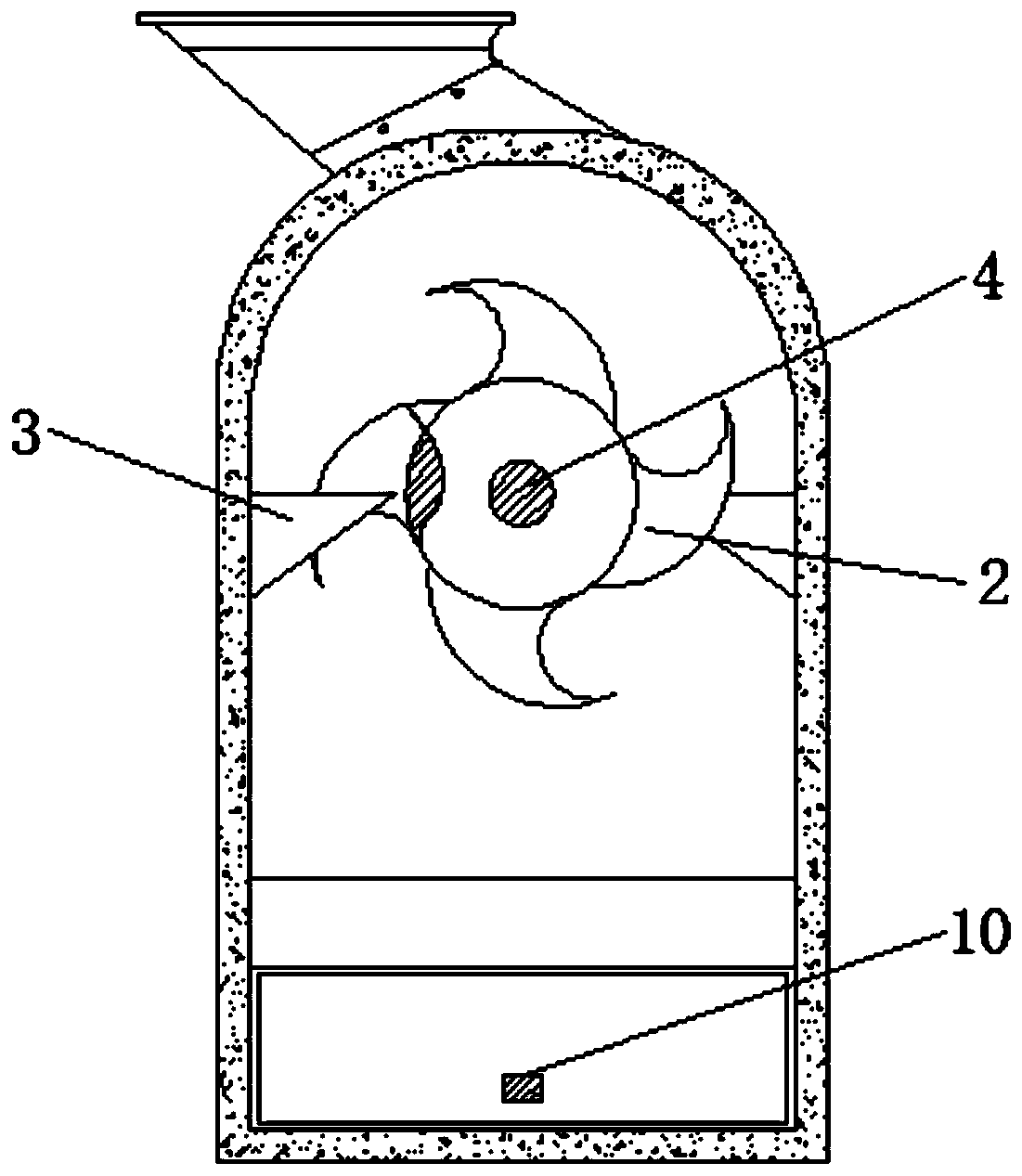

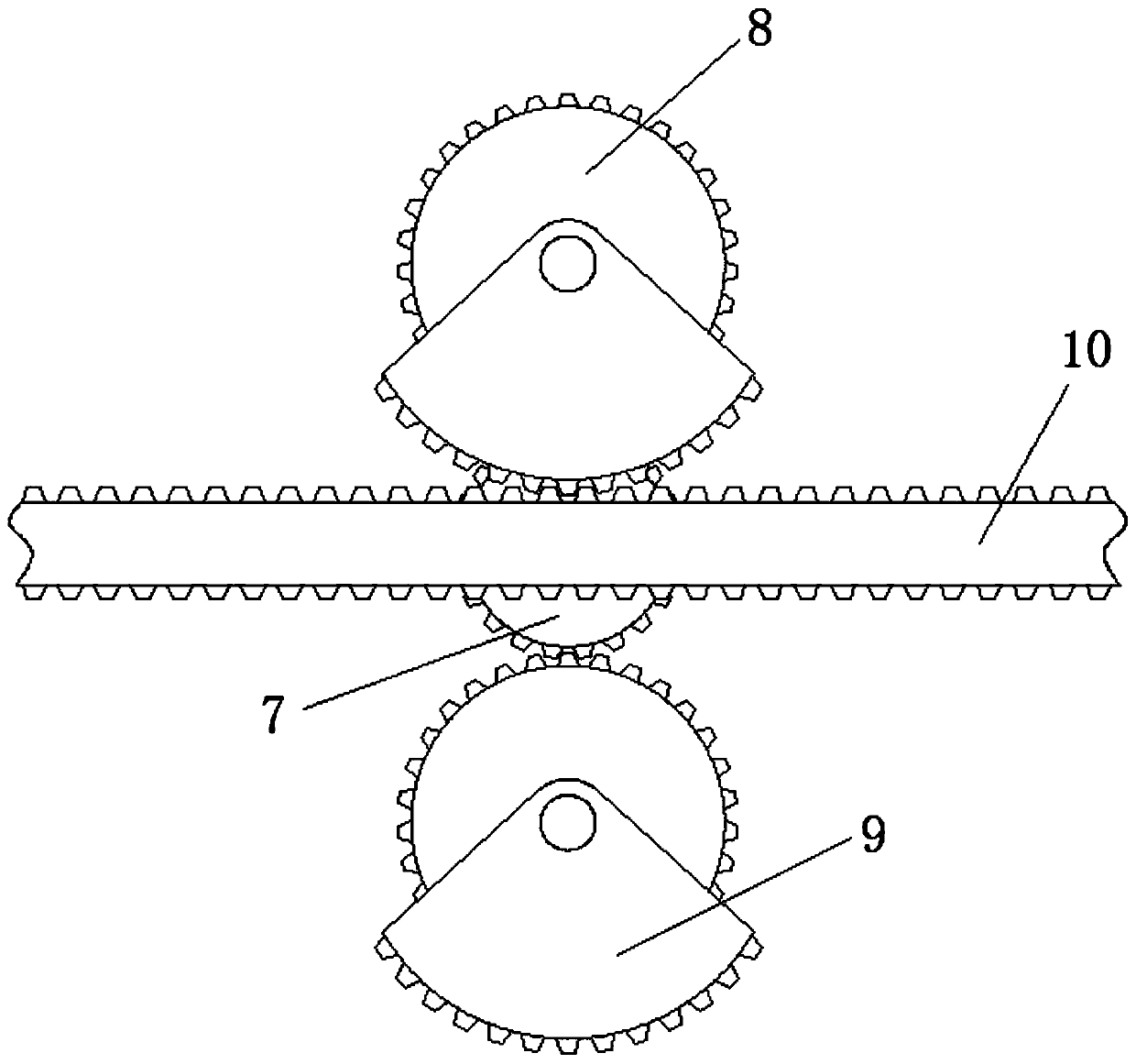

High-efficient crushing device for building garbage

ActiveCN108160289ARealization of rotary extrusion crushingAchieve primary crushingGrain treatmentsDrive shaftArchitectural engineering

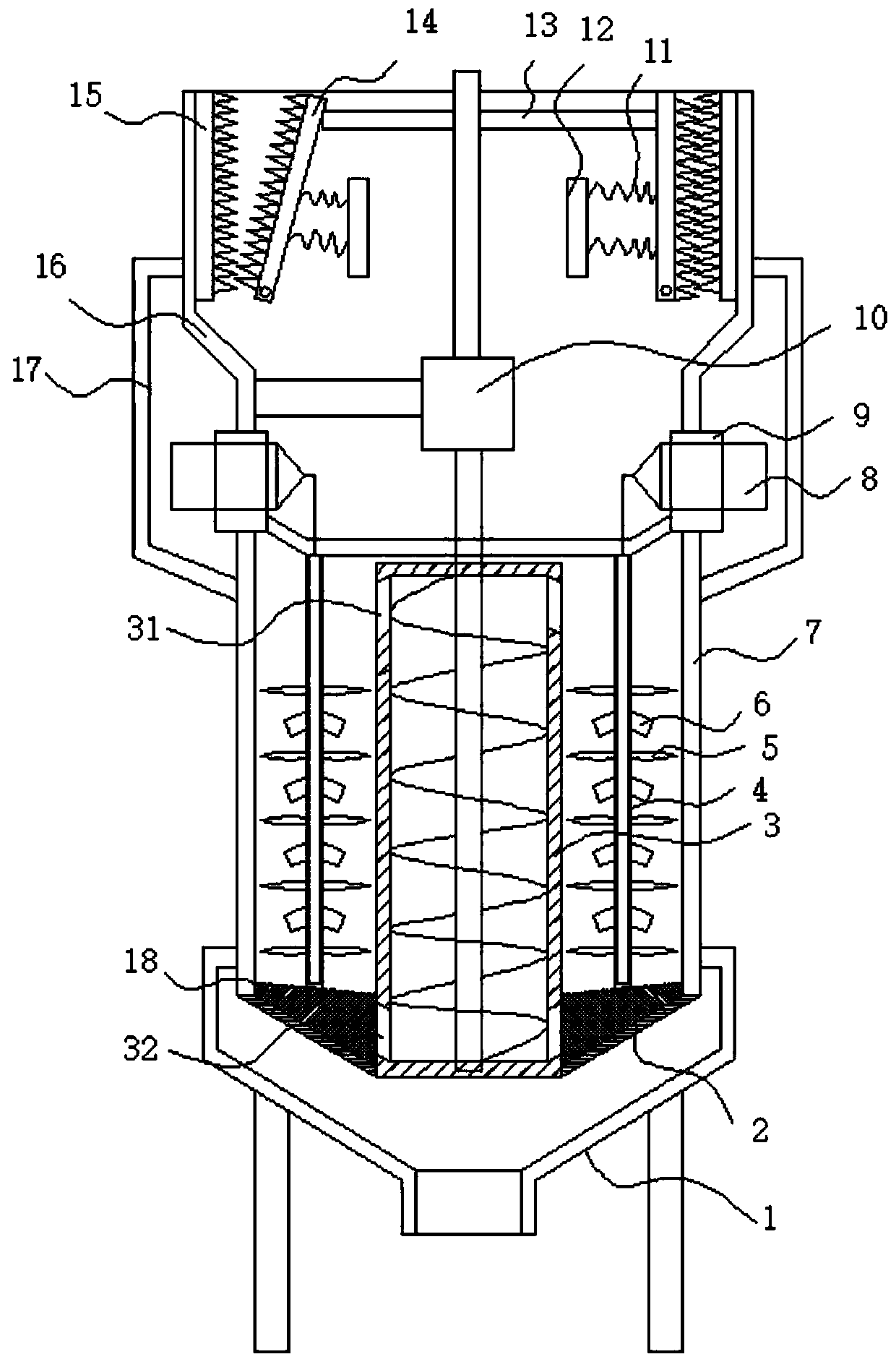

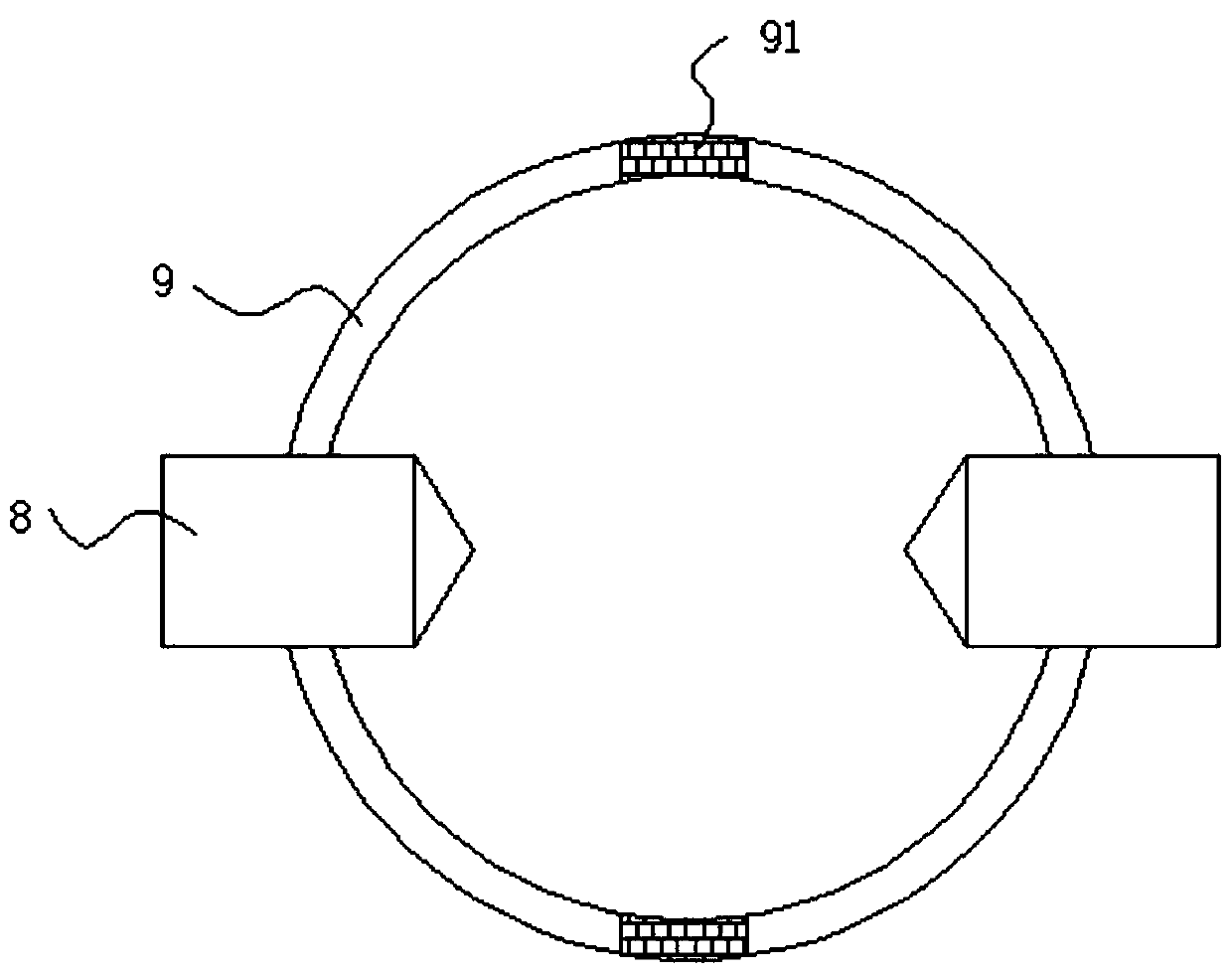

The invention discloses a high-efficient crushing device for building garbage. The high-efficient crushing device for the building garbage comprises a support frame, wherein a crushing barrel is vertically and fixedly arranged on the support frame; a first horizontal rod and a second horizontal rod are horizontally and fixedly arranged in the crushing barrel; a first driven shaft, a second drivenshaft and a driving shaft are rotatably arranged on the first horizontal rod and the second horizontal rod; the upper end of a first driving rod is hinged to a bottom surface of a crushing groove; andfeeding pipes are arranged on upper side walls of the left and the right of the crushing barrel. According to the high-efficient crushing device for the building garbage provided by the invention, the building garbage is rotatably squeezed and crushed through a first crushing roller, a second crushing roller and a third crushing roller so as to be preliminarily crushed, the building garbage in the crushing groove is further rotatably squeezed and crushed through the rotation of a crushing plate and the swinging of the crushing groove, and the building garbage is promoted to be uniformly pavedand scattered on a bottom surface in the crushing groove through the swinging of the crushing groove, so that the building garbage is fully and comprehensively crushed in a rubbing way, and the crushing efficiency is higher.

