Waste treatment device for production of automobile electronic products

A technology for waste disposal and automotive electronics, applied in the direction of grain processing, etc., can solve the problem of no waste disposal and recycling of electronic products, and achieve the effect of convenient secondary utilization, easy recycling and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

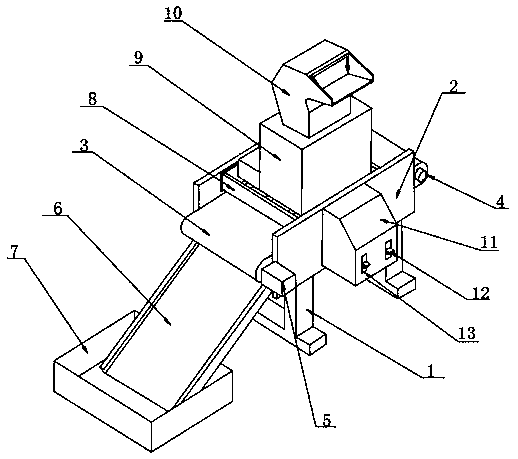

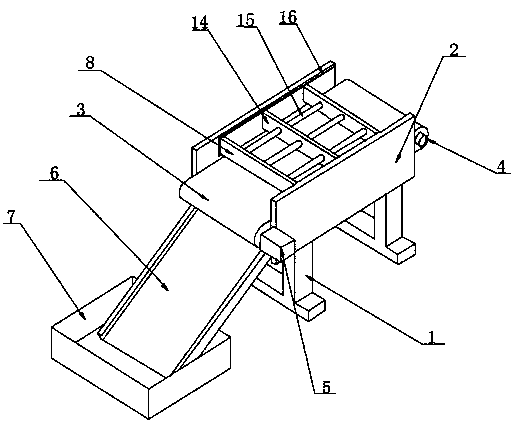

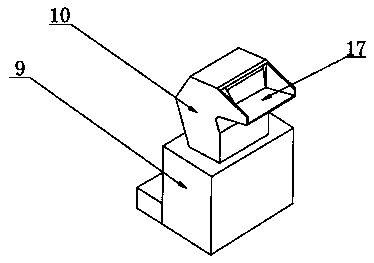

[0022] see Figure 1~4 , in an embodiment of the present invention, a waste processing device for the production of automotive electronic products includes a foot 1, a box body 2 is fixedly installed on the upper end of the foot 1, a conveyor belt 3 is arranged in the center of the box body 2, and one side of the box body 2 Control box 11 is arranged at the end, and one end of conveyor belt 3 is fixedly connected to the upper end joint of slideway 6, and the lower end joint of slideway 6 extends into waste debris collection box 7, and sieve plate 8 is set above the middle part of conveyor belt 3, and the sieve plate 8 The upper position is fixedly installed the crushing material cabinet 9, and the upper end of the crushing material cabinet 9 is fixedly connected to the lower end of the feeding head 10.

[0023] exist figure 1 Middle: In this embodiment, preferably, the front and rear ends of the conveyor belt 3 are rotatably mounted on the outer surface of the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com