Hedging twisting double-vortex kinetic energy pulping equipment

A dual-scroll, kinetic energy technology, applied in raw material separation, recycling technology, paper recycling, etc., can solve problems such as high energy consumption and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

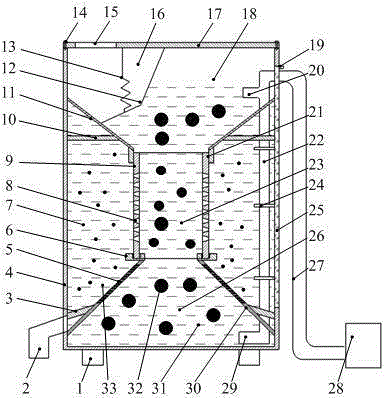

[0029] Such as figure 1 As shown in Fig. 1, a kind of double-scroll kinetic energy pulping equipment with opposing intertwisting, mainly includes water inlet and feeding device, air intake device, upper vortex kinetic energy generating device, lower vortex kinetic energy generating device, crushed material and filtering device and liquid pulp storage device. The slurry storage device is mainly composed of the middle part of the pulping cylinder 4, the lower cone cylinder 30 and the outside of the crushing material cylinder 9, and the area surrounded by it is the slurry storage area 33; , four circumferentially evenly distributed pillars 1 are installed at the bottom end of the pulping cylinder 4 .

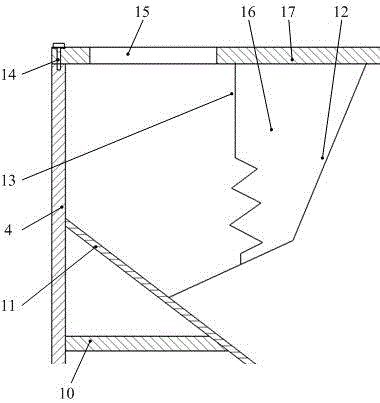

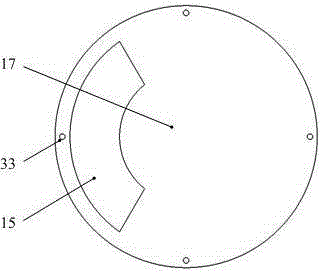

[0030] combine figure 1 , figure 2 , image 3As shown, the water inlet and feeding device is mainly composed of a water inlet 15, a spring 13, a buffer plate 12, a maximum liquid level indicator rod 19 and a liquid level observation plate 25, and the water inlet 15 is a fan-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com