Owner:山西华正创新技术研究院有限公司

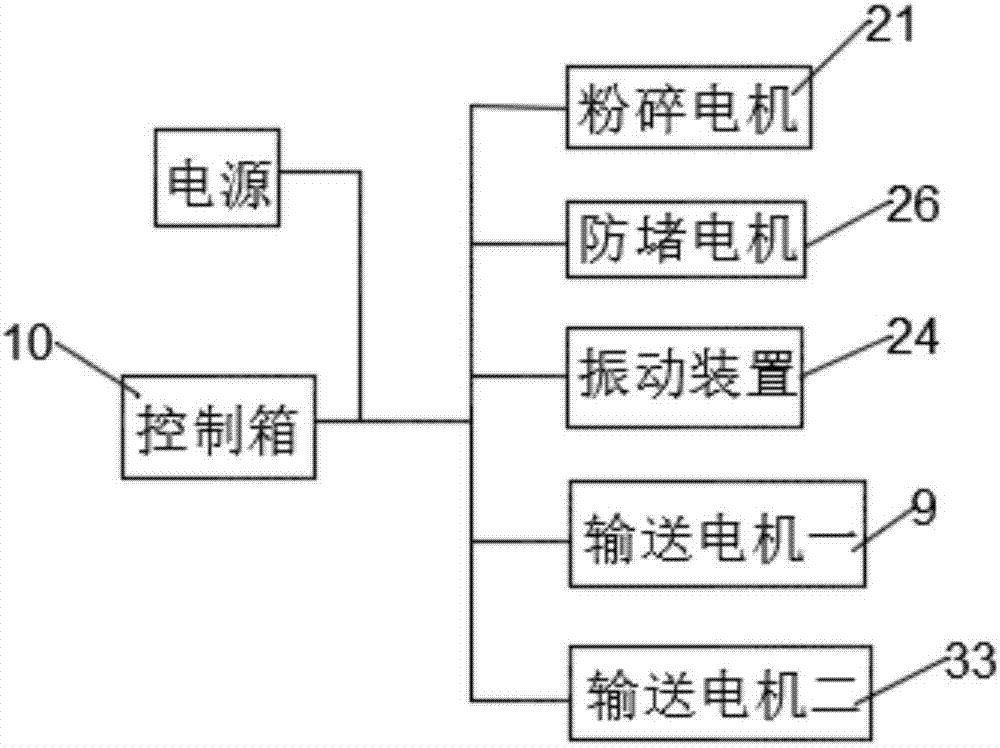

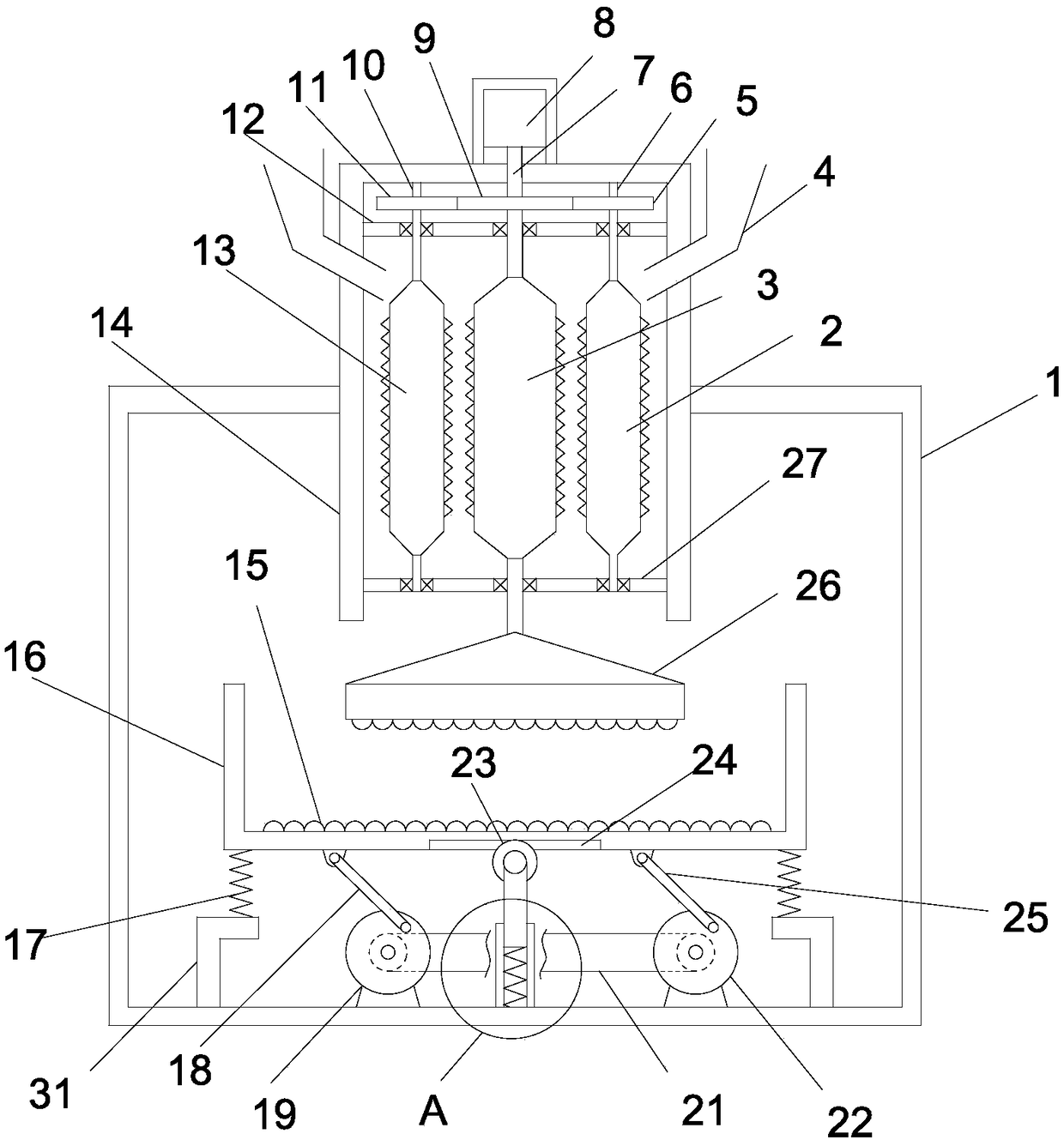

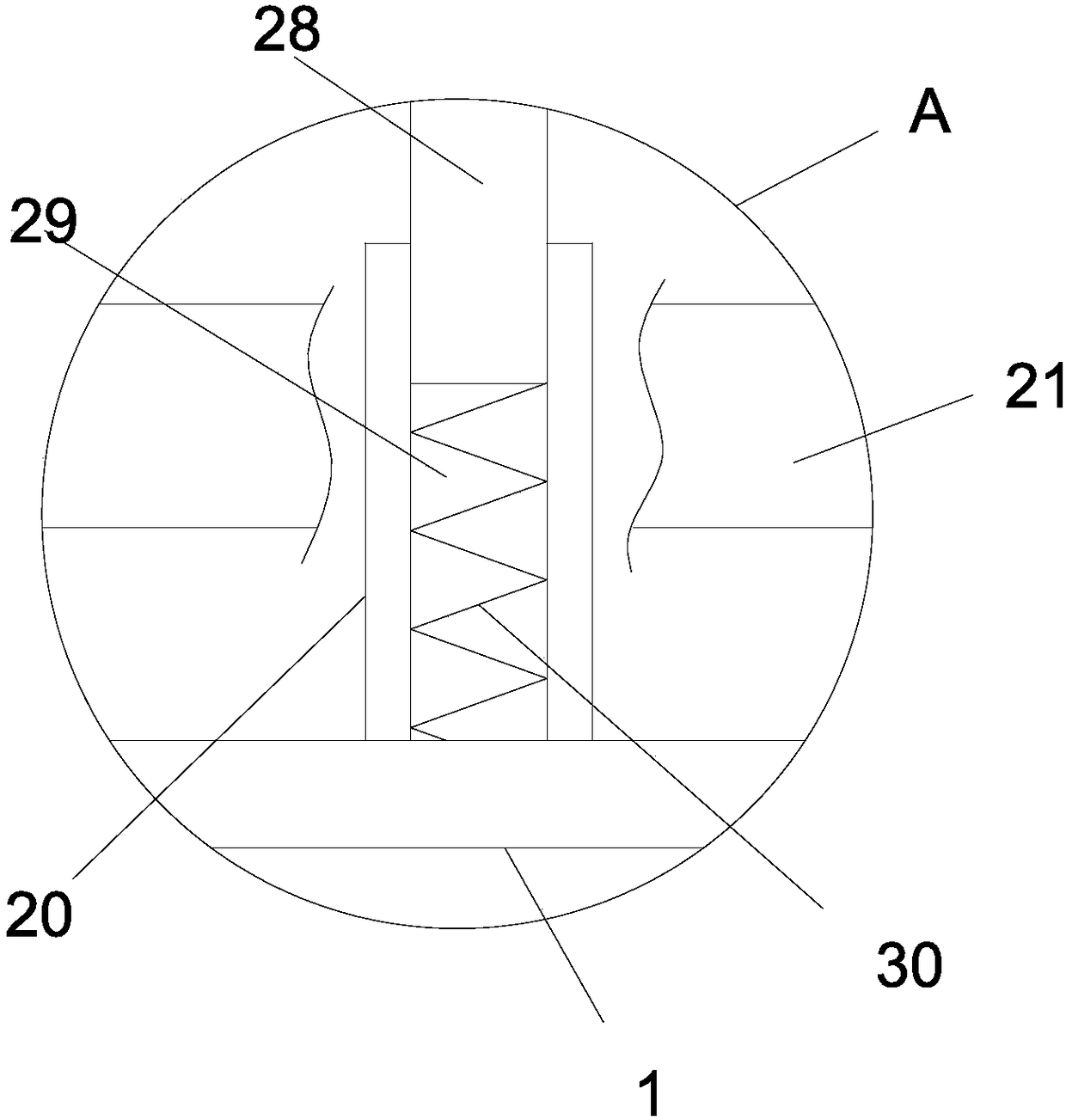

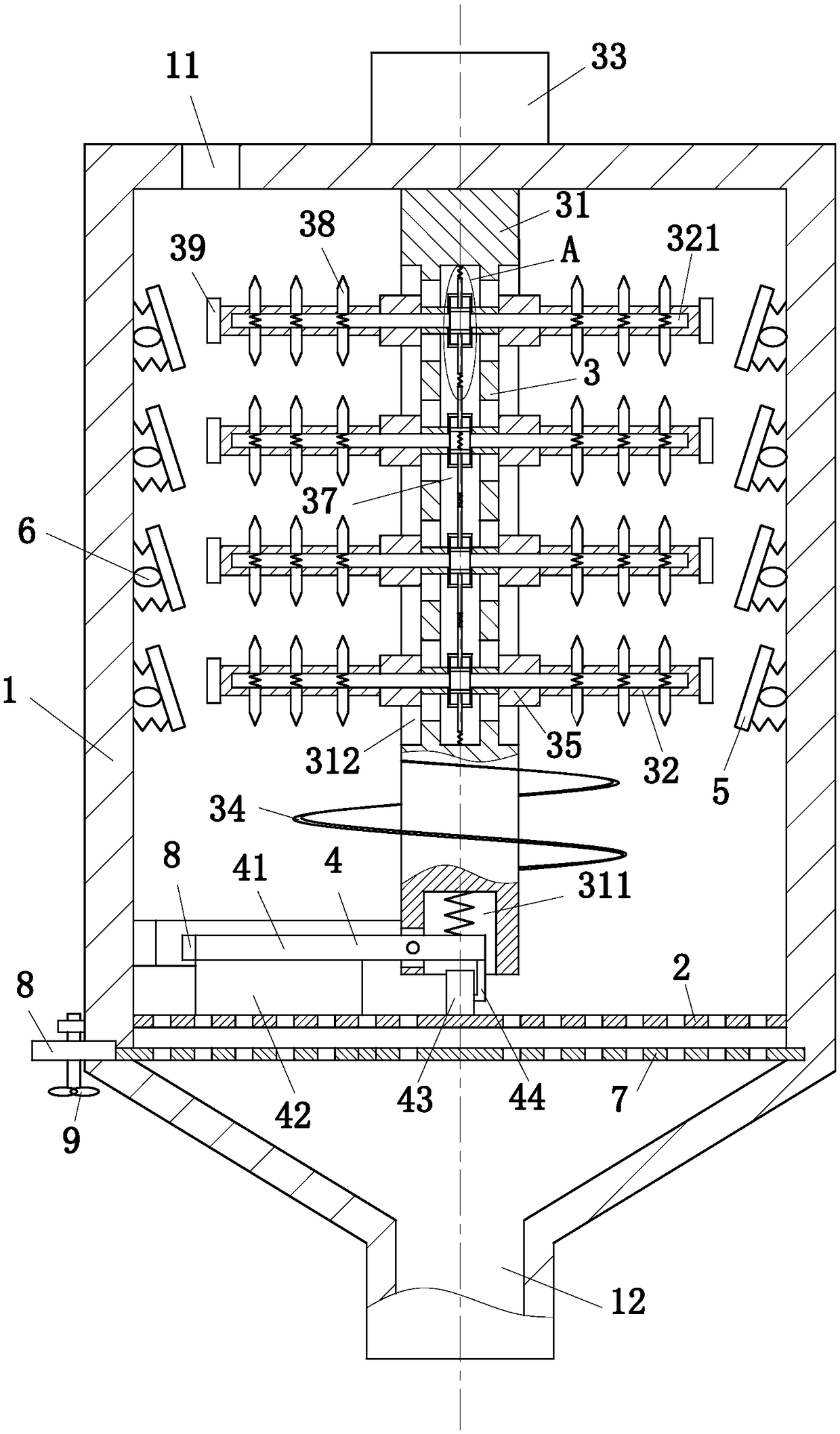

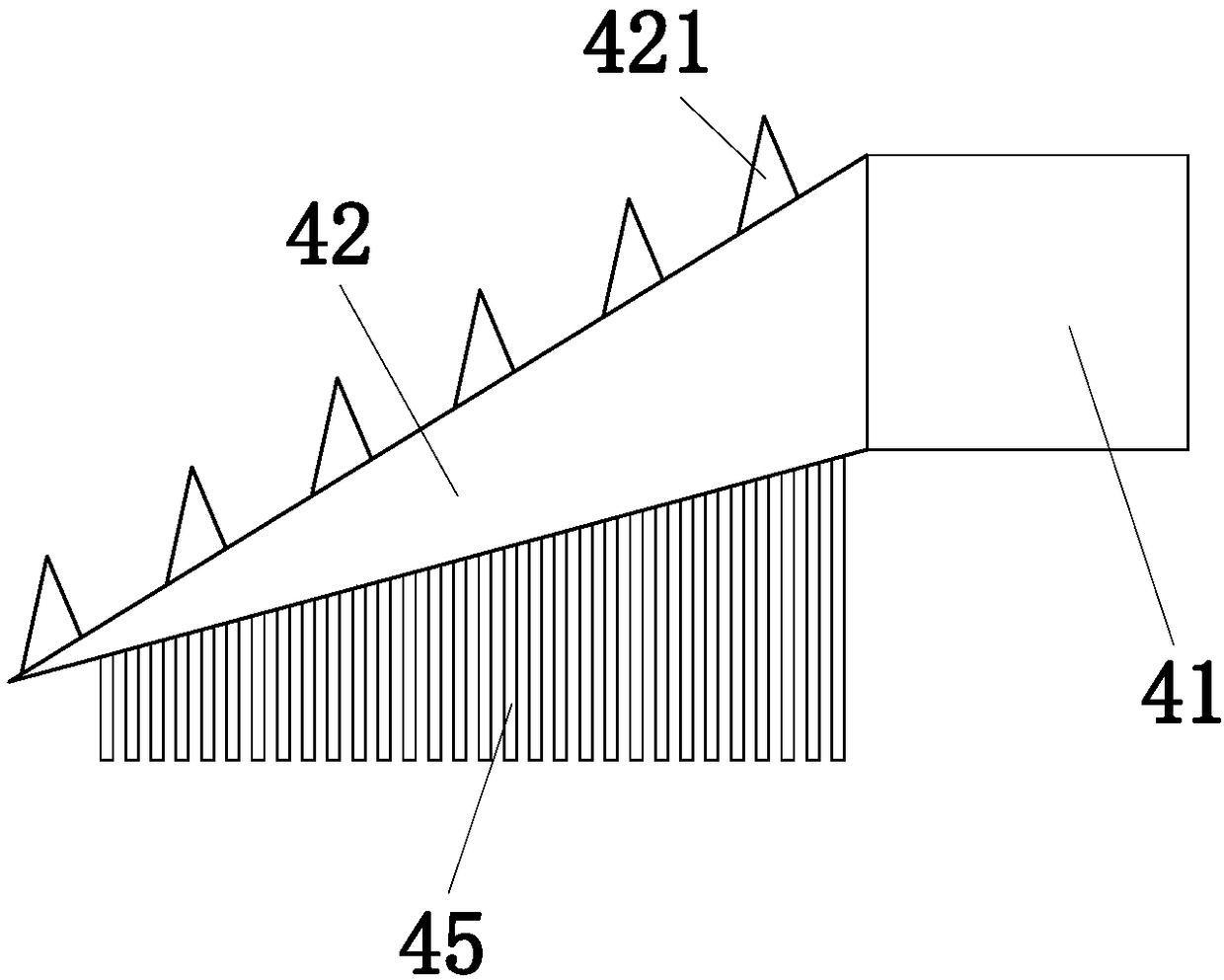

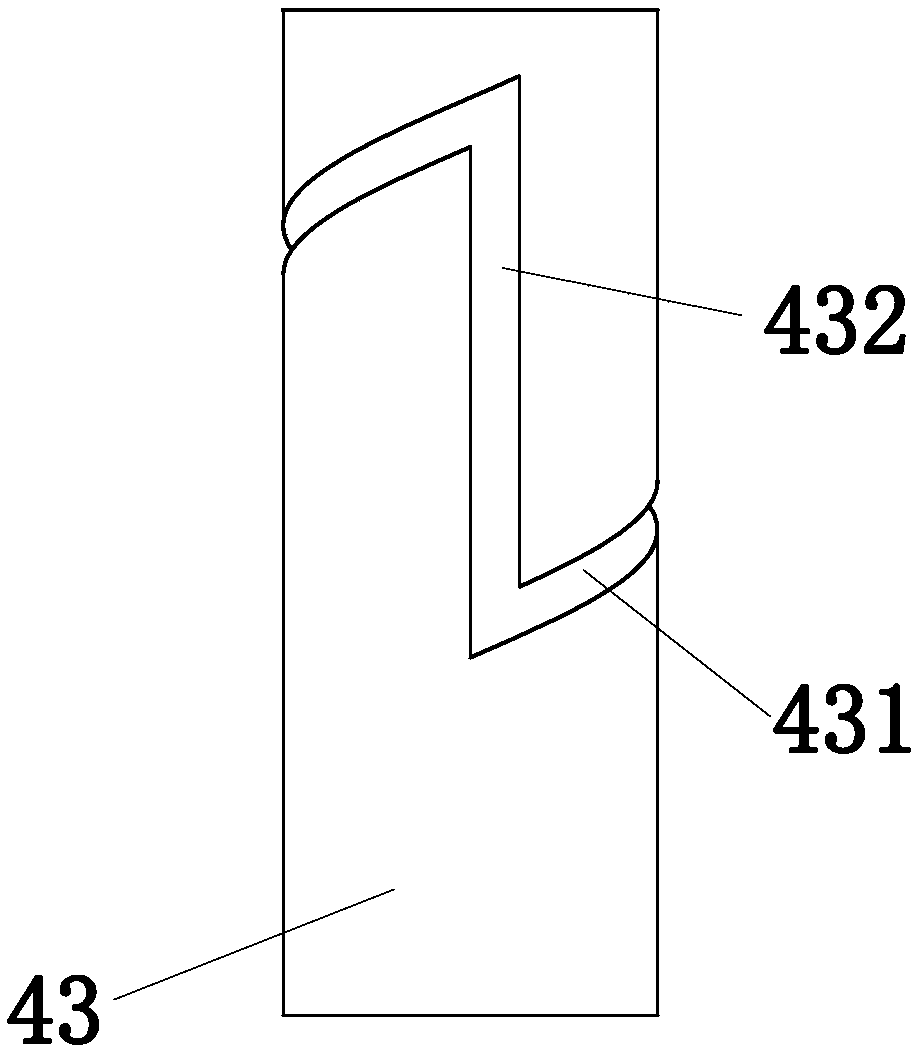

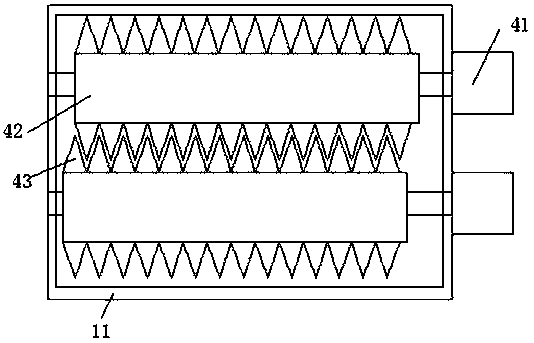

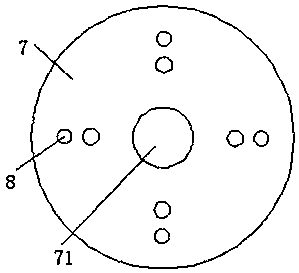

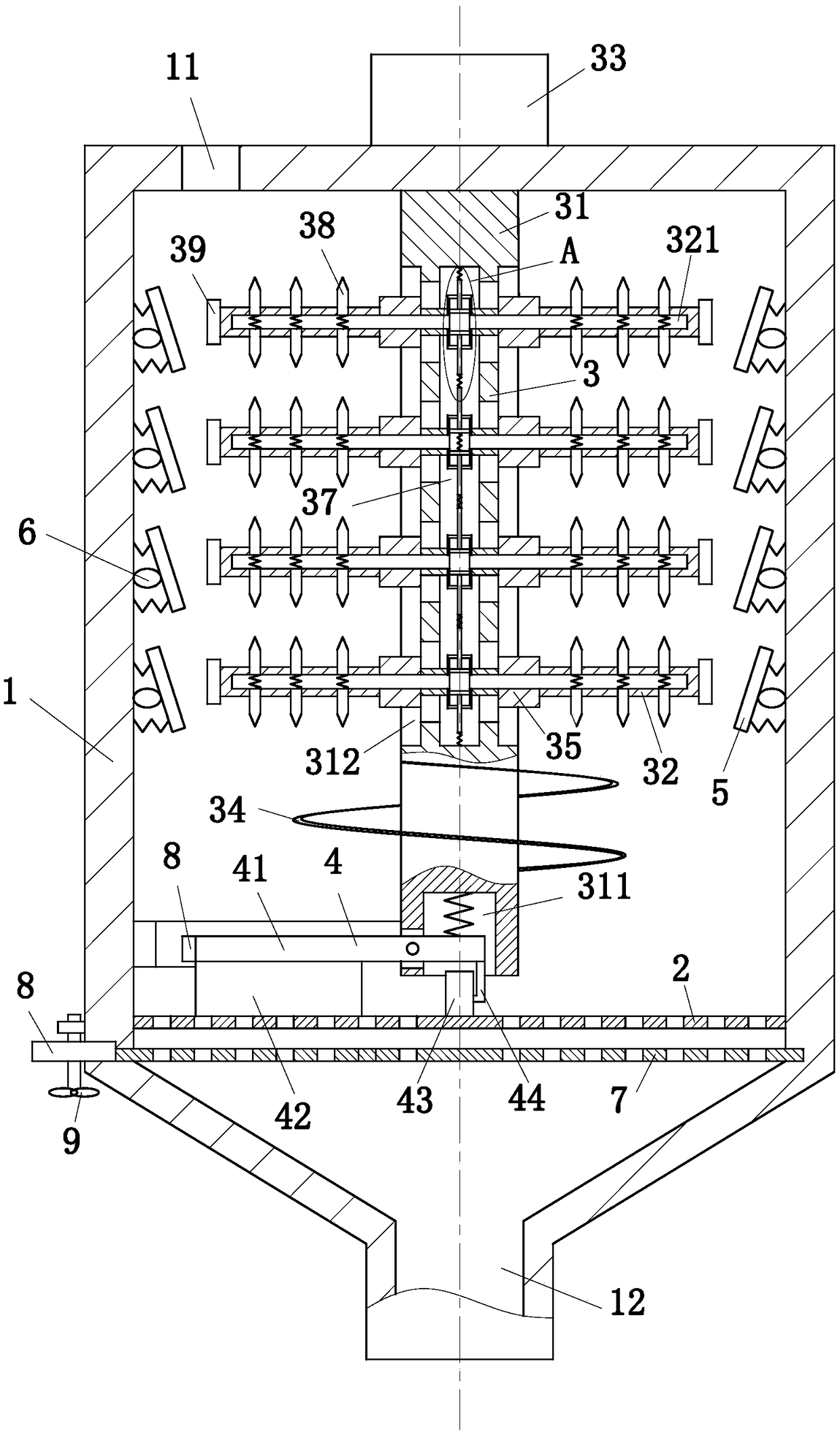

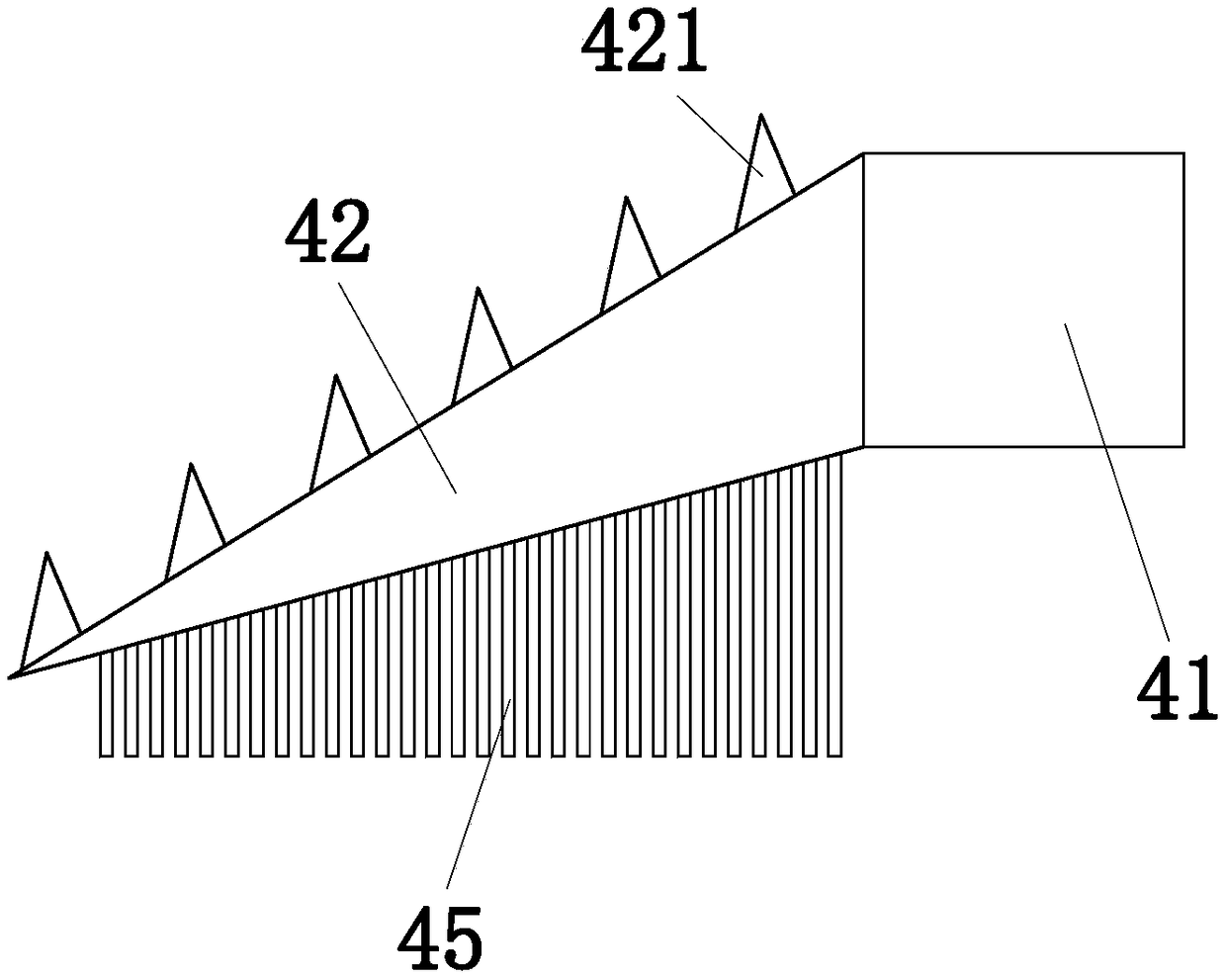

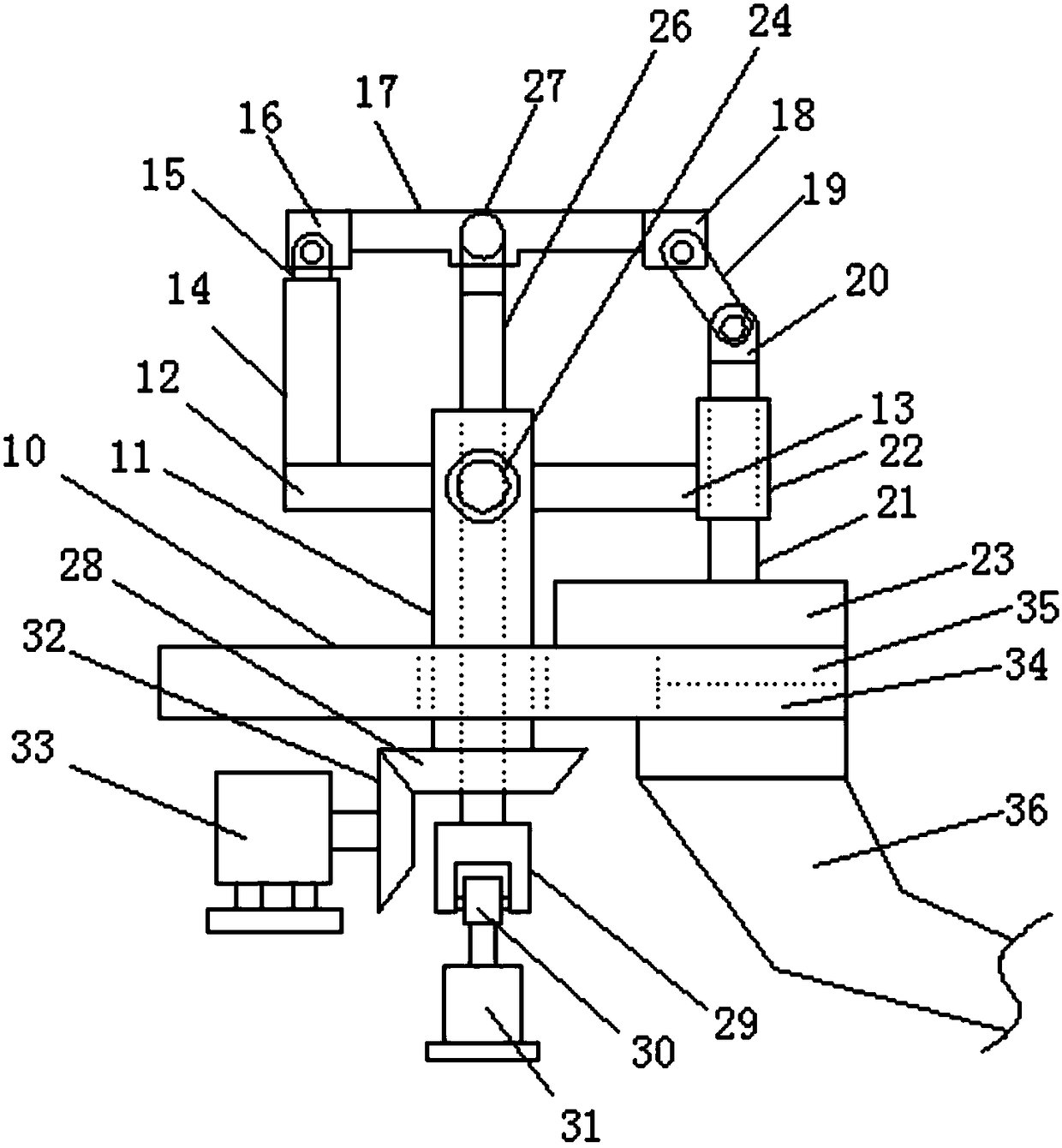

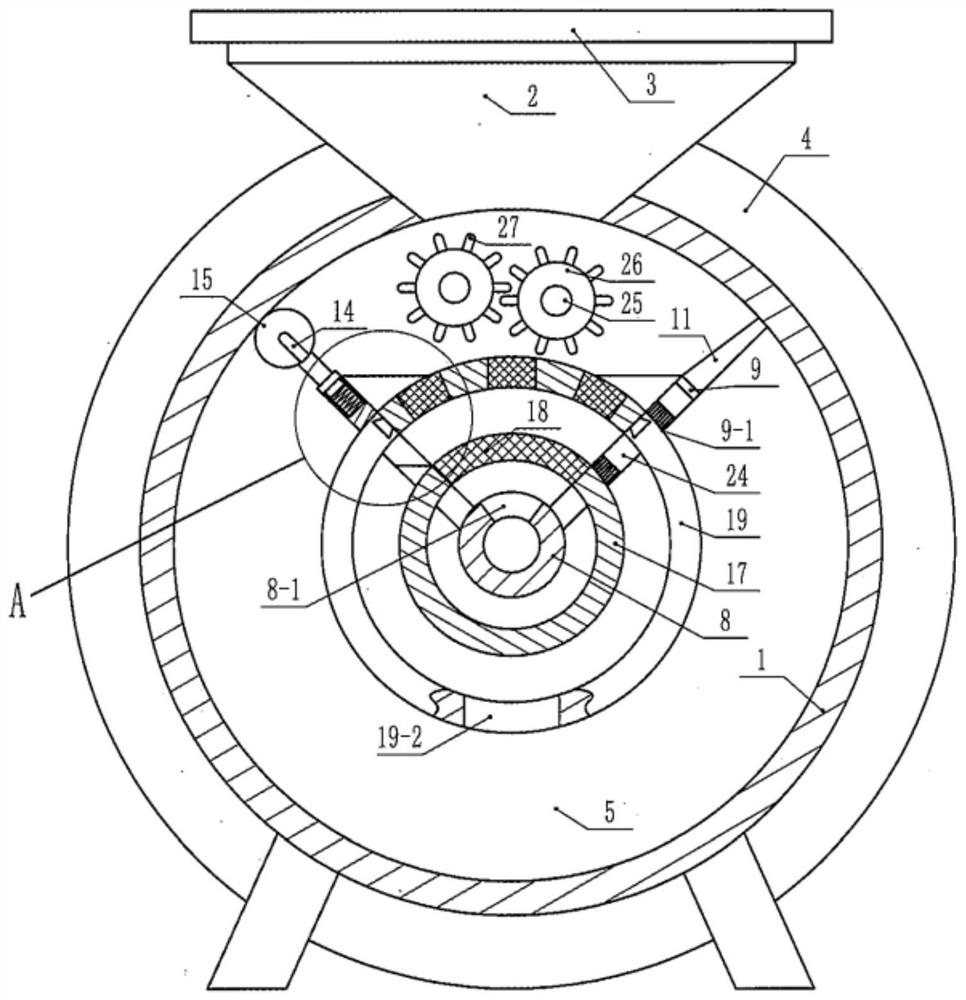

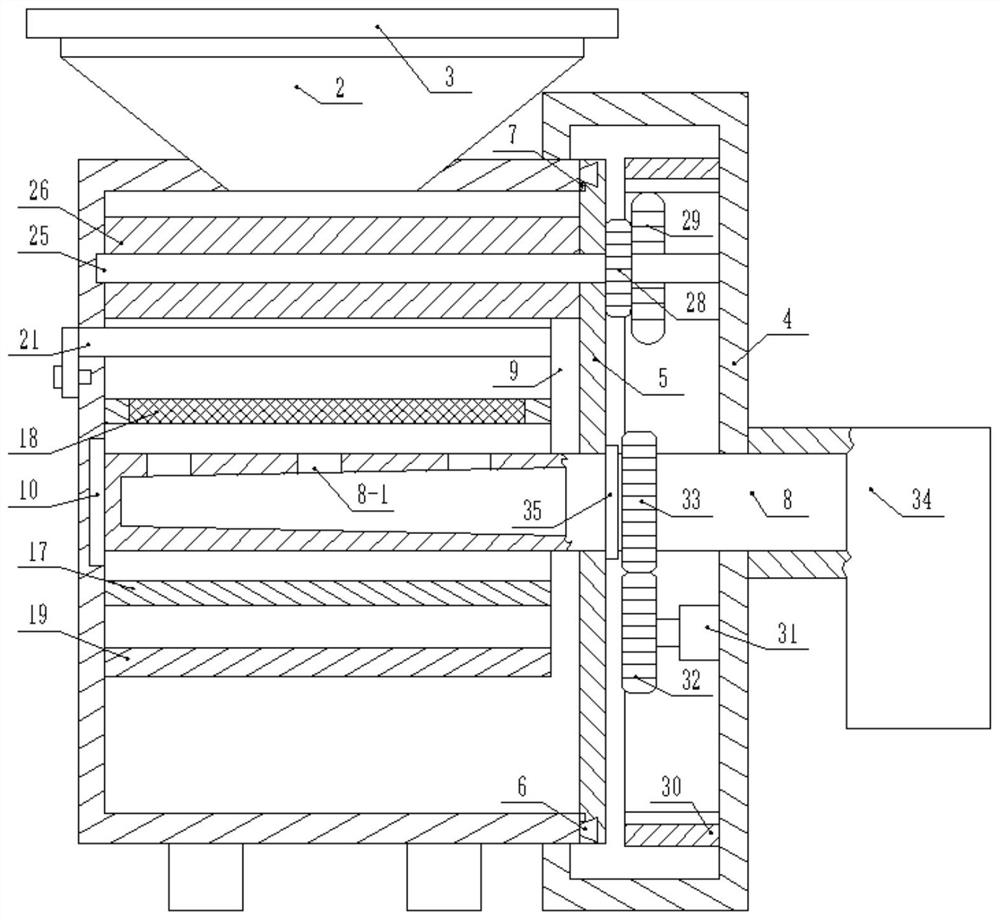

Rare earth ore fine-processing device and control system thereof

ActiveCN109277170AGuaranteed withdrawalImprove the effectCocoaGrain treatmentsEngineeringControl system

The invention belongs to the technical field of rare earth production, and particularly relates to a rare earth ore fine-processing device and a control system thereof. The rare earth ore fine-processing device comprises a box body, a filtering plate, a crushing unit and a turning unit, wherein the filtering plate is mounted at the bottom of the box body and used for filtering crushed rare earth ore; the crushing unit comprises a rotating shaft, crushing rods and a motor; the rotating shaft is vertically mounted in the box body; the crushing rods are horizontally mounted on the rotating shaftand used for crushing the rare earth ore inside the box body; the motor is used for driving the rotating shaft to turn; the turning unit is positioned at the bottom of the box body; and through the cooperation between the turning unit and the crushing unit, the rare earth ore which is incompletely crushed can be raised and crushed again, thereby guaranteeing the rare earth ore crushing uniformityand the rare earth ore utilization ratio. By the adoption of the rare earth ore fine-processing device provided by the invention, the comprehensive crushing of rare earth can be achieved and the sufficient extraction of a rare-earth raw material can be guaranteed.

Owner:GANZHOU FORTUNE ELECTRONICS

Ultrasonic wave crusher

The present invention relates to the technical field of crushers, particularly to an ultrasonic wave crusher, which comprises an ultrasonic wave generating barrel, a crushing barrel embedded in the ultrasonic wave generating barrel, a motor, ultrasonic wave generators, a stirring shaft, cutting cutters, fixation members, horizontal shafts and sleeve connection members, wherein the motor is arranged on the upper end of the crushing barrel, the stirring shaft is arranged on the top plate of the crushing barrel in