Pediatric medicine stamping and pulverizing equipment

A technology of grinding into powder and medicine, which is applied in the direction of grain processing, etc., can solve the problems of large particles of medicine particles, low grinding efficiency, etc., and achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

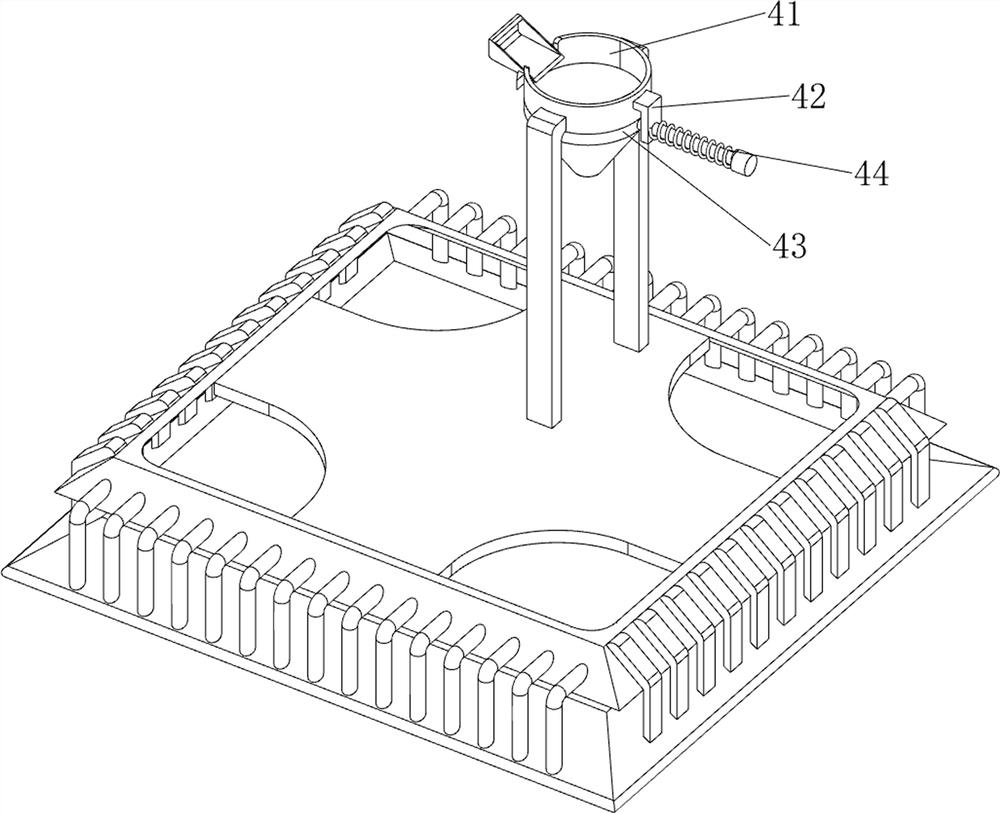

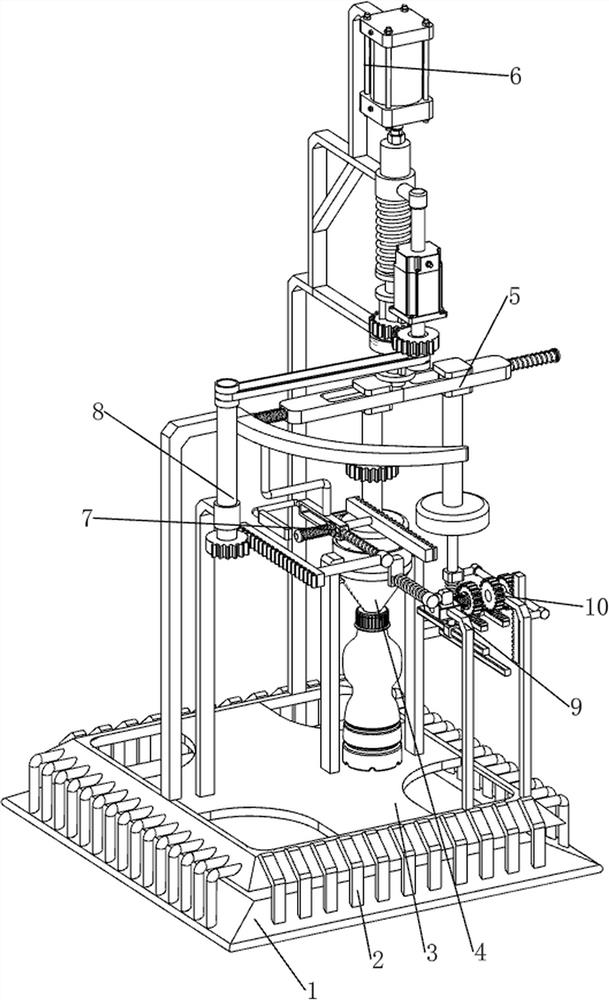

[0028] A kind of stamping and grinding powder equipment for pediatric medicine, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a bottom plate 1, a connecting plate 2, a support plate 3, a feeding mechanism 4, an intermittent hammering abrasive mechanism 5 and an automatic rotary stamping mechanism 6. The bottom plate 1 is provided with a connecting plate 2, and the connecting plate 2 is provided with a support Plate 3, the support plate 3 is provided with a feeding mechanism 4, the connecting plate 2 is provided with an intermittent hammering abrasive mechanism 5, and the intermittent hammering abrasive mechanism 5 is provided with an automatic rotary stamping mechanism 6.

