Fine grinding device for producing and processing powder cosmetics

A technology of fine grinding and cosmetics, applied in the direction of grain processing, etc., can solve the problems of unfavorable cosmetics production and processing, poor grinding effect, insufficient and thorough grinding of cosmetics, etc., and achieve the effect of good grinding effect, strong practicability, and sufficient grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

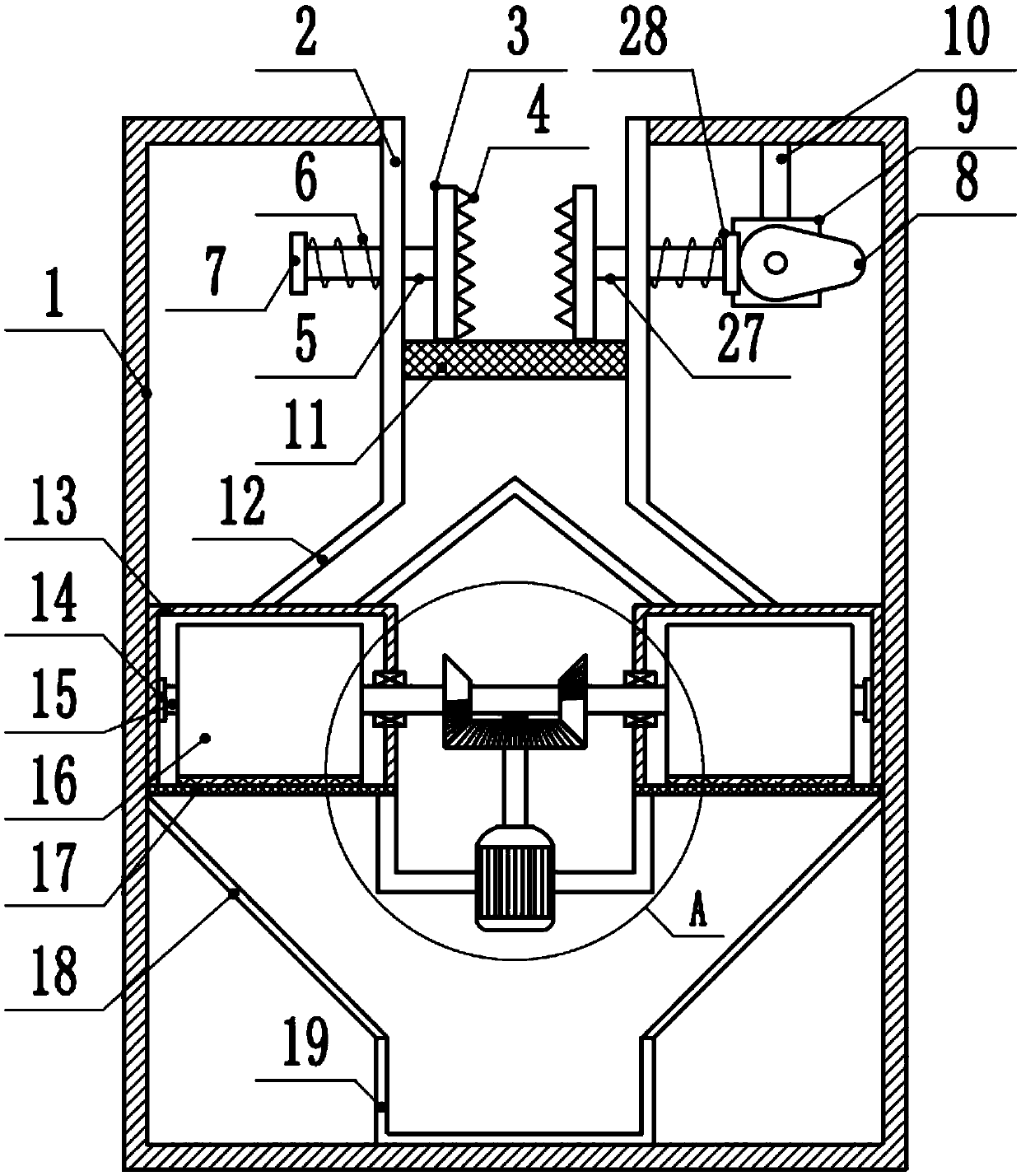

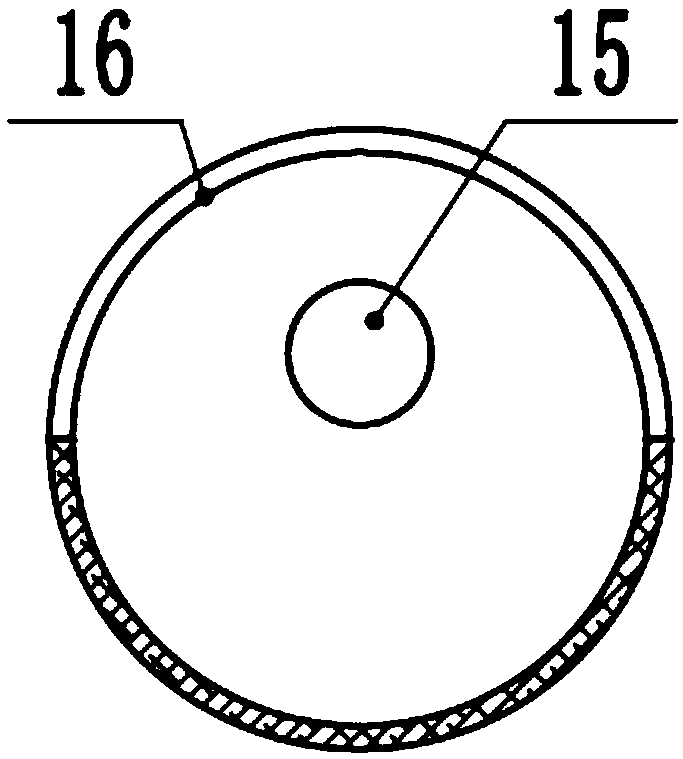

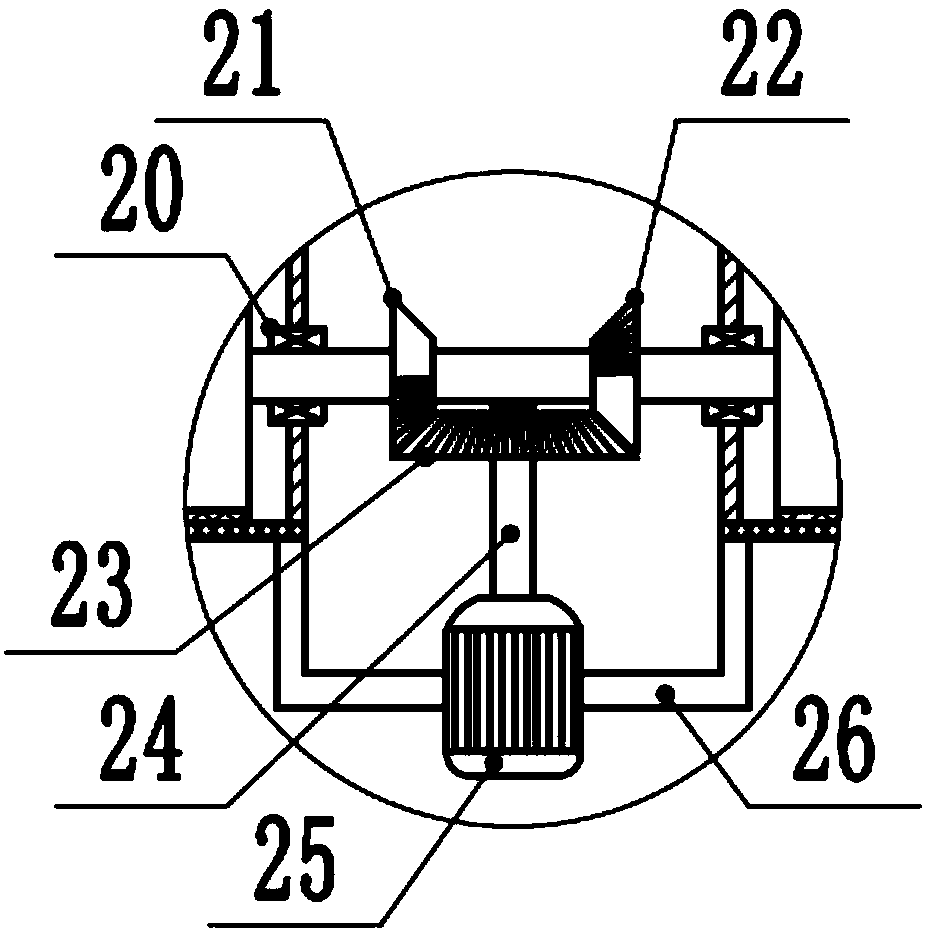

[0021] see Figure 1-3 , a fine grinding device for the production and processing of powder cosmetics, including a device box 1, a crushing cylinder 2 is fixedly connected inside the middle of the box above the device box 1, and a first pusher is connected in the middle of the box on the left and right sides of the crushing cylinder 2 in a contact manner. The rod 5 and the second push rod 27, the right end of the first push rod 5 and the left end of the second push rod 27 are respectively fixedly connected with an extruding plate 3, and the surface of the extruding plate 3 is respectively fixedly equipped with crushing teeth 4, and the crushing teeth 4 are connected to each other. Mesh connection, the left end of the first push rod 5 is fixedly connected with the first block 7, and the outer surface of the left end of the first push rod 5 is contact-connected with the spring 6, which has the effect of shock absorption and buffering, and the other end of the spring 6 and the sec...

Embodiment 2

[0024] see figure 1 , the difference between the second embodiment and the first embodiment is that the lower surface of the extruding plate 3 is contact-connected with a leakage plate 11, and the left and right ends of the leakage plate 11 are fixedly connected with the inner walls of the left and right sides of the crushing cylinder 2. By installing There is a leaking plate 11 to control the flow of the cosmetic raw material, so that the cosmetic raw material can be fully crushed, and the fully pulverized cosmetic raw material falls into the grinding box 13 through the leaking plate 11, so that it can be more refined in the grinding box 13. Grind well.

[0025] The fine grinding device for the production and processing of powder cosmetics can drive the cam 8 to rotate through the first motor 9, thereby driving the second push rod 27 to reciprocate left and right to realize the preliminary crushing of cosmetic raw materials. Enter the grinding box 13, and drive the bevel gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com