a penetrating manner, the upper end of the stirring shaft is connected with the motor, the lower end of the stirring shaft extends into the crushing barrel, the horizontal shaft is vertically fixed on the stirring shaft through the sleeve connection member, the cutting cutter is symmetrically arranged on the horizontal shaft through the fixation member relative to the stirring shaft, the ultrasonic wave generator is arranged outside the ultrasonic wave generating barrel, the motor drives the cutting cutter to rotate so as to carry out primary crushing on the material in the crushing barrel, and the ultrasonic wave generator emits ultrasonic waves so as to crush the material into the nano-scale material.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

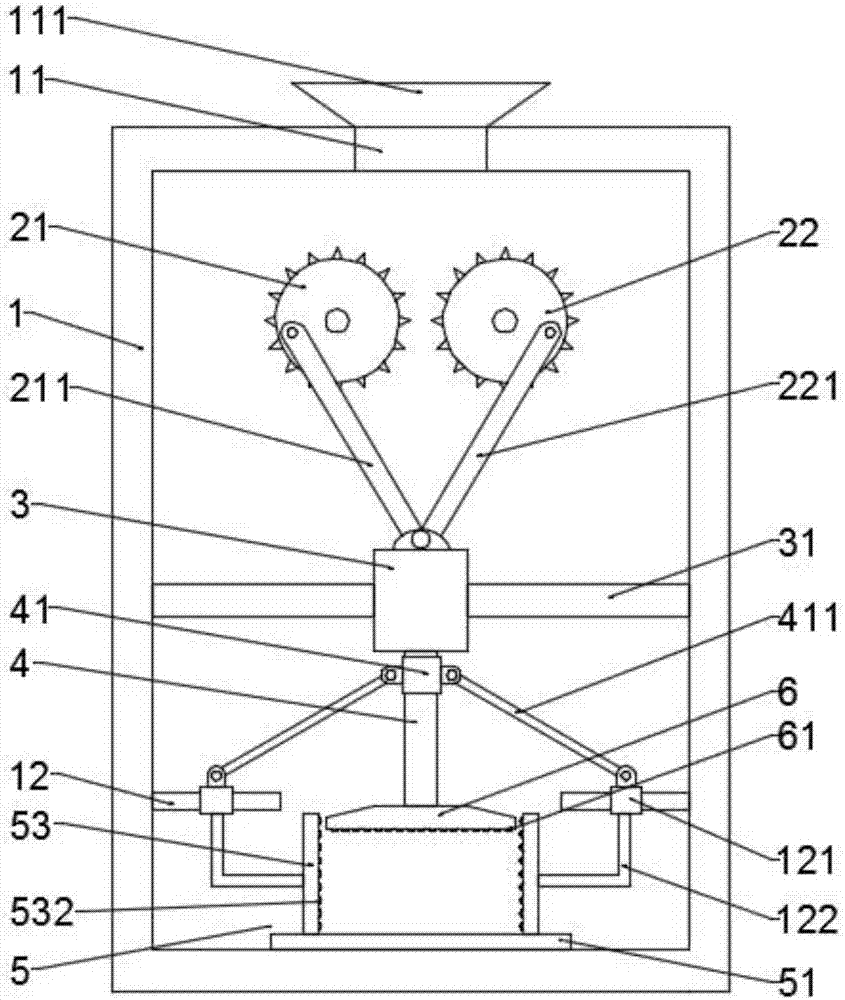

Pulverizing machine for fiber board machining

InactiveCN109622130AImprove crushing effectAchieve multiple crushingCrop conditionersMowersFiberEngineering

The invention belongs to the field of pulverizing machines, and particularly relates to a pulverizing machine for fiber board machining. For the problems that most of existing pulverizing machines arepoor in pulverizing effect, only one-time or two-time pulverizing is conducted, and pulverizing is incomplete, the following scheme is provided at present, the pulverizing machine for fiber board machining comprises a shell, a supporting frame is arranged on the bottom wall of the shell, a discharging port is formed in the bottom wall of the shell, an opening is formed in the top end of the shell, and the opening position is provided with a top cover; a feeding port is formed in one side of the top cover, a primary crushing mechanism is arranged at the upper portion in the shell, the shell isinternally provided with a plurality of partition plates located below the primary crushing mechanism, and the sections of the partition plates are conical; and through holes are formed in the middlepositions of the partition plates, a third motor located below the partition plates is fixed in the shell through a support, and an output shaft of the third motor is connected with a rotation shaftlocated in the through holes. By means of the pulverizing machine, multi-time material pulverizing can be achieved, so that material pulverizing is uniform and thorough, and the pulverizing effect isgood.

Owner:安徽喜聚美家居有限公司

Multi-stage efficient stone breaking device

InactiveCN107377161ABroken comprehensiveImprove crushing efficiencyGrain treatmentsAgricultural engineeringEngineering

Owner:六安市金安区一元通包装设计中心(普通合伙)

