Environment-friendly device for making fertilizer by grinding leaves

A leaf and crushing technology is applied in the field of leaf crushing and fertilizer making devices for environmental protection, which can solve the problems of separation of iron waste and leaf cutting, and achieve the effect of easy collection and moist leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

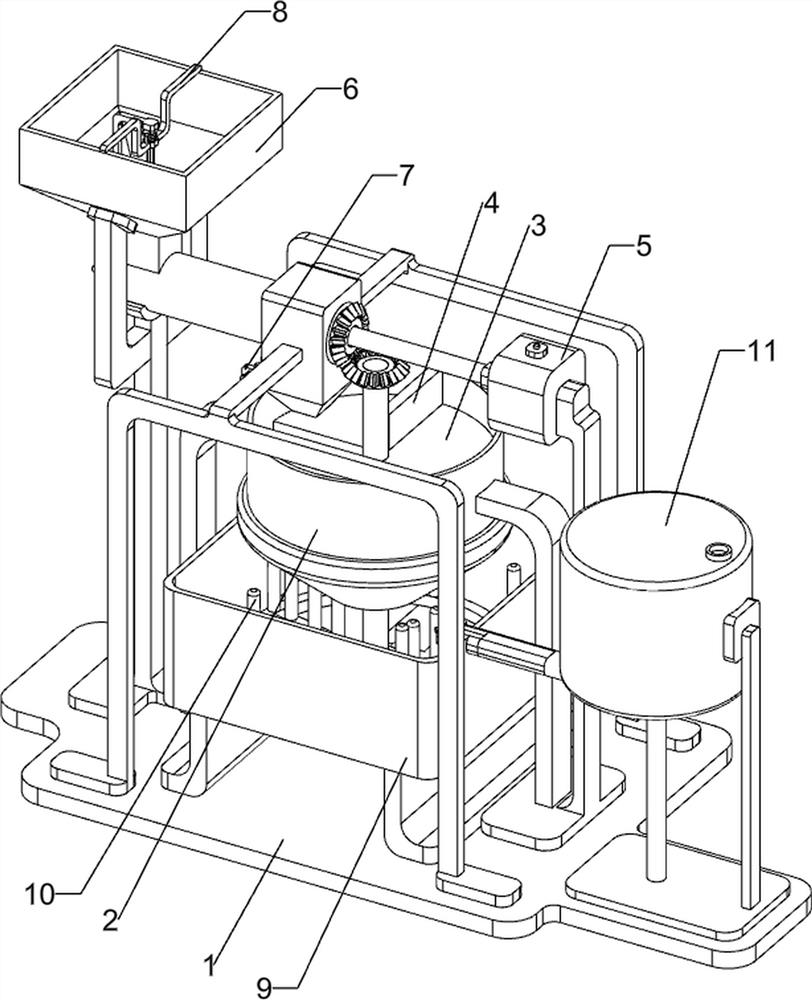

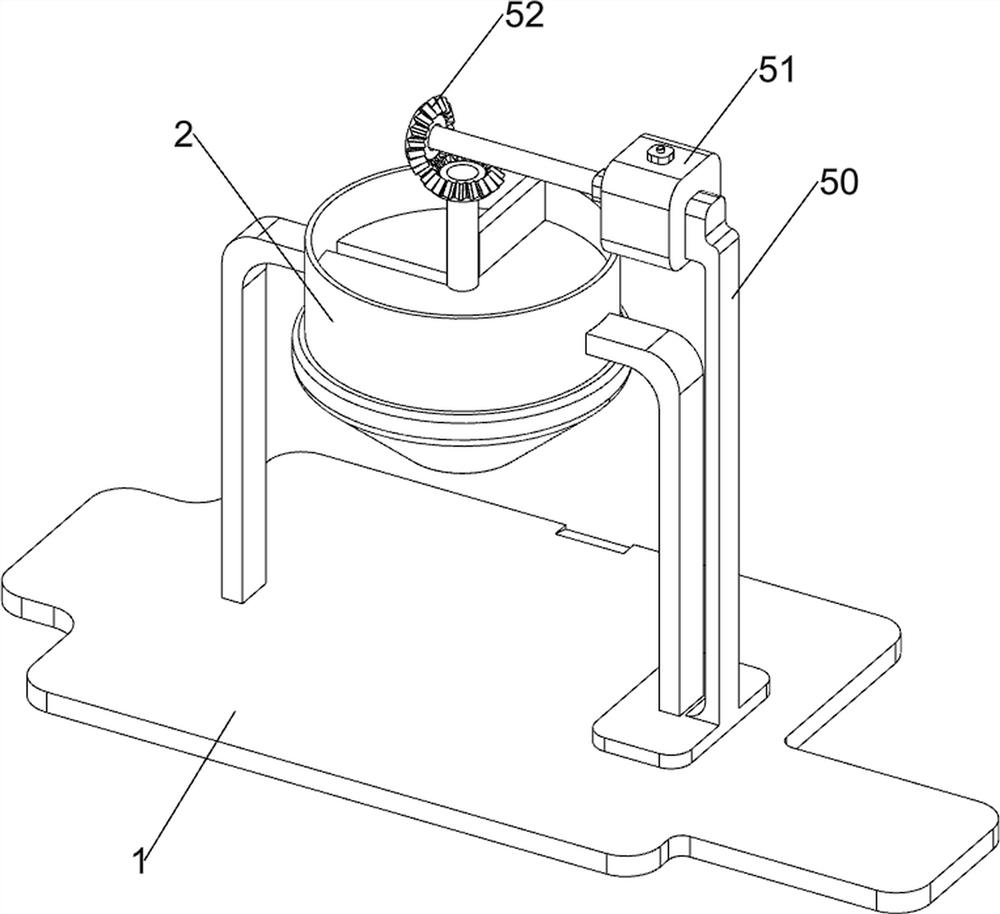

[0033] A kind of environment-friendly leaf crushing fertilizer making device, such as figure 1 and figure 2 As shown, it includes a base 1, a first mounting block 2, a grinding disc 3, a baffle plate 4 and a rotating mechanism 5. The top of the base 1 is provided with a first mounting block 2 in the middle, and the inner side of the first mounting block 2 is provided with a grinding disc 3 in a rotating manner. The rear side of the inner wall of the first mounting block 2 is provided with a baffle plate 4, and the baffle plate 4 is located above the grinding disc 3, and the top of the base 1 is provided with a rotating mechanism 5, and the rotating mechanism 5 includes a second mounting block 50, a servo motor 51 and a bevel gear. Group 52, the