Process for finely treating rare-earth ores

A rare earth ore and processing technology, which is applied in the direction of grain processing, process efficiency improvement, etc., can solve problems such as damage to human health, extensive rare earth raw ore crushing process, waste of resources and the environment, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

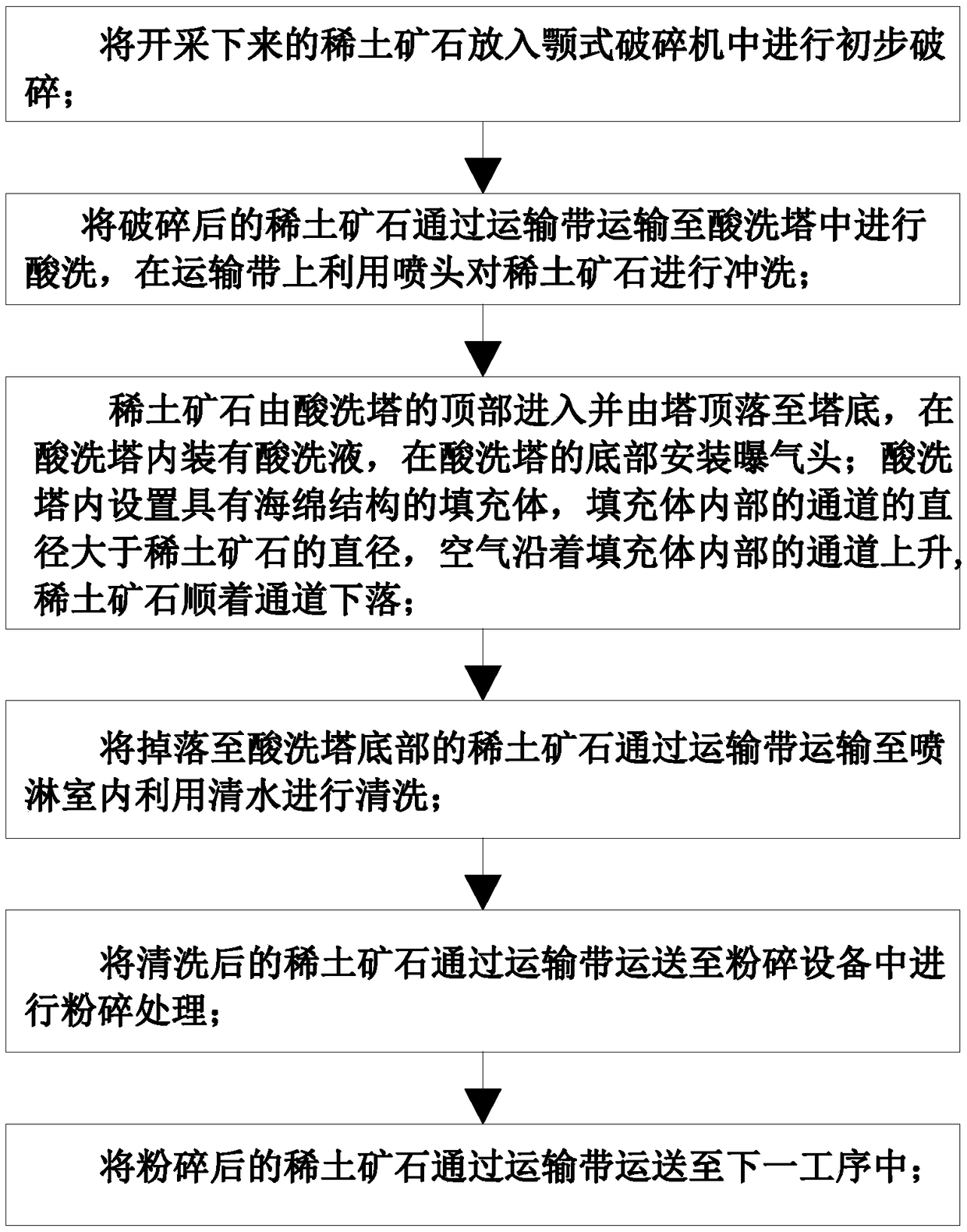

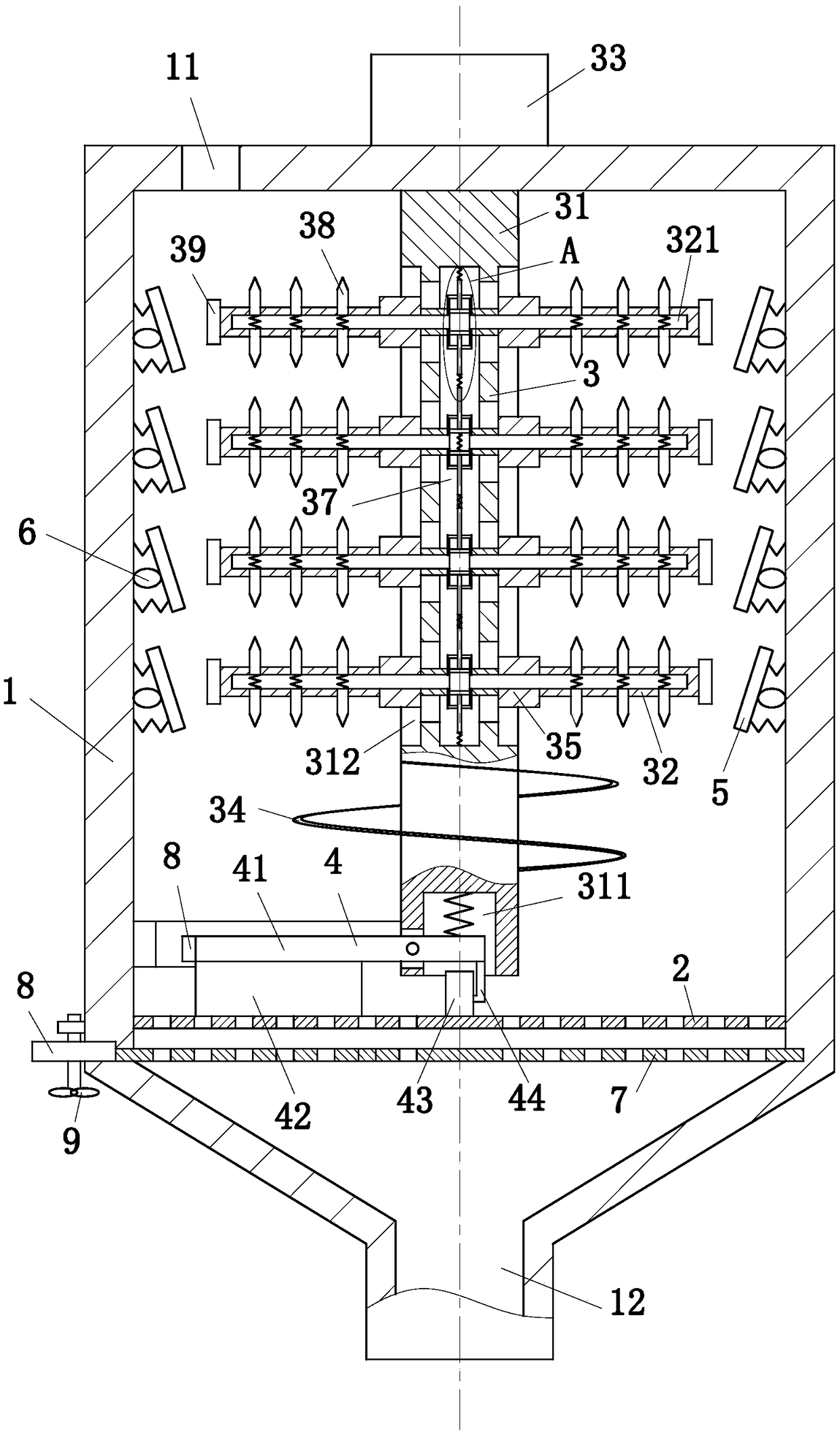

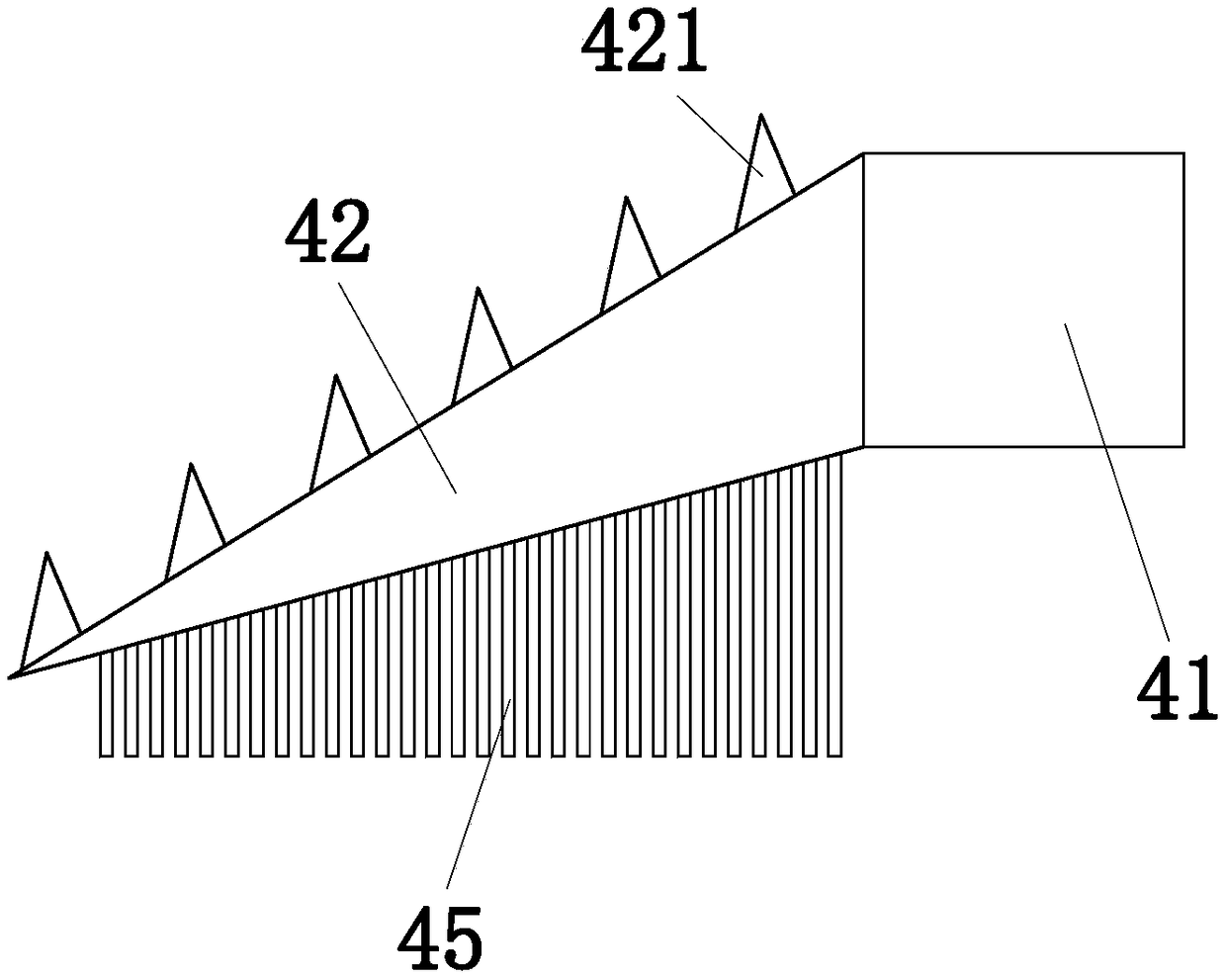

[0028] use Figure 1-Figure 5 A refinement treatment process of rare earth ore according to an embodiment of the present invention is described as follows.

[0029] Such as Figure 1-Figure 5 Shown, a kind of rare earth ore refinement processing technique described in the present invention, this technique comprises the steps:

[0030] S1, putting the mined rare earth ore into a jaw crusher for preliminary crushing, so that the size of the rare earth ore is appropriately reduced;

[0031] S2, then the rare earth ore crushed in S1 is transported to the pickling tower through the conveyor belt for pickling, and the rare earth ore is washed with the nozzle on the conveyor belt, and the nozzle is used to flush the rare earth ore to remove the sundries on the surface;

[0032] S3, the rare earth ore enters from the top of the pickling tower and falls from the top of the tower to the bottom of the tower. The pickling tower is equipped with pickling liquid, which is used to dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com