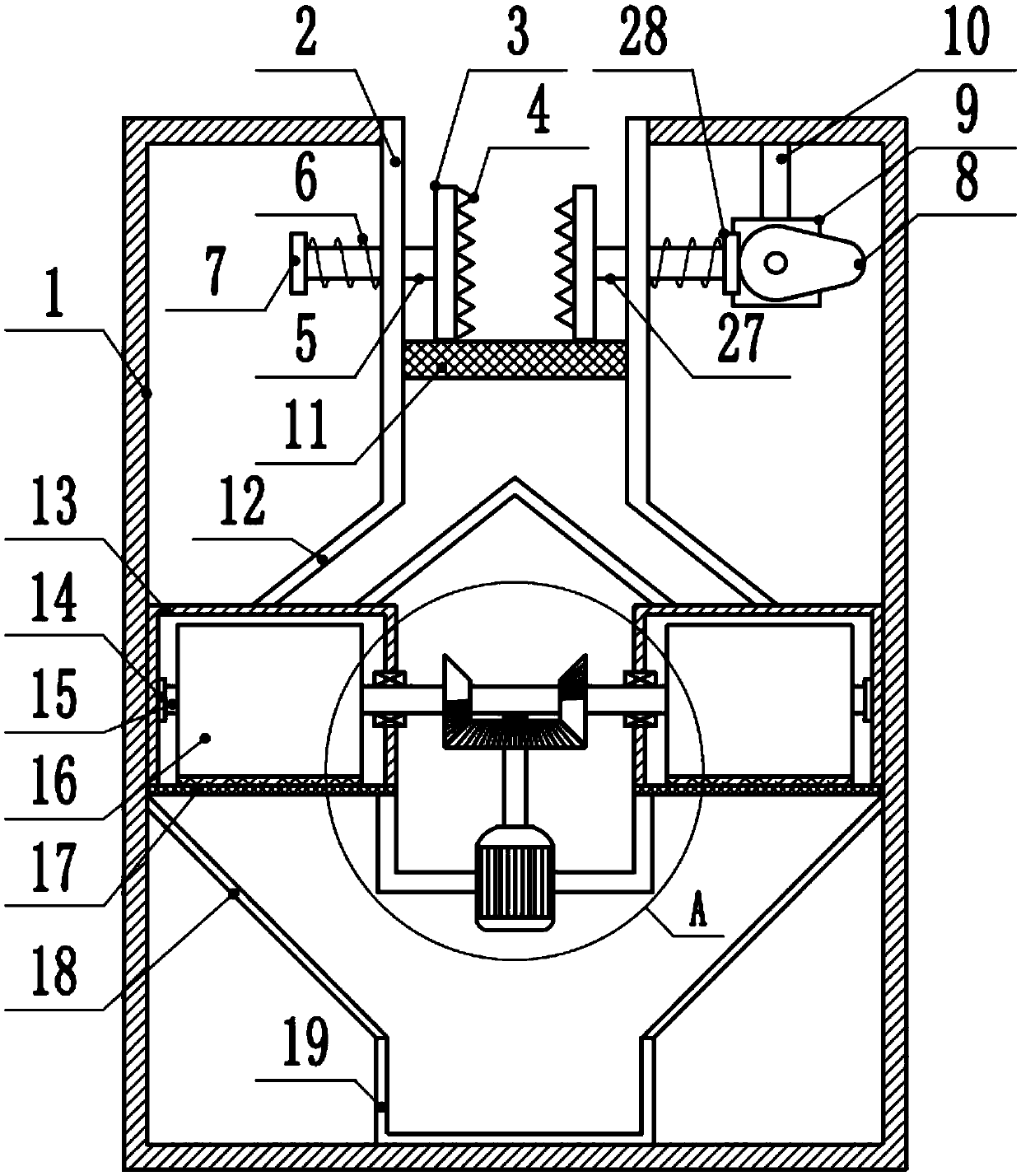

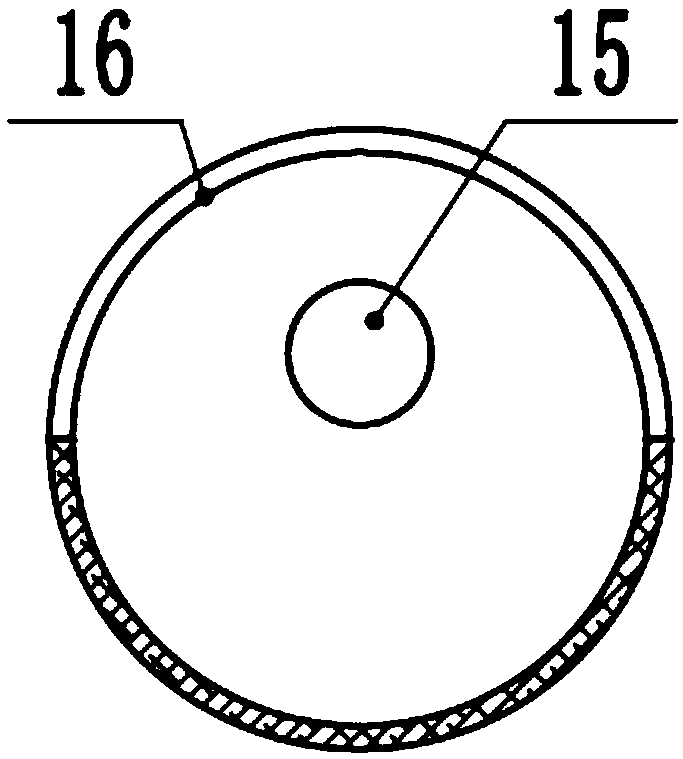

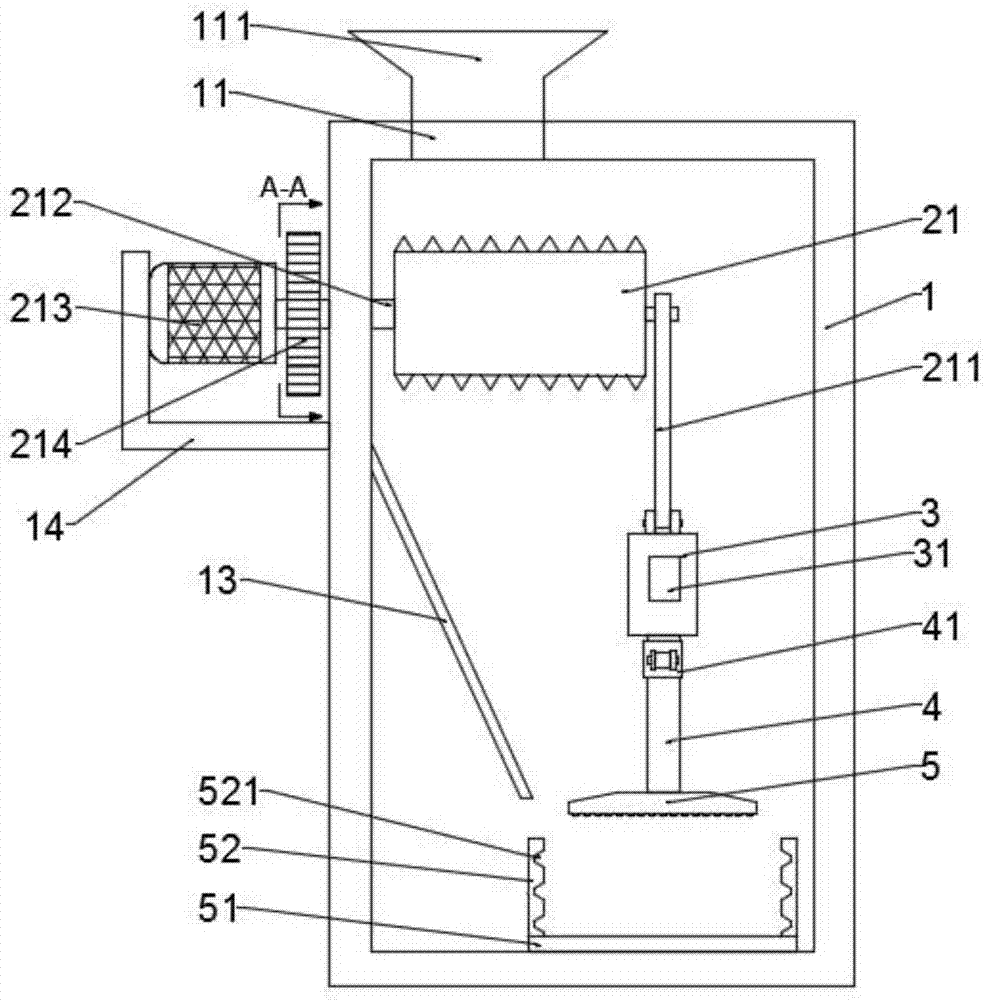

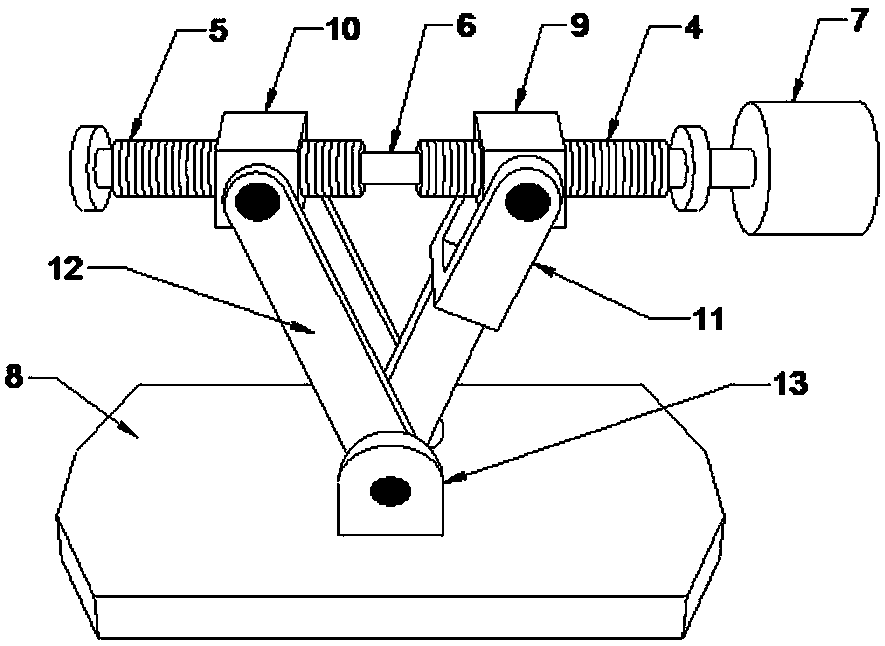

Farmland greening hardened soil remediation restoration device

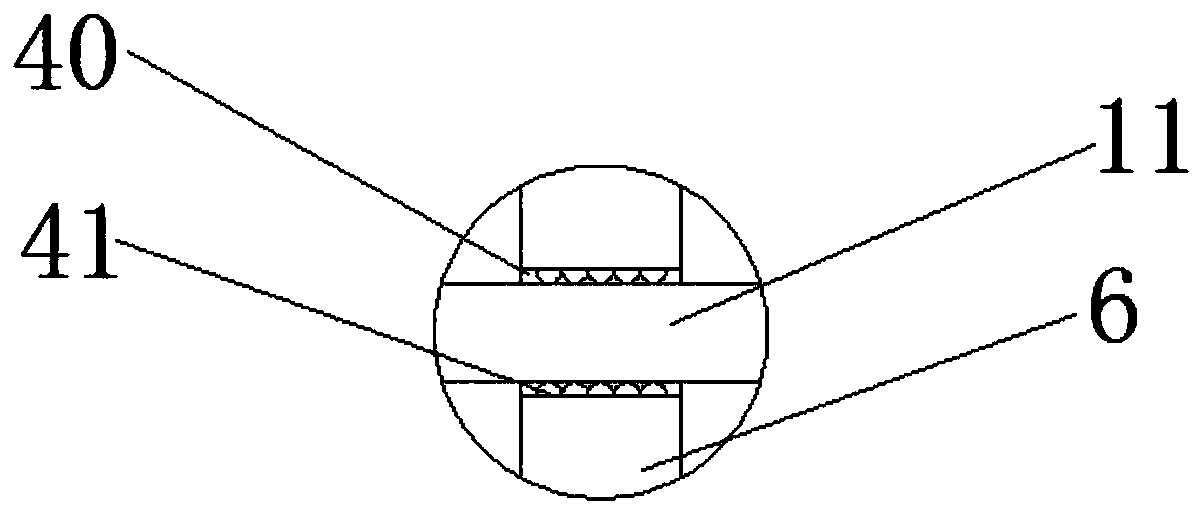

InactiveCN109382406AAchieve primary crushingPromote repairContaminated soil reclamationGrain treatmentsRestoration deviceSoil remediation

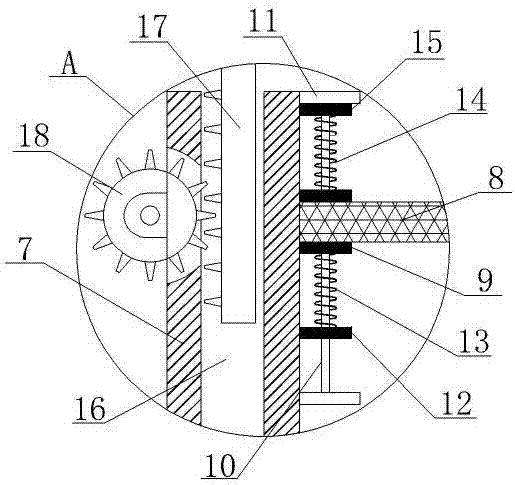

The invention discloses a farmland greening hardened soil remediation restoration device, and belongs to the field of soil restoration. The farmland greening hardened soil remediation restoration device comprises a soil restoration box; the middle internal part of an upper part box body of the soil restoration box is fixedly connected with a blanking box; the internal part of the left side of theblanking box is fixedly connected with a first crushing gear; the middle internal part of the left side box body of the blanking box is fixedly connected with a fixing slide block; the horizontal direction middle internal part of the fixing slide block is contacted with a top rod through contact connection; the left end of the top rod is fixedly connected with an extruding plate; the left side surface of the extruding plate is fixedly connected with a second crushing gear; the second crushing gear and the first crushing gear are arranged in a misalignment manner; the right end of the top rod is connected with a cam through contact connection; the back side of the center of the cam is connected with a third motor. The farmland greening hardened soil remediation restoration device is used for double crushing of hardened soil, the crushing effect is excellent, restoration liquid sprayed using spray nozzles can be contacted with soil fully, and it is beneficial for soil restoration.

Owner:霸州市辉月网络技术有限公司

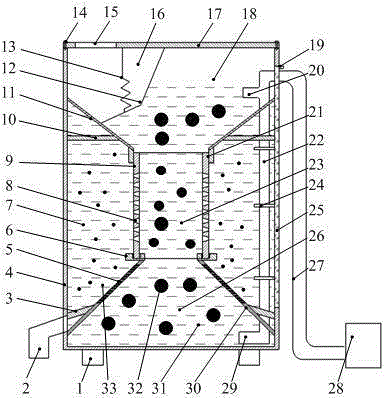

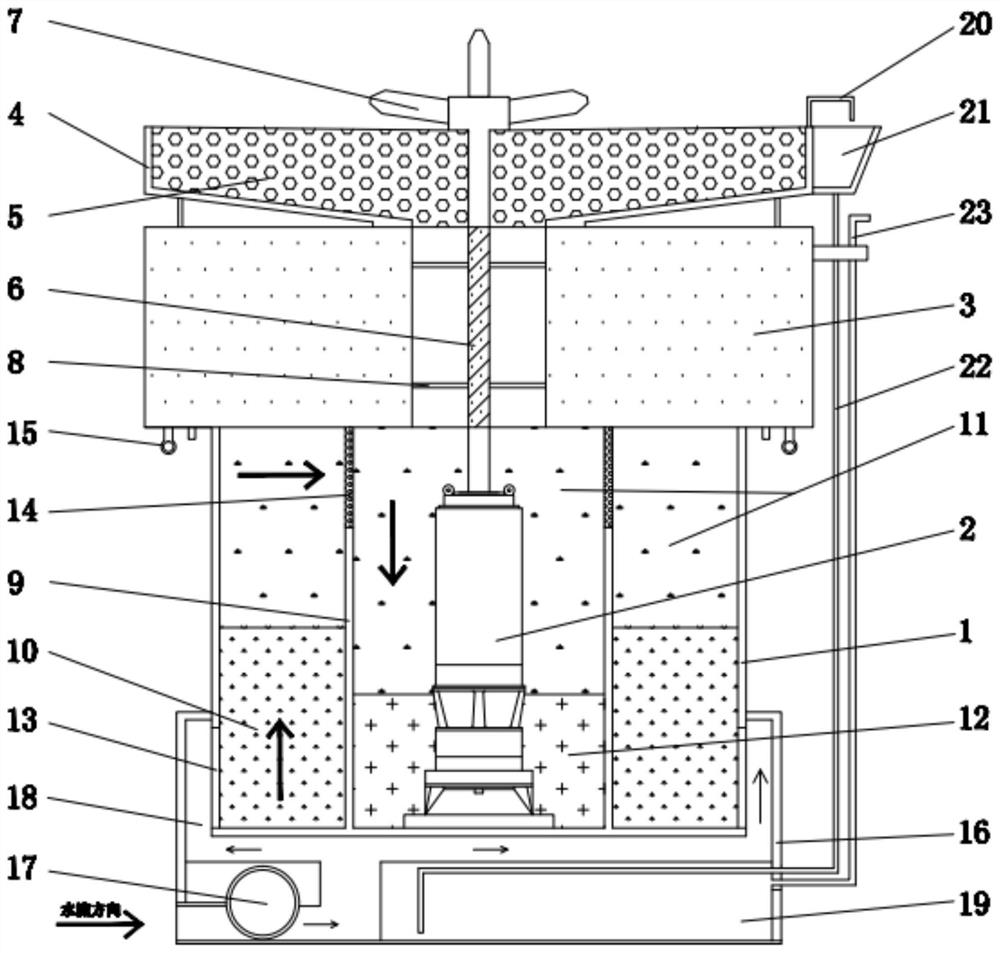

Hedging twisting double-vortex kinetic energy pulping equipment

InactiveCN105155321AAchieve primary crushingAchieve secondary crushingPaper recyclingRaw material divisionFiltrationEngineering

The invention provides hedging twisting double-vortex kinetic energy pulping equipment. The equipment mainly comprises a water charging and feeding device, an air charging device, an upper vortex kinetic energy generating device, a lower vortex kinetic energy generation device, a smashing and filtering device and a liquid slurry storing device. The hedging twisting double-vortex kinetic energy pulping equipment is characterized by reverse vortex hedging twisting material breaking. Feeding amount can be controlled and a water charging and feeding buffering area can be sealed via a buffering plate; a liquid level can be controlled by a highest liquid level indicating rod and a liquid level observation plate; with an anticlockwise upper air inlet and a clockwise lower air inlet and an upper and lower conical cylinders, upper and lower vortex air flows can be accelerated, hedging twisting smashing force and equipment homonymous impact vibration can be achieved; with conical holes having large inner holes and small outer holes and arranged in an intersected way, broken material filtration and blocking prevention can be realized; filtering efficiency and impact stirring can be improved; fluid mutual flow between a slurry storage area and the lower vortex kinetic generation area and slurry storage area impact stirring can be realized via parallel holes.

Owner:UNIV OF JINAN

Treatment device for building material processing wood chips

InactiveCN109483669ARealize screeningAchieve smashBark-zones/chip/dust/waste removalEngineeringMaterials processing

The invention discloses a treatment device for building material processing wood chips. The treatment device for the building material processing wood chips comprises a first smashing box, a second smashing box, and an extrusion forming box, wherein a first motor is arranged on the other side of the top of the first smashing box; a first rotating shaft is arranged on one end of the first motor; acircle hob is arranged on the outer ring of the first rotating shaft; a dull polishing device is arranged in the first smashing box; two second motors are correspondingly arranged on the two sides ofthe outer portion of the second smashing box; one end of each second motor is provided with a second rotating shaft; one ends of the second rotating shafts extend into the second smashing box; bladesare arranged on the second rotating shafts through bolts; a buffering device is arranged on the side of the interior of the extrusion forming box through the bolts; a buffering block is arranged at the side, away from a controller, of the buffering device; a sliding block is arranged on the other side of the interior of the extrusion forming box; and a first connecting rod is arranged at one end,away from the buffering block, of the sliding block. By using the treatment device for the building material processing wood chips, the advantage of processing the wood chips into blocks is achieved.

Owner:甘肃优护送紧急救援有限公司

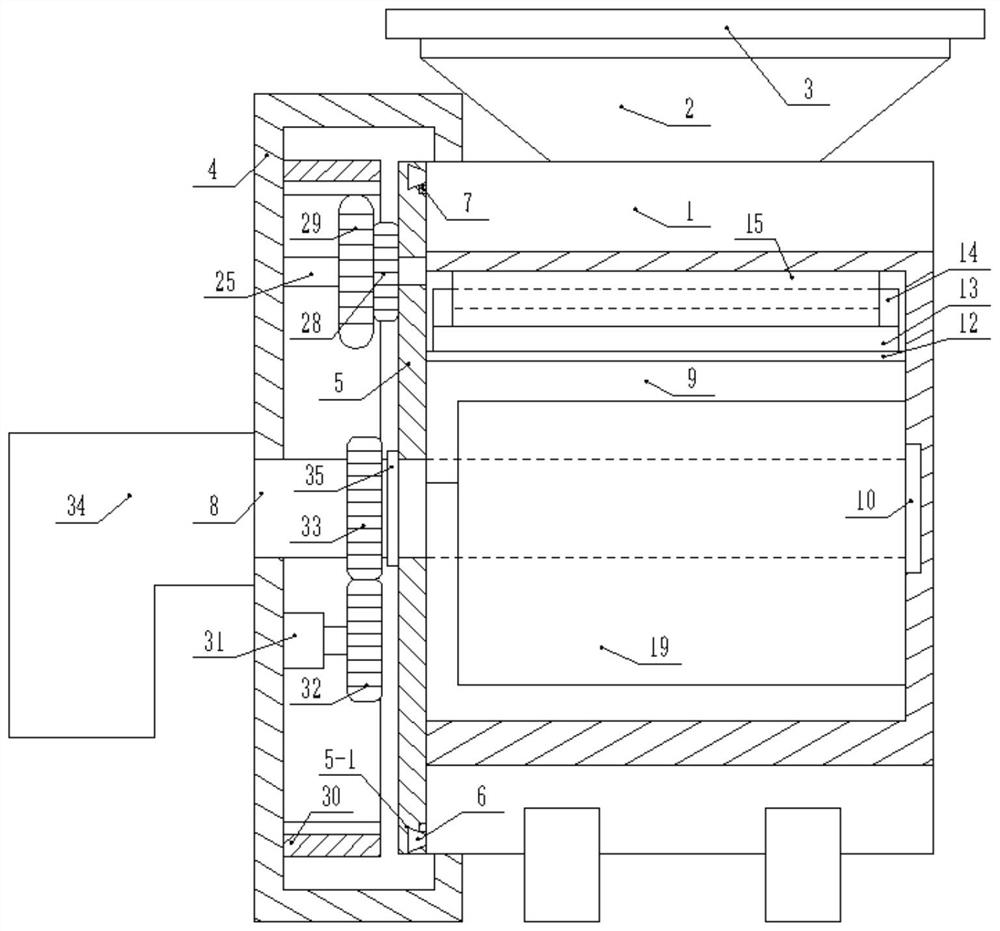

Chinese traditional medicine smashing device

InactiveCN107570264AAchieve primary crushingAchieve sievingGrain treatmentsGranularityChinese traditional

The invention relates to the technical field of medical instruments, in particular to a Chinese traditional medicine smashing device. The Chinese traditional medicine smashing device comprises a device outer shell and supporting plates installed on the two sides of the device outer shell, and a feeding hopper is installed at the top end of the device outer shell. Two separation plates are installed inside the device outer shell and divide the inner space of the device outer shell into a middle smashing area and discharging areas on the two sides, an upper set of smashing rollers and a lower set of smashing rollers are arranged in the smashing area, and primary smashing of Chinese traditional medicines is realized. Second fans are installed in the discharging areas to blow primarily smashedmedicine residues towards a collecting pipe. Large-granularity and small-granularity medicine residues can be sieved through the action of a third separation net, so that the small-granularity medicine residues are collected, and the large-granularity medicine residues fall into a first separation net in the smashing area. The large-granularity medicine residues are then fed into an area above the smashing rollers through a first fan, a secondary smashing effect is realized, and high smashing efficiency and a high-uniformity smashing effect can be further realized.

Owner:朱雪梅

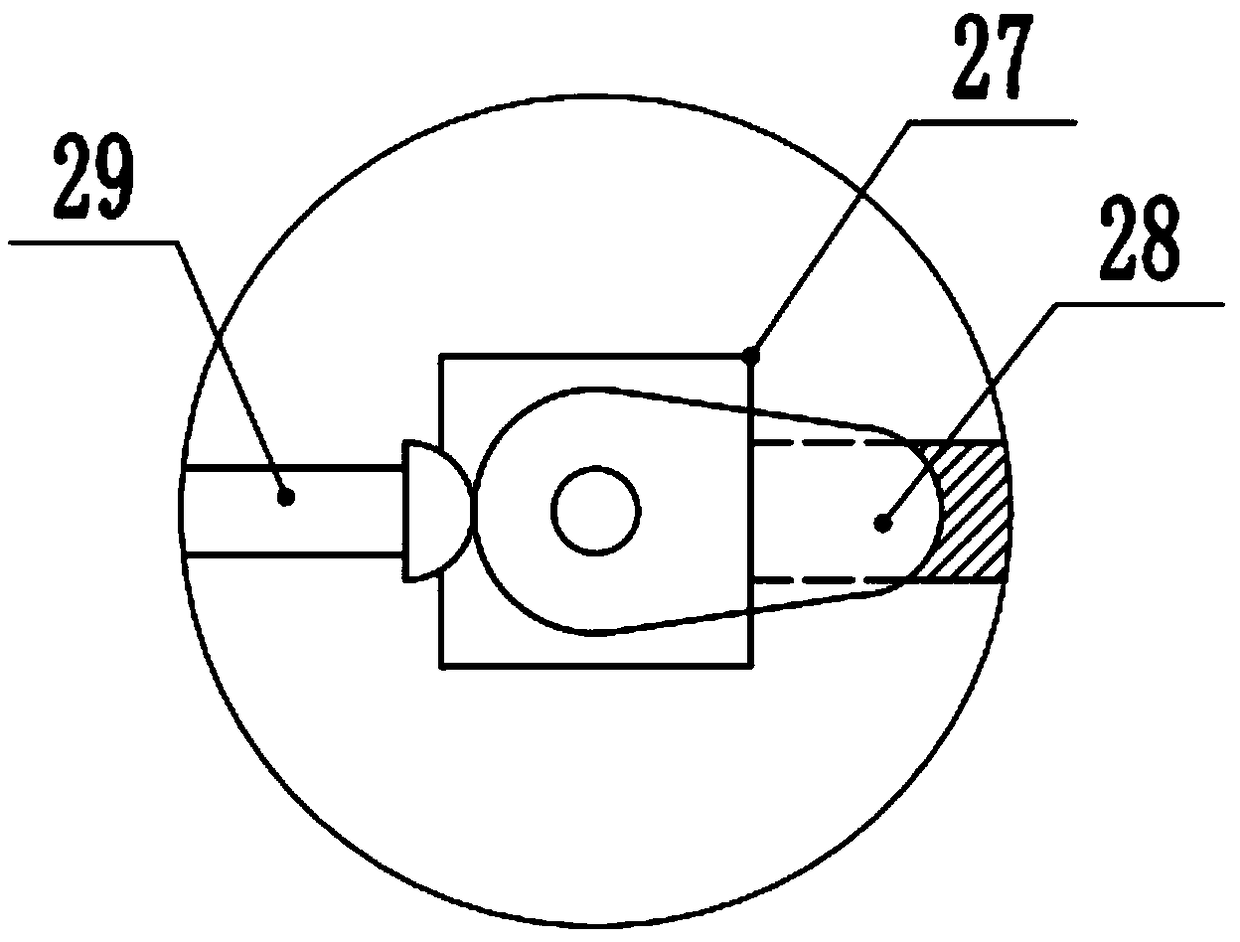

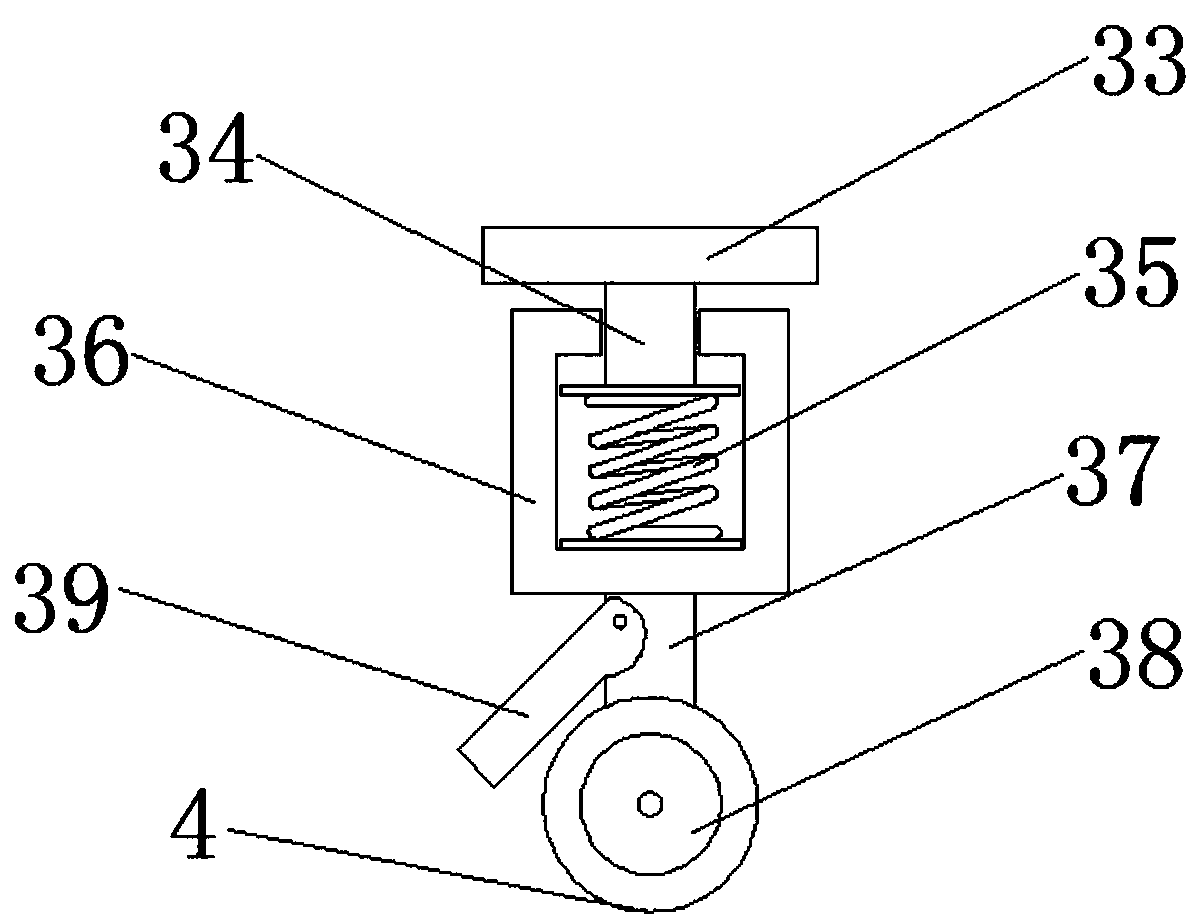

PVC material smashing and recycling device

InactiveCN110450315ASolve problems that need smashingQuick breakPlastic recyclingDrying gas arrangementsEngineeringCam

The invention belongs to the field of PVC material recycling treatment, and particularly relates to a PVC material smashing and recycling device. The PVC material smashing and recycling device comprises a discharging cylinder, a fixed cylinder and a connecting cylinder, the bottom end of the discharging cylinder is provided with a supporting frame, an opening in the top end of the discharging cylinder is fixedly connected with the fixed cylinder, the top end of the fixed cylinder is fixedly connected with the connecting cylinder through a connecting frame, the bottom end in the connecting cylinder is fixedly provided with a dual-shaft motor through a support, a top end output shaft of the dual-shaft motor is connected with a horizontal cam, fixed extrusion plates are fixed to the inner walls of the two sides of the connecting cylinder, one sides of the fixed extrusion plates are provided with movable extrusion plates rotatably connected into the connecting cylinder, the cam is in sliding connection with the two movable extrusion plates, the two sides of the lower portion of the cam are provided with fixed plates fixed to the inner wall of the connecting cylinder, and springs are connected between the fixed plates and the movable extrusion plates. Rapid breaking of PVC materials can be achieved, and through repeated smashing and screening, the smashing effect is good.

