Device for preparing high-organic carbon fertilizer from kitchen waste

A kitchen waste and high organic technology, which is applied in the field of kitchen waste treatment, can solve the problems of a large amount of debris in organic carbon fertilizers and the difficulty of decomposing solid kitchen waste, and achieves a high degree of material mixing, shortens stirring time, and reduces energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

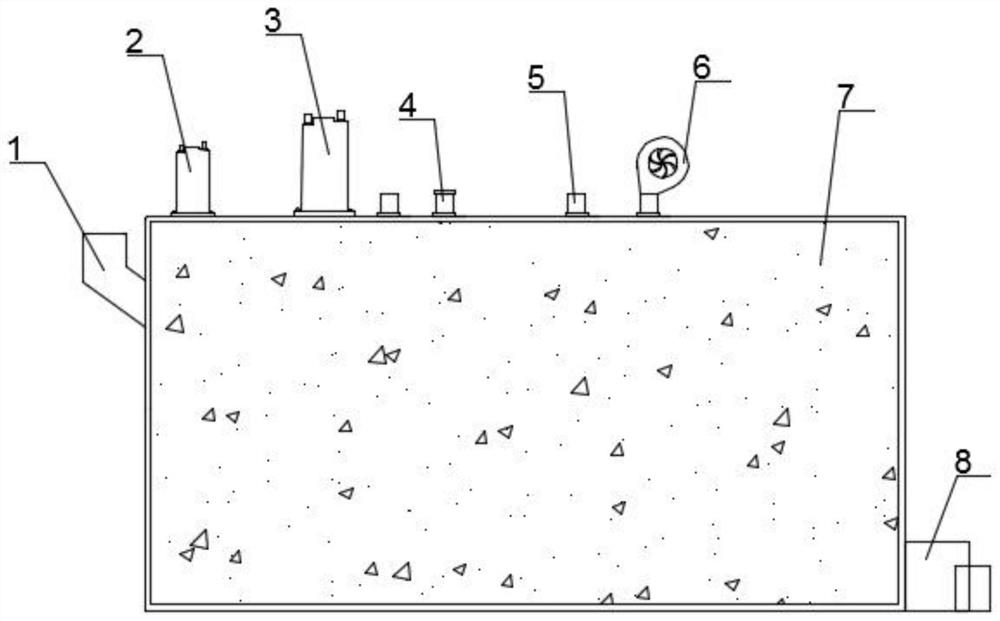

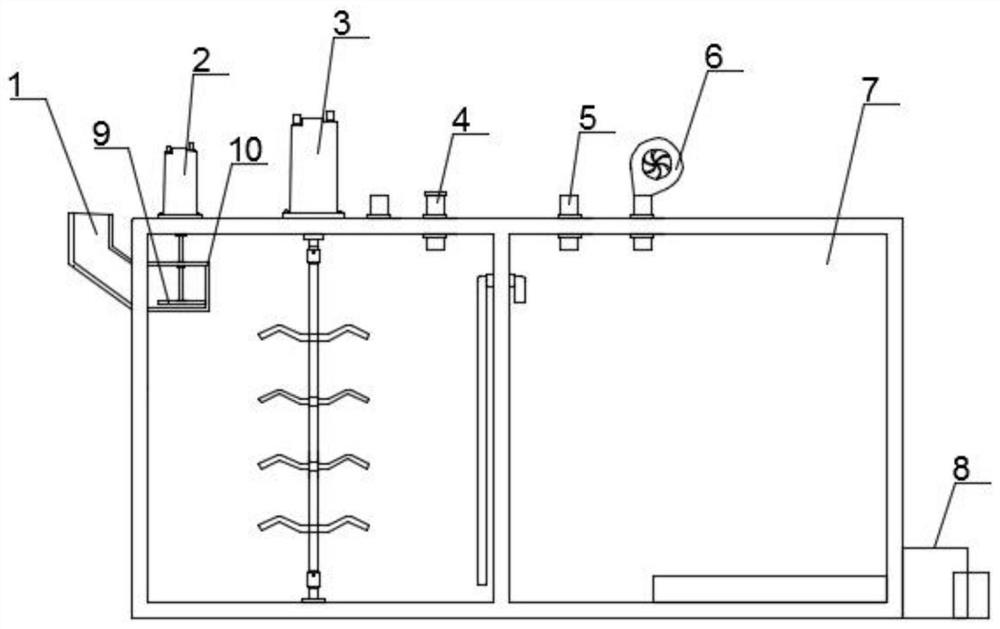

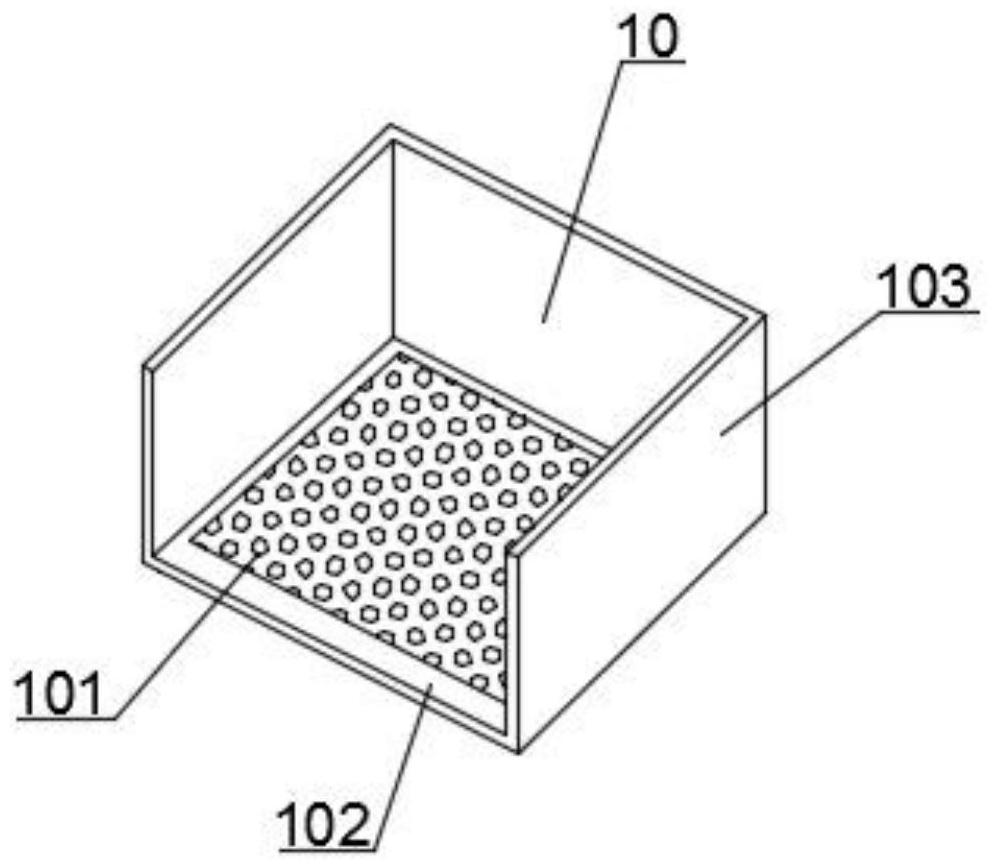

[0024] Such as Figure 1-3 As shown, a device for producing high organic carbon fertilizer from food waste includes a box body 7, which is divided into a stirring zone and a biological reaction zone, and a material guide pipe runs through the wall of the box body 7 in the stirring zone 1. The connecting end of the material guide pipe 1 in the mixing zone is a pressing assembly 10; the pressing assembly 10 includes a crushing plate 101 and an aggregate frame 103, and the aggregate frame 103 is fixed on the side wall of the box body 7, and the aggregate frame 103 The bottom end port of the bearing plate 102 is connected with a crushing plate 101 inserted through the carrying plate 102, and a number of small holes are arranged in the crushing plate 101; a crushing assembly 9 is arranged above the crushing plate 101, and the crushing assembly 9 moves up and down on the aggregate In the frame 103 , the maximum descending position of the crushing assembly 9 is the place where it con...

Embodiment 2

[0027] Such as Figure 3-4 As shown, a device for producing high organic carbon fertilizer from food waste, the crushing assembly 9 includes a pressing plate 91 and a conducting rod 92, the pressing plate 91 moves up and down in the pressing assembly 10, and the bottom end of the pressing plate 91 is provided with several Conducting rod 92, the conducting rod 92 and the small hole at the crushing plate 101 are arranged in a matching manner, the center of the conducting rod 92 is vertically coincident with the center of the small hole at the crushing plate 101, and the conducting rod 92 can be placed on the crushing plate. 101 small holes are interspersed.

[0028] In this embodiment, based on the guide rods 92 provided at the bottom of the pressing plate 91, when the pressing plate 91 presses and contacts the crushing plate 101 downwards, the several small holes provided at the crushing plate 101 are closed via the conducting rods 92. Carry out conduction treatment, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com