PVC material smashing and recycling device

A technology of PVC materials and recycling equipment, which is applied in the direction of mechanical material recycling, plastic recycling, recycling technology, etc., can solve problems such as crushing, and achieve fast crushing and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

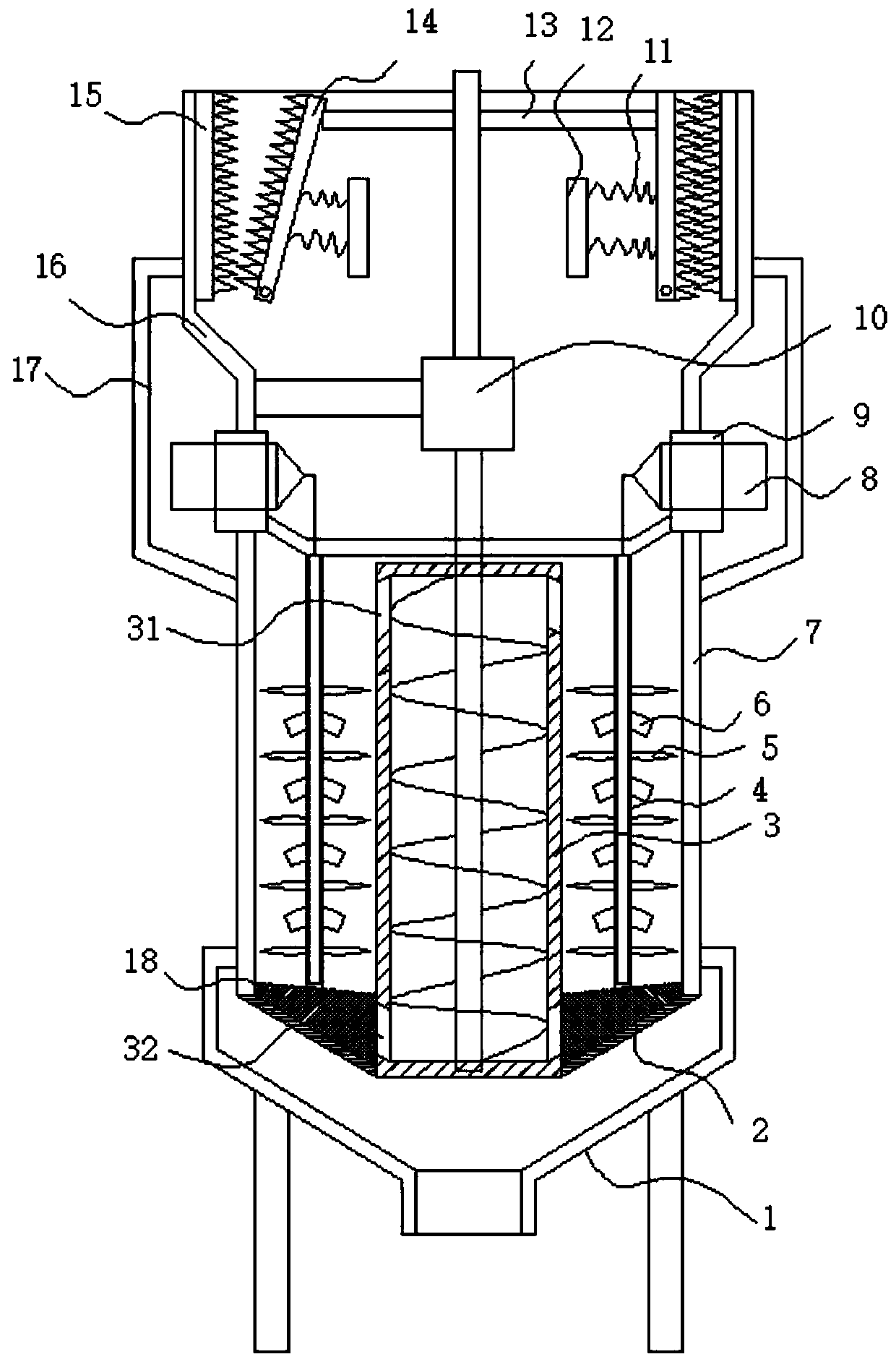

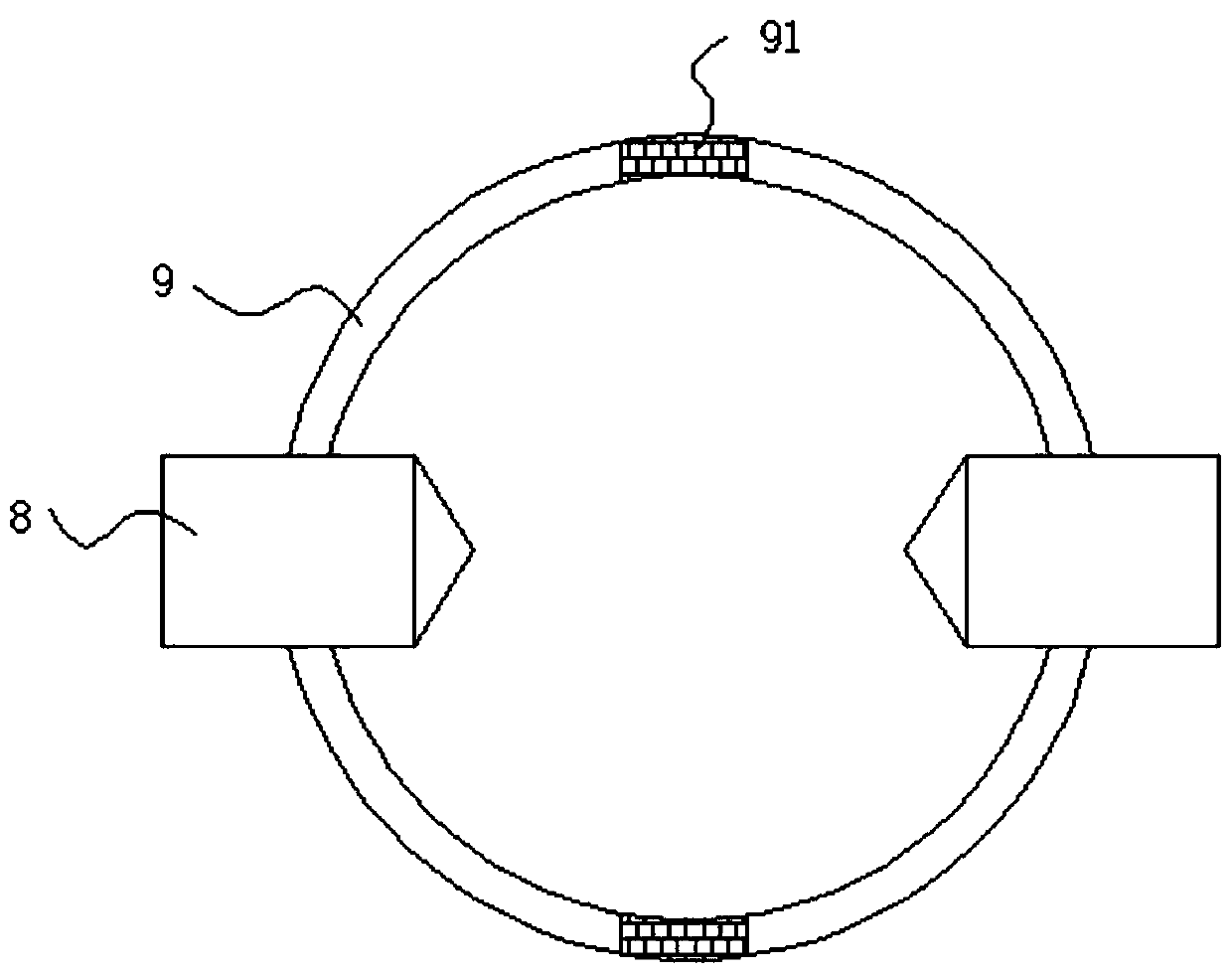

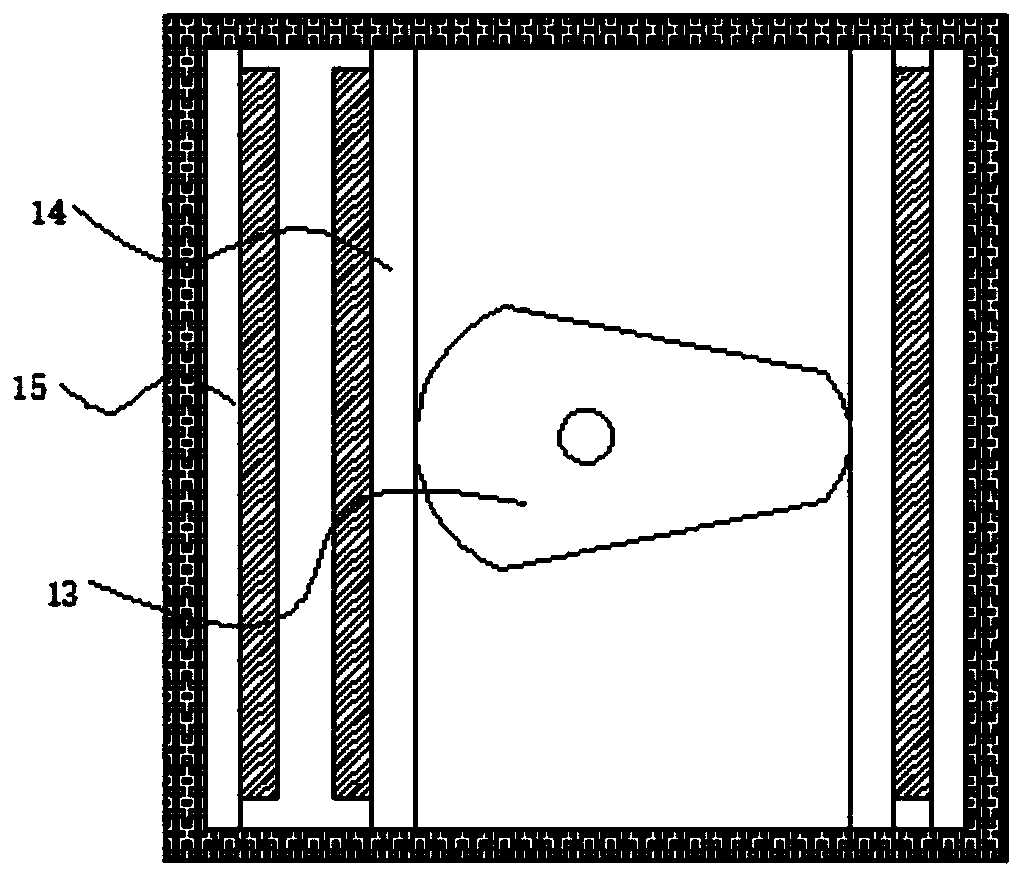

[0029] Embodiment 1: refer to Figure 1-5 , a PVC material crushing and recycling equipment, including a lower material cylinder 1, a fixed cylinder 7 and a connecting cylinder 16, a support frame is installed at the bottom of the lower material cylinder 1, and a fixed cylinder is fixedly connected to the top opening of the lower material cylinder 