right side of the top of the base 1 is provided with a second mounting block 50, the top of the second mounting block 50 is provided with a servo motor 51, and a bevel gear set 52 is provided between the output shaft of the servo motor...

Embodiment 2

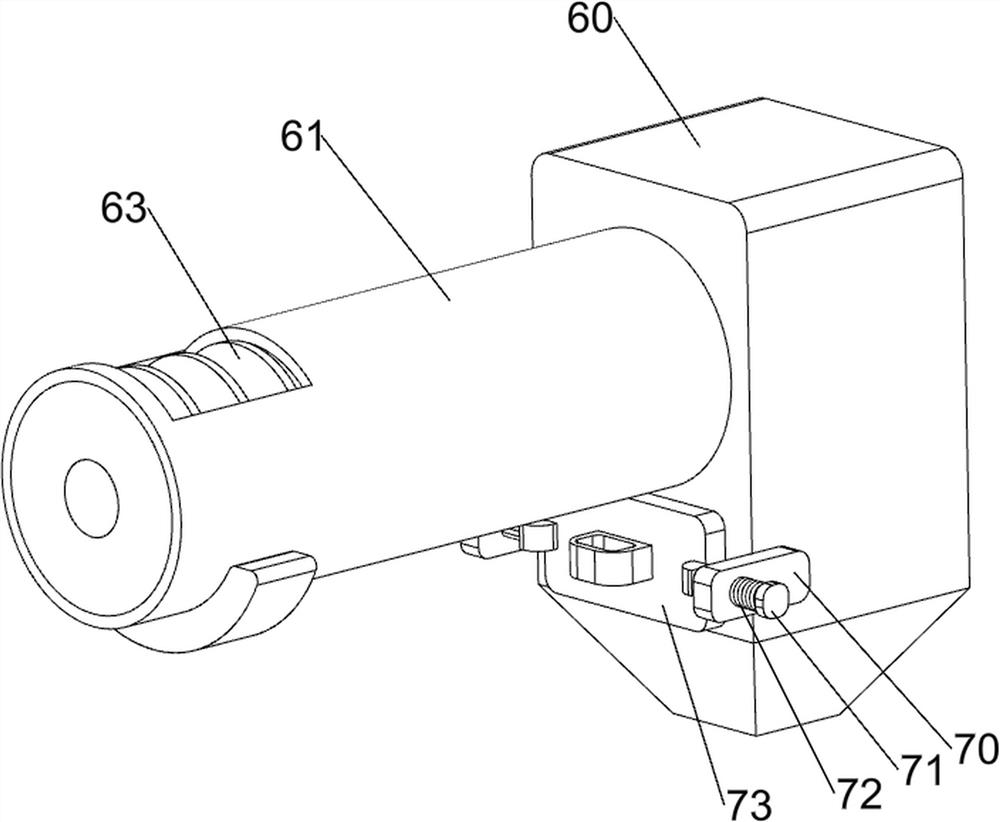

[0036] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a feeding mechanism 6 is also included, and the feeding mechanism 6 includes a third mounting block 60, a first connecting block 61, a funnel 62 and a second connecting block 63, and the top of the base 1 is provided with a third mounting block 60, said The bottom of the third mounting block 60 is provided with an opening, the left side of the third mounting block 60 is provided with a first connecting block 61, the first connecting block 61 is far away from the second mounting block 50, and the left side of the top of the base 1 is provided with a funnel 62, so The upper part of the funnel 62 is connected to the first connecting block 61 , and a second connecting block 63 is rotatably provided between the third mounting block 60 and the first connecting block 61 , and the second connecting block 63 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com