A tungsten gold ore crushing and screening device

A screening device and technology for gold mines, which are applied in screening, solid separation, chemical instruments and methods, etc., can solve problems such as single function, and achieve the effect of easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

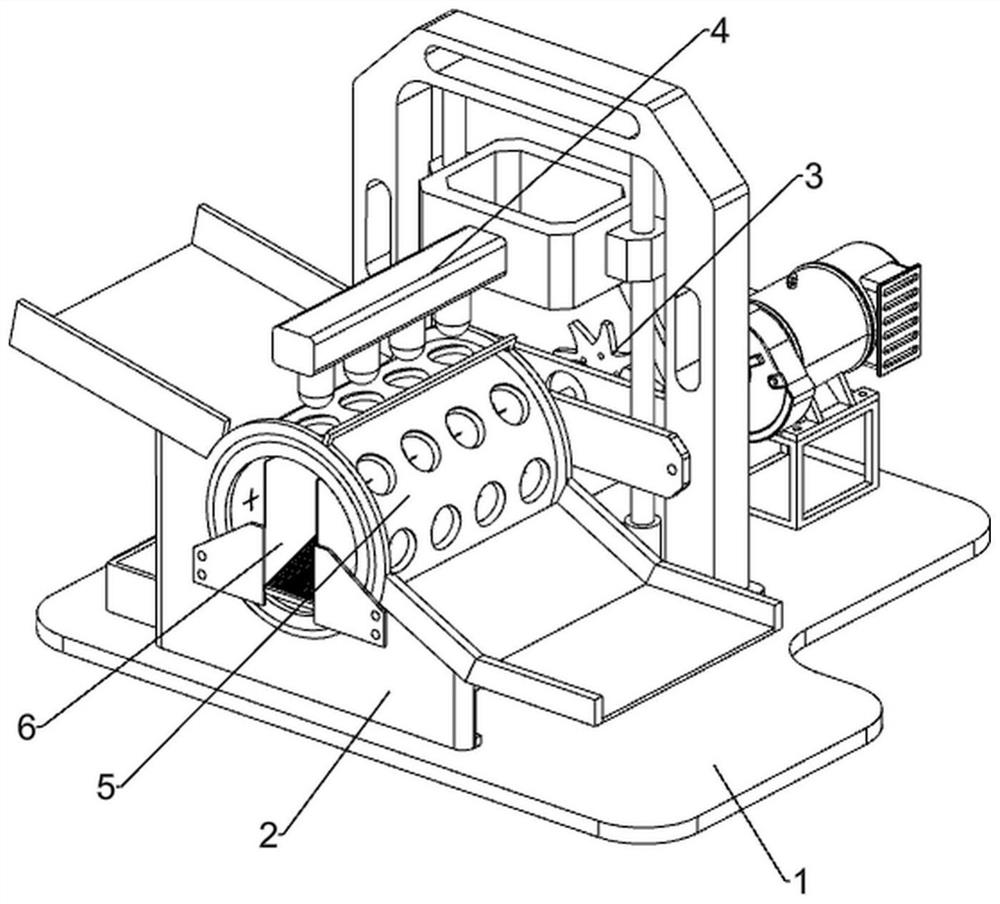

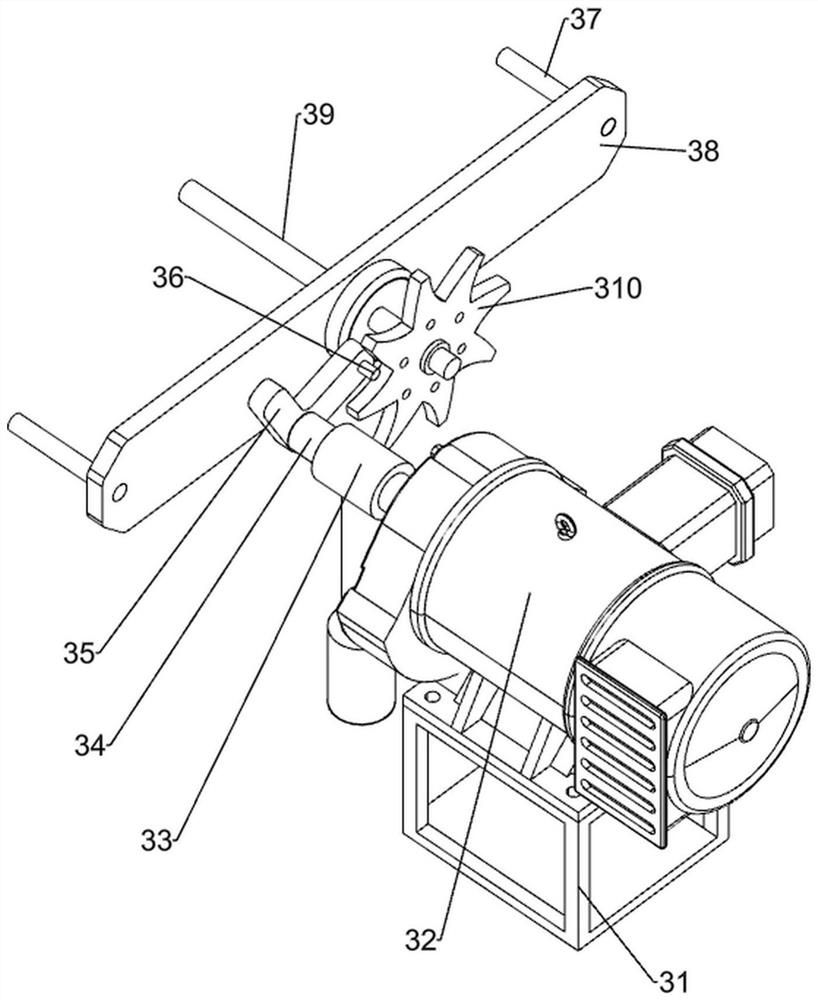

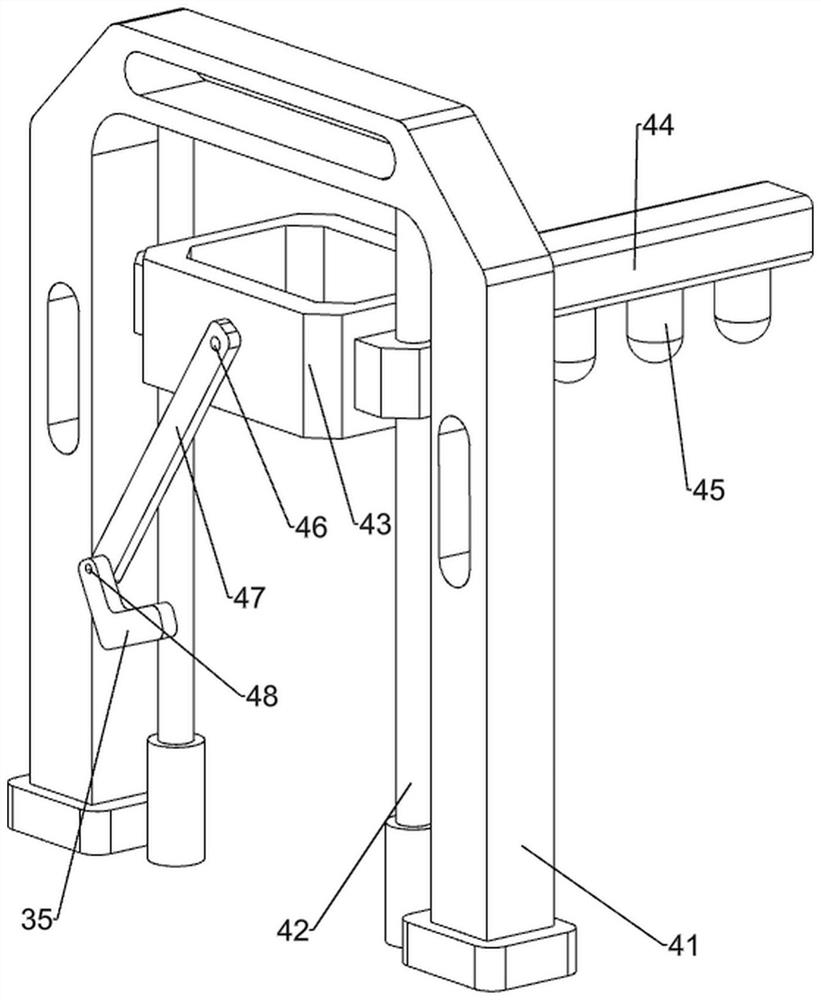

[0027] A tungsten-gold ore crushing and screening device, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a bottom plate 1, a worktable 2, a rotary drive mechanism 3, a grinding mechanism 4 and a rotary screening mechanism 5. The bottom plate 1 is provided with a workbench 2, the bottom plate 1 is provided with a rotary drive mechanism 3, and There is a milling mechanism 4, and a rotating screening mechanism 5 is provided on the workbench 2 in a rotating manner.

[0028] First, people place the tungsten-gold ore in the rotary screening mechanism 5, and place the collection tools in the workbench 2 below the rotary screening mechanism 5 and on the right side of the bottom plate 1, and then start the rotary drive mechanism 3, and the rotary drive mechanism 3 The rotation further drives the rotary screening mechanism 5 to rotate intermittently, and at the same time, the rotary drive mechanism 3 drives the grinding mechanism 4 to move up and down con...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 , Figure 5 , Figure 6 and Figure 7As shown, it also includes a filter screening mechanism 6, the filter screening mechanism 6 includes a second fixed plate 61, a second fixed rod 62 and a screen 63, and the workbench 2 is provided with a plurality of second fixed rods 62, two close A second fixing plate 61 is arranged between the second fixing rods 62 , and a screen 63 is arranged between the second fixing plates 61 , and the screen 63 is located inside the screening liner 52 .

[0035] When the crushed tungsten-gold ore falls on the screen cloth 63 from the material guide hole 53, the larger tungsten-gold ore will remain on the screen cloth 63 and slide forward by the screen cloth 63, while the smaller tungsten-gold ore The gold ore powder then falls downwards from the screen 63, so that the crushed tungsten-gold ore can be screened to ensure the quality of the tungsten-gold ore powder.

[0036] It also includes a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com