1 7. The top of the fixed cylinder 7 is fixedly connected to the connecting cylinder 16 through the connecting frame 17, and the inner bottom of the connecting cylinder 16 is fixed with a biaxial motor 10 through a bracket, and the top output shaft of the biaxial motor 10 is connected to a horizontally arranged cam 13. The inner walls of both sides of the connecting cylinder 16 are fixed with a fixed extrusion plate 15, and one side of the fixed extrusion plate 15 is provided with a movable extrusion plate 14 that is rotatably connected to the inside of the connection cylinder 16. The cam 13 is connected with the two movable extrusion...

Embodiment 2

[0041] Embodiment 2, with reference to Figure 5-6 : When different from Embodiment 1, the feeding mechanism positioned at the top of the connecting cylinder 16 is also installed on this device.

[0042] Described feeding mechanism comprises the charging cylinder 20 of top opening, has two feeding openings 19 that are positioned at the top of fixed extruding plate 15 on the bottom wall of charging cylinder 20, and the top rotation center of cam 13 is connected with Slidingly connected to the rotating plate 21 inside the charging cylinder 20, the top of the rotating plate 21 is equipped with a vibrating rod 22.

[0043] When working: PVC material is loaded into the charging cylinder 20, and the rotation of the cam 13 drives the rotating plate 21 to rotate through the rotating shaft. When the rotating plate 21 rotates, different feeding ports 19 are opened. Close to realize the blanking of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com