Pulverizing machine for fiber board machining

A pulverizer and fiberboard technology, which is applied in the direction of wood processing equipment, applications, harvesters, etc., can solve the problems of incomplete pulverization and poor pulverization effect, and achieve the effect of uniform and complete pulverization and good pulverization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

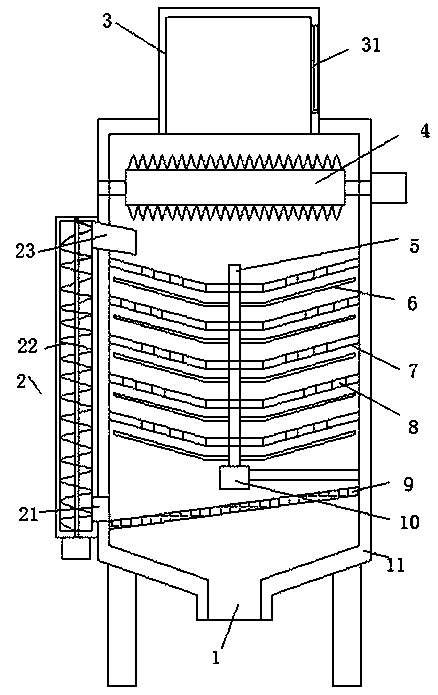

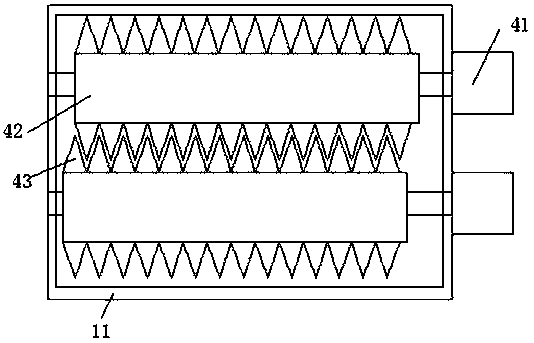

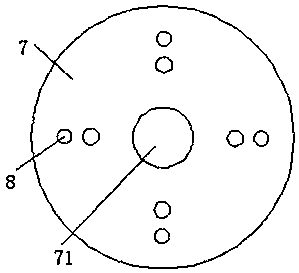

[0027] Reference Figure 1-3 , A pulverizer for fiberboard processing, comprising a shell 11, a support frame is installed on the bottom wall of the shell 11, a discharge port 1 is opened on the bottom wall of the shell 11, and an opening is provided at the top of the shell 11 , A top cover 3 is installed at the opening, a feed port is provided on one side of the top cover 3, a primary crushing mechanism 4 is provided above the inside of the housing 11, and a plurality of primary crushing mechanisms 4 are provided inside the housing 11 The lower partition plate 7 has a tapered cross section, a through hole 71 is opened in the middle of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com