Owner:HWASU

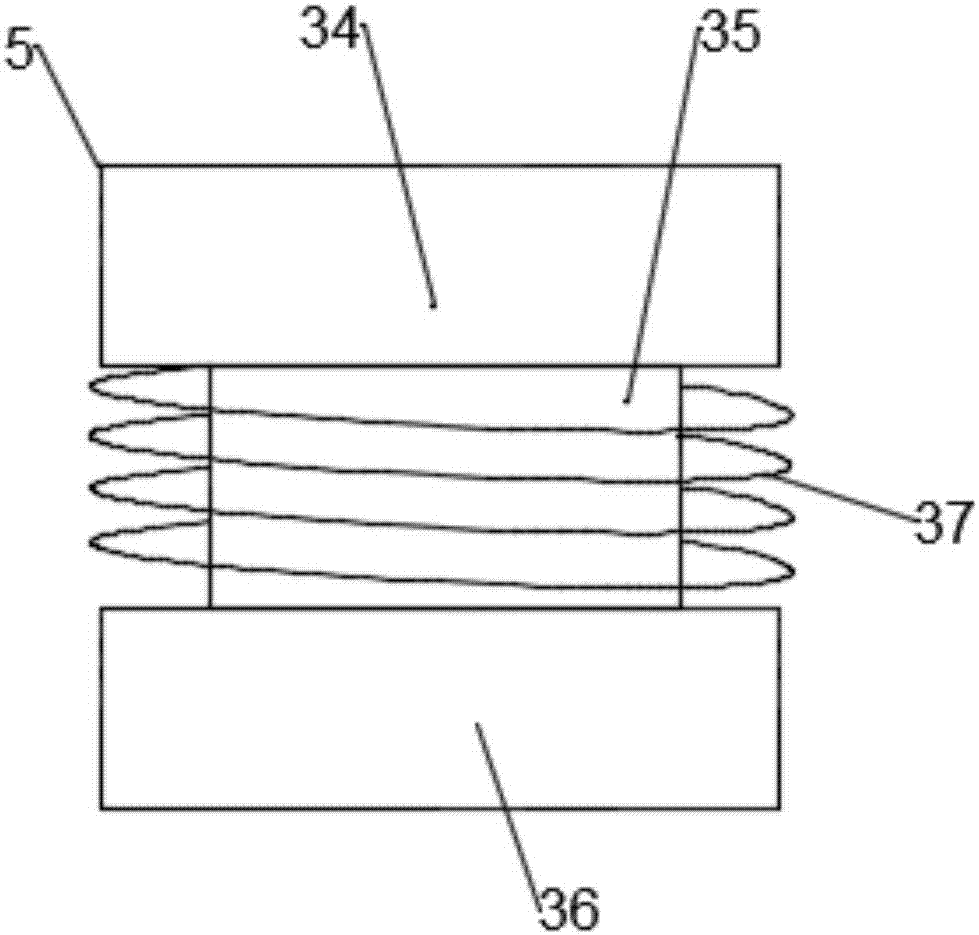

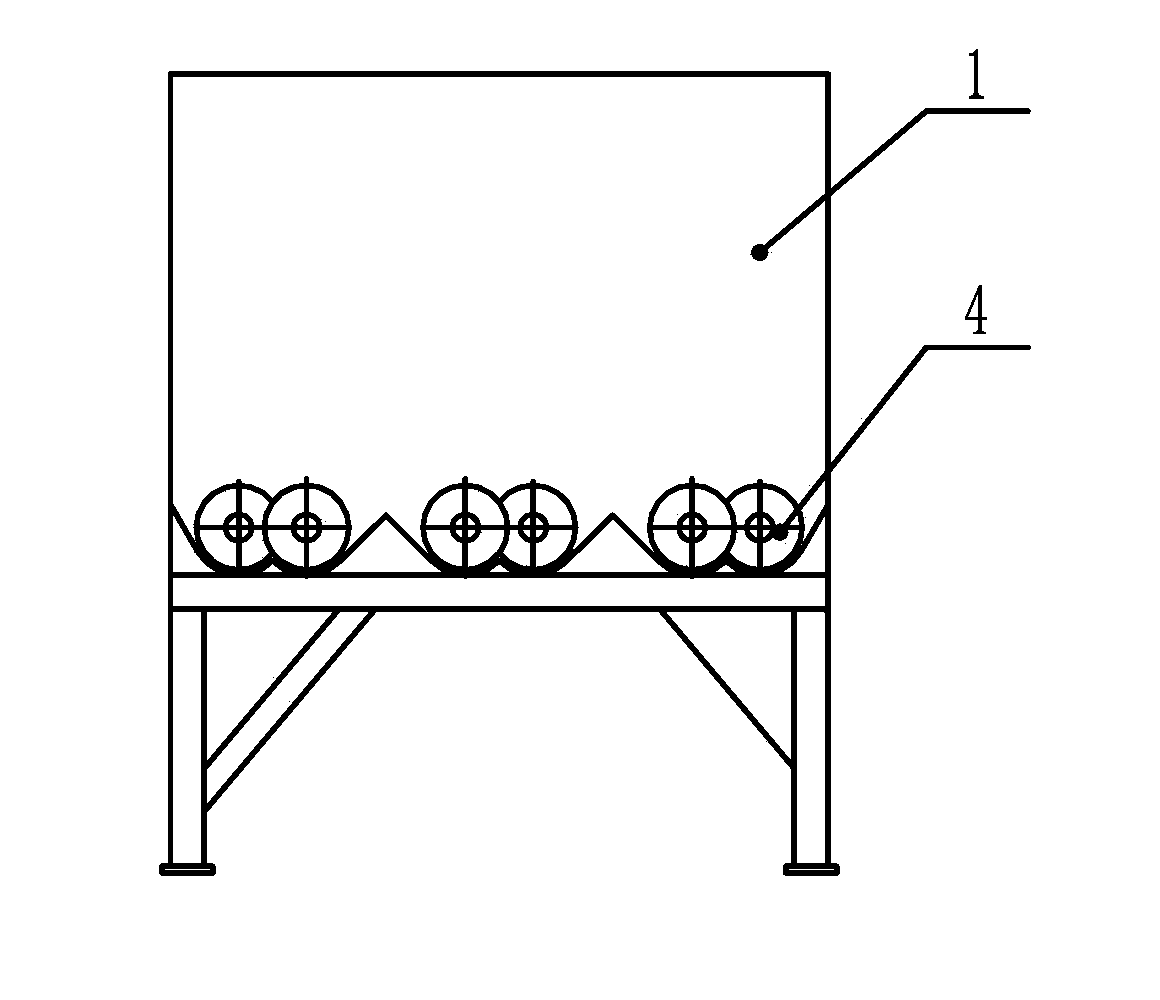

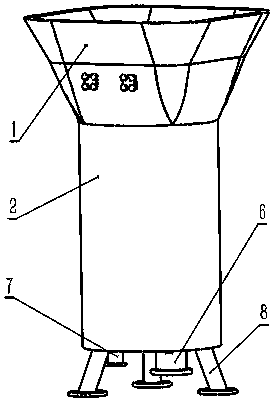

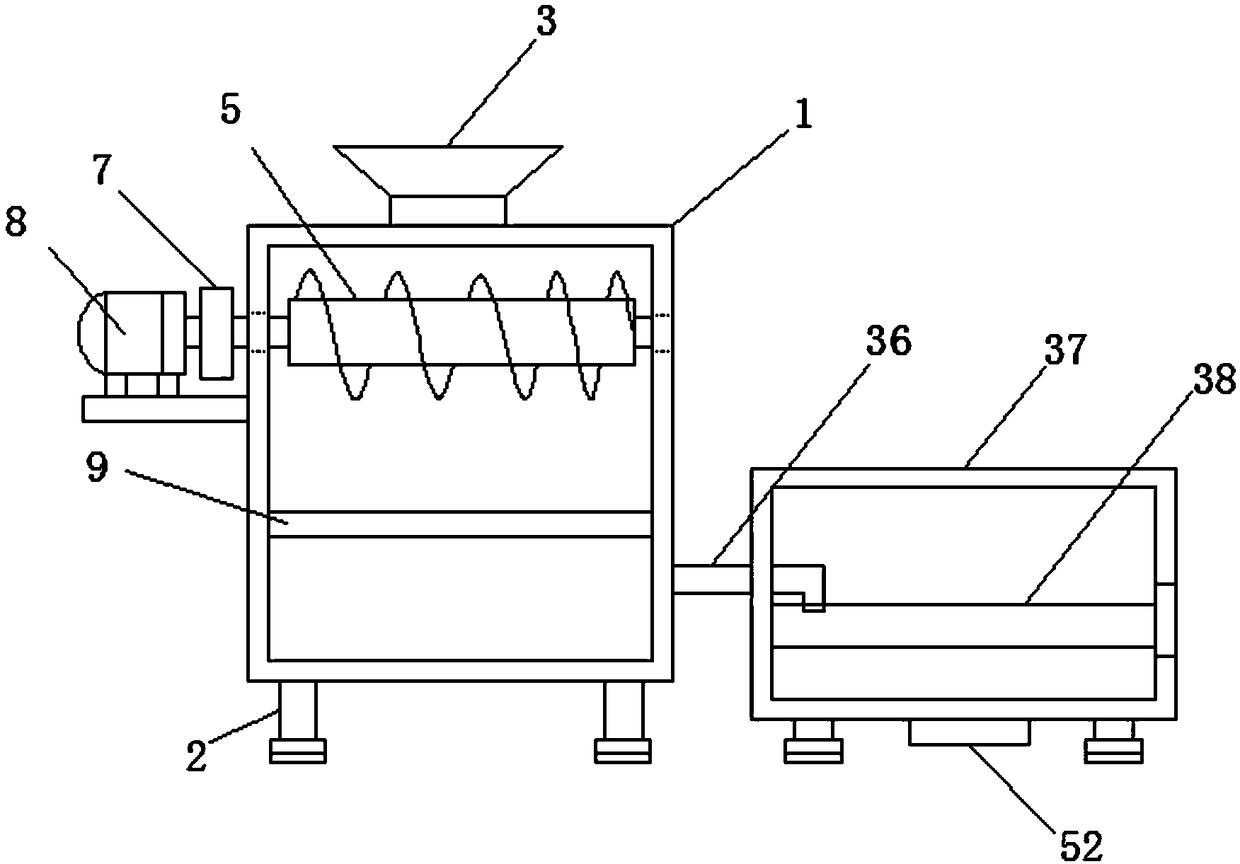

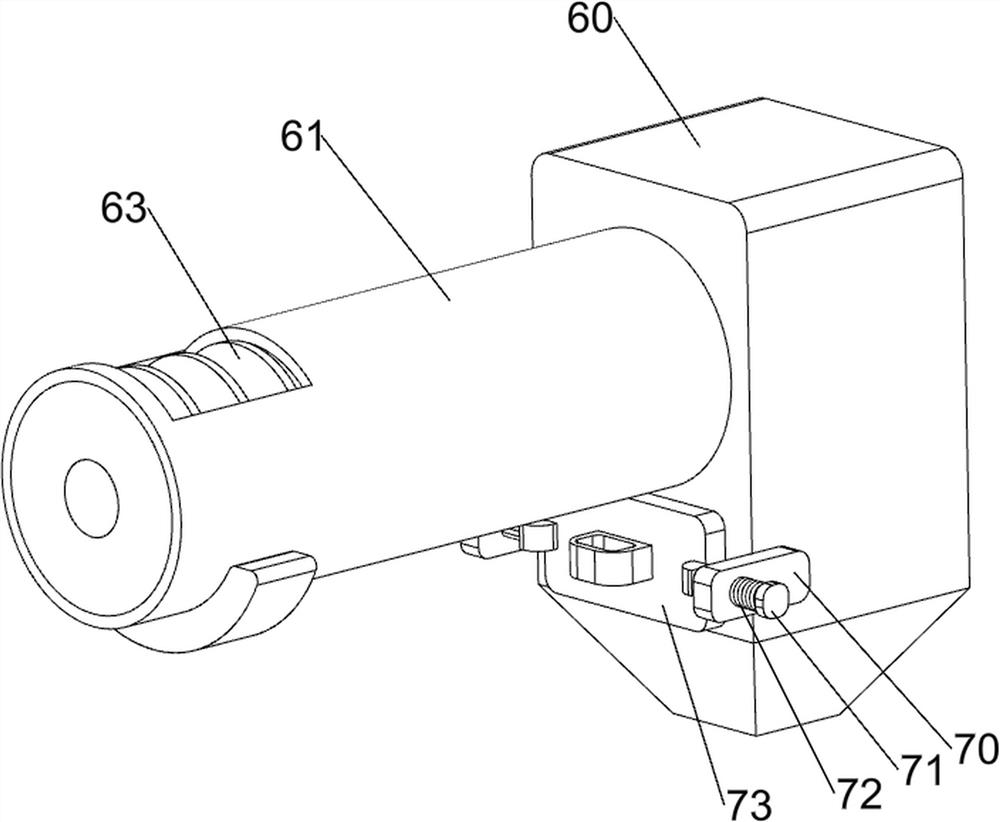

Caching feeding bin

ActiveCN103612924AAdjust the output speedPrevents reduction in feeding functionLarge containersLoading/unloadingWaste management

A caching feeding bin comprises a storage bin body, a discharge tube body, a discharge hopper, discharge spiral units and a discharge spiral unit drive mechanism. The discharge tube body is arranged on the side wall of the storage bin body. The discharge hopper is sequentially connected and communicated with the discharge tube body and the storage bin body. The discharge spiral units are arranged in the storage bin body, the discharge tube body and the discharge hopper and used for pushing materials in the storage bin body into the discharge hopper. The output end of the discharge spiral unit drive mechanism is connected with the discharge spiral units and drives the discharge spiral units to rotate. Due to the fact that the discharge speed of the materials is related to the rotating speed of the discharge spiral units, the constant discharge speed can be adjusted by controlling the rotating speed of the discharge spiral units.