[0029] First, people pull the 4 parts of the discharging mechanism to the right, so that the discharge port of the discharging mechanism 4 is closed, then the tablet is placed in the discharging mechanism 4, and the medicine bottle is placed under the discharging mechanism 4,...

Embodiment 2

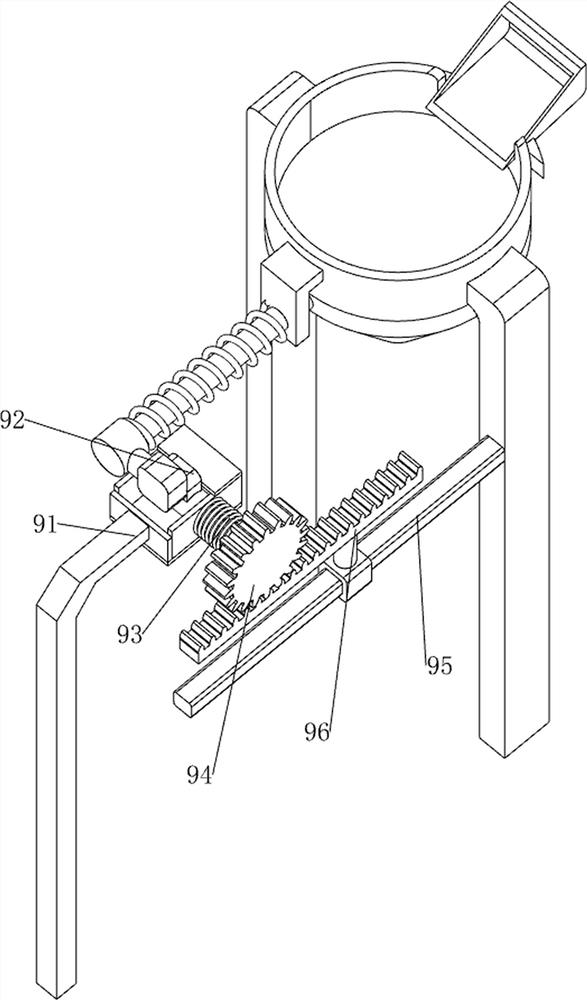

[0035] On the basis of Example 1, such as figure 1 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the grinding mechanism 7 is also included, and the grinding mechanism 7 includes a second spur gear 71, a sliding connection frame 72, a baffle plate 73, a sliding connecting rod 74, a fourth spring 75, a sliding rack 76 and an elastic member 77, The stamping grinding plate 57 on the front side is provided with a second spur gear 71, the top of the inclined plate 66 is provided with a sliding connection frame 72, the left side of the sliding connection frame 72 is provided with a baffle plate 73, and the sliding connection frame 72 is provided with a sliding connection frame. Connecting rod 74, the fourth spring 75 is provided between the sliding connecting rod 74 and the sliding connecting frame 72, the sliding rack 76 is slidably arranged on the sliding connecting rod 74, and elastic spring 76 is arranged between the sliding rack 76 and the sliding connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com