Crushing and screening device for feed grease processing

It is a technology of oil processing, crushing and screening, which is applied in the direction of filter screen, solid separation, grille, etc. It can solve the problems of slow feed screening speed, insufficient crushing, and poor feed crushing effect, so as to improve the crushing effect and improve the screening efficiency. Separation efficiency, convenient and fast screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

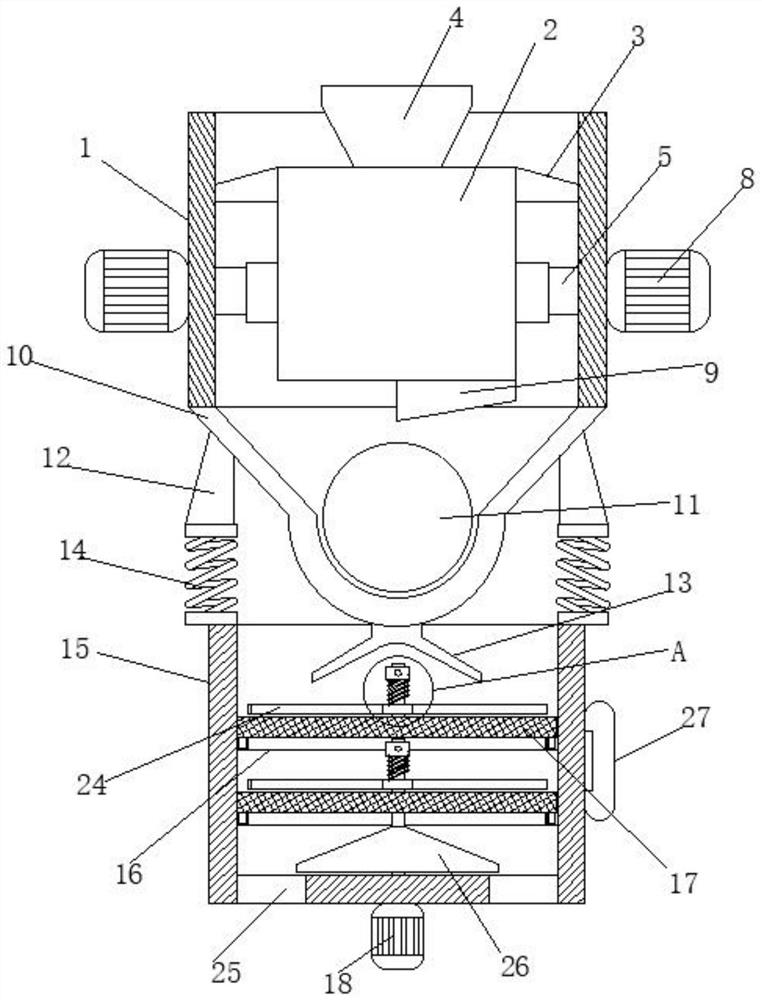

[0029] Attached below Figure 1-5 The present invention is further described with embodiment:

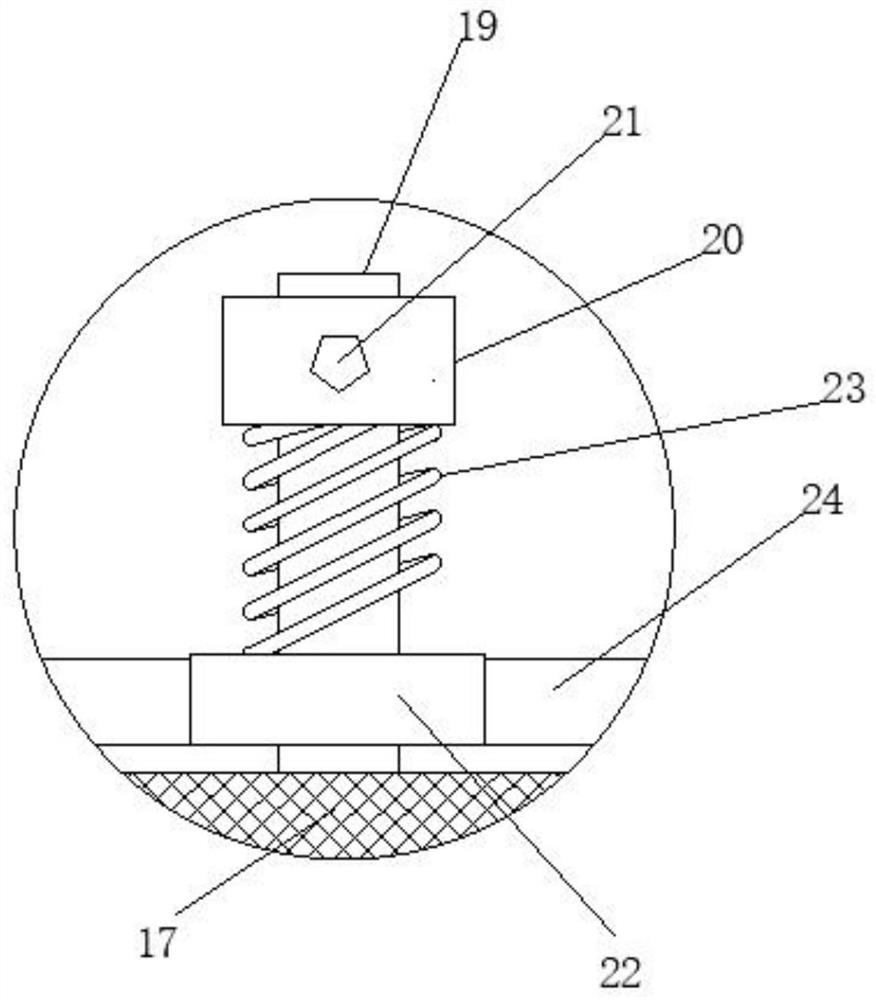

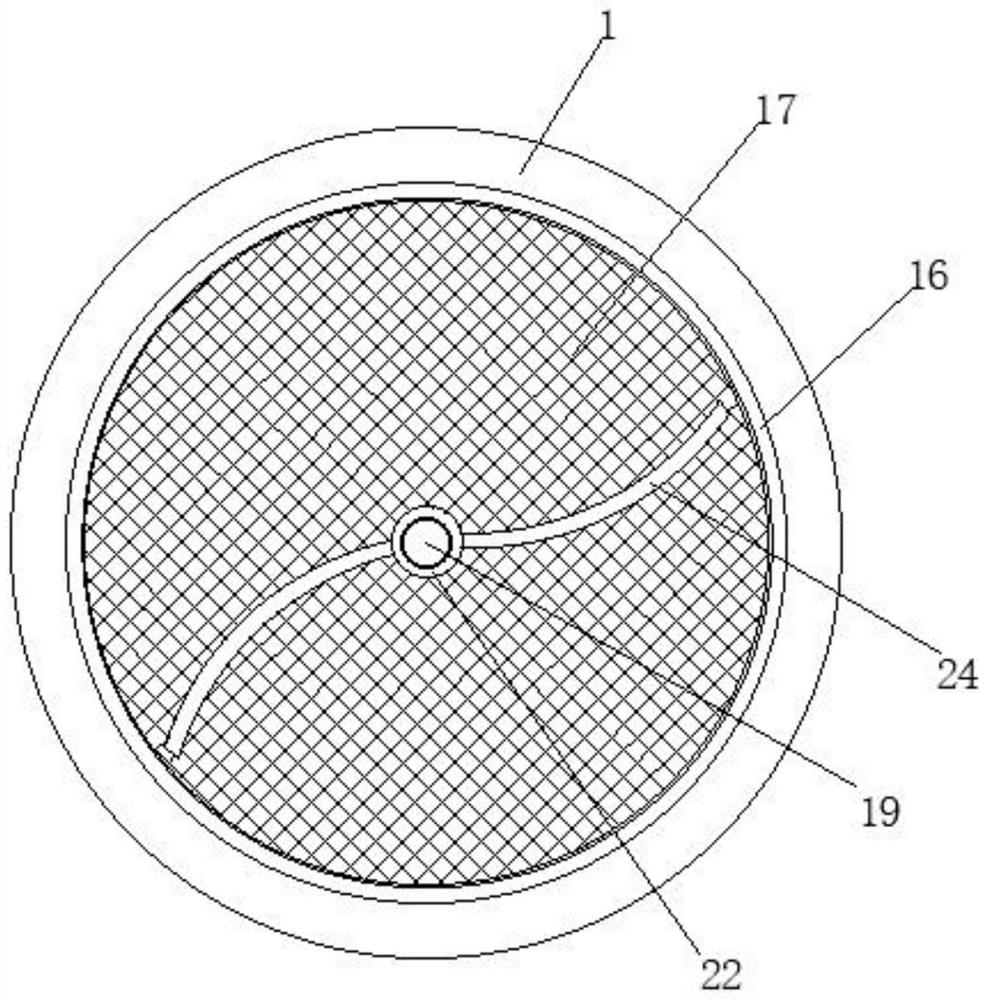

[0030] A crushing and screening device for feed oil processing, comprising an outer cylinder 1, a crushing cylinder 2 is arranged inside the outer cylinder 1, and the crushing cylinder 2 is used for primary crushing of feed, and a feeding hopper is arranged at the top of the crushing cylinder 2 4. The inside of the crushing cylinder 2 is provided with two rotating rods 5 arranged in parallel, one of the rotating rods 5 is located on the inner section of the crushing cylinder 2, and the outer wall is provided with first flails 6 distributed equidistantly, and the other is provided with The outer wall of the inner section of the rotating rod 5 located in the crushing cylinder 2 is provided with second throwing knives 7 equidistantly distributed, and the end of the rotating rod 5 extends to the outside of the outer cylinder 1 and is connected with a motor 8. The bottom end is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com