Owner:光大清洁技术股份有限公司

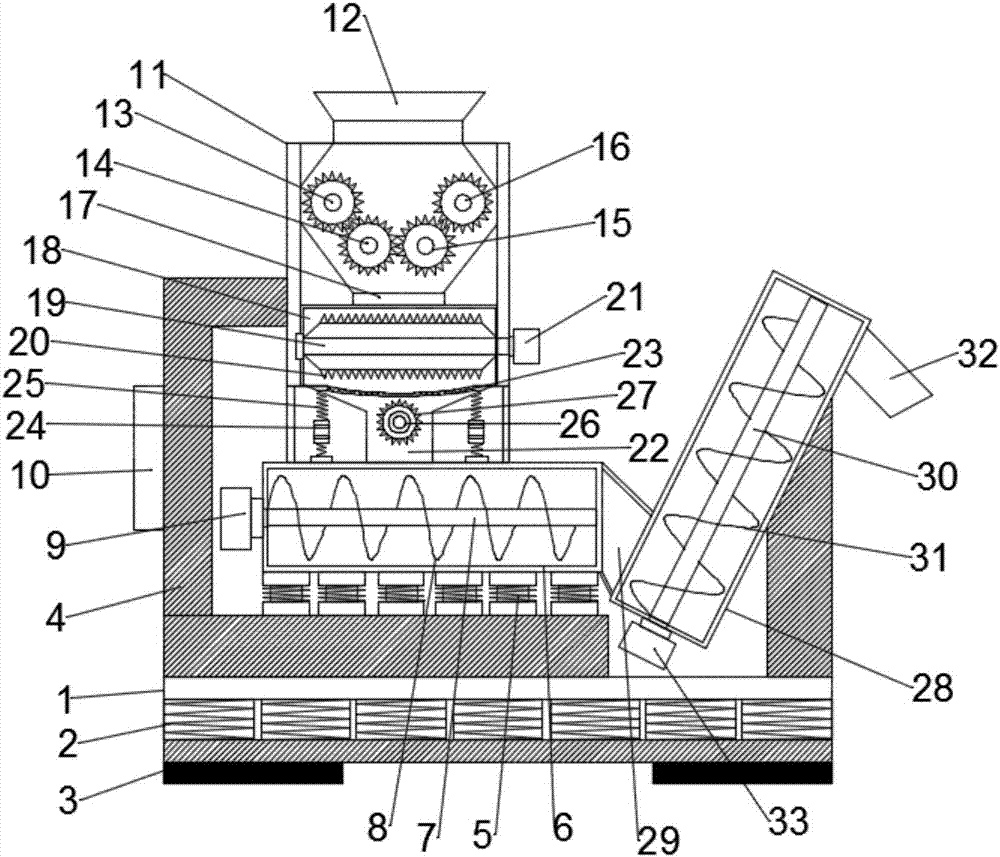

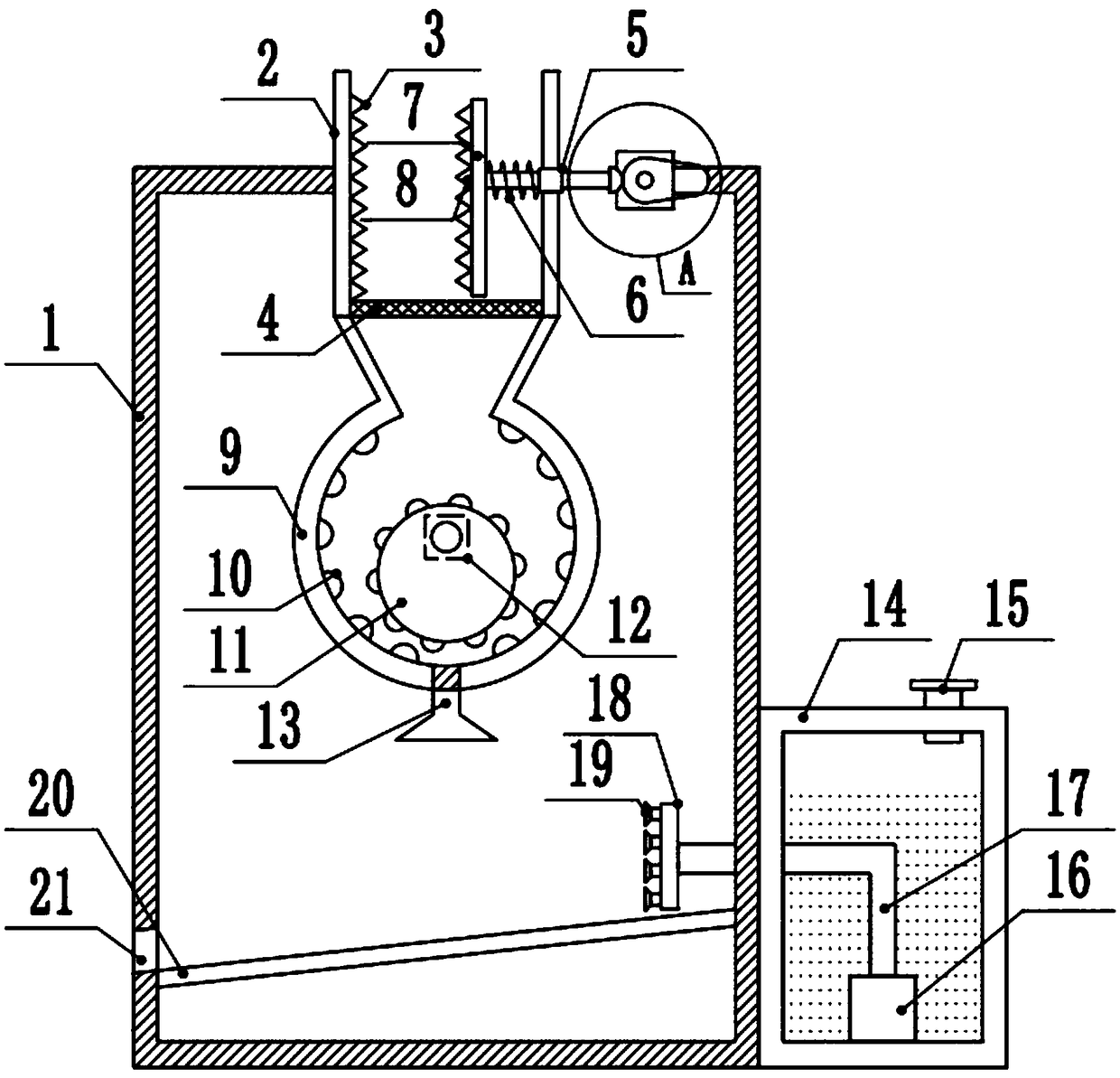

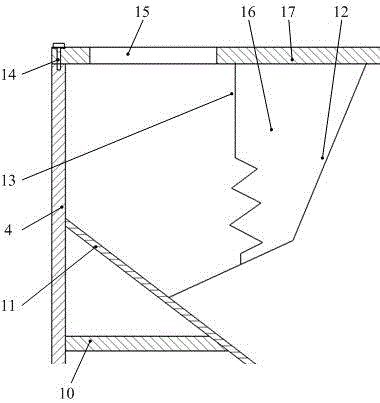

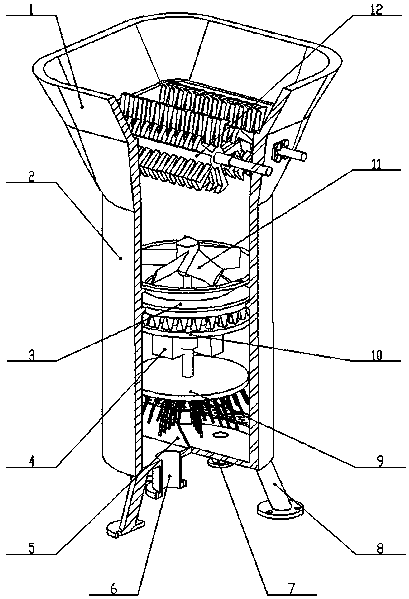

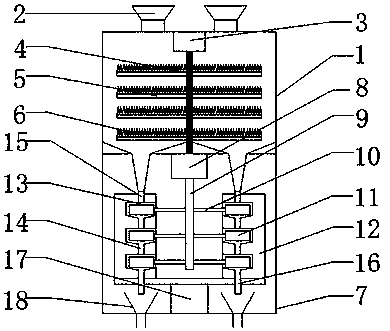

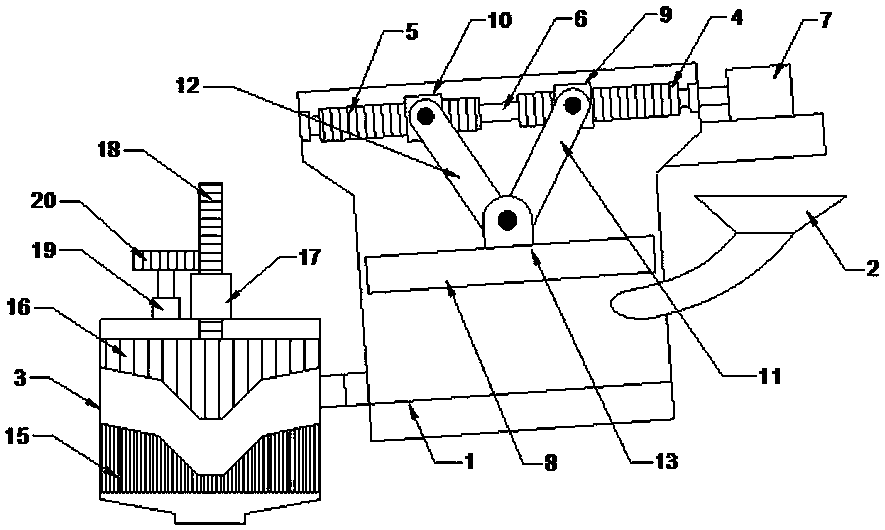

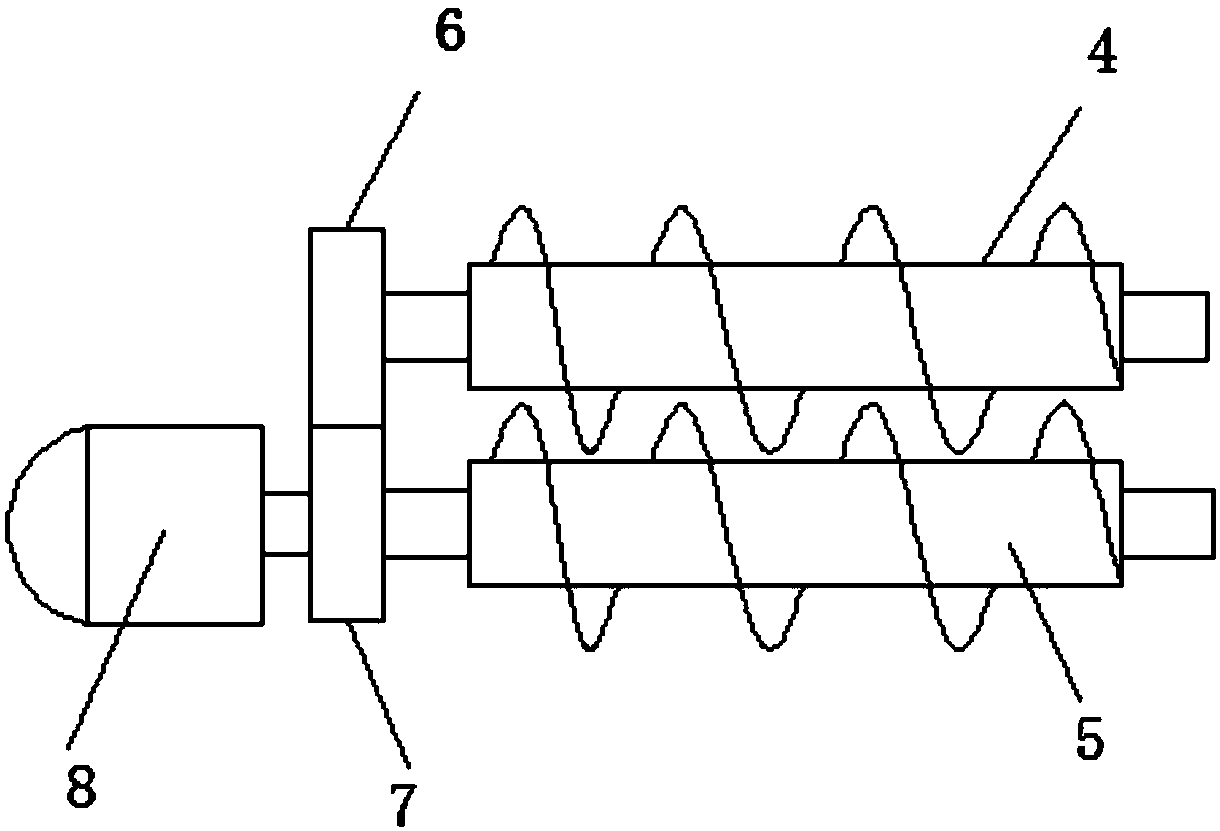

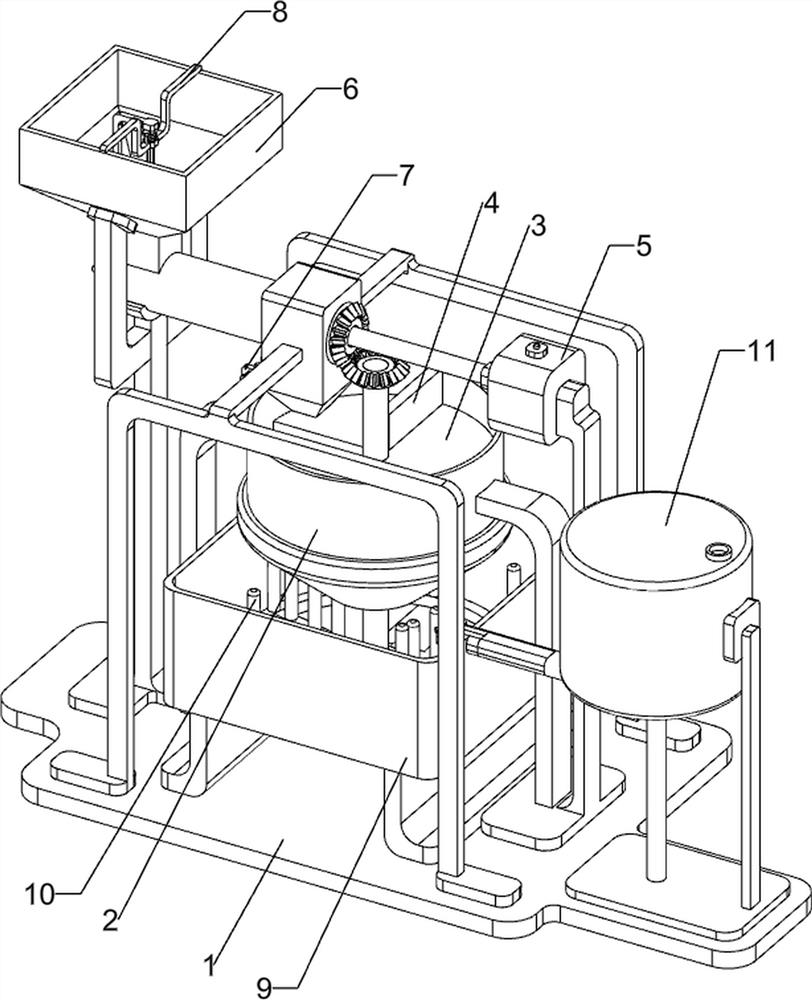

Powdering and then grinding type pulping equipment

PendingCN107604725AQuick cropImprove efficiencyPulp beating/refining methodsRaw material divisionLiquid waterSlurry

The invention provides powdering and then grinding type pulping equipment. The equipment mainly comprises a conical feeding inlet device, a rectangular tooth-shaped roller device, a stirring device, aconical grinding roller device, a bevel gear drive device and an inclined filter device. The equipment is characterized in that paper sheets are smashed and recycled through rectangular tooth-shapedrollers, and then slurry grinding is performed through a conical grinding roller. The recycled paper sheets are smashed in advance through shear force formed by the rectangular tooth-shaped roller device; the paper sheets and liquid water are stirred through rotation of the stirring device, and feed liquid soaking stirring and accelerated downward flowing are achieved; slurry is ground through thehigh-speed rotating conical grinding roller, and fine grinding of the paper sheets is achieved; due to rotation of the inclined filter device, liquid water and slurry separation is achieved.

Owner:UNIV OF JINAN

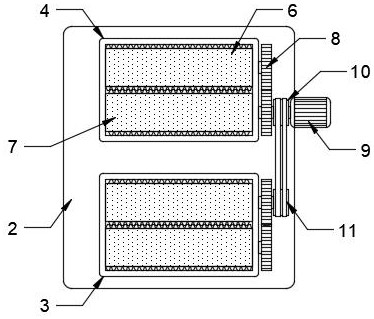

Powdery coating material powder milling machine

The present invention discloses a powdery coating material powder milling machine, which comprises a body, wherein the body comprises a crushing bin and a powder milling bin, the crushing bin is positioned above the body, two material inlet hoppers are arranged above the crushing bin, a motor 1 is fixedly arranged on the inner-upper wall of the crushing bin, the lower end of the motor 1 is provided with a rotation shaft 1, the rotation shaft 1 is provided with a plurality of cutter blade brackets, the cutter blade brackets are provided with a plurality of cutter blades, the powder milling binis connected below the crushing bin, and a motor 2 is arranged on the inner-upper wall of the powder milling bin. According to the present invention, by arranging the crushing bin, the primary crushing of the powdery coating material raw material is achieved; by arranging the three groups of the grinding rollers and the annular grinding groove in the powder milling bin, the secondary efficient power milling of the powdery coating material raw material can be achieved; and by matching the crushing bin and the powder milling bin, the powdery coating material powder milling machine of the presentinvention has advantages of high powder milling rate and strong practicability.

Owner:TIANJIN SHENGXINLONG POWDER PAINT

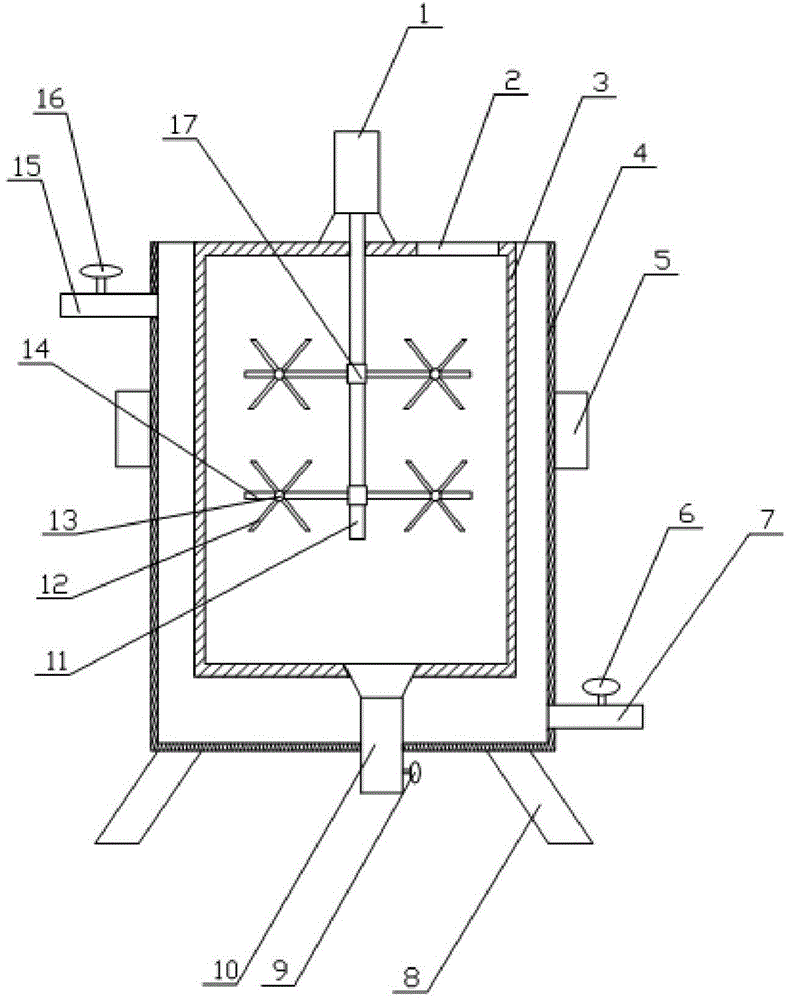

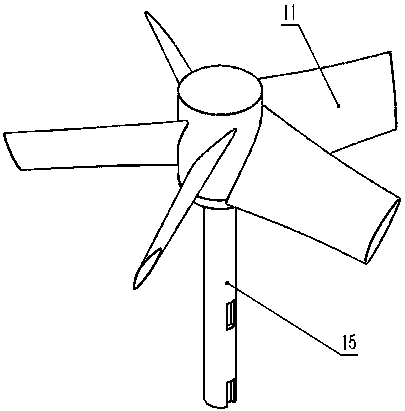

Automatic water environment treatment and purification equipment based on microbial nest

ActiveCN113149365ATo achieve the ultimate goal of ecological restorationDisadvantages of changing the separation effect and not being able to unify the coordination effectWater/sewage treatment by centrifugal separationTreatment using aerobic processesMicroorganismDecomposition

The invention provides automatic water environment treatment and purification equipment based on a microbial nest. The equipment comprises a main body, the main body is a hollow cylinder, a floating block is fixedly installed at the upper end of the main body and is in a circular ring shape, a drop biological disc is fixedly installed on the floating block, water is sucked through a submersible pump, and then the water body passes through a filler area to provide a breeding environment for microorganisms; meanwhile, the water body is sprayed out from the spray head, one part of the water body is diffused around, the other part of the water body flows back and enters a second filler area on the upper layer in the main body again, an aerobic environment is formed in the second filler area, aerobic microorganism biocenosis is increased, and the operation is repeated to continuously provide oxygen and microorganisms for the surrounding water body; therefore, the defect that the traditional water body aeration and microbial separation effects cannot be unified and coordinated is overcome, the strong decomposition capability of microbial cenobium on water body pollutants in the breeding process is fully exerted, the purification function of the water body ecological system is promoted to be recovered, and the final purpose of water body ecological restoration is achieved.

Owner:QINHUANGDAO PENYAO ENVIRONMENTAL PROTECTION ENG

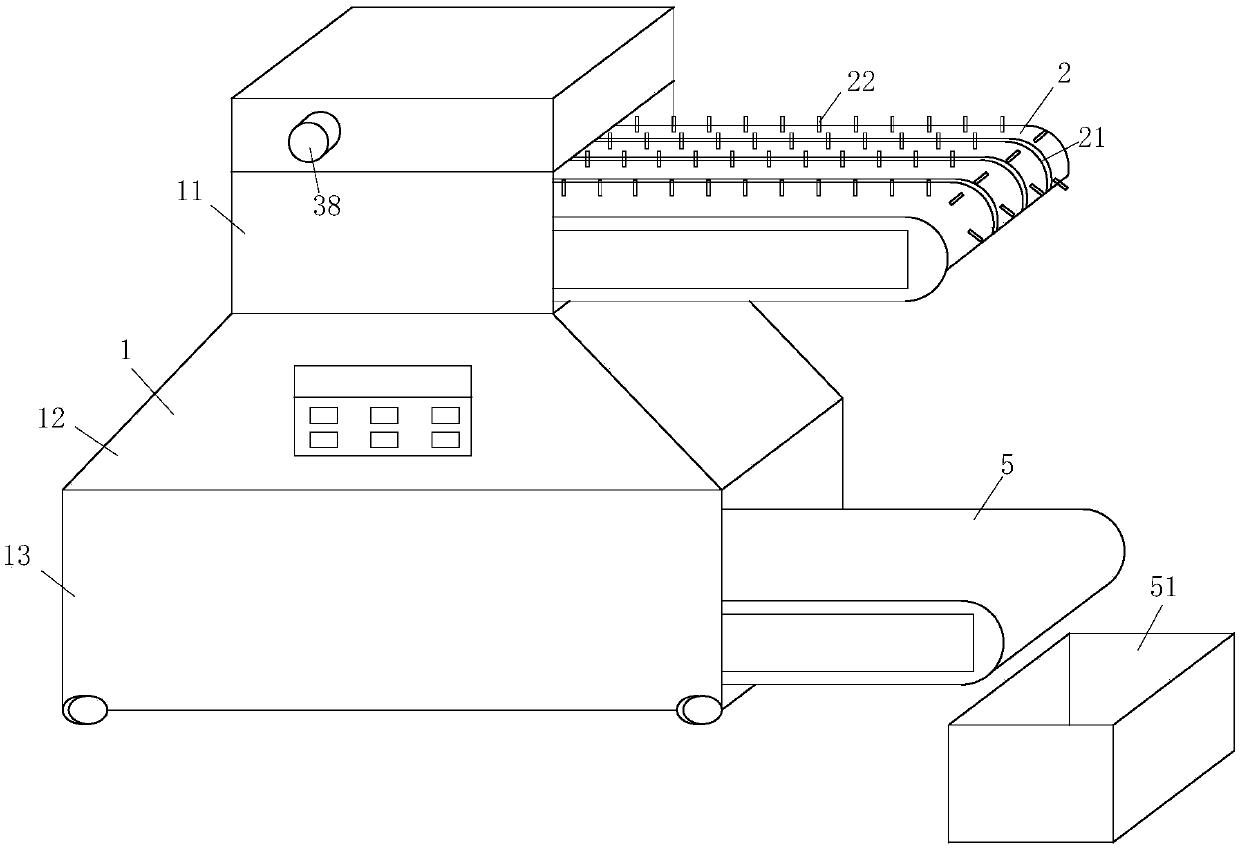

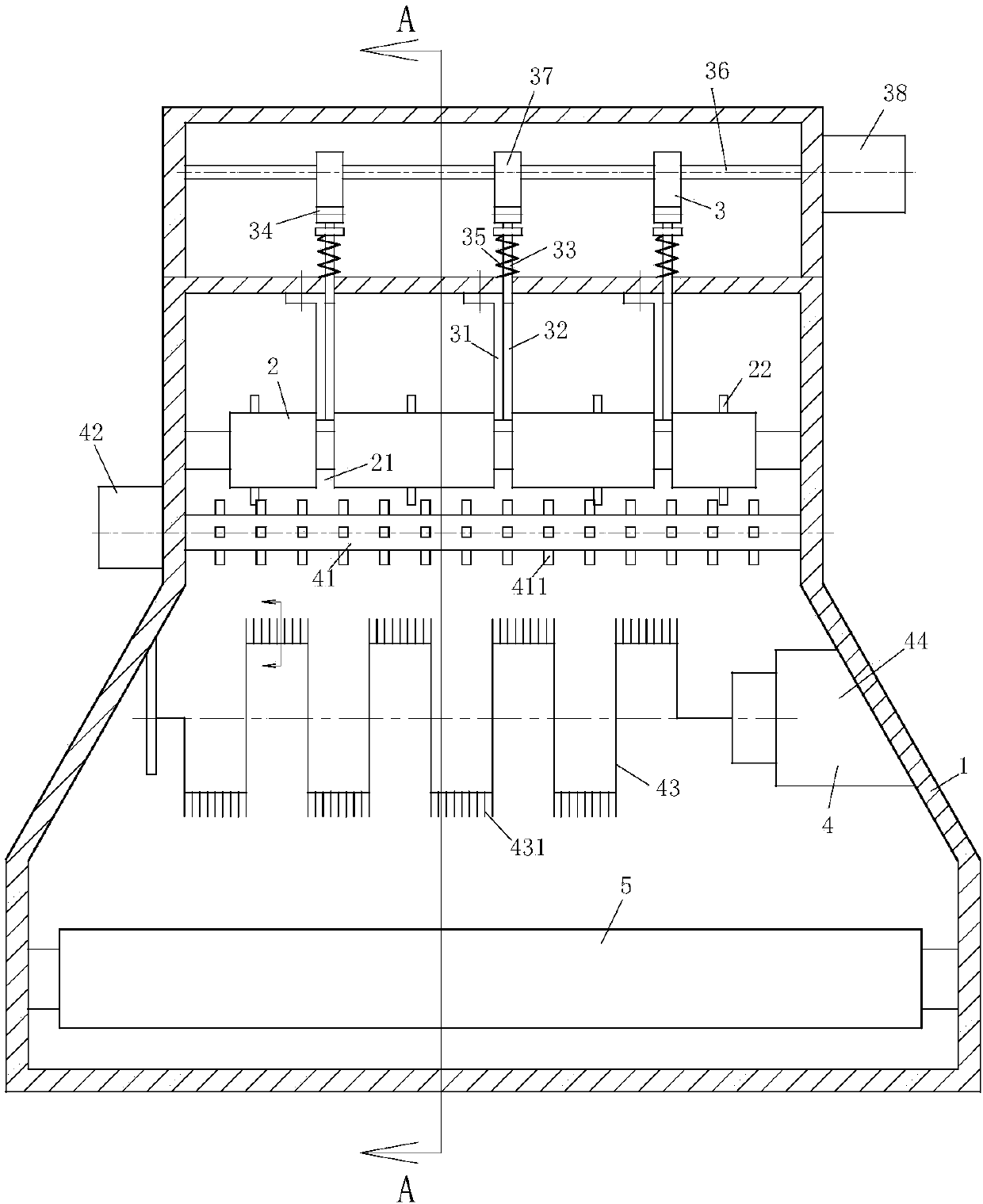

Cloth smashing machine at low rotating speed

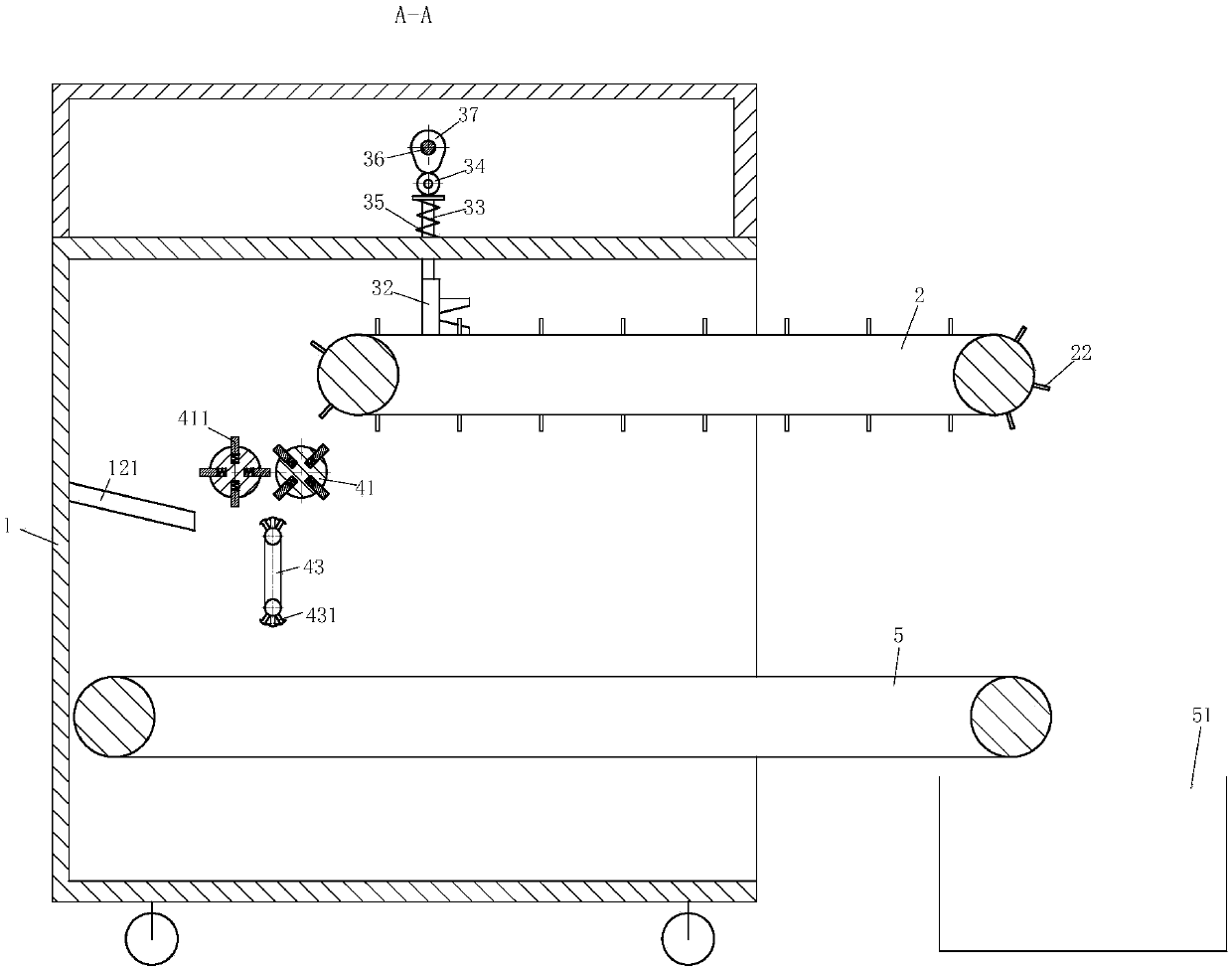

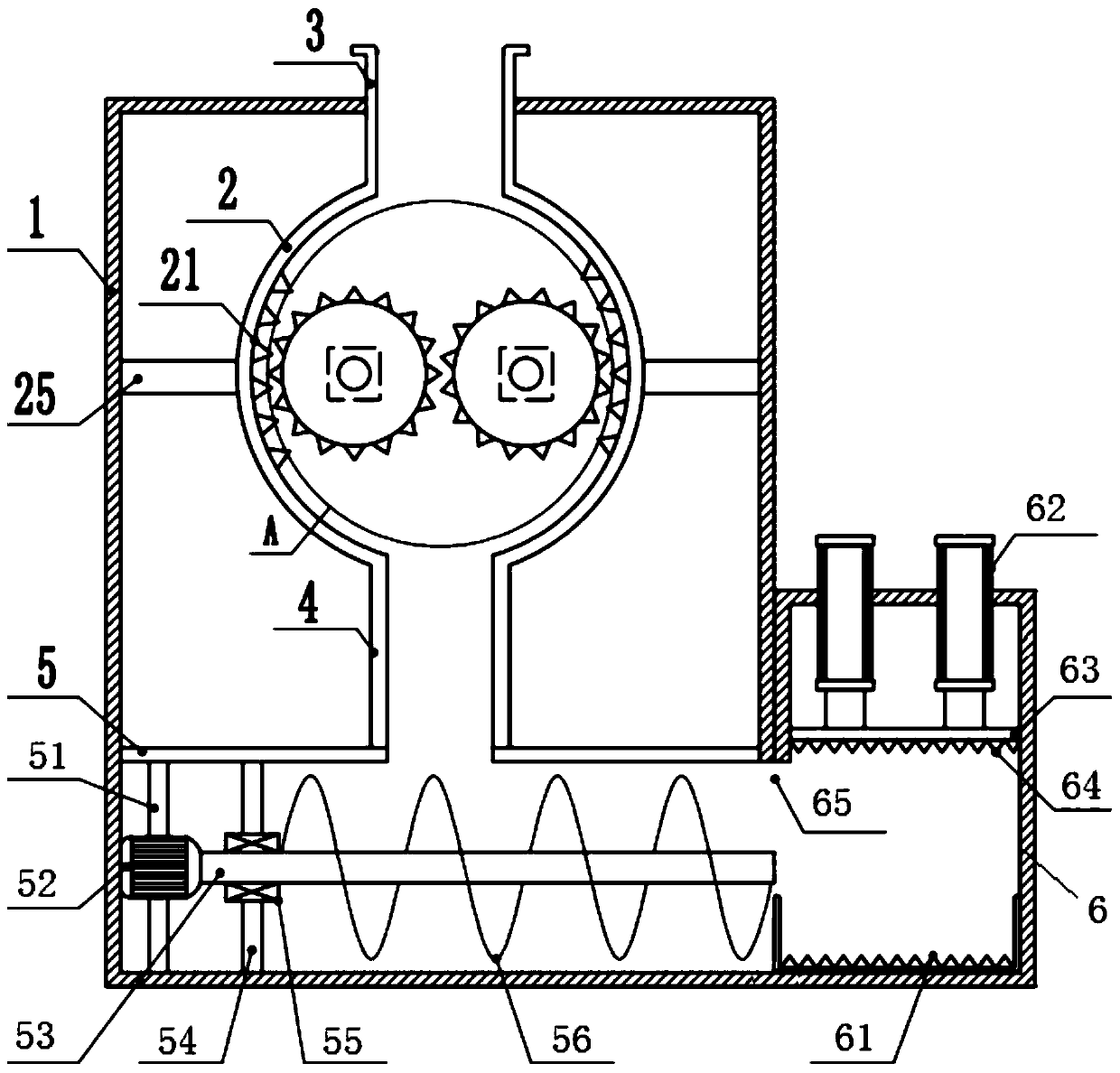

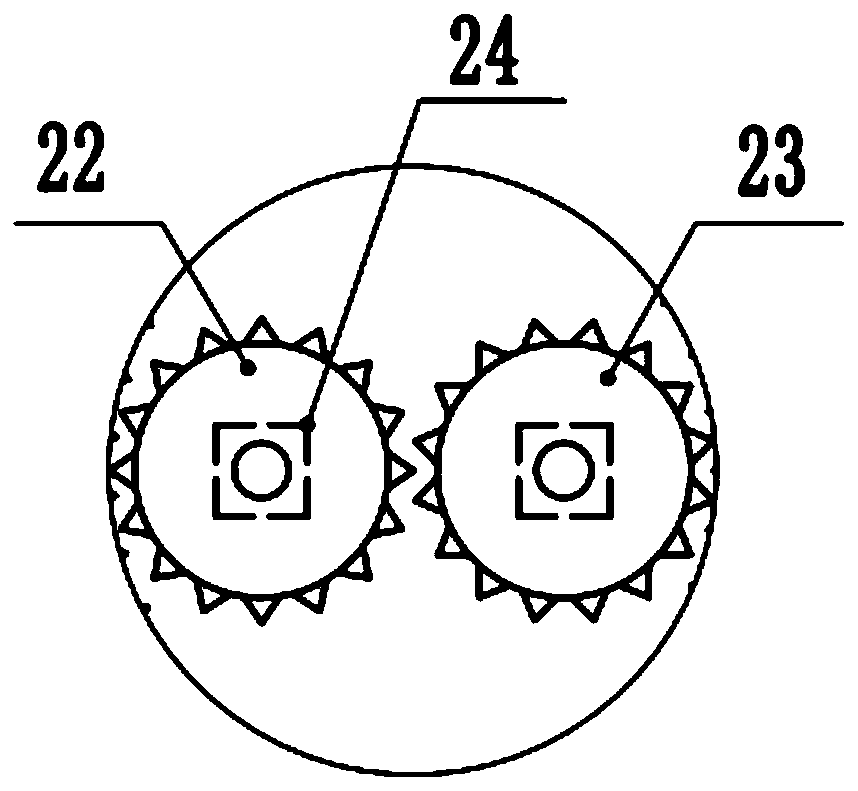

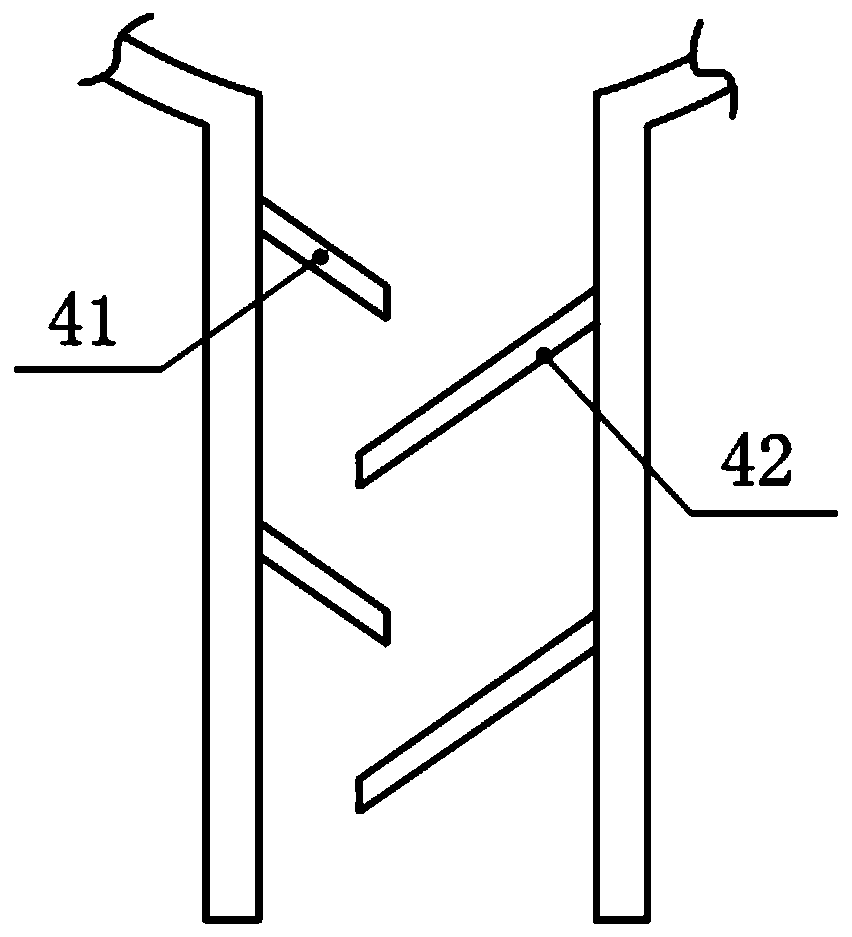

ActiveCN107604485AAchieve primary crushingAchieve final crushingTextile disintegration and recoveryFibre disintegrationLow speedConveyor belt

The invention relates to the technical field of crushing, in particular to a cloth smashing machine at a low rotating speed. The cloth smashing machine comprises a box, a feeding conveyor belt, a shearing module, a smashing module, a discharging conveyor belt and a controller, wherein the box comprises a shearing box located on the upper portion of the box, a smashing box located on the middle portion of the box and a discharging box located on the lower portion of the box, and the discharging conveyor belt is horizontally arranged and used for conveying cloth material into the shearing box; the shearing module is located in the shearing box and used for conducting primary shearing on the cloth material so that strip cloth material can be formed, wherein the cloth material is sheared intostrips so that low-speed smashing conducted on the cloth material in the subsequent step can be convenient; the smashing module is located in the smashing box and used for smashing the strip cloth material; the discharging conveyor belt is located in the discharging box and used for conveying out smashed rag material, and a storage box used for receiving the rig material is arranged at the tail end of the discharging conveyor belt. By means of the machine, the cloth material can be crushed at the low rotating speed, and noise and heat can be effectively reduced.

Owner:绍兴柯桥靓绣纺织有限公司

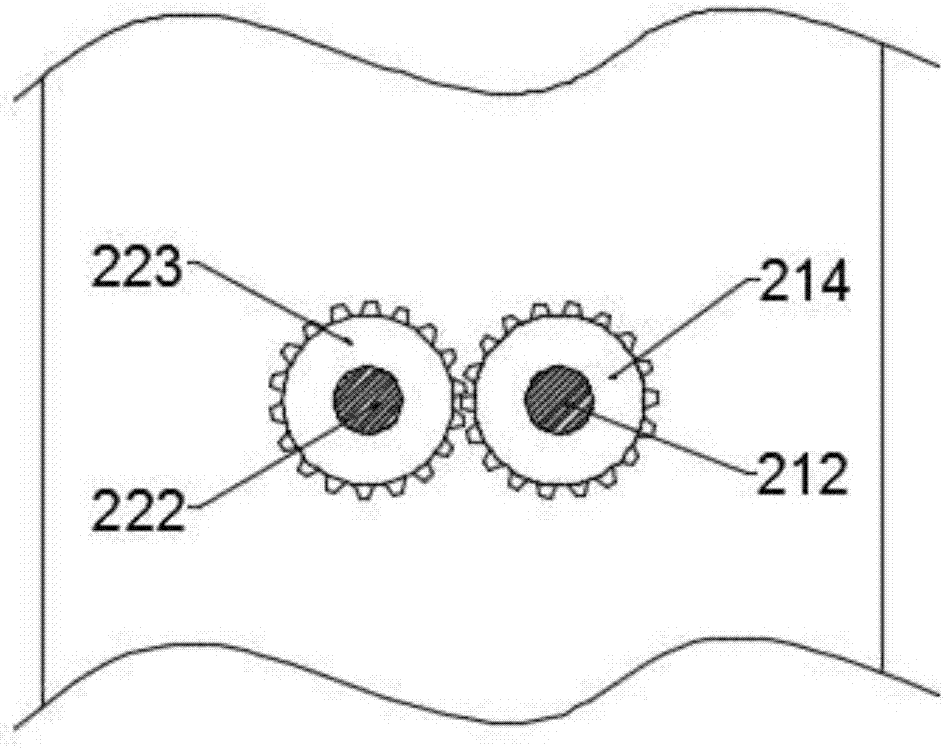

Household garbage crushing machine

InactiveCN110152784AAchieve primary crushingAchieve Double SmashGrain treatmentsMechanical engineeringExtrusion

The invention relates to a household garbage crushing machine. The household garbage crushing machine comprises a crushing box, a conveying box and a crushed garbage box, wherein the crushing box communicates with a feeding cylinder and a discharging cylinder, the crushing box communicates with the conveying box through the discharging cylinder, the crushing box is internally provided with a firstcrushing gear and a second crushing gear which are meshed with each other, the first crushing gear is in driving connection with a crushing motor, first crushing teeth corresponding to the first crushing gear and the second crushing gear are correspondingly arranged on the two sides of the inner wall of the crushing box, a conveying motor is arranged in the conveying box, the conveying motor is in driving connection with a conveying rod, the periphery of the conveying rod is fixedly connected with a spiral conveying blade, the spiral conveying blade extends into the crushed garbage box, second crushing teeth are arranged at the bottom end of the interior of the crushed garbage box, an extrusion plate is arranged at the upper end of the crushed garbage box, the lower surface of the extrusion plate is fixedly connected with third crushing teeth corresponding to the second crushing teeth, and the extrusion plate is driven by a telescopic air cylinder. The crushing machine is good in crushing effect, high in crushing efficiency and high in practicability.

Owner:SUZHOU INST OF INDAL TECH

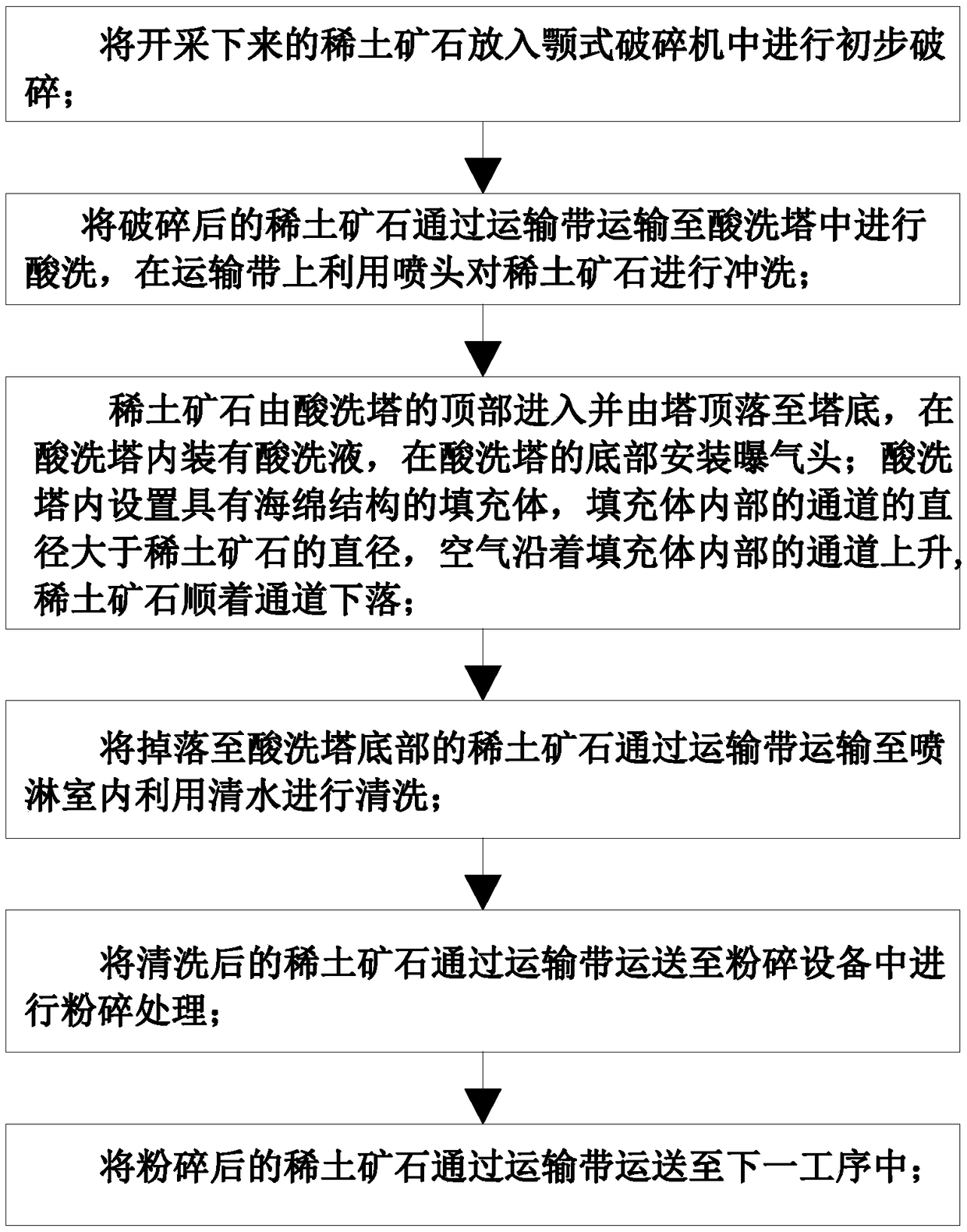

Process for finely treating rare-earth ores

ActiveCN109182790AAchieve primary crushingEnough to raiseProcess efficiency improvementGrain treatmentsChemical reactionSlag

The invention belongs to the technical field of rare-earth production, and particularly relates to a process for finely treating rare-earth ores. The process comprises the following steps: grinding and preliminarily filtering collected rare-earth raw ores with a grinding device; adding calcium-containing minerals and a carbon-containing solid reducer into the ground rare-earth ore; reducing and melting the rare-earth ore in a smelting furnace at the temperature of 1500-1700 DEG C to obtain rare-earth slag and molten iron; cooling the rare-earth slag and molten iron, crushing the rare-earth slag, removing iron shot by adopting a magnetic separation mode to obtain a finished product rare-earth slag. The process can realize comprehensive grinding, ensures sufficient chemical reaction of the rare-earth raw ore and improves the enrichment ratio of rare-earth.

Owner:金寨智行知识产权运营有限公司

Preparation device of anti-tumor drug and using method of preparation device

InactiveCN111889184AAchieve primary crushingAchieve hybridTransportation and packagingMixersPharmaceutical drugMixing effect

The invention discloses a preparation device of an anti-tumor drug and a using method of the preparation device. The preparation device comprises a box body and a connecting cover, wherein the connecting cover is arranged on the top of the box body. The preparation device further comprises primary crushing mechanisms, a rolling mechanism and a fine grinding mechanism, wherein a first feeding portand a second feeding port are formed in two ends of the top of the connecting cover respectively, the primary crushing mechanisms are arranged in the first feeding port and the second feeding port correspondingly, and the rolling mechanism is arranged at the top end of the interior of the box body. According to the preparation device of the anti-tumor drug, materials can be preliminarily crushed by the aid of the arranged primary crushing mechanisms, the preliminarily crushed materials can be further rolled and crushed by the rolling mechanism, meanwhile, two raw materials can be mixed under the matching action of a rotating shaft and a turning plate in a mixing tank after rolling and crushing, the two materials are further turned and mixed under the action of the turning plate, a better mixing effect is achieved, the follow-up mixing steps are reduced, and the preparation efficiency of the drug is improved.

Owner:阮玫

Smashing device for food detection

PendingCN108844795AEasy to achieve primary crushingAchieve primary crushingPreparing sample for investigationTesting foodDrive shaftEngineering

Owner:冒志华

Construction waste treatment equipment and construction waste regeneration system

InactiveCN112916175AEasy to reuseEasy to useGrain treatmentsVibration suppression adjustmentsArchitectural engineeringEngineering

The invention discloses construction waste treatment equipment and a construction waste regeneration system. The construction waste treatment equipment comprises a shell, a feeding port is formed in the top end of the shell, a discharging port is formed in the bottom end of the shell, supporting legs are arranged below the shell, two movable blocks are arranged between two first jaw plates, second jaw plates are arranged on the side, close to the first jaw plates, of the movable blocks, the second jaw plates are fixedly connected to the movable blocks, first connecting blocks are arranged on the sides, away from the first jaw plates, of the movable blocks, the first connecting blocks are fixedly connected to the movable blocks, and the first connecting blocks are fixedly connected to traction frames through bolts. According to the construction waste treatment equipment and the construction waste regeneration system, a first crushing mechanism is driven by a driving mechanism to work, so that blocky construction waste entering the shell is preliminarily crushed and then falls into a second crushing mechanism to be crushed again, fine particles are obtained, recycling is facilitated, the use method is simple, the working efficiency is high, and the practicability is high.

Owner:王锟

Treatment device for civil engineering construction waste

InactiveCN108620216AAchieve brokenAchieve primary crushingGrain treatmentsWater wheelTreatment effect

The invention discloses a treatment device for civil engineering construction waste. The treatment device for the civil engineering construction waste comprises a support frame and a support base, wherein a crushing box is fixed on the support frame through a limit ring seat, a fourth crushing cutter wheel is mounted on the crushing box, a first crushing cutter wheel, a second crushing cutter wheel and a third crushing cutter wheel are mounted at the inner lower part of the crushing box, the inlet end of the first crushing cutter wheel extends into the outer part of the side wall of the crushing box, and is coaxially and fixedly connected with a first transmission gear, the inlet end of the second crushing cuter wheel extends into the outer part of the side wall of the crushing box and iscoaxially and fixedly connected with a second transmission gear, the input end of the third crushing cutter wheel extends to the outer wall of the side wall of the crushing box and is coaxially and fixedly connected with a third transmission gear, a feeding port is formed in the upper part of the crushing box, a first transmission shaft is mounted on the edge of the feeding port, a second transmission shaft is mounted on the support base, the first transmission shaft is in transmission connection with the second transmission shaft through a conveyor belt, and a detachable solid pressure blockis arranged on the support base. The treatment device for the civil engineering construction waste disclosed by the invention has the beneficial effects of high automation degree, convenient feeding,high work efficiency and good treatment effect on the waste.

Owner:高光光

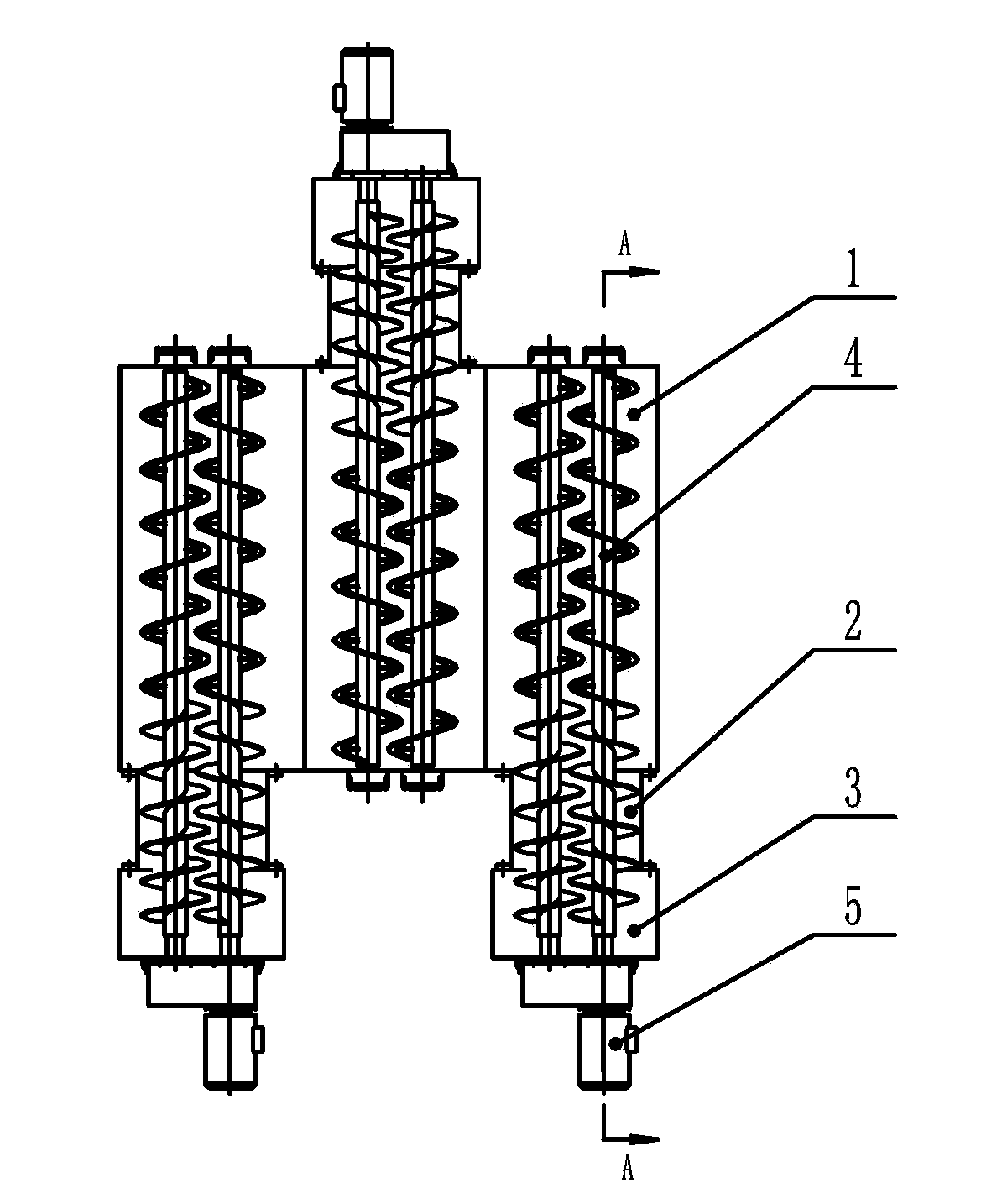

Environmental governance waste crushing treatment device

InactiveCN111068820AImprove crushing efficiencyImprove crushabilityGrain treatmentsScrew threadWaste material

The invention relates to a crushing treatment device, in particular to an environmental governance waste crushing treatment device. A first screw, a second screw, an upper grinding plate and a lower grinding plate are arranged in a first grinding mechanism, a first connecting block and a second connecting block can move along the first screw and the second screw through threads when the first screw and the second screw rotate, and therefore the distance between the top end of a first connecting frame and the top end of a second connecting frame can be changed, the first connecting frame and the second connecting frame can drive the upper grinding plate to move longitudinally, and particles can be primarily crushed through the upper grinding plate; and an upper grinding block and a lower grinding block are arranged in a second grinding mechanism, the bottom end of the upper grinding block protrudes downwards, a grinding groove is formed in the top end of the lower grinding block, and therefore the upper grinding block can be moved down, input powder can be further ground through the upper grinding block, the grinding efficiency can be improved, and the grinding effect can be improved.

Owner:XUZHOU UNIV OF TECH

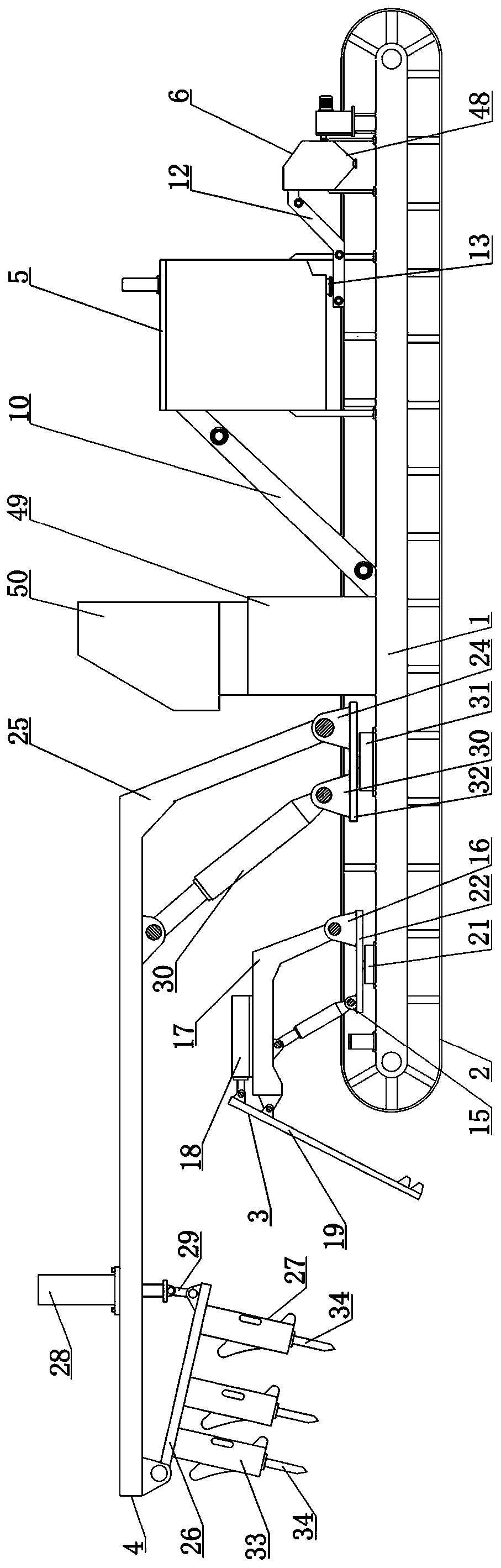

Crushing and screening device for feed grease processing

InactiveCN111659515AFacilitate subsequent processingAchieve primary crushingSievingScreeningElectric machineryStructural engineering

The invention relates to the technical field of feed grease processing, in particular to a crushing and screening device for feed grease processing. The crushing and screening device comprises an outer tube; a crushing tube is arranged in the outer tube, and an adding hopper is arranged at the top end of the crushing tube; two parallelly-arranged rotating rods are arranged in the crushing tube, wherein the outer wall of an internal section, in the crushing tube, of one of the rotating rods is provided with first flail knives which are distributed at equal distances, and the outer wall of an internal section, in the crushing tube, of the other rotating rod is provided with second flail knives which are distributed at equal distances; and the tail ends of the rotating rods extend outside theouter tube and are connected with a motor. By starting the motor, a transmission rod is driven by an output shat of the motor to rotate and drives a sleeve to rotate, the sleeve drives a base to rotate through a spring, the base drives a homogenizing plate to rotate along the end face on a screen net, the homogenizing plate can spread out crushed materials at the upper end of the screen net, quick screening of the crushed materials is convenient, and the screening efficiency of the crushed materials is greatly improved.

Owner:ANHUI WANSHAN FOODS

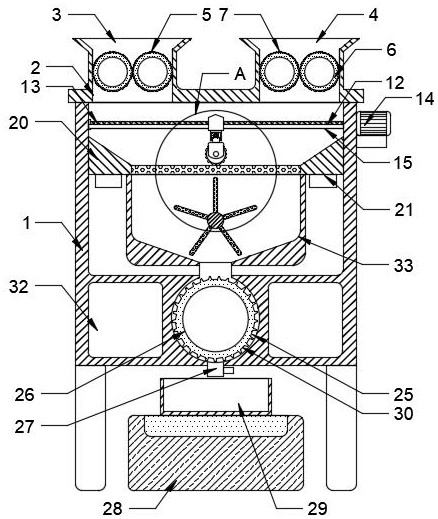

Grinding device for rare earth materials

The invention discloses a grinding device for rare earth materials. The grinding device comprises a crushing box and supporting columns, the bottom end of the crushing box is provided with the multiple uniformly-distributed supporting columns, a feeding port is formed in the top end of the crushing box, a first crushing roller is arranged at the top of a cavity of the crushing box, one side of thefirst crushing roller is provided with a second crushing roller engaged with the first crushing roller, roller shafts at one end of the first crushing roller and one end of the second crushing rollerextend to the inner wall of the crushing box, a roller shaft at the other end of the first crushing roller penetrates the crushing box to be connected to a first gear located on one side of the crushing box, and a roller shaft at the other end of the second crushing roller penetrates the crushing box to be connected with a second gear located on one side of the crushing box. The grinding device has the beneficial effects that overall design is simple and reasonable, fine grinding is performed after crushing to enable rare earth to be ground more thoroughly, the rare earth grinding efficiencyis improved, and the crushing, grinding and screening processes are interlocked to improve the rare earth grinding quality.

Owner:嘉善中嘉化工有限公司

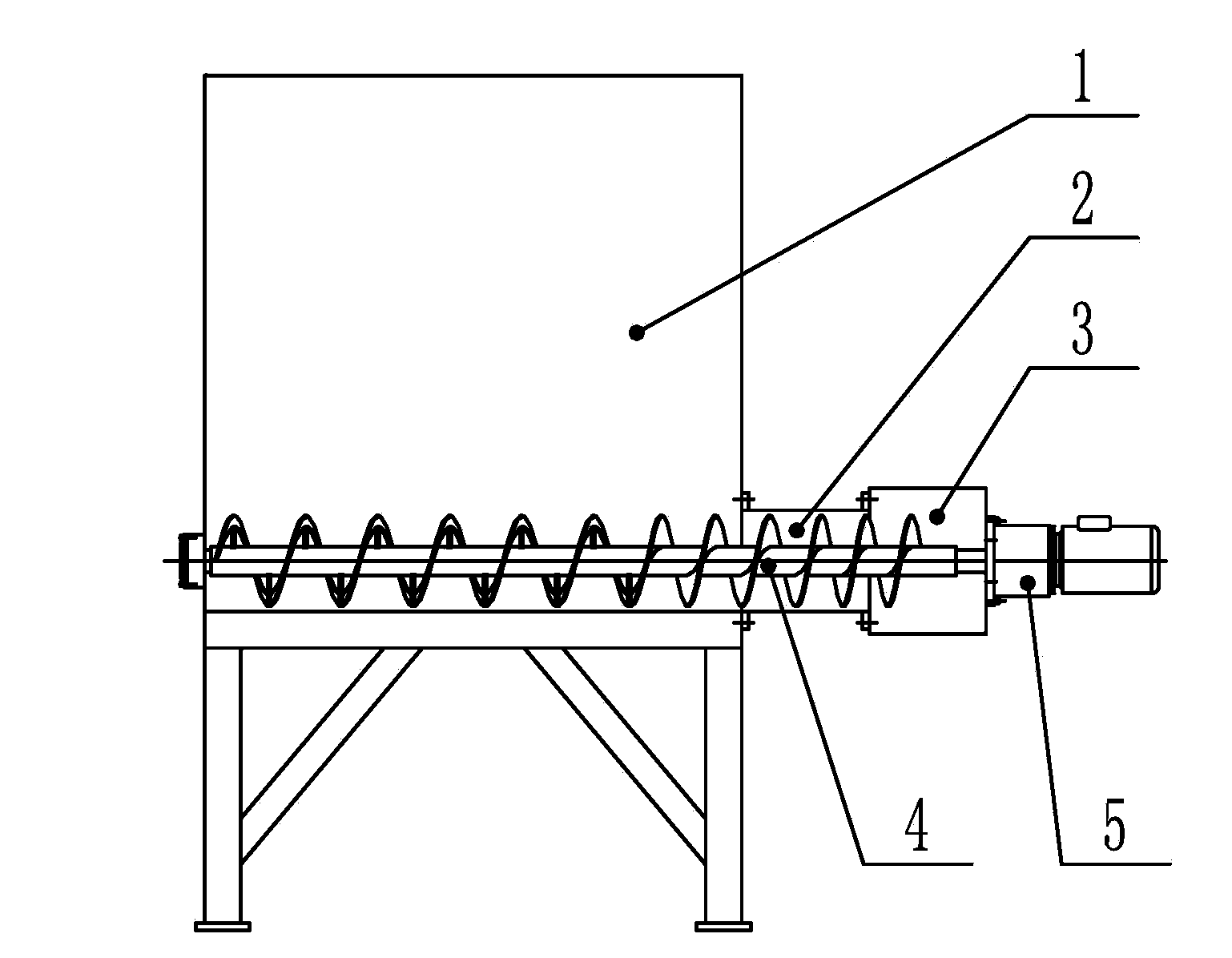

Ore mining and crushing integrated efficient-mining device and method

ActiveCN111594172AImprove mining efficiencyShorten the timeUnderground miningSurface miningHydraulic cylinderMining engineering

The invention discloses an ore mining and crushing integrated efficient-mining device and method. The ore mining and crushing integrated efficient-mining device comprises a mining device, wherein themining device comprises a chassis and walking mechanisms; the walking mechanisms are correspondingly arranged on the front and rear sides of the chassis; a rock collecting mechanism, an ore layer crushing mechanism, a first jaw crusher and a second jaw crusher are sequentially arranged at the top of the chassis from left to right; the ore layer crushing mechanism is used for crushing a dense ore layer into loose rocks; a pressing mechanism used for pressing ore is arranged above the crushing zone of the first jaw crusher; a hydraulic cylinder and a first screw conveyor are arranged below the chassis; the outlet end of the first screw conveyor extends into the feeding port of the first jaw crusher; the inlet end of the second screw conveyor communicates with the discharging port of the first jaw crusher; and the outlet end of the second screw conveyor extends into the feeding port of the second jaw crusher. The ore mining and crushing integrated efficient-mining device and method have the beneficial effects that the ore mining efficiency is improved; the rock crushing efficiency is improved; the crushed ore particle size uniformity is improved; and the operation is simple.

Owner:广西东创智能科技有限公司

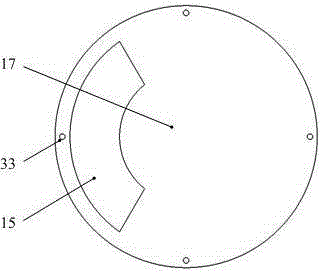

High-efficiency seasoning grinding device

ActiveCN112973859ARealize multiple screeningAchieve primary crushingSievingScreeningGear wheelAdhesive glue

The invention discloses a high-efficiency seasoning grinding device. The high-efficiency seasoning grinding device comprises a grinding barrel, an inner gear ring is meshed with a second gear, a three-phase asynchronous motor is fixedly connected to the inner side wall of a cover body, the surface of a discharging barrel fixedly sleeves with a gear ring, the gear ring is arranged in the cover body, the second gear is meshed with the gear ring, and the inner diameter of the discharging barrel is gradually increased from the position away from a bearing; the side wall of the cover body is fixedly connected with a discharging pipe, the discharging pipe is in an L shape, the other end of the discharging barrel penetrates into the discharging pipe, the discharging barrel sleeves with a second sealing ring in an attached and rotating mode, the second sealing ring is fixedly connected with the side wall of a vertical plate through glue, the model of the three-phase asynchronous motor is Y2-80M2-4S150, the wall thickness of a C-shaped buckle is 8 mm-10 mm, and a V-shaped barrel is made of alloy steel materials, so that seasoning can be screened for a plurality of times, a sieve does not need to be replaced repeatedly, working efficiency is improved, the seasoning can be crushed for the first time, grinding is convenient, and therefore the quality of finished products is indirectly improved, and use requirements are met.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

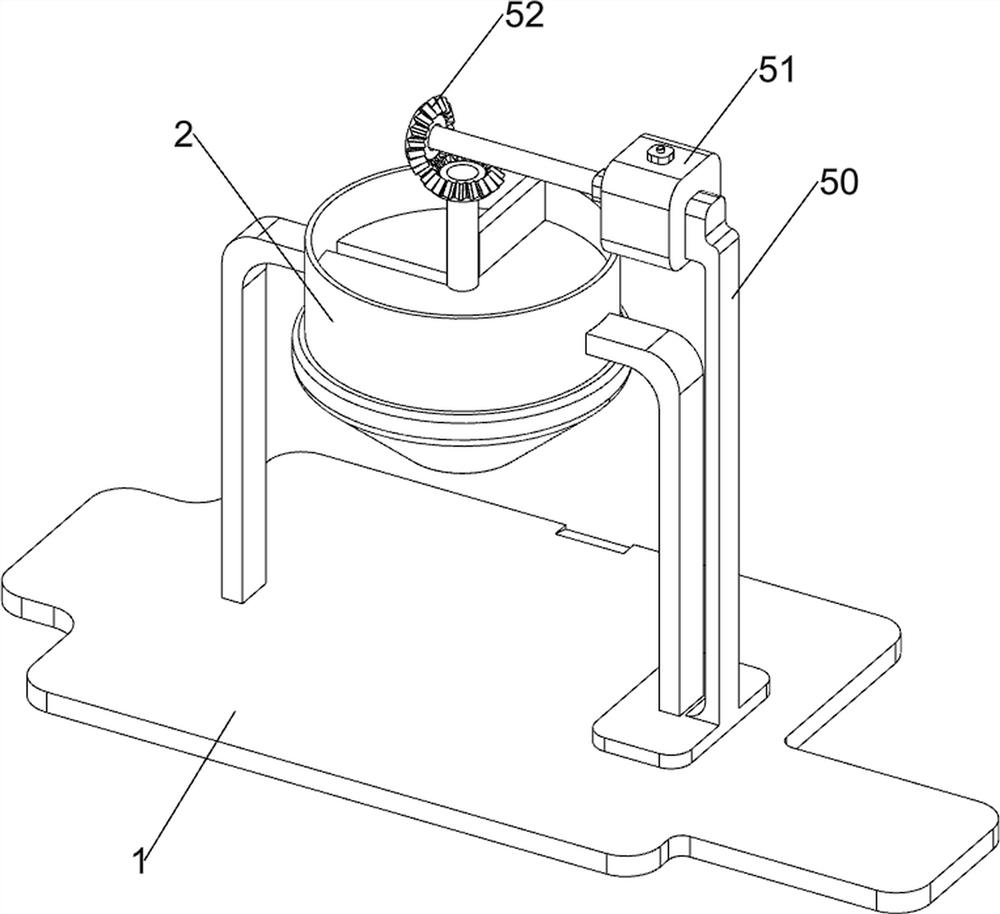

Environment-friendly device for making fertilizer by grinding leaves

InactiveCN113414223AAchieve crushingAchieve primary crushingUsing liquid separation agentSolid waste disposalAgricultural scienceAgricultural engineering

The invention relates to a fertilizer making device, in particular to an environment-friendly device for making fertilizer by grinding leaves. The environment-friendly device for making the fertilizer by grinding the leaves can be used for better separating iron waste out and is convenient for people to collect ground leaves. The environment-friendly device for making the fertilizer by grinding the leaves comprises a base, a millstone, a baffle and a rotating mechanism. A first mounting block is arranged on the top of the base; the millstone is rotationally arranged on the inner side of the first mounting block; the baffle is arranged on the upper part of the first mounting block and is located above the millstone; and the rotating mechanism is arranged on the top of the base. According to the environment-friendly device for making the fertilizer by grinding the leaves, the rotating mechanism is started to drive the millstone to rotate, and then the leaves are ground; and by arranging a feeding mechanism, the leaves can be preliminarily ground and conveyed.

Owner:肖泽慧

Straw incineration device based on special-shaped gear transmission principle

PendingCN111457386AAchieve primary crushingImprove incineration effectIncinerator apparatusSteering wheelGear wheel

The invention relates to the technical field of environmental protection, and discloses a straw incineration device based on a special-shaped gear transmission principle. The straw incineration devicecomprises a frame body, a material guide wheel is movably connected in the frame body, a cutting knife is movably connected to the outside the material guide wheel, a material guide rod is fixedly connected in the material guide wheel, a steering wheel is fixedly connected to the outside of the material guide rod, a connecting rod is fixedly connected to the outside of the steering wheel, a maingear is fixedly connected to the outside of the connecting rod, a connecting gear is connected to the outside of the main gear in an engaged manner, and a sector gear is fixedly connected to the outside of the connecting gear. Through cooperative use of the material guide wheel, the cutting knife, the main gear, the connecting gear, the sector gear and a straight toothed bar, straw is preliminarily crushed, the straw incineration effect is improved, the straight toothed bar pushes the straw so as to guarantee that the straw can smoothly enter an incineration chamber, the straw is prevented from being stuck, and therefore smooth operation of the equipment is guaranteed.

Owner:伍冬秋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com